Professional Documents

Culture Documents

PCB Layout When Using Through-Hole Components On A Double-Sided Board Without Through-Hole Plating

Uploaded by

Anonymous FKMfvCbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCB Layout When Using Through-Hole Components On A Double-Sided Board Without Through-Hole Plating

Uploaded by

Anonymous FKMfvCbCopyright:

Available Formats

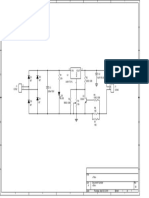

PCB Layout when Using Through-Hole Components on a Double-Sided

Board without Through-Hole Plating

25 Feb 2008

Boards without through-hole plating, whether they are milled or etched, need to be layed out

slightly differently than boards with plate-through holes. This arises because without through-

hole plating there is no guarantee of connection between the top and bottom copper trace layers

unless both the top and bottom layers have a soldered connection between them.

Rule of thumb: when routing traces around parts that obscure the through-hole footprint, be

sure to start the copper trace on the bottom (solder) layer. You may make a connection to the

top layer using a separate via which will need to be soldered in by hand.

Outline of IC Socket

IC socket

Trace on top side

Trace on top side

PCB substrate

A A

Pad on bottom side

Solder joint

IC socket pin

Top View Cross Section View A−A

Fig. 1 – A representation of the problem that arises without through-hole plating. As shown in the cross-

section view, the trace on the top side cannot be soldered to the IC socket pin since the socket obscures the

hole. As a result, there is no connection between the socket pin and the trace on the top side.

Trace on bottom side Pad on top side

Via

A A

Wire

Trace on bottom side

Top View Cross Section View A−A

Fig. 2 – The problem repaired by appropriate signal routing. The signal is brought to the top side for

further routing by taking the signal off the IC socket pin on the bottom layer and routing to a via that can

be soldered on both bottom and top sides. Note that this via could actually be implemented using a non-

obscured through-hole component, such as a resistor.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Multiplexing: VT Amp TDocument31 pagesMultiplexing: VT Amp T권순태No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Intro To DigiCom IIDocument81 pagesIntro To DigiCom IIAnonymous FKMfvCbNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AC Drives: Need For Electric Drive VFD VFD As Energy Saver Control TechniquesDocument31 pagesAC Drives: Need For Electric Drive VFD VFD As Energy Saver Control TechniquesAnonymous FKMfvCbNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Diode OperationDocument3 pagesDiode OperationAnonymous FKMfvCbNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Programming Logic Controllers: Number Systems and Codes - Chapter 3Document11 pagesProgramming Logic Controllers: Number Systems and Codes - Chapter 3Anonymous FKMfvCbNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Information To Be Added To The State Portal For Goa Government Revised 19augDocument3 pagesInformation To Be Added To The State Portal For Goa Government Revised 19augAnonymous FKMfvCbNo ratings yet

- Soldering and DesolderingDocument24 pagesSoldering and DesolderingMedley CharlesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SchematicDocument1 pageSchematicAnonymous FKMfvCbNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PCB Fabrication Tolerances and Process InformationDocument1 pagePCB Fabrication Tolerances and Process InformationMusa Mohd YusufNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- PCBlayout PDFDocument2 pagesPCBlayout PDFMusa Mohd YusufNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Board Bringup Color PrintDocument67 pagesBoard Bringup Color PrintAnonymous FKMfvCbNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- National Institute of Electronics and Information Technology, CalicutDocument5 pagesNational Institute of Electronics and Information Technology, CalicutAnonymous FKMfvCbNo ratings yet

- Feb2021 Test 1 1Document3 pagesFeb2021 Test 1 1Anonymous FKMfvCbNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- National Institute of Electronics and Information Technology, CalicutDocument7 pagesNational Institute of Electronics and Information Technology, CalicutAnonymous FKMfvCbNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Introduction To Practical Exercises Using MODICOM 2 ... - LJ Create PDFDocument8 pagesIntroduction To Practical Exercises Using MODICOM 2 ... - LJ Create PDFAnonymous FKMfvCbNo ratings yet

- ReceiptDocument1 pageReceiptAnonymous FKMfvCbNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Introduction To Practical Exercises in Sampling Practical ... - LJ Create PDFDocument4 pagesIntroduction To Practical Exercises in Sampling Practical ... - LJ Create PDFAnonymous FKMfvCbNo ratings yet

- RecruitmentNotice Operations Assistant SWD 05 March 2020Document2 pagesRecruitmentNotice Operations Assistant SWD 05 March 2020Anonymous FKMfvCbNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MODICOM 3 Setup Procedures - LJ Create PDFDocument4 pagesMODICOM 3 Setup Procedures - LJ Create PDFAnonymous FKMfvCbNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Recruitment Notice Technician EEE 05 March 2020 PDFDocument2 pagesRecruitment Notice Technician EEE 05 March 2020 PDFAnonymous FKMfvCbNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Validation of MODICON 3-2 Receiver Board Operation - LJ Create PDFDocument3 pagesValidation of MODICON 3-2 Receiver Board Operation - LJ Create PDFAnonymous FKMfvCbNo ratings yet

