Professional Documents

Culture Documents

Frequency of Test NHA, AASHTO & ASTM: C/Agg

Uploaded by

Najia SiddiquiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frequency of Test NHA, AASHTO & ASTM: C/Agg

Uploaded by

Najia SiddiquiCopyright:

Available Formats

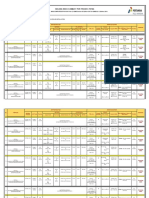

Frequency of test NHA , AASHTO & ASTM

ITEM Earth Work Subbase AGG. B/C ASPhALT CONCRETE STEEL

EMBANKMENT AND SUBGRADE GRANULAR SUBBASE AGGREGATE BASE COURSE ASPHALTIC BASE COURSE WEARING COURSE C/Agg CONCRETE Deformend steel bar

CLASS (ITEM NO. 108 TO 113) (ITEM NO. 201) (ITEM NO. 202)

TEST (ITEM NO. 203) (ITEM NO. 305) (ITEM NO. 401) ASTM-615A

Reference As per Reference As Reference As per Reference As per Reference As per Gradation 2/Stockpile plus

TEST Frequency

Item

Frequency per Item

Frequency Item C/Agg Frequency

Item

Frequency

Item AASHTO T-27 1/1000M³

401.2.3 Number of Test :For Bar Size No

#(3~11)(10~36mm) Inclusive one Tension Test And

Bend Test Shall Be Made Of The Largest Size

Unit Wt. 1/Source plus Rolled From Each Heat .If However Material Form

Sieve # (T-27) 3 / Source plus 1 / 1000 M³ 3/Source plus 1/1000 M 202.2 (a) Sieve # (T-27) 1/1000 M³ — 1/1000 M³ —

AASHTO T-19 1/1000 M³ One Heat Diffese By Three or Mor Desgnation

Numbers one Tension and one Band test Shall be

For use in Made frome both the highest and lowest

108.2, 109.2.5, 3 / Source plus as L.A.Abrasion 3/Source/stock pile plus 3/Source plus 1/5000 Sp. Gravity 2/Source plus

LIQLID LIMIT(T-89) 1 / 2000 M³ 203.2.1 (a) 305.2.1 (a) preparation of mix Desgnation number of the deformed Bars Rolled

110.2 etc required based on 3/Source plus as required (T-196) 1/5000 M³ M³ AASHTO T-85 1/1000 M³ design. For No (14~18) (43~57mm)one Tension Test And

visual observation. based on visual 202.2 (e)

one Bend Test Shall be Made of Each Size Rolled

observation Stripping 3/Source plus 1/5000 Absorption 1/Source plus From each heat

Plasticity Index(T-90) AASHTO T-182

3/Source plus 2/5000 M³ 203.2.1 (b)

M³

305.2.1 (b)

AASHTO T-85 1/500 M³

Moisture Density (Lab) No. 201.2 Visual 3/Source plus as

Abrasion 1/Source plus

(T-180) 108.3, 1/1000 M³ 1/1000 M³ 203.3.3. Fractured faces required based on visual 203.2.1 305.2.1

AASHTO T-96 1/5000 M³

401.2.3

observation. Visual 3/Source plus Prestressing Reinforcement Steel (item 405.2.1

1 / 2,000 M as required based on Astm A-416) Uncoated Seven Wire For

visual observation. Prestressed Concrete

3/Source plus as required 3/Source/stock pile plus as Visual 3/Source plus as

Soundness 1/Source plus

C.B.R (T-193) 108.2 and 110.2 based on variation in required based on 202.2 (f) Flat and Elongated Particle. required based on visual 203.2.1 (e) 305.2.1 (e)

AASHTO T-104 1/5000 M³

401.2.3

gradation or 1/1000 M³ variation in gradation observation.

Deleterious

Sodium Sulphate Soundness 3/Source plus 1/5000 1/Source plus

Swelling (T-193) 1 / 2,000 M³ 108.2 — — —

AASHTO T-104

3/Source plus 1/5000 M³ 203.2.1 (b)

M³

305.2.1 (b) Substance

1/5000M³

401.2.3

One Specimen For Test Shall Be Taken From

AASHTO M-80

Each (20 Ton) Production Lot of Finished

Specific Gravity.

