Professional Documents

Culture Documents

Ferval Tools Tools Kit Emilia Romagna Italy Klass Hardwares Wholeasalers Diy Store Hydraulic Bottle Jack Operator Manual - Rc36

Uploaded by

Taddese TesfawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ferval Tools Tools Kit Emilia Romagna Italy Klass Hardwares Wholeasalers Diy Store Hydraulic Bottle Jack Operator Manual - Rc36

Uploaded by

Taddese TesfawCopyright:

Available Formats

POSSIBLE PROBLEMS AND SOLUTIONS TEST CERTIFICATE

Product HYDRAULIC BOTTLE JACK

Valves may not be closed or have foreign matter present. To flush valves. Lower the saddle

and close the release. Manually lift the saddle several inches, open the release valve and

Item

HYDRAULIC BOTTLE JACK

Jack may be low on oil. Remove filler plug and fill reservoir with clean hydraulic jack oil.

Inspector

Jack may be air-bound. Open the release valve and pump the handle several times.

Date of Package

Reservoir may be overfilled. Remove filler plug and drain excess oil.

Close the release valve and operate. Repeat if necessary.

SOLUTIONS

then force the saddle to lower as rapidly as possible.

Release valve may not be tightly closed.

MAIN TECHNICAL DATA

Lifting Minimum Lifting Adjusting Net

ITEM Capacity Height Height Height Weight

(TON) (mm) (mm) (mm) (kg)

T90204 2 181 116 48 2.9

ht

T90204S 2 181 116 48 2.9

eig

h

ll

T90404 4 194 118 60 3.6

fu

k

f t

ac

li

ot

T90404S 4 194 118 60 3.6

b

n

s

lie

ill

dl r lo k w

rf

T90604 6 216 127 70 4.8

o

c

es

Ja

r d

is

e a

T90604S 6 216 127 70 4.8

y

a

ng

a e

g

H nd

lu

sp

T90804 8 230 147 80 6.3

n

p

u

ls

r

le

e

fe

fil

T91004 10 230 150 80 6.8

m

p

m

fro

ad

Pu

T91204 12 230 155 80 8

g

lo

n

ki

er

l

ea

ul

T91504 15 230 150 80 8.9

n

f

l

SS ll noacit rs u

or

il

O

d

T92004 20 242 150 60 11.5

a

P w ca ow

LE lo

y

l

B t lift

T93004 30 285 180 / 21

c

Ja

i p

T95004 50 300 180 / 30

cked

I

J at

r

a

O

MAINTENANCE CONSTRUCTION DIAGRAM

1. Read, study and understand all warnings and operating Adding Oil/ Lubrication (Fig.4)

Fig.4

instructions prior to use. 1. Place the jack in an upright position.

2. Do not overload this jack beyond the rated capacity.

2. Lower pump and piston to full down

3. This jack is designed for use only on hard level surfaces

capable of sustaining the load. position. Oil Plug

4. This is a lifting device only, immediately after lifting, support 3. Remove rubber oil plug on jack.

the vehicle with jack stands. 4. Fill with GOOD GRADE HYDRAU-

5. Do not get under or allow anyone under the vehicle until it has LIC OIL only. (Fill to lower rim of oil

been supported by jack stands. Oil Level

6. Lift only on areas of the vehicle as specified by the vehicle fill hole.) Purge system of air as

manufacturer. described below ( purging air from

7. Center load on saddle prior to lifting. Hydraulic System).

8. Some vehicles require an adapter to properly engage the 5. Replace rubber oil plug.

frame for lifting. use vehicle manufacturers instructions on 6. Lubricate pivoting joints and screw

proper lifting.

9. No alterations to the jack shall be made. extension periodically for proper

(Fill to Rim of Oil Plug Hole)

10. Only attachments, restraints, or adapters supplied by the maintenance.

manufacturer shall be used.

11. Failure to heed these warnings may result in personal injury

and/or property damage.

PURGING AIL FROM HYDRAULIC SYSTEM

Occasionally, air bubbles become trapped inside the jack,

reducing its efficiency. Bleed air out of the jack’s hydraulic system as

INSTRUCTIONS FOR USE

follows:

TO RAISE: 1. Open release valve, remove oil plug.

1. With narrow end of jack handle, close release valve tightly by

2. Operate pump rapidly sever times to force air out.

turning it clockwise. (Fig.1)

3. Close release valve, replace oil plug.

2. Place jack under vehicle at proper lifting location. (Refer to

vehicle Owner’s Manual.) If needed, turn the extension screw on Jack should now operate normally. If not, repeat purging procedure

jack counterclockwise until it comes into contact with vehicle.(Fig.2) as needed.

