Professional Documents

Culture Documents

Flygt SUBCAB Kablolar

Uploaded by

Andrey GyrychCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flygt SUBCAB Kablolar

Uploaded by

Andrey GyrychCopyright:

Available Formats

SUBCAB cables ®

OPTIMIZED FOR LONG-LIFE SUBMERSIBLE DUTY

• Long lifetime thanks to highly

resistant materials

• Reliable leak-free fit

• Prevent insulation deterioration

• Built-in monitoring cores

• Screened versions for variable

frequency drive (VFD) operation

• Approved for explosion-proof and

mining applications

1237 . Subcab . 1 . Master . 2 . 20130129

SUBCAB® cables KEY FEATURES

Highly resistant outer sheath Built-in monitoring cores

Ensure long cable lifetime thanks to extremely low water Secure proper monitoring and easy connection of pump

absorption rates, superior mechanical strength and high sensors without the need for auxiliary cables. Screened

temperature, chemical, abrasion, tear, ozone, oil and control cores have been specifically adapted for the use

flame resistance. of the Flygt MAS 800 pump supervision system.

Reliable leak-free fit High quality

Tight outer diameter tolerances ensure conductor insulation

a perfect fit with the cable entry sleeve.

Minimizes the risk of insulation

By retaining its mechanical and physical

cracks, thereby preventing insulation

properties the cable withstands the high

deterioration.

pressure of the seal sleeve.

Screened versions for variable Ex-approved

frequency drive (VFD) applications Approved for explosion-proof applications with

Flygt pumps and mixers in accordance with FM (US)

Ensure correct communication with supervision units.

and INERIS (Europe) and for mining applications in

Reduce electromagnetic emissions to other electronics.

accordance with DIN VDE 0207.

Cable comparison

Features Flygt SUBCAB cable Standard H07RN-F cable

Expected lifetime 4 times H07RN-F and H07RN8-F. Slow aging due to carefully selected

high-quality materials.

Qualified for permanent use in water Yes, according to EN 50525-2-21 and VDE 0298-300 standards. No

Tested for long-term sealing in Flygt Yes. Cable tested at a water pressure of 5 bar and temperature of 70°C. No

pumps Sealing specifically adapted to Flygt pumps. Optimized outer diameters.

Maximum outer sheath and insulation Resists 70°C at outer sheath, 90°C at insulation. Resists 40°C at outer sheath, 60°C

temperature at insulation

Extra heavy-duty cable for mining Yes, meets material standard 5GM5 for mining industries. Resistant to No

applications mechanical wear.

Weather resistant Yes, tested for UV and ozone resistance. No

Integrated control cores Yes, screened and unscreened. No separate control cable needed. No

Ex approval Yes, approved as explosion protected together with Flygt pumps and No

mixers in Europe (INERIS) and the US (FM).

Electrical and materials approvals Yes. Europe (VDE), North America (CSA), China (CCC). No

Screened versions for VFD and EMC Yes. The screened cable attenuates electromagnetic interference No

applications produced by the use of variable frequency drives (VFDs).

Special cable specification Yes. Well specified for its purpose by Xylem. No

SUBCAB product range

SUBCAB range 3-power cores (1-phase) 4-power cores (3-phase) 7-power cores (Y/D-start)

SUBCAB without control cores 3G1.5 – 3G2.5 4G1.5 – 4G6

SUBCAB with control cores 4G1.5 + 2×1.5 to 4G6 + 2×1.5, 7G2.5 + 2×1.5, 7G4 + 2×1.5,

4G10 + S(2×0.5) to 7G6 + S(2×0.5)

3×120 + 2G70/2 + S(2×0.5)

Screened SUBCAB with control cores S3×1.5 + 3×1.5/3 + S(2×0.5) to

S6×95 + 95 + S(4×0.5)

Flygt is a brand of Xylem. For the latest version of this © 2012 Xylem, Inc. All rights

reserved.

document and more information about Flygt products

visit www.flygt.com

You might also like

- Siemens Cable Catalogue Australia v2Document276 pagesSiemens Cable Catalogue Australia v2jaimeNo ratings yet

- Glider Aerobatics ManualDocument36 pagesGlider Aerobatics ManualmichetraviNo ratings yet

- Siemens Flex Cable PDFDocument107 pagesSiemens Flex Cable PDFeliahud100% (1)

