Professional Documents

Culture Documents

Unesco - Eolss Sample Chapters: Industrial Uses of Enzymes

Uploaded by

David ShitimaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unesco - Eolss Sample Chapters: Industrial Uses of Enzymes

Uploaded by

David ShitimaCopyright:

Available Formats

BIOTECHNOLOGY –Vol.

VI - Industrial Uses of Enzymes - Michele Vitolo

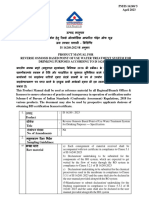

INDUSTRIAL USES OF ENZYMES

Michele Vitolo

Department of Biochemical and Pharmaceutical Technology, School of Pharmacy,

University of São Paulo, Brazil.

Keywords: Enzymes, immobilization, downstream, enzyme kinetic, baking, starch

conversion, brewing, protein modification, dairy products, pectinase, cellulase,

amylases, proteases, enzymes as medicines.

Contents

1. Introduction

2. Sources of Enzymes

3. Enzyme Production

S

TE S

3.1. An Overview on Downstream Processing

R

AP LS

3.1.1. Filtration

3.1.2. Centrifugation and Sedimentation

3.1.3. Flocculation and Coagulation

C EO

3.1.4. Cell Disruption

3.1.5. Extraction

3.1.6. Precipitation

3.1.7. Chromatography

3.1.8. Finishing Operations

E –

H

3.1.9. Invertase Production: As a Case

4. Fundamentals on Enzyme Kinetic

PL O

4.1. Introduction

M SC

4.2. Specificity

4.3. Enzyme Activity

4.3.1. Quantification of the Enzyme Activity

4.3.2. Expression of the Enzyme Activity

SA NE

4.3.3. Factors Affecting the Enzyme Activity

4.3.4. Briefing on Thermodynamic of the Enzyme catalysis

4.3.5. An Overview on Enzyme Immobilization

U

5. A Briefing on the Uses of Enzymes

5.1. Baking

5.2. Starch Conversion

5.3. Protein Modification with Enzymes

5.3.1. Introduction

5.3.2. Brewing

5.3.3. Dairy Industry

5.3.4. Miscellaneous uses of Proteolytic Enzymes

5.4. Enzymes in Fruit Juices

5.5. Miscellaneous

5.5.1. Detergents

5.5.2. Effluent and Waste Treatments

5.5.3. Flavor Production with Enzymes

5.5.4. Leather

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

5.5.5. Textiles

5.5.6. Pulp and Paper

5.5.7. Edible Oils

5.5.8. Enzymes in Animal Feeding

5.5.9. Enzymes as Analytical Tools

5.5.10. Enzymes as Medicines

5.5.11. Enzymatic Biotransformations

6. Conclusion

Glossary

Bibliography

Biographical Sketch

Summary

Enzymes are proteins capable to convert a specific compound (the substrate) into

S

TE S

another (product) at a high reaction rate. They also are enantioselective catalysts, which

R

AP LS

enable them to be used either in the separation of enantiomers from a racemic mixture

or in the synthesis of chiral compounds. Although the enzymes utilized today are also

found in animals (chimosin, pepsin, trypsin and pancreatin) and plants (ficin, papain and

bromelain), the bulk of them are of microbial origin (pectinases, glucoamylase, α-

C EO

amylase, among others). As the microorganisms present high growing capability, huge

amounts of enzymes can be produced in a short period of time as well as the strains can

be genetically manipulated, in order to improve their enzyme production capability.

Moreover, microbial enzymes are plentiful supplied, well standardized and marketed by

E –

H

several competing companies. Depending on the kind of process, enzymes can be

employed in two forms, i.e., soluble (animal proteases and lipases in tannery, for

PL O

example) or immobilized (isomerization of glucose to fructose by glucose isomerase,

for example). Today, the enzymes are envisaged as the core kernel of biotechnology,

M SC

because they are the main tools for the application of the basic biotechnological

techniques (restriction enzymes for DNA-recombinant and cell fusion procedures) and

processes (fermentation and cell culture). Moreover, they are largely used in analytical

SA NE

procedures, in human and animal therapy – as medicines or as target to drugs -, and in a

variety of industrial processes (baking, brewing, starch conversion, protein

modification, detergents, tannery, textiles, edible oils production, effluent and waste

U

treatment, among several others).

1. Introduction

Enzymes are proteins having catalytic capability, i.e., they convert a compound – called

substrate – into another at a high reaction rate. For example, the hydrolysis of sucrose

into glucose and fructose catalyzed by invertase (a glycoprotein extracted mainly from

yeasts) occurs almost instantaneously.

