Professional Documents

Culture Documents

NHA SPECIFICATOIN (1998) For Construction Material

NHA SPECIFICATOIN (1998) For Construction Material

Uploaded by

Abdul SaboorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NHA SPECIFICATOIN (1998) For Construction Material

NHA SPECIFICATOIN (1998) For Construction Material

Uploaded by

Abdul SaboorCopyright:

Available Formats

NHA SPECIFICATOIN (1998) For Construction Material

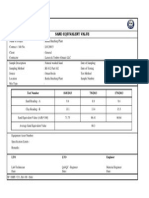

ITEM Subbase AGG. B/C ASP B/C ASP W/ C PROPERTIES OF ASPHALT MIX CONCRETE REQUIREMENTS TRAFFIC ROAD SIGNS item .607

N.M Size Str Metal Beam Guard Rail

GRADING OF COURSE AGG FOR CONCRETE FINE AGG item Cemt W/c CEMENT# item 401.2.1 ASTMC-150 Metal Posts Nuts and Bolts

CLASS Class of C/Agg Mini Slump mm item . 604.2 AASHTO M 180

(ASP B/C item#203.2) ASP ASP item #401.2 #401.2 Kg/m³ Ratio OPC TYPE 01 item - 607.2.3 ASTM- A 501

NHA Spec item NHA Spec item NHA Spec item NHA Spec item kg/ cm²

(ASP W/C itm#305.2) B/C W/C

#201.2 #202.2 #203.2 #305.2 A2,D1,D2, steel posts of minimum internal and external

Sieve # A" B" A" B" A" ~ B" A" ~ B" B, LEAN A3,C A1 Y Sieve Pasing A1 300 20mm 210 0.58 25-75 Air Content By Vol 12 max Yield Point Mini 3500 kg/ cm²

D3 diameters of sixty three (63) mm and seventy

2"1/2 100 Air Voids (%) 4~8 4~7 100 9.5mm 100 A2 350 25mm 245 0.58 100-150 Fineness m²/kg 160 mini five (75)

Tensile Strength Mini 4900 kg / cm²

Not more than 5%

2" 90~100 100 100 100 100 VMA (%) Mini 13.0 Mini 13.0 90~100 100 #04 95~100 A3 400 38mm 280 0.58 100-150 Air permeability 280 mint Tensile Strength Mini 400Mpa -58000 Psi

shall Pass#08

1".1/2 — — — — 90~100 100 Stability Kgs Mini 2250 Mini 1000 35~70 95~100 100 #16 45~85 B 250 51mm 170 0.65 25-75 Autoclave Expansion 0.8max yield Strength Mini 250Mpa -36000 Psi

Elongation in (2") Mini 12%

1" 50~80 55~85 70~95 75~95 — 75~90 100.0 Loss of Stability % Mini 25.0 Mini 20 0~15 − 95~100 100 #30 10~30 C 275 38mm 210 0.58 25-75 Strength Psi Elongation - 2" Mini 23%

3/4" — — — — 56~75 65~80 90~100 100.0 Flow 0.25mm0.01 in 12~21 8~14 − 35~70 − 90~100 100 #50 2~10 D1 450 25mm 350 0.40 50-100 3 Day 1740 Wide flange ASTM A 283 Grade D.

The bolted connection of the rail element to

1/2" — — — — — 55~70 — 75~90 Stripping test T- 182 Above95 Above95 0~5 − 25~60 − 90~100 #200 0~3 D2 500 25mm 425 0.40 50-100 7 Day 2760 the post shall withstand a two thousand two

3/8" — 40~70 30 - 65 40~75 — 45~60 56~70 60~80 Asphalt Content % Mini 3.0 Mini 3.5 10~30 − 20~55 40~70 F:M % D3 550 25mm 500 0.40 50-100 Setting Time Tensile Strength 415~550 Mpa hundred seventy (2270) kg pull at right angles

No. 4 35~70 30~60 25 - 55 30~60 23~40 30~45 35~50 40~60 0~5 0~10 0~10 0~15 2.3 ~ 3.1 Y 400 13mm 210 0.58 25-75 Initial Mint 45 yield Strength Mini 230 Mpa to the line of the railing.