- Wireless Flex Twist Waveguide BR-105349Document6 pagesWireless Flex Twist Waveguide BR-105349flizcaNo ratings yet

- Radio Controls Setup GuideDocument52 pagesRadio Controls Setup GuideHaitham Mohamed100% (1)

- Application Guide Nordberg GP Series Cone CrushersDocument14 pagesApplication Guide Nordberg GP Series Cone CrushersAndrey Gyrych100% (1)

- Monarch-Nice 1000 Electric Drawing PDFDocument9 pagesMonarch-Nice 1000 Electric Drawing PDFGalang AntoNo ratings yet

- CA Bayonet PDFDocument56 pagesCA Bayonet PDFwww.erwer9No ratings yet

- Technical User Guide for 127 - 500 kV High Voltage XLPE Cable SystemsDocument12 pagesTechnical User Guide for 127 - 500 kV High Voltage XLPE Cable Systemsmani_208eeNo ratings yet

- Process Dynamic and Control Lecture NoteDocument120 pagesProcess Dynamic and Control Lecture NoteUb UsoroNo ratings yet

- WEG Weg Insulation System Micatherm 50105432 Brochure EnglishDocument8 pagesWEG Weg Insulation System Micatherm 50105432 Brochure Englishhsu cuterNo ratings yet

- Dry Type Plugin TerminationsDocument4 pagesDry Type Plugin Terminationsrjk941-1No ratings yet

- Spec 01228Document24 pagesSpec 01228NICOLASNo ratings yet

- EPP-1496-3-09 DA1 Series IECDocument12 pagesEPP-1496-3-09 DA1 Series IECshemakkmkNo ratings yet

- Cabling Products and Solutions: CATALOGUE 2010/2011Document196 pagesCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovNo ratings yet

- Trex Onics High Flex Profinet 2Document1 pageTrex Onics High Flex Profinet 2Ricardo GonzalezNo ratings yet

- Fiber Optic Cable: Features ApplicationsDocument2 pagesFiber Optic Cable: Features ApplicationswawanNo ratings yet

- Trident Range Oil RMUEnglishDocument1 pageTrident Range Oil RMUEnglishdip461No ratings yet

- Data Sheet EverGuard TPO 60mil Membrane 342 PDFDocument3 pagesData Sheet EverGuard TPO 60mil Membrane 342 PDFKarina RiveraNo ratings yet

- Sound proof water cooled generators under 40 charactersDocument2 pagesSound proof water cooled generators under 40 charactersRafael Ribeiro LandmachineryNo ratings yet

- MARINE CablesDocument98 pagesMARINE Cablespantek anjingNo ratings yet

- Baterias SecasDocument2 pagesBaterias SecasLEONARDO BALTAZAR ACARAPINo ratings yet

- Bateria Seca - CatalogoDocument2 pagesBateria Seca - CatalogoDan QspNo ratings yet

- FG Od en V2.0Document2 pagesFG Od en V2.0Hedi Ben MohamedNo ratings yet

- CO Wireless Detector Series 600 Safe Air ITIDocument2 pagesCO Wireless Detector Series 600 Safe Air ITIOmar Andres Novoa MartinezNo ratings yet

- Spec 55: ApplicationsDocument10 pagesSpec 55: ApplicationsfrdrfdederNo ratings yet

- Cambium Networks Data Sheet Gigabit Ethernet Surge SuppressorDocument1 pageCambium Networks Data Sheet Gigabit Ethernet Surge SuppressorrafaeleqbrNo ratings yet

- Grid Solutions: Gas-Insulated Substations 170 KV, 50 Ka, 4 000 ADocument4 pagesGrid Solutions: Gas-Insulated Substations 170 KV, 50 Ka, 4 000 ALalit KotturiNo ratings yet

- Buje-Grid Solutions PNRDocument4 pagesBuje-Grid Solutions PNRjasonNo ratings yet

- Bus & Industrial Ethernet Cables GuideDocument18 pagesBus & Industrial Ethernet Cables GuideGabriel Montoya CorreaNo ratings yet

- Topcable Powerflex RV-K enDocument2 pagesTopcable Powerflex RV-K enreivin27No ratings yet

- Insulation Protection Systems: Technical GuideDocument12 pagesInsulation Protection Systems: Technical GuideWilliam BlackNo ratings yet