The enzymes have been used along the centuries in industrial processes as tannery,

brewing, bakery, dairy, etc. Depending on the kind of the process, the enzymes were

employed as soluble catalysts – as the proteases and lipases from animal origin in

tannery or gastric juice from the abomasum of the suckling calf in dairy – or through the

use of whole microorganisms cells, mainly in fermentation processes like brewing and

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

bakery. In spite of the role of the microbial cells in the fermentation process was well

established by Pasteur in 1876, the enzymatic mechanisms began to be understood only

between the end of 19th and the beginning of the 20th centuries, when some enzymes

were isolated and produced in industrial scale, mainly invertase and amylase (which

hydrolyses the starch), and their kinetic behavior determined through appropriate math

modeling. Indeed, the study on the enzymatic catalysis goes on beyond to the

foreseeable future, insofar as molecules other than proteins (ribonucleic acids,

structurally modified antibodies, synthetic peptides and chemically modified proteins)

can present such capability. Besides, the development of the immobilization techniques

– in which a catalyst is attached to an inert material aiming to carry out the reaction as a

continuous process and to allow the recuperation of the catalyst after the reaction ended

– enlarged the use of the enzymes, as will be discussed further.

Nowadays, the enzymes are considered the core kernel of the biotechnology, because

they are the main tools for the application of the basic biotechnological techniques( the

S

TE S

DNA-recombinant and cell fusion), the target of therapeutics drugs and the

R

AP LS

indispensable intermediate in all biotechnological processes (fermentation and cell

culture). Besides, they have a fundamental role in maintaining the life of any kind of

organism, because the occurrence of all cell metabolic pathways depend on the

C EO

participation of at least one enzyme.

Today, enzymes are used in analytical procedures, in human and animal therapy as

drugs or as target to drugs and in industrial processes.

E –

2. Sources of Enzymes

H

PL O

The enzymes can be attained from animals (chimosin, pepsin, trypsin, for example),

plants (ficin, papain and bromelain) and microorganisms (pectinases, glucoamylase, α-

M SC

amylase, among others). [See also– Enzyme Production]. However, the nature of the

source dictates the availability, the cost of source material, the ease of recovery and

many other factors.

SA NE

From the microorganisms, in principle, it can be obtained any kind of enzyme similar to

those of animals and plants. The tendency is to use the microbial enzymes on an

U

industrial scale, because of they are plentiful supplied, the producer can control all

phases of the enzyme production, the commercial enzyme preparation is well

standardized, the enzyme market has a lot of competing suppliers, the source, i.e., the

microorganism, presents a high growing capability, so that huge amounts of enzyme can

be produced in a short period of time as well as the microbial strain can be genetically

manipulated - through the DNA recombinant technique, mainly - in order to improve its

enzyme production capability. As a microorganism strain can often produce several

different enzymes, the producer can operate the fermentation plant in order to shift the

production to one enzyme in detriment of the others, so coping with the market

fluctuations.

In particular for enzymes used in food processing, the supplier must inform the

costumer if the microbial source was an engineered strain. This is due simply to the fact

that the producer has to cope with rigid legal obligations. In that way, the fact that the

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

enzyme is produced by means of engineered microorganism may require a new

approval for the enzyme, and possibly also any food prepared using it may then become

a “novel food” and subject to completely different testing for approval. Another point of

great interest for the enzyme user – still regarding the use of an engineered strain –

refers to the eventual presence into the enzyme preparation of a different compositional

spectrum of enzymes and side activities. This fact can affect negatively the costumer’s

process by introducing new by-enzymes in the reactor leading to unexpected

characteristics into the final product. In short, the good supplier-costumer relationship is

a critical point regarding the efficient employment of enzymes in industry.

3. Enzyme Production

As all commercially valuable enzymes are proteins, so they can be produced through

processes using quite similar unit operations, i.e., extraction from an adequate source

(animal, vegetal or microbial), filtration, centrifugation, precipitation, purification,

S

TE S

drying, stabilization, standardization and packaging. In biotechnology, all unit

R

AP LS

operations comprised between filtration and packaging are generally said downstream

processing.

C EO

The enzymes of animal and plant origin are produced through the maceration of tissues,

organs, leaves and fruits – often residual materials from the cattle rising and agriculture

activities - followed by the extraction with water or organic solvent. Differently, the

microbial enzymes are attained from either procariotic (bacteria) or eucariotic (yeasts,

fungi, mainly) cells cultured in a liquid or semi-solid medium, carried out in a special

E –

reactor called fermenter, being the process known as fermentation.

H

PL O

The semi-solid culture – used in large scale by the first time in 1894 for the production

of amylase from Aspergillus oryzae grown in humidified cooked rice mass for one week

M SC

(“Koji Process”) – occurs as follows: a) The semi-solid medium (corn bran, wheat bran,

soy bran, rice, barley, for instance), is submitted to vapor jets for cooking and

sterilization; b) The semi-solid medium is distributed uniformly throughout several

SA NE

trays, then they are inoculated with the microbial pure strain, in general a fungus; c) The

fermentation is left to occur under aseptic conditions for 6 or 7 days. After that, the

fermented semi-solid medium (FSSM) containing the desired enzyme can be treated by

U

one out of two possible procedures. If a crude enzyme preparation is desired, the FSSM

is directly submitted to drying, grinding and sieving followed by the standardization and

packaging of the final product. Otherwise, the FSSM is submitted to the aqueous

extraction, filtration, centrifugation, precipitation, purification, drying, stabilization,

standardization and package of the final product. This process is quite good when the

enzyme is excreted into the solid medium by the microorganism, such as pectinases,

fungal amylase and cellulases.

