Professional Documents

Culture Documents

User'S Manual: 1. General Information 2. Product Identification

User'S Manual: 1. General Information 2. Product Identification

Uploaded by

AmirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User'S Manual: 1. General Information 2. Product Identification

User'S Manual: 1. General Information 2. Product Identification

Uploaded by

AmirCopyright:

Available Formats

USER’s MANUAL

1. GENERAL INFORMATION 2. PRODUCT IDENTIFICATION

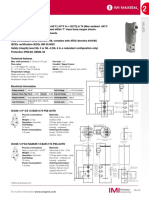

The MICROSOL intrinsic safety solenoid valves produced by 2.1 MICROSOL Solenoid valves codification

Fluid Automation Systems SA are dedicated to piloting fluids in

explosive atmospheres according to the ATEX 94/9/CE directive, Solenoid valve codification

and for which the Examination Certificates EC-Type INERIS 01 - P H

02ATEX0007X and additionally 02ATEX0007X/01 and 02 have Sealing 0 = NBR / 1 = FPM / 5 = EPDM /

6 = FFPM / P = PUR

material

been delivered. Valve body

H = PPS

material

00- = 0.5mm / 01- = 0.8mm / 011 = 1.1mm

Body orifice

Their Ex „ia‟ protection mode enables these solenoid valves:

02- = 1.2mm / 015 = 1.5mm / 03- = 1.6mm

diameter 04- = 2.0mm / 036 = 3.6mm

Connection P- = Pilote ARP / PI = Pilote PAR /

- to be used in ATEX dangerous zones 0 and 20 or lower risk type E- = Sub-base

1 = Direct / 2 = Servo operated /

ones (1/21, 2/22), Actions

3 = Separated Media

1 = NC / 2 = NO / 3 = UNI /

- in the IIC and IIIC group explosive atmospheres or lower Functions

4 = IMPULSION

inflammability zones. Number of

ways

2 = 2 ways / 3 = 3 ways

These solenoid valves have to be supplied by a linear voltage Number of

Valves

- = Simple / 2 = 2 positions manifold /

3 = 3 positions manifold / etc.

source, intrinsic safety type, located in a safe area. Product

11 = PICOSOL

Range

Please follow the recommendations given in this user‟s manual

Electrical specifications codification

as well as all the safety parameters. We decline all responsibility

V C . W

should these recommendations not be followed. Nominal

0.05W to 1W at the nominal voltage

power

Current D = continu / A = alternatif

Nominal

12V / 24V

voltage

Suffix codification

H 01

Specific Construction specification : coil orientation,

Number connector type, protection device, etc…)

Product

01= MICROSOL

Range

H = Special ATEX suffix (EXplosive ATmosphere)

M010.1171-en – 06.01.2014 Page 1/6

USER’s MANUAL

2.2 Marking and electrical characteristics Table 1: Working conditions:

Trade agent Nominal Nominal Resistance Nominal Minimal Maximal

(optional)

area : voltage Power [in ] current switching recommended

[V]ac/dc [W] at 20[°C] [mA] voltage voltage

Manufactured Fluid Automation Systems

by: 12 0.55 280 46 -10% +25%

Route de l'Etraz 126

CH 1290 Versoix / Genève 24 0.7 1150 30 -10% +25%

Suisse

Coils are designed to be permanently under voltage.

Notifed body : INERIS : CE0080

Table 2: Temperature classes:

Type : 01.......... (see codification) Possible performances for 12Vac/dc & 24Vac/dc solenoid valves

H012…

..V AC/DC …W Coil type Temperature class Conditions of use

Coil Gas Combustible Ambient Ui (V) Ii (mA)

Production WW –YY week - year Voltage

resistance (*) dusts (**) temperature (****) (****)

date : (serial number) Vac/dc

range

12 280 Ω T6 T85°C -20°C à +55°C 16 330

12 280 Ω T5 T100°C -20°C à +70°C 16 330

Specific II 1 GD IP65 12 280 Ω T5 T100°C -20°C à +50°C 30 330

ATEX Ex ia IIC T.(*) Ga

marking : Ex ia IIIC T... (**) Da 12 280 Ω T4 T135°C -20°C à +85°C 30 330

INERIS 02ATEX0007X

24 1150 Ω T6 T85°C -20°C à +60°C 30 330

(see table 2)

24 1150 Ω T5 T100°C -20°C à +75°C 30 330

24 1150 Ω T4 T135°C -20°C à +110°C 30 330

M010.1171-en – 06.01.2014 Page 2/6

USER’s MANUAL

The data regarding the maximum surface temperatures is

linked to the ambient conditions (for example, cascade

assembly, built-in or reduced space).