- Product Data Sheet Anodeflex 3000 Ti Core Rev. 0 04NOV20Document2 pagesProduct Data Sheet Anodeflex 3000 Ti Core Rev. 0 04NOV20Fareed KhanNo ratings yet

- Ideal Weatherproof™ and Underground™ Wire Nut®: P7372D - Rev 3Document2 pagesIdeal Weatherproof™ and Underground™ Wire Nut®: P7372D - Rev 3rt1973No ratings yet

- Conectores Unipolares LevitonDocument60 pagesConectores Unipolares LevitonJuan Diego Arroyave SernaNo ratings yet

- Datatuff Cat 6aDocument2 pagesDatatuff Cat 6aCENo ratings yet

- Grid Solutions: Gas-Insulated Substations 420 KV, 63 Ka, 5 000 A, 2 CyclesDocument4 pagesGrid Solutions: Gas-Insulated Substations 420 KV, 63 Ka, 5 000 A, 2 CyclesLalit KotturiNo ratings yet

- Data Sheet: HFBR-53A5VEMZ/HFBR-53A5VFMZDocument13 pagesData Sheet: HFBR-53A5VEMZ/HFBR-53A5VFMZBANo ratings yet

- EPR-Flexible cable-MLG2-MultiDocument2 pagesEPR-Flexible cable-MLG2-MultipcNo ratings yet

- Ramcro Instruments Cable - CatalogueDocument160 pagesRamcro Instruments Cable - Cataloguetodayr2021No ratings yet

- DW 450 FL - Devilead F 450 °fDocument2 pagesDW 450 FL - Devilead F 450 °fJava Cable CenterNo ratings yet

- Galvashield FMADocument2 pagesGalvashield FMAm.elsanee.cubicNo ratings yet

- 38RMDocument26 pages38RMMohamed SaadAllah67% (3)

- Atex3 Kj4003x1-Bd1 4widevertplussisnetrepeatcarrDocument1 pageAtex3 Kj4003x1-Bd1 4widevertplussisnetrepeatcarrJoona HakkarainenNo ratings yet

- Brochure - FlexTwist® WaveguideDocument6 pagesBrochure - FlexTwist® WaveguideROBERT KOUAKOUNo ratings yet

- EverExceed Modular Max AGM Range VRLA - V2.5 - 2020.08.10Document13 pagesEverExceed Modular Max AGM Range VRLA - V2.5 - 2020.08.10maher100% (1)

- Epp 2154Document4 pagesEpp 2154RazkulNo ratings yet

- AWG Cable (Belden)Document31 pagesAWG Cable (Belden)febripepNo ratings yet

- Brochure DT1-362Document2 pagesBrochure DT1-362Ingeniería SalcoNo ratings yet

- GroE Fiam ImoedanceDocument2 pagesGroE Fiam ImoedanceJawad AmjadNo ratings yet

- 27 Topcable Xtrem H07RN-FDocument1 page27 Topcable Xtrem H07RN-Fdavid.darmaji009No ratings yet

- Gore Aerospace Fiber Optic Cable: 1.2mm SimplexDocument4 pagesGore Aerospace Fiber Optic Cable: 1.2mm SimplexRoad BlasterNo ratings yet

- PRAMAC GSW275V-590V 20 SoundproofDocument2 pagesPRAMAC GSW275V-590V 20 SoundproofRafael Ribeiro LandmachineryNo ratings yet

- DEL Assembly InstructionsDocument8 pagesDEL Assembly InstructionsKarl Ove BlindheimNo ratings yet

- Bowthorpe EMP LV/MV Outdoor Surge ArrestersDocument24 pagesBowthorpe EMP LV/MV Outdoor Surge ArrestersjdzarzalejoNo ratings yet

- 400Y Torrent Engineering - v27 PDFDocument16 pages400Y Torrent Engineering - v27 PDFKrishna N HNo ratings yet

- Fusibles y Canister PDFDocument8 pagesFusibles y Canister PDFjavier vargasNo ratings yet

- FTA064 Rev5Document2 pagesFTA064 Rev5Catalin FilipNo ratings yet

- Atlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Serban Aurel CosminNo ratings yet

- CF31 Sort110 EU Data Sheetchainflex CF31Document6 pagesCF31 Sort110 EU Data Sheetchainflex CF31Luiz Felipe OliveiraNo ratings yet

- Brugg Cables Presentation ECMC PDFDocument47 pagesBrugg Cables Presentation ECMC PDFlilcristiNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Wedeco Effizon Ozon TeknolojisiDocument12 pagesWedeco Effizon Ozon TeknolojisiAndrey GyrychNo ratings yet