The submerged culture is the preferred fermentation process for growing enzyme

producing microorganisms. The microbial cells are maintained in suspension through

constant agitation and under controlled growing conditions (pH, temperature, nutrients,

dissolved oxygen concentration, among others). The medium is an aqueous solution of

substances readily available in large quantities at low cost – raw material costs will be

related closely to the value of the final product, mainly in the case of the enzymes,

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

which are mostly low volume and medium cost products -, such as starch hydrolysate,

molasses, corn steep liquor, whey and many cereals. At the completion of the

fermentation the enzyme may be present within the microorganism or excreted into the

medium. When inside the cell, then the suspension is centrifuged or filtered and the

supernatant or filtrate is discharged and the cell cake collected; otherwise the cell cake

is discharged and the liquid phase is collected. Depending on the enzyme to be intra or

extracellular, the fermentation must be carried out in a way that the cell growth is

optimized or not, respectively.

3.1. An Overview on Downstream Processing

The downstream comprehends several unit operations which are aimed at concentration

and purification of the enzyme, often present in a raw extract of disrupted cells. The

main unit operations employed are filtration, centrifugation, sedimentation, flocculation,

coagulation, cell disruption, extraction, ultrafiltration, precipitation, crystallization,

S

TE S

chromatography, evaporation, drying and packaging.

R

AP LS

The first task in formulating a downstream strategy is to define or acknowledge the

required purity of the enzyme. The allowable ranges of impurity concentrations, and the

C EO

specific impurities which may be tolerated, will be dictated by the end-use of the

catalyst. All microbial enzyme products to be used in foods or medicines are required to

meet stringent purity requirements with regard to toxicity. At present only a small

number of microorganisms are used for enzyme production. Responsibility for the

safety of an enzyme product remains with the manufacturer. In practice, a safe enzyme

E –

product should cause no allergy and be free from toxic substances and pathogenic

H

microorganisms. It must be borne out that the enzyme recovery usually accounts for a

PL O

large portion of the product cost and in some cases is the major manufacturing cost.

M SC

3.1.1. Filtration

The rate of passage of a liquid through a filter of unit area is dependent on the pressure

SA NE

difference applied, the resistance of the filter material, the viscosity of the liquid, and

the resistance produced by cake already present. Thus the effectiveness of a filter will

initially be high, but will fall as material accumulates and perhaps compresses. Filter

U

aids, such as diatomaceous earth, retain finer particles and are valuable in enzyme

isolation, but they tend to occlude liquor containing the enzyme and will damage

downstream equipment if allowed to pass into the filtrate. Siliceous materials constitute

a health hazard and must be treated with care, particularly when dry.

The commonest forms of industrial filter are the plate and frame press, and the rotary

drum filter. The former consists of filter cloths trapped between corrugated plates; fluid

passes in at one side of the cloth and out, via the corrugations, to a pipe serving all the

units in the battery. To remove the solids the plates must be parted manually or semi-

automatically and the cloths thoroughly cleaned. Fungal mycelia are readily removed in

this manner, as are bacteria after flocculation and enzymes precipitated by ammonium

sulphate.

In the rotary drum filter, vacuum is applied to the inside of a hollow drum rotating in a

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

trough containing the material to be filtered. Sediment accumulates on a filter cloth

from which it may be removed by a multiplicity of methods.

When a common paper or cloth filter is substituted by a membrane capable to separate

from a suspension or solution, respectively, particles (including molecular aggregates)

or molecules (or macromolecules) with mean diameter smaller than 5μ, the unit

operation would be named microfiltration, ultrafiltration, nanofiltration or reverse

osmosis (a particular kind of ultrafiltration, in which the membrane allows the passage

of solvent molecules only). The microfiltration membrane has a mean pore diameter

between 0.05 and 5μ, meanwhile the ultra, nano and reverse osmosis membranes have

pores running through it of average diameter 500-5000 Å. Thereby, these membranes

are capable for separating substances having a molecular weight between 500 and

300.000. Very small molecules will pass through the membrane and large ones will be

retained at the filter surface. Intermediate-sized molecules will be retained within the

structure of the membrane and will eventually block the pores. For this reason

S

TE S

microporous filters have been superseded by diffusive membranes. Indeed, the diffusive

R

AP LS

membranes are formed by thousands layers of special polymers toughly superposed,

through which the molecules with a certain mol weight can trespass each layer when

submitted to an electric field - applied across the membrane - or a concentration,

C EO

pressure or temperature gradient. In other words, the ultrafiltration is basically a

molecular diffusion throughout the membrane. Thus the transport of a molecule across

the membrane requires kinetic energy and occurs more readily at high temperatures. A

readily permeable membrane would be readily hydrated and composed of a polymer

E –

with a strong specific affinity for its solvent. Conversely, a relatively unhydrated, rigid

H

membrane would have low permeability, particularly when there was reduced affinity

between the membrane polymer and the solvent.

PL O

M SC

In the most general sense a synthetic membrane is a barrier which separates two phases

and restricts the transport of various chemical species in a rather specific manner. A

membrane can be homogeneous or heterogeneous, symmetric or asymmetric in

structure, it may be neutral, may carry positive or negative charges, or may be bipolar.