These temperature ranges may be limited by the operating

temperature range of the solenoid valve. Please, confirm the

operating temperature range in “Technical Specifications” for

each valve!

Apparent electrics parameters of solenoid valves:

Ci [F] Li [mH]

0 0

M010.1171-en – 06.01.2014 Page 3/6

USER’s MANUAL

3. INSTRUCTIONS of USE The sealing between the

base and the valve is

The assembly, installation, use and maintenance operations are ensured by the gasket (1) or

the responsibility of the user and must be carried out by qualified the plate and the gasket (2)

and authorized personnel. The personnel working on these supplied with the solenoid

products must be trained and have a complete knowledge of the valve

current safety rules and requirements concerning the products,

the devices, the machines and the electrical installations (for

valves, solenoid valves, electronic controls and air treatment).

The user‟s manual must be in the installer‟s language, must be

supplied with each valve.

Before any intervention (assembly, disassembly and 1

connection), the installer must make sure that the electrical

2

power is off and that all the components are switched off.

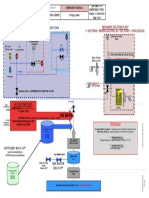

3.1 Pneumatic assembly and fixation.

Pipe connexions

2/2 and 3/2 valves

The solenoid valve can be mounted in any position. In order to

connect the solenoid valve in the best conditions, the The fixing of the solenoid valve is secured by the use of 2 fixing

dimensions of the following fixation drawings must be respected. screws M3 x 18mm (min.) adapted to the valves. They can be

supplied on request.

A tightening torque of 0.6NM minimum should be applied to the

screw.

M010.1171-en – 06.01.2014 Page 4/6

USER’s MANUAL

It is recommended that the pipes be cleaned before installation of Located in a safe area, the barriers and interfaces are allowed to

the solenoid valve. The use of a filter upstream of the solenoid supply the intrinsic safety solenoid valve installed in an explosive

valve is strongly recommended. atmosphere. They must be bought from certified equipment

manufacturers, according to the safety parameters of the solenoid

The solenoid valve can be used exclusively with the fluids that valve. We decline all responsibility for the use of products sold by

are listed in the technical datasheet. other suppliers and the possible modifications of their

characteristics.

3.2 Electrical connection

3.3 Adjustment

In order to ensure the correct use of the solenoid valve without

any risk of damage, you must respect the polarity, which is The MICROSOL solenoid valve does not require any special

identified by a “+” on the plastic housing (1) or by the colour of adjustment.

the wires. The use of a waterproof connector (2) or an adapted

moulded cable is required to ensure the IP65 protection of the

solenoid valve. The metallic insert M3 (3) ensures that the

connector is held in place by a fixing screw (4). 4. SPECIAL CONDITIONS

The solenoid valve must be connected only to a type intrinsic

certified power supply. These combinations must be compatible

with the rules of intrinsic safety and the ambient conditions must

not go beyond the stipulated values (see intrinsic safety electrical

data and temperatures given in the safety parameters tables, table

1 and 2 on page 2).

In the case of use in the 0 zone of the IIC group or in 20 zone of

the IIIC group, the solenoid valve must be protected against

environmental air flow and friction in order to avoid any

electrostatic charge of the covering synthetic material.

M010.1171-en – 06.01.2014 Page 5/6

USER’s MANUAL

5. MAINTENANCE and WARRANTY 6. ADDITIONAL DOCUMENTATION

When used under the conditions defined in the technical Each solenoid valve will be delivered with the CE declaration of

datasheet and the user‟s manual, the solenoid valve does not conformity and a copy of this original user‟s manual.

require any maintenance.