REQUIREMENTS FOR ASPHALT CEMENT

No. 8 15~30 15~35 23~35 20~40 (AASHTO M-20) item- 301-2

PRIME COAT REQ FOR Medium-Cuing Type Asphalt item- 301-3 ( Lean 175 51mm 100 – – Final Mint 375 Elongation-2"Mini 23% Connections and Splices .All bolts and nuts item-

(AASHTO- M-82)

No. 10 — 20~50 15 - 40 20~50 — — — — Tack Coat Rapid-Curing item- Grouting of Bonded Steel :One part cement to 0.75 part sand .W/C Ratio .45 Maxi Elongation-8"Mini 20%

604.2.3 ASTM A 153

No. 40 — 10~30 8 - 20. 12~25 — — — — Penetration Grade TYPE 301-4(AASHTO- M-81) .strength 170Kg / Cm² after 7Day

Test Req Test Req Zinc coating g/m² 550 Mini

No.50 4~10 5~15 5~12 5~15 60~70 80~100 MC.70 MC.250 RC-70 Rc-250

REQUIREMENTS FOR EMULSIFIED ASPHALTS Sign Panels

Penetration at (25 oC)

No. 200 2~8 5~15 2 - 8. 5~10 3~6 2~7 2~8 3~8 60~70 80~100 Water, percent 0.2max 0.2max 0.2max 0.2max item 301-5 (AASHTO M-140) item 607.2.1 Coating thick (micron) 79 Mini

100g 5 sec.

Flash point, Cleveland Open Aluminium alloy conforming to

L.A.Abrasion (T-196) Max .50% Max .40% Max .40% Maxi .30% 232mini 232 mini Flash point (tag. open cup), Degree C 38 Mini 66 Mini − 27 Mini Test on Emulsions RS-1 RS-2 SS-1

Cup, (oC) ASTM- B 209 alloy 5052 - H38 Guard Rail Posts

— Ductility at (25 oC) 5cm per Kinematic Viscosity at 60oC (140oF) (See (A) item604.2.4 ASTM A -183

Soundness(T-104) Max . 12% Max . 12% Maxi . 12%

min, cm.

100 mini 100 mini Note 1) Centistokes

70~140 250~500 70~140 250~500 Viscosity,Saybolt Furol at (25oF)Sec 20~100 − 20~100 Tensile Strength Mini 270Mpa

Sand Equivalent(T-176) Min .25% Min.45% Min.45% Mini .45% Solubility in trichloroethylene % 99.0 99.0 Distillation test: Viscosity,Saybolt Furol at (50 oC)Sec − 75~400 − yield Strength Mini 220Mpa Yield Point Mini 250 Mpa

Thin-film oven test, 1/8 in.

C.B.R (T-193) Min. 50% Min.80% (3.2mm), (163 oC) 5 hr Loss on 0.8Max 1.0Max Distillate, percentage by volume of total distillate at 360oC Settlement 5 days, percent (a) 05 Maxi 05 Maxi 05 Maxi Elongation - 2" Mini 4% Tensile Strength Mini 400~550 Mpa

— — heating, percent

LIQLID LIMIT(T-89) Max .25% Max .25% Max .25% Max .25%

Penetration, of residue, % of

54mini 50mini at 190oC 20max 10max 10 Mini − Storage stability test 1 day (b) 01 Maxi 01 Maxi 01 Maxi Nuts and Bolts item -607.2.5 Elongation in (8") Mini 20%

original.

Ductility of residue at (25oC) 5 heavily galvanized quality ten (10) mm dia

Plasticity Index(T-90) Max . 6% Max . 6% Max . 6% Max . 4%

cm. per min., cm.

50mini 75mini at 225oC 20max 10max 50Mini 35Mini Demulsibility,35 m1. 0.02 NCaCl2 % 60 Mini 60 Mini − (G.I.) or aluminium alloy.galvanised according End or Buffer Sections

at 260oC to ASTM A 153. item - 604.2.2

Proctor (T-180) No Req No Req — — STONE FOR RIPRAP item 509.2.1 20~60 15~55 70 Mini 60Mini Cement mixing test, percent − − 02 Maxi

Moisture Content OMC±1 OMC±1 — — water absorption 6Maxi at 315 oC 65~90 60~87 85Mini 80Mini Sieve test, percent .10 Maxi .10 Maxi .10 Maxi zinc coating g/m² 550 Mini Yield Point Mini 227 Mpa

mini apparent specific

2.5mini mortar of

Residue from distillation at 360 oC (680 oF)