3. Insert jack handle into handle socket. Pump the handle to lift

T90204 - T92004

vehicle to desired height. (Fig.3)

RUST PREVENTION

TO LOWER: Keep Piston, Pump and Extension Screw in full down position

CAUTION: LOWER VEHICLE SLOWLY! TURN RELEASE VALVE 1. Release valve lever

when not in use. Avoid contact with moisture. If contact with

SLOWLY!

1. Remove handle, use small end to open release valve. (To open moisture occurs, wipe dry and grease/lubricate all jack parts. 2. Base

release valve turn it SLOWLY in a counter clockwise direction.) 3. O-ring

NOTE: DO NOT OPEN RELEASE VALVE MORE THAN ONE (1)

FULL TURN 4. Hydraulic cylinder

2. When vehicle is fully lowered. Remove jack. (If Extension Screw 5. Ram

has been extended, turn it clockwise until it retracts enough to FOR YOUR SAFETY AND TO PREVENT INJURY:

move jack away from vehicle.) 6. Hydraulic oil

Use jack for 7. Oil-tight tank

lifting purposes 8. Extension screw

Fig.1 Fig.2 Fig.3

ONLY.

9. Top cap

Extension

Screw Jack

Handle Socket Always support 10. Pump plunger

vehicle with

Jack 11. Pump body

Handle jack stands.

Release Pump 12. O-ring

Valve

Safety Valve 13. Safety valve

You might also like

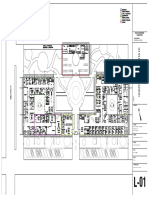

- Drawing Sanitary, PlumbingDocument1 pageDrawing Sanitary, Plumbingkhairil mohdNo ratings yet

- 3412 Shematic 4 PDFDocument2 pages3412 Shematic 4 PDFDmitry100% (2)

- SCBD Golf Studio & Dining - Layout Plan v32Document1 pageSCBD Golf Studio & Dining - Layout Plan v32Giovanni MikeNo ratings yet

- Agcx Deuge Valve 2-2.5-3Document7 pagesAgcx Deuge Valve 2-2.5-3sreeramNo ratings yet

- Bird SM000-1 C100-001 ZoomedAreaDocument1 pageBird SM000-1 C100-001 ZoomedAreaRoberto BravoNo ratings yet

- 250613DLDND2241 Exco00 01Document1 page250613DLDND2241 Exco00 01Mohammed HijaziNo ratings yet

- Section "B-B" Barrel Details Detail "A": Hydraulic ElementsDocument1 pageSection "B-B" Barrel Details Detail "A": Hydraulic Elementston carolinoNo ratings yet

- Milliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomFrom EverandMilliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomNo ratings yet

- Kafd A1 111 Comn NSF XXXXX WSP Phe DWG 00013Document1 pageKafd A1 111 Comn NSF XXXXX WSP Phe DWG 00013YazNo ratings yet

- Sample MDRDocument4 pagesSample MDRchristi SNo ratings yet

- CH 1 Text SolutionsDocument14 pagesCH 1 Text SolutionsElvis wuNo ratings yet

- Cuadro de Simbología: Universidad Católica de El SalvadorDocument1 pageCuadro de Simbología: Universidad Católica de El SalvadorAlex MendozaNo ratings yet

- 900-0094 - FOLHA 1 - DIAGRAMA MULTIFILAR GERADOR FIXO-ModeloDocument1 page900-0094 - FOLHA 1 - DIAGRAMA MULTIFILAR GERADOR FIXO-ModeloPaulo CravoNo ratings yet

- PS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5Document1 pagePS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5yusak adi setiawanNo ratings yet

- Kafd A1 111 Comn NSF XXXXX WSP Phe DWG 00011Document1 pageKafd A1 111 Comn NSF XXXXX WSP Phe DWG 00011YazNo ratings yet

- Overall Wiring Diagram: Xelos A 22Document20 pagesOverall Wiring Diagram: Xelos A 22Biju PrestcomNo ratings yet

- Produced by An Autodesk Student Version: Existing Repair & Maruti PointDocument1 pageProduced by An Autodesk Student Version: Existing Repair & Maruti PointAvinash SharmaNo ratings yet

- 5.1ls of Leading Channel To 2a Pumphouse Link Canal-ModelDocument1 page5.1ls of Leading Channel To 2a Pumphouse Link Canal-ModelNaveen NagisettiNo ratings yet

- Staff Houses Sewer LayoutDocument1 pageStaff Houses Sewer LayoutOBERT MASALILANo ratings yet

- Borrador 2025Document1 pageBorrador 2025Jhon James Rojas CarhuamacaNo ratings yet

- Septic Vault Cover Plan: LegendDocument1 pageSeptic Vault Cover Plan: LegendLizabeth Pillos MarquezNo ratings yet