SA NE

Its thickness may vary between less than 100 nm to more than a centimeter. The

electrical resistance may vary from several megaohms to a fraction of an ohm. The term

“membrane” includes a great variety of materials and structures and a membrane can

U

often be better described in terms of what it does rather than what it is. All materials

functioning as membranes have one characteristic property in common: they restrict the

passage of various chemical species in a very specific manner. Asymmetric membranes

are surface filters and retain all rejected materials at the surface where they can be

removed by shear forces applied by the feed solution moving parallel to the membrane

surface. The so called “membrane polarization” is a phenomenon arising as a build-up

of rejected solute at the membrane surface. This impedes solvent flux so that eventually

it may no longer respond to an increase in hydraulic pressure. Thus the design of

ultrafiltration apparatus is aimed at minimizing the build-up of such polarization layers,

in small scale apparatus by stirring, and in larger equipment by maintaining high fluid

flow rates over the membrane surface. They are used primarily in pressure driven

membrane processes, such as reverse osmosis, ultrafiltration or gas separation. In other

words, applications of these processes to enzyme isolation – or to another kind of

biomolecules - at the pilot scale and industrial level are centered upon concentration.

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

As the micro and ultrafiltration membranes have been developed and improved, an

apparatus known as membrane reactor (MR) has also been developed. This device can

be used in enzyme continuous processes as an alternative to the conventional reactors

(mainly, the continuous stirred tank reactor [CSTR], the packed- or fluidized-bed

reactor). As a general rule, the conventional reactors operate with the enzyme linked to

an insoluble inert support, whereas the membrane reactor can operate with the enzyme

free in solution or linked to the membrane (the enzyme is confined on the surface or

within the membrane). The MR can be shaped either as a CSTR coupled with a

semipermeable membrane or as a hollow-fiber reactor, i.e., a tank without stirring filled

with a sheaf of straight-lined hollow-fiber tubes of semipermeable membrane. However,

the membrane/biocatalyst arrangement can involve or not an interaction between them.

If they are linked, the membrane acts as catalysis and separation surface simultaneously;

otherwise, it functions only as a separation surface. When the enzyme is in the soluble

form, the membrane reactor can involve the recycle of the enzyme (the CSTR and the

ultrafiltration membrane module are connected in series, generally called bimodule-

S

TE S

MR) or not (the ultrafiltration membrane is adapted to the bottom of the CSTR as in a

R

AP LS

stirred ultrafiltration cell, generally called unimodule-MR). The main operational

features of the MR are the homogeneous catalysis, the high activity per unit of volume,

the absence of conformational and difusional effects and – if needed – the MR can be

C EO

operated under aseptic conditions as well as with multienzymatic systems. Those

features are gradually shifting the industry preference from the traditional immobilized

enzyme reactors (packed- or fluidized bed reactor and CSTR) to the MR. This tendency

is borne out by the use of the membrane reactor in a dozen processes, resulting in a

large variety of products (gluconic acid, glucose, fructose, cyclodextrins, cathecol,

E –

among others).

H

PL O

3.1.2. Centrifugation and Sedimentation

M SC

These unit operations are both based on density differences between insoluble particles

and the surrounding fluid. Sedimentation relies on gravity and settling to achieve solid-

liquid separation, and is generally performed in rectangular or circular flow tanks.

SA NE

Centrifugation, in turn, involves mechanical application of a centrifugal force to obtain

a solid concentrate and clarified supernatant.

U

Centrifugation has become a widespread technique for the removal of solids,

particularly under circumstances where filtration is ineffective - when, for instance, it is

desired to remove a precipitated protein, which is frequently gelatinous or colloidal in

nature – or unwanted.

There are several types of centrifuges for enzyme isolation, being broadly employed the

tubular bowl centrifuge, multichamber centrifuge, disc bowl centrifuges, solid-bowl

scroll centrifuge and perforate bowl basket centrifuge.

At this point, the ultracentrifugation unit operation must be remembered. The

ultracentrifugation is based upon use of the ultracentrifuge, in which materials may be

subjected to centrifugal forces many thousands of times stronger than the force of

gravity. Ultracentrifuges have been constructed in which the rotor revolves 60,000 times

per minute, giving centrifugal forces of the order of 500,000 times gravity.

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

Ultracentrifugation is valuable in determining the purity of colloids, and it has been

applied especially to proteins. When solutions of proteins or other colloidal solutions

are placed in glass or quartz cells in the rotor of the ultracentrifuge, they are subjected to

a force depending on the angular velocity of the centrifuge and the distance of the

colloidal particles from the axis of rotation. The rate at which the particles move is

dependent upon this force and also upon the shape, size, and density of the particles, and

upon the density and viscosity of the suspending medium. With homogeneous

substances where the particles are all alike, the particles move under the centrifugal

force as a sharp single boundary in the medium, whereas mixtures of particles of

different kinds give multiple boundaries and fuzzy zones. For example, the

ultracentrifugation is used in the separation and purification of virus proteins mixed

with tissue proteins. The virus proteins, of very large molecular size, are centrifuged to

the bottom of the cell at a centrifuge speed at which the smaller tissue proteins are left

suspended in the medium. Also, ultracentrifugation is used in the separation of

mitochondrial, microsomal, and nuclear fractions from disrupted tissue cells.