For use in /Source for each size Strand. And Tested For Breaking Strength

Relative Density. and Absorption 4/Source for each size in Hot For use in

Fine Aggregate

1 / 1,000 M 109.2.2 — — — preparation of in Hot bins of Asphalt

preparation of JMF. .Yield Strength And Elongation

ASTM D-4254-83 AASHTO T-85 bins of Asphalt Plant

JMF. Plant

Gradation 2/Source plus Metal Beam Guard Rail

L.A.Abrasion (T-196) 3/Source plus 1/500M³ No. 201.2 3/Source plus 1/5,000 M³ 202.2 Fine/Agg AASHTO M-6 1/1000M³

401.2.2

item . 604.2 (AASHTO M 180)

3/Source plus as required 3/Source plus as

Sand Equivalent Unit Wt. 4/Source plus one piece sample from each 200 pieces in a

Soundness(T-104) — — 3/Source plus 1/5,000 M³ 202.2 (d)

T-176

based on visual observation. 203.2.1 © required based on 305.2.1 ©

AASHTO T-19 1/800M³ lot .

2/1000 M³ visual observation

3/source plus as Specific Gravity For use in

3/source plus as required Plasticity Index. 4/Source plus 1/1000

Sand Equivalent(T-176) required based on visual No. 201.2

based on visual observation

202.2(e)

AASHTO T-89 and T-90.

2/1000 M³ 203.2.1 (d) 1/1000 M³ 305.2.1 (d) AASHTO T-84

M³

preparation of mix Guard Rail Posts item . 604.2.4 (AASHTO-183)

observation design.

as required based on as required based on Specific Gravity. For use in Absorption 1/Source plus 1/1000 Frequency of testing sample according to AASHTO

Specific Gravity (T-84 ) variation in gradation variation in gradation AASHTO T-84

4 4/Source. 2/Source

preparation of JMF. AASHTO T-84 M³ T-243 (5.2.2) 3 Specimen from 15 ton of a lot.

For use in

Visual 3/Source plus as preparation of JMF.

Friable Particles Organic Impurities 1/Source plus

Fractured faces — — required based on visual 202.2 (b)

AASHTO T-112

2/5000 M³ 1/5000 M³ —

AASHTO T-21 1/1000M³

401.2.2 Sign Panels

observation

as required based on as required based on variation Soundness 1/Source plus 1/5000

D60/D10 T-27 variation in gradation in gradation

Bitumen AASHTO T-104 M³

ASTM B-209 ;one sample shall be taken from

each parent plate, but not more than one

4/layer/400 M laid 3 4/layer/400 M laid 3 sample per 1000kg of sheet or 2000kg of

Specific Gravity For use in Fineness 1/Source plus

Compaction(T-191) 1 / 200 M. 108.3, 109.2.2 Minimum/layer if less than No. 201.3.4. Minimum/layer if less than 202.3.3.

AASHTO T-228

2/Shipment.

preparation of JMF.

2/Shipment. —

1/1000M³

401.2.2 plate or part thereof, in a lot shall be required.

400 M laid 400 M laid AASHTO M-6

Penetration. 3/Week of plant operation 3/Week of plant operation

Reflection sheet (item.607.2.2)

Paving Blocks item Sampling of Bitumen Thermoplastic road paints AASHTO T-49 Samples taken from heating 203.2.2. Samples taken from heating 305.2.2

Deleterious Substance 1/Source plus 1/5000 The sheeting manufacturer shall provide a test

217.2.7.1 item 608.3 (aashto m-249) AASHTO M-6 M³

tank at staggered intervals. report from British Standards Institution (BSI) or

material Concrete pipe tank at staggered intervals.

401.2.2

any internationally recognised laboratory stating

item 301 (AASHTO M-20 bitumen, M-81

ITEM 501 (AASHTO M-170)

tackcoat,M-82 prime coat, M-140 that the sheeting meets the requirements

ASPHALTIC BASE COURSE WEARING COURSE 1/Source plus 1/5000

Emulsified asphalt) TEST Petrographic –

Before laying paving blocks, PLANT MIX (ITEM NO. 203) PLANT MIX (ITEM NO. 305) M³ according to BSI 873 Part 6. or FP 92 of FHWA. A

divide each designated section, The minimum batch of thermoplastic full width by 1-yard (0.9m) long sample is

comprising not more than 5000 traffic striping material sampled and Reference As per Reference As per selected at random to represent the entire

Mixture Frequency Frequency

blocks, in a consignment into tested shall not be less than 1360 kg Item Item sheet,roll, or lot , for the testing the coefficient of

According to T-40; The required

eight approximately equal groups,

number of sample shall be taken from unless the total order is less than this Cement retroflectivity 3 sample shall be spaced.