Specific Gravity (T-84 ) No Req No Req — —

Volume percentage of sample by difference 55 Mini 67 Mini 55 Mini 65 Mini Residue by distillation, % 55 Mini 63 Mini 57 Mini coating thick (micron) 79 Mini Tensile Strength Mini 310 Mpa

gravity ratio 1:3

Flat&Elogated Particles(D- — — Maxi 15% Maxi 10% L.A.Abrasion (T-196) 45Maxi Tests on residue from distillation Test on Residue from Distillation Test Reflective Sheeting item Bolts and nuts item

4791) 100~200 100~200 100~200

D60/D10 T-27 Min . 3% Min. 4% — — Class : A -Weight Kgs 15~25 20kg +50% penetration, 100g., 5 sec., at 25 oC 120~250 120~250 80~120 80~120 Penetration,(25 oC)100g.5 Sec 607-2 BSI 873 Part 6 604.2.3. requirements of ASTM A 307

Compaction(T-191) 98 100 97 97 Class :B -Weight Kgs 30~70 50kg +50% Ductility, 5 cm/min, cm (see note 2) 100 Mini 100 Mini 100 Mini 100 Mini Ductility, (25 oC), 5 cm/min. cm 40 Mini 40 Mini 40 Mini Minimum Coefficient of Retrofelection Type A B C

(Candelas per footcandel per square foot) Tensile Strength Mpa

FORMATION OF EMBANKMENT:item108.2 STONE PITCHING item 511.2.1 Class :C -Weight Kgs 60~100 80kg +50% Solubility in Trichloroethylene,% 99 Mini 99 Mini 99 Mini 99 Mini Solubility in trichloroethylene,% 97.5 Mini 97.5 Mini 97.5 Mini 415 415~690 400~550

( Mini

2nd

(D15Filter)>(4*

1st

condition

use AASHTO Class A-1, A-2, A-3, A-4 or A-5 soil as

D15Filter)<(4*D85Embankment)

Class : A - 20~25 Grade MC-70 Furol Viscosity Yield Point Mpa

20kg 60~120 60~120 Elastomeric Bearing Pads ITEM Elastomer for Deck Expansion Joint Seals Observation Entrance

specified in AASHTO M-145 or other material approved by 15~25 cm Class : A mini thickness 20 cm − −

ITEM 406.2.3 Angle (o) white yellow 50

the Engineer Weight Kgs +50% depth

at 50oC sec sec 406.2.5 Angle (o) Mini

CBR (T-193):05% Mini Swell value (0.5)%Maxi below TEST ASTM

D15Embankment)

Class : B - 15~20 Grade MC-250 Furol Viscosity Elongation in

12kg 125~250 125~250 TEST ASTM

subgrade Level Compaction (T-191): (Over 75cm 90 %)

Weight Kgs 10~15 cm Class: B mini thickness 45 cm at 60oC

−

sec

−

sec Designation Spec Designation Spec 0.2 -4 250 170 (2") Mini

18 18 23

(30 to 75cm 93%)(0 to 30cm 95 %) +50% depth

Hardness, Durometer A,

Subgrade in Embankment : item 109.2.5 Grouted Pitching mortar of ratio 1:3 Class:C mini thickness 60 cm Site Spray rate L/m² 0.65 ~ 1.75 0.2 ~ 0.4 Tensile strength, Kgs/ cm2 ASTM D.412 160Mini 45±5 points 0.2 30+ 150 100 bolts and nuts galvanised according to

ASTM D 2240

CBR (T-193):07% Mini Swell value WATER BOUND MACADAM BASE Quantities of Materials for Bituminous Surface Treatments Tensile Strength, 127 Kgs/ cm2

ASTM A 153. (9.52mm AboveThick

GABIONS item 1 507.2 Elongation at break, percent ASTM D.412 350 Mini ASTM D 412 0.5 -4 95 62 305gm / m²(9.52mm underThick 259gm/m²

(0.3)%Maxi Compaction (T-191) 95 % ITEM 206.2 ITEM . 304-1 min.