S

TE S

R

AP LS

3.1.3. Flocculation and Coagulation

Coagulation is the result of direct adherence among very small particles present in a

C EO

medium, due to the neutralization of the charge on the particles by adding polyvalent

ions of opposite charge, thus permitting coalescence. Inorganic salts have long been

used for this purpose while more recently organic polyelectrolytes have gained in

popularity. Flocculation, in turn, refers to the formation of much more open aggregates

in which the flocculating agent acts – a variety of natural polymers, such as gelatine,

E –

and a number of synthetic polymers (electrolytes or not) - as an extended bridge

H

between particles. Inorganic ions cannot cause flocculation although they may be used

PL O

to neutralize charge and assist flocculation. However, organic polyelectrolytes may

cause simultaneous coagulation and flocculation. These techniques have been applied to

M SC

whole cells, cell debris, and soluble proteins (enzymes included).

-

SA NE

-

-

U

TO ACCESS ALL THE 85 PAGES OF THIS CHAPTER,

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

Bibliography

Blanch, W.H.; Clark, D.S. (1996). Biochemical Engineering, 702 pp. New York, USA: Marcel Dekker

Inc. [This book describes several unit operations employed in downstream protocols].

Godfrey, T.; West, S. (1996). Industrial Enzymology, 609 pp. New York, USA: Stockton Press. [A

comprehensive treatise on the overall application of enzymes as well as a good reference for enzyme

kinetic and legislation related to the use of enzymes].

Lauwers, A.; Scharpè, S. (1997). Pharmaceutical Enzymes, 401 pp. New York, USA: Marcel Dekker. [A

treatise on the main enzymes employed as medicines, including data concerning pharmacological,

©Encyclopedia of Life Support Systems (EOLSS)

BIOTECHNOLOGY –Vol. VI - Industrial Uses of Enzymes - Michele Vitolo

bioequivalence, among other medical aspects].

Nagodawithana, T.; Reed, G. (1993). Enzymes in food Processing. 480 pp. San Diego, CA, USA:

Academic Press Inc. [A quite complete treatise on the use of enzymes in food technology as well as an

extensive description of the main enzymes used in food industry].

Ribeiro, Z.R.; Silva, D.P.; Vitolo, M.; Roberto, I.C.; Pessoa-Jr., A. (2007). Partial purification of glucose

6-phosphate dehydrogenase by aqueous two-phase poly(ethyleneglycol)/phosphate systems. Brazilian

Journal of Microbiology 38, 78-83. [This represents one of the plausible approaches to the use of reverse

micelles for purifying enzymes].

Roberts, M.S.; Turner, J.N.; Willetts, A.J.; Turner, M.K. (1995). Introduction to Biocatalysis Using

Enzymes and Microorganisms, 195 pp. Cambridge, UK: Cambridge University Press. [This describes

several biotransformations using cells or enzymes for industrial and analytical interest].

Said, S.; Pietro, R.C.L.R. (2004). Enzymes as Biotechnological Agents, 412 pp. Ribeirão Preto, São

Paulo, Brazil: Legis Summa. [This presents a comprehensive discussion on the use of enzymes as drugs,

analytical tools and in several industry sectors (food, chemical-pharmaceutical)].

Tomotani, E.J.; Vitolo, M. (2007). Production of high fructose syrup using immobilized invertase in a

S

TE S

membrane reactor. Journal of Food Engineering 80, 662-667. [Full description of the use of the

unimodule-type membrane reactor coupled with a micro-filtration membrane on the hydrolysis of sucrose

R

AP LS

immobilized by adsorption on anionic resin].

Tomotani, E.J.; Vitolo, M. (2007). Immobilized glucose oxidase as a catalyst to the conversion of glucose

into gluconic acid using a membrane reactor. Enzyme and Microbial Technology 40, 1020-1025. [This

C EO

describes the suitability of the membrane reactor as a tool for carry out an oxidation/reduction process].

Biographical Sketch

Prof. Dr. Michele Vitolo attained the degree in Pharmacy at the Sciences Pharmaceutical School of

E –

University of São Paulo (FCFUSP), Brazil. At the same University attained the Master degree in

H

Biochemical and Pharmaceutical Technology and the PhD. in Biochemistry. Today, he is full Professor at

FCFUSP, in which teaches the under-graduate course “Pharmaceutical Biotechnology” and the post-

PL O

graduation courses “Industrial Uses of Enzymes” and “Application of Immobilized Enzymes and Cells”.

Over the last three decades has published about 150 full papers and more than 200 abstracts and short

M SC

communications in the proceedings of international congresses. Supervised more than 30 Thesis. Two

patents on the application of enzymes in sugar industry were asked to the Brazilian Patent Office. Today,

his research interest relates to the use of membrane reactor for carrying out enzyme catalyzed reactions.