The user‟s manual will be provided with a translation in the

Any use of the valve out of the stipulated conditions given by the installer‟s language.

technical datasheet or the user‟s manual will be considered as

not compliant. The Examination Certificates EC type examinations are available

on the manufacturer's website (see address below).

Any intervention inside the solenoid valve will be considered as

not compliant. The disassembly of the solenoid valve is We reserve the right to change specifications without notice

forbidden as no repairs will be possible!

In the case of inaccurate use, the warranty will not be granted 7. ADRESSES

and FAS declines all responsibility regarding the possible

following damage. Head Office Manufacturing Office

Fluid Automation Systems s.a. Fluid automation systems technologies s.a.

In case of a failure under the normal conditions of use described Route de l'Etraz 126 Zone industrielle

in the technical datasheet and the user‟s manual, the solenoid CH-1290 Versoix Suisse CH-1607 Palézieux-Gare Suisse

valve can be returned to the supplier. Tel : +41 (0) 22 775 10 00 Tel : +41 (0) 21 907 79 71

Fax : +41 (0) 22 775 10 01 Fax : +41 (0) 21 907 74 03

E-mail : fas@fas.ch E-mail : fas@fas.ch

http://www.fas.ch http://www.fas.ch

M010.1171-en – 06.01.2014 Page 6/6

You might also like

- Firo B TestDocument9 pagesFiro B TestAjey BhangaleNo ratings yet

- User Manual B60 Midmark PDFDocument36 pagesUser Manual B60 Midmark PDFNassima Belil67% (3)

- Basic Structural Eng GDocument43 pagesBasic Structural Eng GDordas Sing33% (3)

- Fscurtis Rsbseriesmanual 2Document40 pagesFscurtis Rsbseriesmanual 2Juan Peraza100% (2)

- Service&Operationinstruction Scope-Cleanersc-10/Sc-20Document21 pagesService&Operationinstruction Scope-Cleanersc-10/Sc-20malucNo ratings yet

- Owner/Operator Manual: MODEL 83513 Air Operated Chassis PumpDocument8 pagesOwner/Operator Manual: MODEL 83513 Air Operated Chassis PumpPutro 10100% (1)

- RFF TB Units 1 6Document89 pagesRFF TB Units 1 6Lucia Silva0% (1)

- TD 90Document44 pagesTD 90bokeNo ratings yet

- Instructions For Use For The SE 571 Series PH Sensors: ManualDocument2 pagesInstructions For Use For The SE 571 Series PH Sensors: ManualAhmad Zahiruddin GhaziNo ratings yet

- AnesDocument18 pagesAnesEun SaekNo ratings yet

- 5HDM AsiDocument13 pages5HDM AsiJavier MejiasNo ratings yet

- User'S Guide Guía Del Usuario: Safety PrecautionsDocument47 pagesUser'S Guide Guía Del Usuario: Safety PrecautionssaxpilotNo ratings yet

- 4ws2em 10 XNDocument16 pages4ws2em 10 XNHardin Agung MehendraNo ratings yet

- Steril Basic 18 ENG FRA ITADocument64 pagesSteril Basic 18 ENG FRA ITAgiuseppeNo ratings yet

- Pinch Valve Model Selection GuideDocument3 pagesPinch Valve Model Selection GuideCristian Alejandro SalvatierraNo ratings yet

- Job Safety Analysis Peondasi BangunanDocument14 pagesJob Safety Analysis Peondasi BangunanWahyu FebriantoNo ratings yet

- Hiradc ServicingDocument4 pagesHiradc ServicingAyub Abd RahmanNo ratings yet

- LV10 102023 en 202312061633042542Document1,288 pagesLV10 102023 en 202312061633042542Alex SinissNo ratings yet

- CAT - SIEMENS - LV-Power Distribution and Electrical Installation TechnologyDocument1,108 pagesCAT - SIEMENS - LV-Power Distribution and Electrical Installation TechnologymarcosNo ratings yet

- ENG COBOSOL Su E4 220430Document4 pagesENG COBOSOL Su E4 220430Jan HuibersNo ratings yet

- Controller For DHW Heat Pump Heaters: EN EnglishDocument4 pagesController For DHW Heat Pump Heaters: EN EnglishToussaintNo ratings yet