- Wedeco Sogutma Suyunda Ozon SistemleriDocument8 pagesWedeco Sogutma Suyunda Ozon SistemleriAndrey GyrychNo ratings yet

- Wedeco Wel Seri Ozon SistemleriDocument4 pagesWedeco Wel Seri Ozon SistemleriAndrey GyrychNo ratings yet

- Wedeco Kagıt EndustrisiDocument7 pagesWedeco Kagıt EndustrisiAndrey GyrychNo ratings yet

- Aquaculture Systems: Optimal Living Conditions. High-Quality Water RecyclingDocument4 pagesAquaculture Systems: Optimal Living Conditions. High-Quality Water RecyclingAndrey GyrychNo ratings yet

- Sanitaire ICEAS SBRDocument12 pagesSanitaire ICEAS SBRAndrey GyrychNo ratings yet

- Sanitaire Membran DifüzörlerDocument8 pagesSanitaire Membran DifüzörlerAndrey GyrychNo ratings yet

- وحدات التطهير بالأوزون الصغيرةDocument4 pagesوحدات التطهير بالأوزون الصغيرةRheoserve100% (1)

- WEDECO Genel KatalogDocument40 pagesWEDECO Genel KatalogAndrey GyrychNo ratings yet

- Xeramic High Efficiency Ceramic Diffuser: Lifelong Reliability. Simple To MaintainDocument4 pagesXeramic High Efficiency Ceramic Diffuser: Lifelong Reliability. Simple To MaintainAndrey GyrychNo ratings yet

- WEDECO 400plus Series Ozone Gas MonitorsDocument4 pagesWEDECO 400plus Series Ozone Gas MonitorsAndrey GyrychNo ratings yet

- Bomba Naranja GodwinDocument20 pagesBomba Naranja GodwinARQUICIVILES SASNo ratings yet

- Sanitaire Enerji VerimliliğiDocument4 pagesSanitaire Enerji VerimliliğiAndrey GyrychNo ratings yet

- Godwin NC Seri PompalarDocument8 pagesGodwin NC Seri PompalarAndrey GyrychNo ratings yet

- Flygt SUBCAB KablolarDocument2 pagesFlygt SUBCAB KablolarAndrey GyrychNo ratings yet

- Flygt Ready Drenaj PompalarıDocument4 pagesFlygt Ready Drenaj PompalarıAndrey GyrychNo ratings yet

- Godwin Vakumlu PompalarDocument4 pagesGodwin Vakumlu PompalarAndrey GyrychNo ratings yet

- Stators: Long-Lasting Performance Down To The CoreDocument2 pagesStators: Long-Lasting Performance Down To The CoreAndrey GyrychNo ratings yet

- Plug-In Seals: Double Mechanical Seal in One Easy-To-Install UnitDocument2 pagesPlug-In Seals: Double Mechanical Seal in One Easy-To-Install UnitAndrey GyrychNo ratings yet

- Xylem TotalcareDocument8 pagesXylem TotalcareAndrey GyrychNo ratings yet

- Flygt DX: Submersible Drainage & Waste Water Pumps, 50 HZDocument4 pagesFlygt DX: Submersible Drainage & Waste Water Pumps, 50 HZAndrey GyrychNo ratings yet

- Monitoring system for Flygt pumpsDocument2 pagesMonitoring system for Flygt pumpsAndrey GyrychNo ratings yet

- Monitoring system for Flygt pumpsDocument2 pagesMonitoring system for Flygt pumpsAndrey GyrychNo ratings yet

- Flygt 2700 Seri Drenaj PompalarıDocument8 pagesFlygt 2700 Seri Drenaj PompalarıAndrey GyrychNo ratings yet

- Flygt DX: Submersible Wastewater & Drainage Pumps, 50HzDocument4 pagesFlygt DX: Submersible Wastewater & Drainage Pumps, 50HzAndrey GyrychNo ratings yet

- Xylem TotalcareDocument8 pagesXylem TotalcareAndrey GyrychNo ratings yet

- Flygt DL Submersible Sewage Pump 50HzDocument4 pagesFlygt DL Submersible Sewage Pump 50HzAndrey GyrychNo ratings yet