SA NE

U

©Encyclopedia of Life Support Systems (EOLSS)

You might also like

- Enzymes: Novel Biotechnological Approaches for the Food IndustryFrom EverandEnzymes: Novel Biotechnological Approaches for the Food IndustrySelim KermashaRating: 4 out of 5 stars4/5 (1)

- .Adjson DataDocument1 page.Adjson DataNotTalkTo codmNo ratings yet

- .Adjson DataDocument1 page.Adjson DataNotTalkTo codmNo ratings yet

- CALLING DATA - RatnagiriDocument24 pagesCALLING DATA - RatnagiriSAGAR SONARNo ratings yet

- Production of Acetone From Isopropyl AlcoholDocument159 pagesProduction of Acetone From Isopropyl AlcoholChaudhry Zaid100% (1)

- Unesco - Eolss Sample Chapters: Industrial MycologyDocument9 pagesUnesco - Eolss Sample Chapters: Industrial MycologyvalentinaNo ratings yet

- InTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological ApplicationDocument15 pagesInTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological Applicationchavi1310No ratings yet

- Module 1: Introduction Lecture1: Introduction: NPTEL: IIT KharagpurDocument6 pagesModule 1: Introduction Lecture1: Introduction: NPTEL: IIT KharagpurShruti PantNo ratings yet

- Gupta, 2002Document18 pagesGupta, 2002jbio2No ratings yet

- Application of Enzyme Immobilization in The Food Industry: M. B. Mandake, Urvashi Das, Laxman Phad, Sakshi BusamwarDocument5 pagesApplication of Enzyme Immobilization in The Food Industry: M. B. Mandake, Urvashi Das, Laxman Phad, Sakshi BusamwarKRISHNA SINGHNo ratings yet

- Why Inspection Microbial EnzymesDocument3 pagesWhy Inspection Microbial EnzymesAbdel Azim MohamedNo ratings yet

- Prospecting of EnzymeDocument11 pagesProspecting of EnzymeAmit PrakashNo ratings yet

- Role of Enzymes in the Pharmaceutical IndustryDocument19 pagesRole of Enzymes in the Pharmaceutical IndustryEduardo Henrique Santos GuedesNo ratings yet

- Presented by - R Hemamalini 2010CYZ8795 Group G1Document29 pagesPresented by - R Hemamalini 2010CYZ8795 Group G1h_rajagopalan100% (1)

- Molecular farming: Low-cost production of high-quality recombinant proteins in plantsDocument20 pagesMolecular farming: Low-cost production of high-quality recombinant proteins in plantsVeerendra Singh NagoriaNo ratings yet

- Commercial Production of EnzymesDocument4 pagesCommercial Production of EnzymesAli RazaNo ratings yet

- Advanced Enzymes White PaperDocument16 pagesAdvanced Enzymes White PaperAnubhav TripathiNo ratings yet

- Green Cell Factories For Advanced Production of Plant Secondary MetabolitesDocument17 pagesGreen Cell Factories For Advanced Production of Plant Secondary MetabolitesSuhasini SharmaNo ratings yet

- Novel Enzymatic Processes Applied To The Food IndustryDocument9 pagesNovel Enzymatic Processes Applied To The Food IndustryAbrahan EstradaNo ratings yet

- Enzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Document141 pagesEnzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Komagatae XylinusNo ratings yet

- Detergent ProteasesDocument5 pagesDetergent ProteasesAbdurahman Yassin100% (1)

- Protease EnzymeDocument22 pagesProtease Enzymeامنة احمد زيدNo ratings yet

- Chbe Engineering Applications in BiotechnologyDocument23 pagesChbe Engineering Applications in BiotechnologyHilmi ÖlmezNo ratings yet

- The Use of Enzymes in Food Processing: A Review: January 2015Document22 pagesThe Use of Enzymes in Food Processing: A Review: January 2015Alexa SanchezNo ratings yet

- NG D NG C A EnzymeDocument17 pagesNG D NG C A EnzymeHau HauNo ratings yet

- Cytochrome P450 From Plants: Platforms For Valuable PhytopharmaceuticalsDocument12 pagesCytochrome P450 From Plants: Platforms For Valuable PhytopharmaceuticalsNurma MarcellaNo ratings yet

- Industrial Production of ProteaseDocument56 pagesIndustrial Production of ProteaseMuskan MishraNo ratings yet

- 15 Yeast in BiotechnologyDocument6 pages15 Yeast in BiotechnologyMichael Vincent MonteroNo ratings yet

- Pplied Enzymology: Enzyme SourcesDocument51 pagesPplied Enzymology: Enzyme SourcesMaha hameedNo ratings yet

- Automated Production in Plant Factories: Submitted By: Eiman Meer. Reg. No.: FA18-BTY-021Document5 pagesAutomated Production in Plant Factories: Submitted By: Eiman Meer. Reg. No.: FA18-BTY-021E MeerNo ratings yet

- Folio Biology EnzymeDocument10 pagesFolio Biology EnzymeIzZati YazidNo ratings yet

- Industrial ApplicationDocument25 pagesIndustrial Applicationphongbui100No ratings yet

- Project ThesisDocument37 pagesProject ThesisAishu SampathNo ratings yet

- Biochemical Processes (Section 2) : What Is Biochemical Process?Document8 pagesBiochemical Processes (Section 2) : What Is Biochemical Process?Ren H. RoxasNo ratings yet

- Prosiding Penelitian Ilmu Hayat-13Document19 pagesProsiding Penelitian Ilmu Hayat-13Dominika Sari HutapeaNo ratings yet