- Diagrama Electrico SplitDocument20 pagesDiagrama Electrico SplitDanielNo ratings yet

- Catalog LV 10 - 10-2019 - Low-Voltage Power Distribution and Electrical Installation Technology PDFDocument1,068 pagesCatalog LV 10 - 10-2019 - Low-Voltage Power Distribution and Electrical Installation Technology PDFNicolae VisanNo ratings yet

- Termination CableDocument29 pagesTermination CableMuhamad HasbiNo ratings yet

- IMI Maxseal ICO3S 1-4, 5-Way, 174 PsiDocument2 pagesIMI Maxseal ICO3S 1-4, 5-Way, 174 PsiDur MuhammadNo ratings yet

- Elltec Animec AM-2S Blood-Infusion Warmer Service ManualDocument29 pagesElltec Animec AM-2S Blood-Infusion Warmer Service Manualpiotr.lompartNo ratings yet

- 15 PowerDistributionBoards LV10 102022 EN 202212120950314857Document216 pages15 PowerDistributionBoards LV10 102022 EN 202212120950314857staffxavierNo ratings yet

- LV10 102020 en 202012170757555345Document1,160 pagesLV10 102020 en 202012170757555345Andrew HearonNo ratings yet

- 15 DistributionBoards LV10 042023 EN 202306071322302373Document222 pages15 DistributionBoards LV10 042023 EN 202306071322302373Anderson BonaNo ratings yet

- Project: List Title: Output Input DO AO AIDocument21 pagesProject: List Title: Output Input DO AO AIobaiNo ratings yet

- 08 SwitchDisconnectors LV10 042023 EN 202306011354213745Document156 pages08 SwitchDisconnectors LV10 042023 EN 202306011354213745hssvaldirNo ratings yet

- 8-SOP For Restoring Supply After KE FailureDocument5 pages8-SOP For Restoring Supply After KE FailureFareh KhanNo ratings yet

- Catalogo ACLDocument280 pagesCatalogo ACLrogerio.aalmeida1No ratings yet

- How To Measure Differential Pressure Using Piezoresistive Sensing ElementsDocument8 pagesHow To Measure Differential Pressure Using Piezoresistive Sensing ElementsTolera WorkuNo ratings yet

- Cooling Tower HiracDocument4 pagesCooling Tower HiracblackyNo ratings yet

- HDM Island Valve PDFDocument26 pagesHDM Island Valve PDFvitgahiNo ratings yet

- HV Work Method Statement-2Document2 pagesHV Work Method Statement-2martins7333% (3)

- Installation Guidelines: Programming of LevelsDocument4 pagesInstallation Guidelines: Programming of LevelsSudipto MajumderNo ratings yet

- NTC 12k: © 2011 OJ Electronics A/SDocument2 pagesNTC 12k: © 2011 OJ Electronics A/SnassimNo ratings yet

- VTSA Valve TerminalDocument2 pagesVTSA Valve TerminalŁukasz OlszewskiNo ratings yet

- 14.operation of FS TMF in Service Mode Rev1Document4 pages14.operation of FS TMF in Service Mode Rev1NishantNo ratings yet

- Mda Tda ManualDocument31 pagesMda Tda Manualvikash yadavNo ratings yet

- M6873 Iss 12 8 EM Op InsDocument28 pagesM6873 Iss 12 8 EM Op Inslaboratorium operasionalNo ratings yet

- Derivador PA t157545 - EngDocument6 pagesDerivador PA t157545 - EngAlexandre CastroNo ratings yet

- Solenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBDocument4 pagesSolenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBYuni MariaNo ratings yet

- Lab Power / Energy Series / Parallel Small Signal ApplicationsDocument12 pagesLab Power / Energy Series / Parallel Small Signal ApplicationsBagher DastkarNo ratings yet

- 7.removing Fixing Demister.Document7 pages7.removing Fixing Demister.Mohammad Fazal KhanNo ratings yet

- Table Top Single CD /Mp3 Pla YER: Operating InstructionsDocument35 pagesTable Top Single CD /Mp3 Pla YER: Operating InstructionsAn BanNo ratings yet