- 1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMDocument12 pages1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMShilu GhoshNo ratings yet

- Schematic Flow ChartDocument1 pageSchematic Flow ChartShawn KamauNo ratings yet

- Strategic Directions 7TM504-2018-2019Document10 pagesStrategic Directions 7TM504-2018-2019Panos AnonioumNo ratings yet

- DDDDDDDDDDocument1 pageDDDDDDDDDNideesh RobertNo ratings yet

- $100 StoryDocument1 page$100 StoryeodwyerNo ratings yet

- D-650 Service Manual AmalgamadorDocument2 pagesD-650 Service Manual AmalgamadorPenny MartiNo ratings yet

- FORM A3P Monthly 2311 MCVDocument1 pageFORM A3P Monthly 2311 MCVLineza Pusat Gmail 1No ratings yet

- Io Ti Lascio Oh Cara Addio K. Anh 245 K.621a Wolfgang Amadeus MozartDocument3 pagesIo Ti Lascio Oh Cara Addio K. Anh 245 K.621a Wolfgang Amadeus Mozart홍동국No ratings yet

- Diagramas 1Document31 pagesDiagramas 1dmb1692No ratings yet

- NFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Document1 pageNFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Projects DPCSNo ratings yet

- Math Workshop, Grade 3: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade 3: A Framework for Guided Math and Independent PracticeNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- 44 MTR - STEEL BRIDGE For Irrigation 30-07-2020-GADDocument1 page44 MTR - STEEL BRIDGE For Irrigation 30-07-2020-GADEr Navneet JassiNo ratings yet

- Plumbing BTDocument1 pagePlumbing BTlucerocatapanggwen.03No ratings yet

- Bluesky+Tvd 2901fs+ +Ken+Brown+Tvd 2101fsDocument4 pagesBluesky+Tvd 2901fs+ +Ken+Brown+Tvd 2101fsValdir GoisNo ratings yet

- IKEA-E-6031 - 6035 Comment and NameDocument6 pagesIKEA-E-6031 - 6035 Comment and Namepasin saekooNo ratings yet

- M-TRAMO I - Mod Editado perfil-DG-5Document1 pageM-TRAMO I - Mod Editado perfil-DG-5Xioxmi HilarioNo ratings yet

- Council DWG-01Document1 pageCouncil DWG-01Janitha SandaruwanNo ratings yet

- Bus Shelter India (Made From Scrap-Steel+aluminium+rubber+plastic)Document2 pagesBus Shelter India (Made From Scrap-Steel+aluminium+rubber+plastic)vanshaj mehtaNo ratings yet

- Peta PerahuDocument1 pagePeta PerahuZuhdaNPrabowoNo ratings yet

- 22 06 VCS de de Duc 03 2Document1 page22 06 VCS de de Duc 03 2MARCELO ALEJANDRO CUEVAS ALBORNOZNo ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- DX300LCA - SEND300A0001 779-ElDocument1 pageDX300LCA - SEND300A0001 779-ElMeterio Cao SuNo ratings yet

- DN#1200-tp 9Document1 pageDN#1200-tp 9Arbaz KhanNo ratings yet

- Cartografía Geológica de La Plancha 62 La Ye Departamentos de Córdoba Y SucreDocument2 pagesCartografía Geológica de La Plancha 62 La Ye Departamentos de Córdoba Y Sucrejaime luis betancourthNo ratings yet

- 65391-Jacked-Cooling-R0 2Document12 pages65391-Jacked-Cooling-R0 2ramesh_madkatte1082No ratings yet

- Plantas Baixas PDFDocument1 pagePlantas Baixas PDFCelimorMoreiraNo ratings yet

- HPS2185FS TV Manuel VieiraDocument1 pageHPS2185FS TV Manuel VieiraIrving DiazNo ratings yet

- Hps2171fsg EeDocument1 pageHps2171fsg Eeapi-3826086No ratings yet

- Temple Drawing-Input DrawingDocument1 pageTemple Drawing-Input Drawingmanoj_civil_mbmNo ratings yet

- DRAFT LAYOUT - FeedbackDocument6 pagesDRAFT LAYOUT - Feedbackyudis tiraNo ratings yet

- Feeder Pillar Shop DrawingDocument6 pagesFeeder Pillar Shop DrawingMohd Yazel Md SabiaiNo ratings yet

- YMM800005Document12 pagesYMM800005Vinicius NevesNo ratings yet

- Facultad de Ingeniería Y ArquitecturaDocument1 pageFacultad de Ingeniería Y ArquitecturaGimena Perez GonzalesNo ratings yet

- 4th - 30th Floor PlanDocument1 page4th - 30th Floor PlanRekha TanpureNo ratings yet