Clearly mark all samples at the Extraction

each delivery of bituminous material to amount.

time of sampling in such a way AN owner of pipe , Whose needs require AASHTO T-164

represent a maximum of 10000 gal.

that the designated section or part shipment at intervals over extend Yield Test for Cement

thereof and the consignment Gradation T-30 1/Lot or 1000 Bags 310.3.3 Metal post (607.2.3)

periods of time, shall be entitled to such Content AASHTO T-121

represented by the sample are Astm A-501(8.2)

Drum barrel carton or bages: if a lot of test , preliminary to delevery of pipe, as Elastomeric Bearing Pads item. Bulk Sp. Gr. Test specimen taken from two lengths of tubing from

Setting Time

clearly defined. Take two (2) material from a singel run of batch of are required by the type of basis of AASHTO T-166 2/day’s 1/Lot or 1000 Bags 401.2.1

blocks from each group. producer , one packge shall be selected

406.2.5 2/day’s production. 203.2.3. 305.2.3. AASHTO T-131 each lot of 500 lengths.

acceptance specified by the Method B production.

accordance with this Part of BS at random and sampled as described

below owner.owner shall be entitled to Maximum Sp. Gr. Mortar Strength REFLECTORIZED PAVEMENT STUDS

6717. 1/Lot or 1000 Bags 401.2.1

additional tests as such time as the AASHTO T-209 AASHTO T-132 (item.609) ASTM D-4280

accordance with this Part of BS

owner may deem necessray, provided The sample shall be taken from each lot

6717. packeges in shipment packeges selected

2-8 2 that the total number of pipe tested of pads or batch of elastomer to be

Air Voids AASHTO T-269

9-27 3 (including preliminary test) shall not furnished, whichever results in the For markers sample size shall be 20 markers

28-64 4

Concrete mix from each lot of 10000 markers or less and

exceed 1 pipe or 1 % whichever is the greater number of samples. The samples Thickness 1/layer @ 100 M interval As per item 1/layer @ 100 M

Bricks item 410.2.5 65-125 5

greater of each size of pipe delivered. will be selected at random at the point of AASHTO T-230 per lane 203.3.11. interval per lane

40 markers from each lot of more than 10000

126-216 6 As per item 305.3.2. .for markers with an abrasion resistant

217-343 7 manufacture or, at the option of the surface , 10 additional sample shall be

10 individual bricks shall be 344-512 8 Compaction Compression (Cube or

513-729 9 Contractor at the job site. 1/layer @ 100 M interval As per item 203.3.9 1/layer @ 100 M 6/Shift or 50 M³(2 sets requried. Lot size shall not exceed 25000

selected from a lot of 1000000 AASHTO T-230 Cylinder)

728-1000 10 per lane A interval per lane of 3 each) markers

bricks or fraction. For a larger AASHTO T-22 401.1.1

1001-1331 11

lot,5 additional specimen shall be

Chain link Fence

selected from each additional Slump AASHTO T-119 2/shift or 50M³ (item-611) aashto-181

500000 bricks or fraction.for

1 Roll from each lot of 50 role sampled for testing

structural clay tile,atleast 5 tile purpose.

shall be selected from a lot of 250 Water

tons or fraction,For a larger lot, Tension wire: 6 specimens from different rolls of a lot

5 additional specimen shall be (defined same size and type presented at one time for

inspection.)3 for breaking load and 3 for mass of coating

selected from each lot of 500 tons Chemical Tests AASHTO T-

26

1/Source 401.2.7

or fraction. post, hardware , fitting sampled in lots of 500 pieces at

All data collected from different spec book . If any mistake then check the refrence or item no given. Prepaired by : AMJAD ALI ( M.E China Beixin company)

one time.

You might also like

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- NHA SPECIFICATION FOR CONSTRUCTION MATERIALS AND ASPHALT MIX DESIGNDocument1 pageNHA SPECIFICATION FOR CONSTRUCTION MATERIALS AND ASPHALT MIX DESIGNSajjad Hussain SolangiNo ratings yet

- NHA SPECIFICATION (1998) FOR CONSTRUCTION MATERIALSDocument2 pagesNHA SPECIFICATION (1998) FOR CONSTRUCTION MATERIALSAbdul SaboorNo ratings yet

- Valve Schedule - 10.5.2021 (LATEST)Document83 pagesValve Schedule - 10.5.2021 (LATEST)rvkheavenNo ratings yet