Compression set, 22 hrs. at 67oC, %

The material shall be declared unsuitable if the Wire tensile strength 4000~6000kg/cm² Sieve # Percent Passing by weight Surface Treatment Aggregate Bit Material Deformed D.395 B

ASTM

25 max Elongation at Break 400%min 0.5 30+ 65 45 The bolted connection of the rail element to

soaked CBR (96 hours) is less than five (5) Elongation mini (10) % Body Wire Inch Size No.

Billet-Steel

Compression Set, 22 Hours at the post shall withstand a two thousand two

Class-A Class-B Class-C Type Application Qty Kg/m² Qty L / m² Bars (Grades Tear Strength Kgs/ cm2 2D 624 (Die C) 13 Min. 20% max. The brightness of the reflective sheeting totally

percent or if falls under A-6 or A-7 of AASHTO 2.3mmSelvedge or Perimeter Wire 2.8mm 40 and 60)

70 degree C. D 395,B

wet by rain, shall be at least ninety (90) % of hundred seventy (2270) kg pull at right angles

soil classification Tying and Connecting Wire 1.95mm coating (4”) 100 Single Single 2 12.5 (A)1.19±15% (B)1.63±15% for Concrete

Reinforceme

Hardness (Shore A ASTM D.2240 60±5 Low Temperature, D 746 Not brittle at 40

degree C

the above values. to the line of the railing.

equal (AASHTO M 120 ) Mini(0.25 Kg/Sq. M) nt-AASHTO M-

Ozone resistance 20% strain, 100 hrs. at 38oC + 1 oC D

31 (ASTM REFLECTORIZED PAVEMENT STUDS item -

BRICK MASONRY item 410.2.5 (3.1/2:) 90-100 First 1 24 (A)1.90±15% (B)2.14±15% A-615) 1149 (except 100 +20 parts per 100,000,000) ( Spec : No Ozone Resistance, Exposure to

Cracks) 100 PPHM Ozone for 70 hours at The reflective sheeting shall be sufficiently 609.2

Double 38 oC. Sample under

No cracks flexible as to permit application over and

standard sizedry Compress strength Rock Fill sizes ranging from t (10) cm Low temperature stiffness, Young's Modulus adhesion to a moderately embossed surface. It Vertical load .Strength

kg/cm² (2000 psi) to (20) cm. Filled gabions shall have a (3”) – 100 Second 3 12.5 (A)1.19±15% (B)1.63±15%

at 35oC Kgs/ cm2 D 797 350 Max.

20%. D 1149.

1000Kgs Mini

(9"x4 1/2"x3") shall not show damage when bent (90) degree Requirement

mini density of (1,360) kg/m³. Void over a (50) mm diameter mandrill.

Absorption Mortar of ratio 1:3 spaces shall be evenly distributed maxi (2.1/2”) Low temperature brittleness, 5 hours at

25 - 60 90 - 100 100 First 1 24 (A)1.90±15% (B)2.14±15%

–40oC ASTM D 736 Passed Oil Deterioration - Vol increase

Chain Link Fabric

16.7%Max after soaking in ASTM oil No. 3 for item-

of (30) % .Sodium Sulphate Soundness ( CR Paint ) CHLORINATED RUBBER PAINT ITEM - 611.2.2 AASHTO M 181

STONE MASONRY item : 411.3.1 Mixi (9) % (2”) – 25 - 75 90-100 Tripple Second 2 12.5 (A)1.19±15% (B)1.63±15%

608.2.1

70 hours at 100oC. D 470:(120%Maxi) The sheeting shall show no cracking or

reduction in reflection after being subjected to

HOT-APPLIED THERMOPLASTIC ROAD the dropping of a (25) mm diameter steel ball Zinc coat strength (kN )

(1.1/2”)

size

Stone Size and Shape Concrete kerbs Stone item :601.2 0 - 15 0 - 15 35-70 Third 3 6.5 (C) .68±15% Test White Yellow Black PAINTS ITEM -608 mm(gauge) type1 , 2 type3 type 4

from a height of two (2) meters onto its (g /m²)

surface.

thickness 20Cm Mini (width 1.5 Time of (1”) – – 0-15 Seal Coat / Pad 4 4 (C) .5±15% (white) Titanium Dioxide Rutile and extenders 100% Binder (resin and oil) 18~22 122.1 9.650 6.940 9.655

pigment

Class 'A' , 'C compressive strength 4.88(6)