- BahanDocument40 pagesBahanCobra QueenNo ratings yet

- BIOCHEMISTRY II MIDTERM REVIEW (1)Document4 pagesBIOCHEMISTRY II MIDTERM REVIEW (1)Biology BảoNo ratings yet

- Enzyme TechnologyDocument13 pagesEnzyme TechnologyJaskirat SinghNo ratings yet

- Transgenic PlantsDocument53 pagesTransgenic PlantsAnuradha KumariNo ratings yet

- Application of Biotechnology For The Biosynthesis of EnzymesDocument9 pagesApplication of Biotechnology For The Biosynthesis of EnzymesEstiarul PranNo ratings yet

- Methods of Immobilizing Enzymes for BioprocessesDocument16 pagesMethods of Immobilizing Enzymes for BioprocessesDavid Muñoz HuachuhuillcaNo ratings yet

- Enzymes As BiocatalystsDocument47 pagesEnzymes As BiocatalystsAnamika ChatterjeeNo ratings yet

- Yeast Transgenic PlantsDocument5 pagesYeast Transgenic PlantsTooba Iqbal67% (6)

- Bioprocess Consideration S in Using Animal CellsDocument26 pagesBioprocess Consideration S in Using Animal CellsAnna Patrice AcobaNo ratings yet

- L. Et Al., 2003) - The Structure and Functionality of Given Protein Is Determined by ItsDocument4 pagesL. Et Al., 2003) - The Structure and Functionality of Given Protein Is Determined by ItsIla RuchieNo ratings yet

- Microbial Fermentation GuideDocument35 pagesMicrobial Fermentation GuidethushalNo ratings yet

- Pichia PDocument7 pagesPichia PSarah SalaNo ratings yet

- Enzyme Screening, Production and ModificationDocument106 pagesEnzyme Screening, Production and ModificationAlbert KuufamNo ratings yet

- Industrial Enzymes - Present Status and Future Perspectives For IndiaDocument16 pagesIndustrial Enzymes - Present Status and Future Perspectives For IndiaNagender SinghNo ratings yet

- Immobilized enzymes and whole cell biocatalysts in bioprocessesDocument28 pagesImmobilized enzymes and whole cell biocatalysts in bioprocesseseffak750iNo ratings yet

- Plant Cell CultureDocument8 pagesPlant Cell Culturenurul9535No ratings yet

- Biotech NotesDocument172 pagesBiotech NotesAshishShuklaNo ratings yet

- Enzymes in Food Bioprocessing - Novel Food Enzymes, Applications, and Related TechniquesDocument6 pagesEnzymes in Food Bioprocessing - Novel Food Enzymes, Applications, and Related TechniquesRogelioSalazarNo ratings yet

- SaurabhChaudharyPaperDocument22 pagesSaurabhChaudharyPaperphucnguyentran2002No ratings yet

- A2 Biology Ch 10 BiotechDocument2 pagesA2 Biology Ch 10 BiotechSamiha AhmedNo ratings yet

- Enzymatic Determination of Catechol Oxidase and Protease From Fruits (Orange, Apple) and Vegetables (Carrot, Tomato)Document7 pagesEnzymatic Determination of Catechol Oxidase and Protease From Fruits (Orange, Apple) and Vegetables (Carrot, Tomato)International Organization of Scientific Research (IOSR)No ratings yet

- Fermentation Optimization for Protease ProductionDocument21 pagesFermentation Optimization for Protease ProductionArvind ManikantanNo ratings yet

- Microbial Enzymes PDFDocument10 pagesMicrobial Enzymes PDFnsiahadamsNo ratings yet

- GEN-BIO Group1Document13 pagesGEN-BIO Group1JUDE LUCKY LESHTER SUNENo ratings yet

- Literature Review On Cellulase ActivityDocument9 pagesLiterature Review On Cellulase Activityzgkuqhxgf100% (1)

- Book - Directed Enzyme Evolution Advancees and Applications PDFDocument286 pagesBook - Directed Enzyme Evolution Advancees and Applications PDFClaudia HerreraNo ratings yet

- Regulation of Secondary Product and Plant Hormone Metabolism: FEBS Federation of European Biochemical Societies: 12th Meeting, Dresden, 1978From EverandRegulation of Secondary Product and Plant Hormone Metabolism: FEBS Federation of European Biochemical Societies: 12th Meeting, Dresden, 1978M. LucknerNo ratings yet

- Recent Advances in Polyphenol ResearchFrom EverandRecent Advances in Polyphenol ResearchCelestino Santos-BuelgaNo ratings yet

- PLL Algorithms GuideDocument2 pagesPLL Algorithms Guideamin124010No ratings yet

- Physical Science GR 12 Nov 2020 P2Document20 pagesPhysical Science GR 12 Nov 2020 P2David ShitimaNo ratings yet

- Introduction to ChemistryDocument137 pagesIntroduction to ChemistryDavid Shitima100% (1)

- Physical Science GR 12 Nov 2020 P1Document20 pagesPhysical Science GR 12 Nov 2020 P1David ShitimaNo ratings yet

- OLL Algorithms (Orientation of Last Layer) : Algorithm Presentation FormatDocument4 pagesOLL Algorithms (Orientation of Last Layer) : Algorithm Presentation FormatZORRO SWAT100% (1)