- Employment Application FormDocument4 pagesEmployment Application FormNikhil VaralaNo ratings yet

- Lab ManualDocument4 pagesLab ManualAnonymous FKMfvCbNo ratings yet

- Employment Application FormDocument4 pagesEmployment Application FormNikhil VaralaNo ratings yet

- 6874883750Document5 pages6874883750Anonymous FKMfvCbNo ratings yet

- 2100857334Document2 pages2100857334Anonymous FKMfvCbNo ratings yet

- PLC Lab ManualDocument64 pagesPLC Lab ManualNaveen Kumar100% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- PLC Lab ManualDocument64 pagesPLC Lab ManualNaveen Kumar100% (4)

- Daq LVDocument52 pagesDaq LVAnonymous FKMfvCbNo ratings yet

- Dorks List For Sql2019 PDFDocument50 pagesDorks List For Sql2019 PDFVittorio De RosaNo ratings yet

- Chapter 10 Outline PDFDocument2 pagesChapter 10 Outline PDFjanellennuiNo ratings yet

- INSURANCE BROKER POLICIES Erna SuryawatiDocument7 pagesINSURANCE BROKER POLICIES Erna SuryawatiKehidupan DuniawiNo ratings yet

- Application Letters To Apply For A Job - OdtDocument2 pagesApplication Letters To Apply For A Job - OdtRita NourNo ratings yet

- 1. Cẩm Nang Sửa Chữa Hệ Thống Điện Xe Honda Civic 2012Document138 pages1. Cẩm Nang Sửa Chữa Hệ Thống Điện Xe Honda Civic 2012Ngọc NamNo ratings yet

- Hood Design Using NX Cad: HOOD: The Hood Is The Cover of The Engine in The Vehicles With An Engine at Its FrontDocument3 pagesHood Design Using NX Cad: HOOD: The Hood Is The Cover of The Engine in The Vehicles With An Engine at Its FrontHari TejNo ratings yet

- Setup LogDocument221 pagesSetup LogCarlos MendezNo ratings yet

- Pfmar SampleDocument15 pagesPfmar SampleJustin Briggs86% (7)

- The Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsDocument6 pagesThe Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsAnatta OngNo ratings yet

- DTDC Rate Quotation-4Document3 pagesDTDC Rate Quotation-4Ujjwal Sen100% (1)

- 1491559890CL 0417 PDFDocument48 pages1491559890CL 0417 PDFCoolerAdsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HR Q and ADocument87 pagesHR Q and Asanjeeb88No ratings yet

- Eudemon8000E XDocument2 pagesEudemon8000E XGladys Medina100% (1)

- Factors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionDocument12 pagesFactors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionYeni Saro ManaluNo ratings yet

- HyderabadDocument3 pagesHyderabadChristoNo ratings yet

- Grade 5 Olympiad: Answer The QuestionsDocument14 pagesGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanNo ratings yet

- Hi 3 Yt 318201Document3 pagesHi 3 Yt 318201partha khatuaNo ratings yet

- General Description Product Summery: Bvdss Rdson IDDocument4 pagesGeneral Description Product Summery: Bvdss Rdson IDJose Angel TorrealbaNo ratings yet

- Energia Eolica Nordex N90 2500 enDocument20 pagesEnergia Eolica Nordex N90 2500 enNardo Antonio Llanos MatusNo ratings yet

- San Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintDocument25 pagesSan Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintFindLawNo ratings yet

- Guide To Networking Essentials Fifth Edition: Making Networks WorkDocument33 pagesGuide To Networking Essentials Fifth Edition: Making Networks WorkKhamis SeifNo ratings yet

- Telstra InterviewsDocument3 pagesTelstra InterviewsDaxShenNo ratings yet

- Toyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Document283 pagesToyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Master Xeoto100% (4)

- A Case Study From The: PhilippinesDocument2 pagesA Case Study From The: PhilippinesNimNo ratings yet

- ASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth ResistanceDocument5 pagesASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth Resistance曾乙申100% (1)

- Evaluation of Performance of Container Terminals T PDFDocument10 pagesEvaluation of Performance of Container Terminals T PDFjohnNo ratings yet

- Advanced Excel Training ManualDocument6 pagesAdvanced Excel Training ManualAnkush RedhuNo ratings yet

- What Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Document5 pagesWhat Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Zahir Rayhan JhonNo ratings yet

- Longley Rice PropagationDocument11 pagesLongley Rice Propagationy_m_algbaliNo ratings yet

- Huzaima ResultDocument2 pagesHuzaima ResultSaif Ali KhanNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)