Coat with

thickness)(Length 1.5 Time of Width) 3000PSI kerbs Bed Compaction (3/4”) 0-5 0-5 0-5

(yellow) Chrome Yellow and

100% Pigment 6 Mini For heat activated material the adhesive shall

3.76(9) 91.5 5.740 4.135 5.740

Aggregate Bituminous material types are (a) asphalt Extenders

permit the reflective sheeting to adhere

90%Mini Mortar of ratio 1:3 Filler material Abrasion test (black) Chrome Black and

100% Pigment and extender 18~22 91.5 3.780 2.715 3.780

Stretchers (width 1.5 Time of thickness ) cement, (b) cut-back or emulsified and (c) Extenders securely forty eight (48) hours after application, 3.05(11)

(AASHTO T-96) asphalt cement, cut-back and emulsified. Modified Chlorinated Rubber at temperatures of up to ninety (90) degree

(Length 2~3.5 Time of thickness) CONCRETE PIPE item :501.2 (M-170) 3/8 100 Maxi (40%) 52±4% Ballotini 20Mini Concrete Posts: Class D1 )Steel Posts AASHTO M 183

Vehicle

liquid Limit Maxi Plasticized and Resin Blend Centigrade

(25) % and a P.I crushing value BS- Aggregate Pigment

linear foot Per

Headers:width mini 1.5 time thikness, length Class 2 4 #4 85-100 Specified Size (Size No&Passing) Solvents 45±4% 78 ~ 82 Deformed Billet-Steel Bars (Grades 40 and 60) for

Pound per

812 Maxi (25%) Extender and ballotini

Diameter

Maxi (6)% The reflective material shall be weather- Concrete Reinforcement- item. 404.2 - AASHTO M-

foot of

mini 2.5 time thikness( Mortar of ratio 1:4) .01"Crack Load 1000 2000 #100 10-30 soundness testing Size No Sieve (mm) Passing Additives 1- 3% Softening point White & yellow 65 ᵒc Mini resistant and following cleaning, shall show no 31 (ASTM A-615)

AASHTO T-104 Size No definite fading, darkening, cracking, blistering

n

Compositio

Paint

Heat stability white 65 Mini Deformed Billet-Steel Bars

Paving Blocks item 217.2.7.1 Ultimate Load 1500 3000 a. Loss Angeles Abrasion Value Max 45% .Maxi (10%) 0~15 Pigments (by Weight) 55±4% or peeling and not less than seventy five (75) % G-40 G-60

01 ~ 18mm 19mm~12.5mm ᵒc yellow 55 Mini Grad

b. Flakiness Index Max 15% flat or Elongated of the specified wet or dry minimum brightness

size length 200mm, width 100mm, c. Sodium Sulphate Soundness test (AASHTO T- Vehicle, Solvent and values when exposed to weathering for five (5)

Ratio 2.5:1 Size No 12.5mm~9.5mm Flow % white Yield Strength PSI Mini 40000

thicknesses are 60mm,65mm,80mm& 104) shall be less than twelve (12). BS-812 02 - 12mm

0~15 Additives (by Weight) 45±5% resistance yellow

25 Max years. 60000

100mm. Wire tensile strength 3,700Kgf/Cm² Mini Maxi (15)

(water absorption of the concrete pipe Size No Applied Rate Paint.1 ~ 2.5L/m². Colour and white 70 Mini Concrete Foundation Blocks

length±2 mm width±2 mm thickness±3 mm 9.5mm~6.3mm 0~15 Tensile Strength PSI Mini 60000 90000

Maxi(8) %) layer will not exceed two and a half (2.1/2) times 03 -9mm ballotini 500g/L.Mini luminance % yellow 55 Mini item- 607.2.9

compressive strength avg 49mpa. the thickness of maximum aggregate size Size No

6.3mm~4.75mm

ballotini(A) seive# No.12 No.20 No.30 No.50 No.80

0~15 Retain % 0 30 50 80 100 Ballotini ( B)400 ~500gm/m² Elongation %

Individual mini 40mpa 04 - 6mm

Defination of soil

Prestressing Reinforcement Steel (item 405.2.1 Astm.A416) The concrete for the foundation #3 (10 mm) 11 9

Cassification of Soil AASHTO M -145 AASHTO M -145 Sieve # 1.7mm, 600 µ, 425µ 300µ 212µ 75µ blocks shall be in situ Class A in