- 06 OvervoltageProtectionDevices LV10 102022 EN 202303231214549114Document30 pages06 OvervoltageProtectionDevices LV10 102022 EN 202303231214549114Debjit GhoshNo ratings yet

- Catalogo de Fusiveis enDocument80 pagesCatalogo de Fusiveis enlazaro santosNo ratings yet

- Direct Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2Document4 pagesDirect Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2MA1357No ratings yet

- Eredeti Használati Utasítás Návod Na Použitie Manual de Utilizare Uputstvo Za Upotrebu Navodilo Za Uporabo Návod K Použití Instrukcja U Ytkowania ŻDocument12 pagesEredeti Használati Utasítás Návod Na Použitie Manual de Utilizare Uputstvo Za Upotrebu Navodilo Za Uporabo Návod K Použití Instrukcja U Ytkowania ŻIancu PetreNo ratings yet

- 140 BARS: Accomodation Sections Plant-12 SectionsDocument1 page140 BARS: Accomodation Sections Plant-12 SectionsImmorthalNo ratings yet

- Sie PC 3va IeccatalogDocument92 pagesSie PC 3va IeccatalogMir Hossein Hashem NezhadNo ratings yet

- Compressors and Pneumatic ToolsDocument3 pagesCompressors and Pneumatic Toolskwame fosterNo ratings yet

- Controllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppDocument2 pagesControllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppMihai Lungu100% (1)

- 679 Volume Flow TransmitterDocument5 pages679 Volume Flow Transmittersinar automationNo ratings yet

- Yokogawa Ut32a Temperature Controller Quick ReferenceDocument12 pagesYokogawa Ut32a Temperature Controller Quick ReferenceDilesh PillaiNo ratings yet

- Denon DNPF109 Manual PDFDocument51 pagesDenon DNPF109 Manual PDFJosé Manuel RamosNo ratings yet

- Dra-F109e2 Ek Eng CD-rom v0Document33 pagesDra-F109e2 Ek Eng CD-rom v0locvanhung11No ratings yet

- H Series Valves-EN PDFDocument12 pagesH Series Valves-EN PDFMauricio GarciaNo ratings yet

- 4 M KLHDocument2 pages4 M KLHmarcusNo ratings yet

- McKinley T34 Ambulatory Syringe Pump Operation ManualDocument26 pagesMcKinley T34 Ambulatory Syringe Pump Operation ManualAmirNo ratings yet

- Drager Oxylog 2000 PMS ProcedureDocument23 pagesDrager Oxylog 2000 PMS ProcedureAmirNo ratings yet

- Drager Narkomed Field Service Procedure Installation of Power Outlet StripDocument12 pagesDrager Narkomed Field Service Procedure Installation of Power Outlet StripAmirNo ratings yet

- Drager Narkomed Field Service Procedure Julian Pfgf-Psys Pressure PCB 8603361 InstallationDocument8 pagesDrager Narkomed Field Service Procedure Julian Pfgf-Psys Pressure PCB 8603361 InstallationAmirNo ratings yet

- Av Comp4500 PY A 7458Document16 pagesAv Comp4500 PY A 7458AmirNo ratings yet

- Venus Basic and Advanced Software Training During 2018Document2 pagesVenus Basic and Advanced Software Training During 2018AmirNo ratings yet

- Ultrasound Device Calibration: To The EditorDocument3 pagesUltrasound Device Calibration: To The EditorAmirNo ratings yet

- Prog ManualDocument20 pagesProg ManualAmirNo ratings yet

- Laborie Sonography Portasan 3D Service ManualDocument43 pagesLaborie Sonography Portasan 3D Service ManualAmirNo ratings yet

- High-Performance Silicon-Gate CMOS: Semiconductor Technical DataDocument6 pagesHigh-Performance Silicon-Gate CMOS: Semiconductor Technical DataAmirNo ratings yet

- HP Sonography Sonos 77025 Service ManualDocument11 pagesHP Sonography Sonos 77025 Service ManualAmir100% (1)

- TD62803P ToshibaDocument6 pagesTD62803P ToshibaAmirNo ratings yet

- Ultrasound Technologies Sonography PD1 Service ManualDocument35 pagesUltrasound Technologies Sonography PD1 Service ManualAmirNo ratings yet