- PEA Zambia 2019 Secondary Catalogue PDFDocument48 pagesPEA Zambia 2019 Secondary Catalogue PDFSavron ScottNo ratings yet

- Chemistry 10 To 12 Notes PDFDocument321 pagesChemistry 10 To 12 Notes PDFMoses NjobvuNo ratings yet

- Physical Science GR 12 Nov 2020 P2Document20 pagesPhysical Science GR 12 Nov 2020 P2David ShitimaNo ratings yet

- Introduction to ChemistryDocument137 pagesIntroduction to ChemistryDavid Shitima100% (1)

- GCSE Chemistry Question and Answers 2015Document46 pagesGCSE Chemistry Question and Answers 2015deeyamullaNo ratings yet

- 5.111 Principles of Chemical Science: Mit OpencoursewareDocument8 pages5.111 Principles of Chemical Science: Mit OpencoursewareSamarjeet Kumar SinghNo ratings yet

- Analisis Molekuler Tingkat Kekerabatan Babi Hutan Dan Babi RusaDocument12 pagesAnalisis Molekuler Tingkat Kekerabatan Babi Hutan Dan Babi Rusanaura ANo ratings yet

- Carbohydrate Research: S.V. Gomand, T. Verwimp, H. Goesaert, J.A. DelcourDocument9 pagesCarbohydrate Research: S.V. Gomand, T. Verwimp, H. Goesaert, J.A. DelcourfrendystpNo ratings yet

- (Reearch) - Tangerine BiochemistryDocument4 pages(Reearch) - Tangerine BiochemistryPaolo VeloceNo ratings yet

- Formation by Vesiculoviruses - Ogino2011Document10 pagesFormation by Vesiculoviruses - Ogino2011Marcus PlungianskiNo ratings yet

- JTBaker Solid Phase ExtractionDocument16 pagesJTBaker Solid Phase Extractionerminb1525No ratings yet

- Hydrogen Storage in The Form of Methylcyclohexane: S. Yolcular and Ö. OLGUNDocument8 pagesHydrogen Storage in The Form of Methylcyclohexane: S. Yolcular and Ö. OLGUNsj singhNo ratings yet

- 2020-I Péptidos y ProteínasDocument4 pages2020-I Péptidos y ProteínasDiana Alexandra Santos RiveraNo ratings yet

- Banana ProductionDocument27 pagesBanana Productiongilmore ramosoNo ratings yet

- Goji Berry Fruit Properties and CompositionDocument5 pagesGoji Berry Fruit Properties and CompositionDanaNo ratings yet

- Eukaryotic DNA Replication EnzymesDocument14 pagesEukaryotic DNA Replication EnzymesmalakmounirNo ratings yet

- CH 28 PDFDocument27 pagesCH 28 PDFkrishnaNo ratings yet

- Common Names (Organic Compounds)Document8 pagesCommon Names (Organic Compounds)Tushar100% (5)

- 6 Crude Oil RefiningDocument57 pages6 Crude Oil RefiningAkashNo ratings yet

- Tokiwa2004. Degradation of Microbial PolyestersDocument9 pagesTokiwa2004. Degradation of Microbial PolyestersEddie MichaelNo ratings yet

- Final PM IS 16240 - 10042023Document15 pagesFinal PM IS 16240 - 10042023exceltechconsultingNo ratings yet

- ChemistryDocument21 pagesChemistryZeeshan KhanNo ratings yet

- Hci 2015 Jc2 Prelim h2 Chemistry Paper 3 Worked SolutionsDocument18 pagesHci 2015 Jc2 Prelim h2 Chemistry Paper 3 Worked SolutionsallahNo ratings yet

- Chemistry 111 Exam on Solids, Liquids, and GasesDocument4 pagesChemistry 111 Exam on Solids, Liquids, and GasesRobyn KentNo ratings yet

- 3 Photo Chemical Rearrangement ReactionsDocument11 pages3 Photo Chemical Rearrangement ReactionsPrakash Rajagopalan100% (1)

- (Raymond Chang) Chemistry by Raymond Chang (B-Ok - Org) Compressed (1) - 546-554Document9 pages(Raymond Chang) Chemistry by Raymond Chang (B-Ok - Org) Compressed (1) - 546-554Hikma AinazzahraNo ratings yet

- Blood Testing For DioxinsDocument2 pagesBlood Testing For DioxinstedmozbiNo ratings yet

- Chapter 8 Cellular Energy: Section 1: How Organisms Obtain Energy Section 2: PhotosynthesisDocument31 pagesChapter 8 Cellular Energy: Section 1: How Organisms Obtain Energy Section 2: PhotosynthesisZ RashNo ratings yet

- Cau 6 Chuong 2Document2 pagesCau 6 Chuong 2Sang PhanNo ratings yet

- Analysis of Contents of Cold DrinksDocument18 pagesAnalysis of Contents of Cold DrinksjyotiNo ratings yet

- How Substances Impact the EnvironmentDocument10 pagesHow Substances Impact the EnvironmentArjan BhargavaNo ratings yet

- Bba - Proteins and Proteomics: SciencedirectDocument12 pagesBba - Proteins and Proteomics: SciencedirectSritapa Basu MallickNo ratings yet