- Flygt Çamur Pompaları Genel KatalogDocument12 pagesFlygt Çamur Pompaları Genel KatalogAndrey GyrychNo ratings yet

- BETA TALKS 2 JUNI 2021 Selected by Extraterrestrials William Tompkins - 2Document31 pagesBETA TALKS 2 JUNI 2021 Selected by Extraterrestrials William Tompkins - 2AnugerahSentotSudonoNo ratings yet

- Pos FormatDocument6 pagesPos FormatChelmarie CuracheaNo ratings yet

- 4FE-28Y-40P With FHU+60Document17 pages4FE-28Y-40P With FHU+60tedychrNo ratings yet

- Experiment 13Document4 pagesExperiment 13Mama ChoiiNo ratings yet

- Fire Alarm On Ms Word 22Document39 pagesFire Alarm On Ms Word 22Sandeep YapashettiNo ratings yet

- Matarbari Ultra Super Critical Coal-Fired Power ProjectDocument1 pageMatarbari Ultra Super Critical Coal-Fired Power ProjectHasan al MahmudNo ratings yet

- SS 460 60MDHDocument2 pagesSS 460 60MDHelisianeNo ratings yet

- Offer For 48V 700AH Li-Ion Battery PDFDocument1 pageOffer For 48V 700AH Li-Ion Battery PDFJosé MoralesNo ratings yet

- JawapanDocument3 pagesJawapanYusfalina Mohd YusoffNo ratings yet

- 7 Things That Affect Your Vibration Frequency From The Point of View of Quantum PhysicsDocument12 pages7 Things That Affect Your Vibration Frequency From The Point of View of Quantum PhysicsLluisNo ratings yet

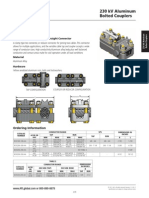

- 230kV Aluminum Bolted Cable Couplers PDFDocument5 pages230kV Aluminum Bolted Cable Couplers PDFCarloNo ratings yet

- Course Title Instructor E Mail Office EL Office Hours ExtbookDocument2 pagesCourse Title Instructor E Mail Office EL Office Hours ExtbookKhairi SalehNo ratings yet

- Notice Inviting Quotation HLL KFC Ducting PDFDocument6 pagesNotice Inviting Quotation HLL KFC Ducting PDFAjeshNo ratings yet

- SPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1Document15 pagesSPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1shayanepmNo ratings yet

- Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloyDocument8 pagesEffect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloysaltbathNo ratings yet

- EMF Measurement Report - HPCL-T1 - JAN 2020Document4 pagesEMF Measurement Report - HPCL-T1 - JAN 2020Prasad GoreNo ratings yet

- AASHTO w-ASTM Equivs 2019-08-26Document11 pagesAASHTO w-ASTM Equivs 2019-08-26ayag allanNo ratings yet

- Calculate the equivalent diameter of a 190 mm x 520 mm rectangular ductDocument10 pagesCalculate the equivalent diameter of a 190 mm x 520 mm rectangular ductKlaikangwol AnuwarnNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument13 pagesExperienced Based Rules of Chemical Engineeringvazzoleralex6884No ratings yet

- MF4202 Additive ManufacturingDocument159 pagesMF4202 Additive ManufacturingOptimMart InternationaleNo ratings yet

- GRE Chemistry Test: Practice BookDocument56 pagesGRE Chemistry Test: Practice BookDave Patrick EscalaNo ratings yet

- Bernoulli's Principle and Application: Ang SovannDocument45 pagesBernoulli's Principle and Application: Ang SovannKantilal MalwaniaNo ratings yet

- IFM - SM7000 - Debitmetre - Sortie AnalogiqueDocument4 pagesIFM - SM7000 - Debitmetre - Sortie Analogiquenapnap5No ratings yet

- How To Decide The Bearing Arrangement KDocument17 pagesHow To Decide The Bearing Arrangement KBurak KoyuncuogluNo ratings yet

- Single-Cell Li-Ion/Li-Polymer Battery Charge Management Controller With Input Overvoltage ProtectionDocument34 pagesSingle-Cell Li-Ion/Li-Polymer Battery Charge Management Controller With Input Overvoltage Protection123No ratings yet

- Ultra-Pod FASTON Fully Insulated Receptacles and Tabs: Application SpecificationDocument13 pagesUltra-Pod FASTON Fully Insulated Receptacles and Tabs: Application SpecificationBrian RuttleNo ratings yet