- API-600-Valve-TrimDocument2 pagesAPI-600-Valve-TrimVictor NairNo ratings yet

- R-216G-311 - 0 Manual Valve With Limit SwitchDocument3 pagesR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiNo ratings yet

- Lifting - Equipment - Matrix1 (Under Constrution)Document1 pageLifting - Equipment - Matrix1 (Under Constrution)PradeepNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- Passingen PDFDocument1 pagePassingen PDFAnonymous Z4Jo4fXVNo ratings yet

- SSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETDocument16 pagesSSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETSasi MesthiriNo ratings yet

- AST-NDE-UT-R-500-4-2 Rev.01 Ultrasonic Testing ReportDocument7 pagesAST-NDE-UT-R-500-4-2 Rev.01 Ultrasonic Testing Reportpankaj ranaNo ratings yet

- EBM A2E AxialFanInChillerDocument10 pagesEBM A2E AxialFanInChillerwillratNo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- ELCOS 3000 RPM INTEL Light RUDocument3 pagesELCOS 3000 RPM INTEL Light RUandreyNo ratings yet

- Ball Valves - 4 Inch - Class 150 - A105N - TR - RFDocument1 pageBall Valves - 4 Inch - Class 150 - A105N - TR - RFsatphoenixNo ratings yet

- Compare ASME and material specsDocument2 pagesCompare ASME and material specsg_sanchetiNo ratings yet

- WELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEDocument6 pagesWELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEFerdie OSNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- Metric fits and tolerances chartDocument1 pageMetric fits and tolerances chartChin Yuan GohNo ratings yet

- 1C4 (KSS021-D-528) - Column-R1Document1 page1C4 (KSS021-D-528) - Column-R1mo3azNo ratings yet

- Material Comparison ListDocument1 pageMaterial Comparison ListaliextomaNo ratings yet

- Given: Project: Kruger FanDocument2 pagesGiven: Project: Kruger FanRoyal EagleNo ratings yet

- Series 307Document4 pagesSeries 307Prathamesh GangalNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- Matrix For Piping Work - ITP - Final - PK3Document4 pagesMatrix For Piping Work - ITP - Final - PK3Trương Ngọc SơnNo ratings yet

- AaaDocument9 pagesAaawretchNo ratings yet

- Step Angle 1.8°Document26 pagesStep Angle 1.8°Miguel MaahNo ratings yet

- Tal Wsa PNG Iso 1CS106701 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106701 - 01 - A01 - 00landeopauloNo ratings yet

- Qap CPVC Pro Fitting SDR 11Document1 pageQap CPVC Pro Fitting SDR 11amit rajputNo ratings yet

- 036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3Document1 page036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2cae02 Iso HL 26330 06 0S2Document2 pages036909C 2cae02 Iso HL 26330 06 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: 3B M1 3B M1 3A M1 FDocument5 pagesBill of Material Sketch List: 3B M1 3B M1 3A M1 FNguyenCanhBaoNo ratings yet

- Auto Generated Isometric for SPOOLGENDocument11 pagesAuto Generated Isometric for SPOOLGENNguyenCanhBaoNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- Catalogue LG 2017latestDocument46 pagesCatalogue LG 2017latestOmar Ardila100% (1)

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- Auto Generated Isometric for LSP Complex ProjectDocument1 pageAuto Generated Isometric for LSP Complex ProjectNguyenCanhBaoNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- Auto Generated Isometric for LSP Complex ProjectDocument8 pagesAuto Generated Isometric for LSP Complex ProjectNguyenCanhBaoNo ratings yet

- Correct Filling Weight: Wiring DiagramDocument1 pageCorrect Filling Weight: Wiring DiagramEko hari PrasetyoNo ratings yet

- 036909C 2cae02 Iso HL 26267 03 1F1S3Document2 pages036909C 2cae02 Iso HL 26267 03 1F1S3NguyenCanhBaoNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- ExpressDocument2 pagesExpressabhi.c01487No ratings yet

- Mo00322 Effpfd2286Document1 pageMo00322 Effpfd2286Phevos DanNo ratings yet

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocument2 pagesREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNo ratings yet

- 793B Truck With VIMS Electrical System: 1HL195-UPDocument2 pages793B Truck With VIMS Electrical System: 1HL195-UPGilvan JuniorNo ratings yet

- 23 07 2018 - DAY-Inspection Log SheetDocument1 page23 07 2018 - DAY-Inspection Log SheetArunNo ratings yet