- Wd11y021s10Document28 pagesWd11y021s10cages48160No ratings yet

- ABNT NBR 15784 - Produtos Químicos Utilziados No Tratamento de Água para Consumo Humano - ANTIGADocument39 pagesABNT NBR 15784 - Produtos Químicos Utilziados No Tratamento de Água para Consumo Humano - ANTIGAJaqueline FrancischettiNo ratings yet

- Advanced Machine Tools Final ExamsDocument11 pagesAdvanced Machine Tools Final ExamsAhmed MohamedNo ratings yet

- DEORE Rear Derailleur: (10-Speed)Document1 pageDEORE Rear Derailleur: (10-Speed)Marcos ZanelliNo ratings yet

- Joker Command: Game Shark CodesDocument3 pagesJoker Command: Game Shark CodesAdytiar PratamaNo ratings yet

- Catalogo Productos CodriseDocument89 pagesCatalogo Productos CodriseJPVYcG4xas100% (1)

- Cam Lab ManualDocument29 pagesCam Lab ManualBalaji ManianNo ratings yet

- Slim Slide 5012 TNDocument1 pageSlim Slide 5012 TNdilnair99No ratings yet

- Afilador Cuchillos Edgeselect Diamond Hone 120Document48 pagesAfilador Cuchillos Edgeselect Diamond Hone 120GonzaloNo ratings yet

- 111Document34 pages111api-3801878100% (1)

- Items: Advanced & Creature: FOWW IUC-45-005Document6 pagesItems: Advanced & Creature: FOWW IUC-45-005Данил КеллерNo ratings yet

- 980G 2KR Plano HidraulicoDocument2 pages980G 2KR Plano HidraulicoCarlos Irabedra100% (1)

- University of Batangas College of Engineering Electrical Engineering Department Hilltop Road, Batangas CityDocument3 pagesUniversity of Batangas College of Engineering Electrical Engineering Department Hilltop Road, Batangas CityErvin MedranoNo ratings yet

- Fed-Std-H28-14a-1983+notice 2019Document12 pagesFed-Std-H28-14a-1983+notice 2019Anthony WeaverNo ratings yet

- Workshop Manual: MXMA 4800 Cone Valve 2014Document28 pagesWorkshop Manual: MXMA 4800 Cone Valve 2014Factory PerformanceNo ratings yet

- Disassembly/Assembly: Dräger Zeus® Breathing SystemDocument2 pagesDisassembly/Assembly: Dräger Zeus® Breathing SystemzhoumengNo ratings yet

- Laporan LateralDocument10 pagesLaporan LateralMuhaidir AnwarNo ratings yet

- Anexo N VF BROKK SACDocument20 pagesAnexo N VF BROKK SACRicardo ChNo ratings yet

- Deni Tool Modulo DDocument4 pagesDeni Tool Modulo DnofearnemNo ratings yet

- Spare Parts & Accessories Catalogue: Version 2.0 (28.02.2013)Document55 pagesSpare Parts & Accessories Catalogue: Version 2.0 (28.02.2013)Maintenance Can-Pack UkraineNo ratings yet

- Dish WasherDocument11 pagesDish WasherMaster OogwayNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Schedule of CommissioningDocument2 pagesSchedule of CommissioningAri Puji HidayatullahNo ratings yet

- List VMS Cantilever 5x2Document7 pagesList VMS Cantilever 5x2Evi Puspita SariNo ratings yet

- PCDO April2020Document39 pagesPCDO April2020TENDER CELL DIESEL SHED GONDANo ratings yet

- Section 5 - Manual Transmissions and TransaxlesDocument6 pagesSection 5 - Manual Transmissions and TransaxlesSuzan KhouryNo ratings yet

- Oversized Primary Pressure Regulator Valve Kit: Jatco/Nissan JF010E (REOF09A/RE0F09B), JF011E (REOF10A)Document1 pageOversized Primary Pressure Regulator Valve Kit: Jatco/Nissan JF010E (REOF09A/RE0F09B), JF011E (REOF10A)SAMADNo ratings yet

- Machine Integration: Coromant Capto®Document7 pagesMachine Integration: Coromant Capto®RomanNo ratings yet

- 1 stj4230 00 00 001 R1Document28 pages1 stj4230 00 00 001 R1Hritika PatelNo ratings yet

- 5600 y 5800 PDFDocument70 pages5600 y 5800 PDFluisxxx1100% (2)

- Wiring List 20 Rtu PDFDocument1 pageWiring List 20 Rtu PDFSree VBroNo ratings yet

- DTC P0776 Pressure Control Solenoid "B" Performance (Shift Solenoid Valve SL2)Document1 pageDTC P0776 Pressure Control Solenoid "B" Performance (Shift Solenoid Valve SL2)limadacarlosNo ratings yet