Group 75µm~ ------- 100 80-100 45-100 10-45 0-25 0-5

A-1-a A-1-b A-3 A-2-4 A-2-5 A-2-6 A-2-7 A-4 A-5 A-6 A-7 silt fraction Mini elongation Minimum Ultimate accordance with Item 401.1.1 and #4,5, 6 (13,16,19mm) 12 9

Classification .002mm

4% 16570Kg / sq.cm

tensile strength shall of the size 450 x 450 x 650 mm

smaller than in 20 bar dia

2.00mm(no.10) 50max clay fraction .002mm for category 1 & 2 and 600 x 600 x #7 , 8 (22 ,25mm) 8

a)White lines Not less than 1.5 mm

smaller than 750 mm for category 3. variation

0.425mm(no.40) 30max 50max 51mini colloids .001mm b)yellow edge lines not less than 0.8

Mini yield strength in unit

.425mm~ Diameters after rupture _0.75mm 9100Kg / sq.cm mm.

0.075mm(no.200) 15max 25max 10max 35max 35max 35max 35max 36mini 36mini 36mini 36mini fine sand at 0.7% extension #9 ,10 .11,14,18 weight at

75µm 7

2.0mm~

(29 ,32,36,43,57mm) least 94%

LIQLID LIMIT 25max 25max 40max 40mini 40max 41mini 40max 40mini 40max 41mini course sand .425mm

75mm~

Diameters tolerance _0.25mm Mini modulus of elasticity 1.75x10 Kg / sq.cm

P.I 6max 6max N.P 10max 10max 11mini 11mini 10max 10max 11mini 11mini stone 2.0mm Prepaired by : Amjad Ali (Material Engineer china Beixin company)

You might also like

- Road Works - ChecklistDocument3 pagesRoad Works - ChecklistHAKAN100% (1)

- Aashto T 99-81Document7 pagesAashto T 99-81ORUSNo ratings yet

- Beer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealDocument8 pagesBeer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealFarhaan MohammedNo ratings yet

- Design, Testing, and Construction of Slurry Seal: Standard Practices ForDocument8 pagesDesign, Testing, and Construction of Slurry Seal: Standard Practices ForaraNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Rapid-Curing Type) : Standard Specification Fordong ganNo ratings yet

- C 183Document8 pagesC 183Ricardo GarzaNo ratings yet

- Tuff Paver SpecsDocument7 pagesTuff Paver SpecsHurriyat Ali100% (1)

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 pagesHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNo ratings yet

- Asphalt Concrete Wearing Course Mixture SpecificationDocument4 pagesAsphalt Concrete Wearing Course Mixture Specificationqadiradnan71770% (1)

- 5 Astm c123 c123m 2011 Lighweight Particles in AggregateDocument4 pages5 Astm c123 c123m 2011 Lighweight Particles in AggregateGeorges Abi JaoudeNo ratings yet

- Concrete Test MonitoringDocument1 pageConcrete Test MonitoringMahmoudNo ratings yet

- Stress-Corrosion Cracking: Materials Performance and EvaluationDocument8 pagesStress-Corrosion Cracking: Materials Performance and Evaluationhamid reza taghdirianNo ratings yet

- TR 513Document266 pagesTR 513Vignesh RamanathanNo ratings yet

- No 4 - BS 812 Section 105.1 1989 - Flakiness IndexDocument6 pagesNo 4 - BS 812 Section 105.1 1989 - Flakiness IndexAnonymous fE2l3DzlNo ratings yet

- Astm 535 PDFDocument3 pagesAstm 535 PDFdana setiawan100% (1)

- Prime Coat and Tack CoatDocument17 pagesPrime Coat and Tack CoatRen SalazarNo ratings yet

- Sub-Base & Base (241199)Document14 pagesSub-Base & Base (241199)Aziz ul Hakeem100% (1)

- Mixing Water Specification BS 3148Document5 pagesMixing Water Specification BS 3148abdulrehman73175% (4)

- AASHTO T 310 (Historial)Document2 pagesAASHTO T 310 (Historial)Stuar TencioNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument7 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestMuhsin KhanNo ratings yet

- Astm D-1883-16 PDFDocument14 pagesAstm D-1883-16 PDFVinayak KaujalgiNo ratings yet