- P-100_CF030F111-2EDocument2 pagesP-100_CF030F111-2EIrsan TasmanNo ratings yet

- PIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameDocument1 pagePIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameJakir HossainNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- QW 483Document2 pagesQW 483Juan Manuel Fabregat MorenoNo ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeNo ratings yet

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Questions Stock & Their ValuationDocument2 pagesQuestions Stock & Their ValuationNajia SiddiquiNo ratings yet

- Job ShadowingDocument2 pagesJob ShadowingNajia SiddiquiNo ratings yet

- Financial Markets and Institutions Course Outline - SINDHUDocument4 pagesFinancial Markets and Institutions Course Outline - SINDHUNajia SiddiquiNo ratings yet

- Project Status at a GlanceDocument7 pagesProject Status at a GlanceNajia SiddiquiNo ratings yet

- Ques Risk and Return & CAPM (S-17Revised)Document6 pagesQues Risk and Return & CAPM (S-17Revised)Najia SiddiquiNo ratings yet

- FORMULA SHEET For Final - FMDocument1 pageFORMULA SHEET For Final - FMNajia SiddiquiNo ratings yet

- Today's FPSC TGT Paper - SanwalDocument2 pagesToday's FPSC TGT Paper - SanwalNajia SiddiquiNo ratings yet

- Current Affairs MCQs (2019 - 2020)Document59 pagesCurrent Affairs MCQs (2019 - 2020)maleeq ul islamNo ratings yet

- The Cost of Capital (WACC)Document3 pagesThe Cost of Capital (WACC)Najia SiddiquiNo ratings yet

- English Vocabulary For CSSDocument19 pagesEnglish Vocabulary For CSSNajia SiddiquiNo ratings yet

- Cash Flow StatementDocument5 pagesCash Flow StatementSara KarenNo ratings yet

- Questions Capital BudgetingDocument2 pagesQuestions Capital BudgetingNajia SiddiquiNo ratings yet

- Macroeconomics 102Document176 pagesMacroeconomics 102Desire FrkNo ratings yet

- FINANCIAL ACCOUNTING Notes (MBA)Document9 pagesFINANCIAL ACCOUNTING Notes (MBA)Najia SiddiquiNo ratings yet

- Human Resource Management: Lesson - 01Document11 pagesHuman Resource Management: Lesson - 01Najia SiddiquiNo ratings yet

- Institute: DOWDocument1 pageInstitute: DOWNajia SiddiquiNo ratings yet

- Marketing Management Section B FinalDocument2 pagesMarketing Management Section B FinalNajia SiddiquiNo ratings yet

- University of KarachiDocument53 pagesUniversity of KarachiWaqasBakaliNo ratings yet

- Literature Review: 2.1 E-CommerceDocument2 pagesLiterature Review: 2.1 E-CommerceNajia SiddiquiNo ratings yet

- Pharma Marketing Trends ShiftDocument2 pagesPharma Marketing Trends ShiftNajia SiddiquiNo ratings yet

- Applied Research Methods: Dr. Sahar AwanDocument20 pagesApplied Research Methods: Dr. Sahar AwanNajia SiddiquiNo ratings yet

- Mid Term - ARMDocument2 pagesMid Term - ARMNajia SiddiquiNo ratings yet

- Microecnomics Section B FinalDocument1 pageMicroecnomics Section B FinalNajia SiddiquiNo ratings yet

- Micro MBA E 1 B Mid Term AssessmentDocument2 pagesMicro MBA E 1 B Mid Term AssessmentNajia SiddiquiNo ratings yet

- Course Outline (Spring 2021)Document4 pagesCourse Outline (Spring 2021)Najia SiddiquiNo ratings yet

- QTM Final 1B Fall2020Document2 pagesQTM Final 1B Fall2020Najia SiddiquiNo ratings yet

- AbstractDocument1 pageAbstractNajia SiddiquiNo ratings yet

- Mid Term Assessment (Assignment) Spring 20201: HRM (Sec A) Marks 20 Monday 5 April, 2021 Google ClassroomDocument2 pagesMid Term Assessment (Assignment) Spring 20201: HRM (Sec A) Marks 20 Monday 5 April, 2021 Google ClassroomNajia SiddiquiNo ratings yet

- IMPORTANT Instructions:: Best of LuckDocument3 pagesIMPORTANT Instructions:: Best of LuckNajia SiddiquiNo ratings yet

- Appliance DocumentationDocument44 pagesAppliance DocumentationВадим КрасноперовNo ratings yet

- Journal Review - Philosophical and Contextual Issue in Nursing Theory DevelopmentDocument4 pagesJournal Review - Philosophical and Contextual Issue in Nursing Theory DevelopmentJULIE ANN PARANo ratings yet

- Common Admission Test (CAT) 2020 Admit Card: BarcodeDocument2 pagesCommon Admission Test (CAT) 2020 Admit Card: BarcodeViraaj ThakurNo ratings yet

- The Maharashtra Shops and Establishments (Regulation of Employment and Conditions of Service) Rules, 2018Document2 pagesThe Maharashtra Shops and Establishments (Regulation of Employment and Conditions of Service) Rules, 2018Gopinath hNo ratings yet

- UG TRB Physical Education Study MaterialDocument17 pagesUG TRB Physical Education Study Materialசண்முக சுந்தரம் குருசாமி100% (2)

- Dokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023Document23 pagesDokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023urexalg AlgériaNo ratings yet

- Naemi Root Crop Rat Killer ResearchDocument3 pagesNaemi Root Crop Rat Killer ResearchJerome BumagatNo ratings yet

- Convenient Regime:: Indications of Stopping The InfusionDocument2 pagesConvenient Regime:: Indications of Stopping The InfusionbabyNo ratings yet

- Sage Yb October2015Document460 pagesSage Yb October2015olopNo ratings yet

- Roofing Section Guide for QCS 2014Document5 pagesRoofing Section Guide for QCS 2014Galfarqatar MEPNo ratings yet

- Eng Ind CS Bangalore Mall PDFDocument4 pagesEng Ind CS Bangalore Mall PDFJessica SyiemliehNo ratings yet

- English Hand Out for Class 3Document19 pagesEnglish Hand Out for Class 3Pat WibawaNo ratings yet

- August 2016Document15 pagesAugust 2016Pumper Trader0% (1)

- SX SeriesDocument6 pagesSX SeriesmattuttezNo ratings yet

- M6 Artificial Disc Failure Report (1st Part)Document21 pagesM6 Artificial Disc Failure Report (1st Part)Keanu ReevesNo ratings yet

- بﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Document202 pagesبﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Moh Al Basher BabikerNo ratings yet

- Imagicle Solutions Available On Cisco DcloudDocument4 pagesImagicle Solutions Available On Cisco Dcloudchindi.comNo ratings yet

- Gym Membership AgreementDocument3 pagesGym Membership Agreementzde thai100% (1)

- TL102 0 2024 Che3701 0Document12 pagesTL102 0 2024 Che3701 0sollomontlou06No ratings yet

- Amal ResumeDocument2 pagesAmal ResumeMunaNo ratings yet

- Clearing Clutter With Eft PDFDocument23 pagesClearing Clutter With Eft PDFIftikhar Hassun100% (2)

- DAVAO DOCTORS COLLEGE NURSING DRUG STUDYDocument3 pagesDAVAO DOCTORS COLLEGE NURSING DRUG STUDYJerremy LuqueNo ratings yet

- Self-Confidence and Satisfaction Among Nursing Students With The Use of High Fidelity Simulation at Arab American University, PalestineDocument10 pagesSelf-Confidence and Satisfaction Among Nursing Students With The Use of High Fidelity Simulation at Arab American University, PalestineArianna Jasmine MabungaNo ratings yet

- SITHPAT006 Student LogbookDocument46 pagesSITHPAT006 Student LogbookÇrox Rmg PunkNo ratings yet

- Bonding in Organic Compounds - Organic Synthesis Marks SchemeDocument96 pagesBonding in Organic Compounds - Organic Synthesis Marks SchemeRaiyan RahmanNo ratings yet

- Caterpillar C18 ACERTDocument2 pagesCaterpillar C18 ACERTMauricio Gomes de Barros60% (5)

- KR1100 2Document1 pageKR1100 2Byron Xavier Lima CedilloNo ratings yet

- KOLHAN UNIVERSITY B.Sc Zoology Semester I Exam 2021 Provisional Marks CardDocument2 pagesKOLHAN UNIVERSITY B.Sc Zoology Semester I Exam 2021 Provisional Marks CardSmritiNo ratings yet

- Econ Double Regulating ValvesDocument18 pagesEcon Double Regulating ValvesElimKaAdda100% (1)

- UK-India Coffee Market ReportDocument27 pagesUK-India Coffee Market ReportNikhil MunjalNo ratings yet