- Aci 211.2 - 1998 PDFDocument18 pagesAci 211.2 - 1998 PDFBhavanishankar ShettyNo ratings yet

- ACI 437-19 TocDocument4 pagesACI 437-19 Tocjamjam75No ratings yet

- Standard Specification For Aggregate For Masonry MortarDocument3 pagesStandard Specification For Aggregate For Masonry MortarAlbertto GuardadoNo ratings yet

- C566 PDFDocument3 pagesC566 PDFNaura RasyidaNo ratings yet

- Construction and Quality Control of Flexible PavementsDocument83 pagesConstruction and Quality Control of Flexible PavementsSayan GharNo ratings yet

- 70-TMSS-03-Rev. 01 Normal Weight Ready-Mixed Portland CementDocument38 pages70-TMSS-03-Rev. 01 Normal Weight Ready-Mixed Portland CementImran KhanNo ratings yet

- ASTM-D4944 SpeedyDocument5 pagesASTM-D4944 Speedyclara97No ratings yet

- Isolated Footing Design (BS 8110-97) : Footing No. Group ID Foundation Geometry - Length Width ThicknessDocument10 pagesIsolated Footing Design (BS 8110-97) : Footing No. Group ID Foundation Geometry - Length Width ThicknessAnonymous mWTB5TaMANNo ratings yet

- Method Statement For Rockfill Works: Doubling Safaga / El Quseir / Marsa Alam Road ProjectDocument4 pagesMethod Statement For Rockfill Works: Doubling Safaga / El Quseir / Marsa Alam Road Projectgad100% (2)

- Itp For U-G2Document7 pagesItp For U-G2Ramzi MusthafaNo ratings yet

- AMANA Specs-ASHPHALTIC CONCRETE WORKSDocument25 pagesAMANA Specs-ASHPHALTIC CONCRETE WORKSJishad NalakathNo ratings yet

- 004-Astm C 138 2007 Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pages004-Astm C 138 2007 Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDiego Gauna100% (1)

- Specs-Pavement MarkingsDocument4 pagesSpecs-Pavement MarkingsAnsar Bedharudeen100% (1)

- Astm D545Document4 pagesAstm D545Mohamed Maamoun T.No ratings yet

- ACES Riyadh-Co - Profile 2022-23-REV0 PDFDocument74 pagesACES Riyadh-Co - Profile 2022-23-REV0 PDFOmar O Fili SalehNo ratings yet

- Properties Concrete Dune SandDocument6 pagesProperties Concrete Dune SandAlanSamNo ratings yet

- Chap10 Batching, Mixing, Transporting and Handling ConcreteDocument11 pagesChap10 Batching, Mixing, Transporting and Handling ConcreteCyrus Hong100% (2)

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDocument1 pageC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- 2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFDocument31 pages2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFkyuguNo ratings yet

- Astm C1064.2104017 1Document3 pagesAstm C1064.2104017 1elmer portilloNo ratings yet

- Inspection & Testing Plan For Asphalt Mixtures During ConstructionDocument2 pagesInspection & Testing Plan For Asphalt Mixtures During Constructionjerin sam kurianNo ratings yet

- Kerb Painting (Alkyd Type N) - Adm Standard SpecDocument3 pagesKerb Painting (Alkyd Type N) - Adm Standard SpecRolando de GuzmanNo ratings yet

- Utilization of Copper Slag in Bituminous MixDocument12 pagesUtilization of Copper Slag in Bituminous MixMuktipada DasNo ratings yet

- Sand Content - Mud TestingDocument1 pageSand Content - Mud TestingYougchu Luan100% (2)

- Aashto T 309-15Document3 pagesAashto T 309-15William VasquezNo ratings yet

- Base CourseDocument3 pagesBase Courseprobook450_ehsanNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- Check List For Inspection Before Approval To Concrete or Pouring of ConcreteDocument2 pagesCheck List For Inspection Before Approval To Concrete or Pouring of ConcreteAnil Kumar T BNo ratings yet

- Aashto T 193-93Document6 pagesAashto T 193-93Hafa Lab100% (1)

- Malaysia ReportDocument47 pagesMalaysia ReportAgim Derguti100% (1)

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- Retro-Reflectivity TestDocument8 pagesRetro-Reflectivity Testjitendra100% (1)

- T119Document2 pagesT119Katerin HernandezNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument10 pagesReady-Mixed Concrete: Standard Specification ForMinor CastroNo ratings yet

- BDS 208 (2009)Document16 pagesBDS 208 (2009)S M Faisal MahmoodNo ratings yet

- IS 2185 (Part 1) 1979Document27 pagesIS 2185 (Part 1) 1979manishparetaNo ratings yet

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarNo ratings yet

- NHA SPECIFICATOIN (1998) For Construction MaterialDocument2 pagesNHA SPECIFICATOIN (1998) For Construction MaterialAbdul SaboorNo ratings yet

- API 600 Valve TrimDocument2 pagesAPI 600 Valve TrimVictor NairNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Frequency of Test NHA, AASHTO & ASTM: C/AggDocument1 pageFrequency of Test NHA, AASHTO & ASTM: C/AggNajia SiddiquiNo ratings yet

- Sword FactsheetDocument2 pagesSword Factsheetskywalk189No ratings yet

- Fine Filter BrochureDocument6 pagesFine Filter BrochurePawan ChaturvediNo ratings yet

- Argentometry PPT TitrationDocument5 pagesArgentometry PPT TitrationSayan RoyNo ratings yet

- DHDSDocument4 pagesDHDSThirumal ThirandasNo ratings yet

- Quality Assurance and Quality Control in The Analytical Chemical LaboratoryDocument5 pagesQuality Assurance and Quality Control in The Analytical Chemical Laboratoryproyec_eNo ratings yet

- SAS FoundationDocument18 pagesSAS FoundationGooddayBybsNo ratings yet

- CFBC DatasheetsDocument5 pagesCFBC Datasheetsanimesh907100% (1)

- 6.metabolism in FungiDocument67 pages6.metabolism in FungiWahyuni Irmal100% (2)

- Long ProposalDocument35 pagesLong ProposalApril Trish AlbañaNo ratings yet

- Piezoelectric NanogeneratorDocument24 pagesPiezoelectric NanogeneratorAkhtharEdavannaNo ratings yet

- Heat Pipe - Scientific AmericanDocument10 pagesHeat Pipe - Scientific AmericanEduardo Ocampo HernandezNo ratings yet

- Green Concrete PresentationDocument17 pagesGreen Concrete PresentationSivaramakrishnan PNo ratings yet

- DamperX ClampDocument2 pagesDamperX ClampMuhammad Fahmi MahmudNo ratings yet

- Para Dia FerroDocument31 pagesPara Dia FerroAnil Kumar DograNo ratings yet

- Water-Cement RatioDocument15 pagesWater-Cement RatioRanjithNo ratings yet

- User Manual Remel RapID ONE SystemDocument30 pagesUser Manual Remel RapID ONE SystemKesmavet UPTDLKKNo ratings yet

- Propepeller DevelopemtDocument42 pagesPropepeller DevelopemtVíctor Manuel HernándezNo ratings yet

- Exhaust Temperature Spread Logic UnforcingDocument1 pageExhaust Temperature Spread Logic UnforcingChidiebere Samuel Okogwu100% (1)

- Asam Oksalat (C2H2O4) PDFDocument6 pagesAsam Oksalat (C2H2O4) PDFhermawanahmadNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Experiment 2: Free & Forced Convection Heat TransferDocument10 pagesExperiment 2: Free & Forced Convection Heat TransferIrfan AmeenNo ratings yet

- 1-Basic Concepts About MatterDocument58 pages1-Basic Concepts About MatterM MNo ratings yet

- Kota Worksheet Chemical BondingDocument16 pagesKota Worksheet Chemical BondingYash GargNo ratings yet

- RBC-ThinSection 081315 WEBDocument136 pagesRBC-ThinSection 081315 WEBHenry PalaNo ratings yet

- Twi Cswip 3.1 Set-4b - 1Document5 pagesTwi Cswip 3.1 Set-4b - 1miteshNo ratings yet

- Science LP 1Document3 pagesScience LP 1Juniel DapatNo ratings yet

- Application of Aerogels in Textile IndustryDocument8 pagesApplication of Aerogels in Textile IndustrySanmedha AmbureNo ratings yet

- PyrometerDocument6 pagesPyrometerCikgu KimpalanNo ratings yet