- TC74HC14AP, TC74HC14AF: Hex Schmitt InverterDocument7 pagesTC74HC14AP, TC74HC14AF: Hex Schmitt InverterAmirNo ratings yet

- Nand Flash GuideDocument11 pagesNand Flash GuideAmirNo ratings yet

- Torres v. Lopez, G.R. No. 24569, (February 26, 1926), 48 PHIL 772-824)Document36 pagesTorres v. Lopez, G.R. No. 24569, (February 26, 1926), 48 PHIL 772-824)yasuren2No ratings yet

- Review of Related LiteratureDocument3 pagesReview of Related LiteratureGaymson BeroyNo ratings yet

- Catholic Social Teaching in PovertyDocument4 pagesCatholic Social Teaching in Povertyapi-266512667No ratings yet

- Paz, Glorilie Perez. EE-221 Bsee-2B Input and Output Characteristics of Transistor CB ConfigurationDocument15 pagesPaz, Glorilie Perez. EE-221 Bsee-2B Input and Output Characteristics of Transistor CB ConfigurationGlorilie PazNo ratings yet

- Thinh Nec Mock TestDocument11 pagesThinh Nec Mock TestQuang VũNo ratings yet

- Electric Start HandbookDocument179 pagesElectric Start HandbookGeronimo JaimeNo ratings yet

- Appendix A - Responsibility Assignment MatrixDocument6 pagesAppendix A - Responsibility Assignment Matrixyamanta_rajNo ratings yet

- Soldering (Acetate)Document11 pagesSoldering (Acetate)Maridee Bitalac AdiongNo ratings yet

- ASP Patch RecsDocument1 pageASP Patch RecsRochester EccNo ratings yet

- Multigrade Teaching Introduction 1212743864627450 8Document10 pagesMultigrade Teaching Introduction 1212743864627450 8Alexis RamirezNo ratings yet

- Two Wheeler Insurance Package Policy (1) - Insurance - ChequeDocument5 pagesTwo Wheeler Insurance Package Policy (1) - Insurance - ChequepriyanshNo ratings yet

- Inclusive Eduation DefinedDocument21 pagesInclusive Eduation DefinedMark DaveNo ratings yet

- Competency Gap Analysis Questionnaire - 1.1Document2 pagesCompetency Gap Analysis Questionnaire - 1.1Tracey MorinNo ratings yet

- Fans, Blowers & Air Coolers June 2020Document2 pagesFans, Blowers & Air Coolers June 2020detailsNo ratings yet

- Overcoming and Understanding of The EmotionalDocument10 pagesOvercoming and Understanding of The EmotionalLojo, CejayNo ratings yet

- Reflections On 6 Years of Public PolicyDocument5 pagesReflections On 6 Years of Public PolicyrmdantonNo ratings yet

- DeltaOhm HD98569 Portatif PH Iletkenlik OksijenDocument5 pagesDeltaOhm HD98569 Portatif PH Iletkenlik OksijenEnisNo ratings yet

- ProClin® Preservatives Mechanisms and Stability For Diagnostic ReagentsDocument4 pagesProClin® Preservatives Mechanisms and Stability For Diagnostic ReagentsSAFC-GlobalNo ratings yet

- Bochure Catalase Enzyme Test PDFDocument2 pagesBochure Catalase Enzyme Test PDF08-Pimlada JakpingNo ratings yet

- Lock Out Tag Out ProgramDocument17 pagesLock Out Tag Out ProgramImtiyaz Akhtar100% (1)

- UAS Genap 2019-2020 Ingg Kls 11Document8 pagesUAS Genap 2019-2020 Ingg Kls 11Frederikus AndreNo ratings yet

- Amega BookDocument8 pagesAmega BookmrajisNo ratings yet

- Orchid Hotel-An IntroductionDocument1 pageOrchid Hotel-An IntroductionSai VasudevanNo ratings yet

- Explosive Gas Atmospheres: Guide To Hazardous LocationsDocument1 pageExplosive Gas Atmospheres: Guide To Hazardous LocationsTasawwur TahirNo ratings yet

- Final Checklist - HospitalDocument21 pagesFinal Checklist - HospitalZandra Lyn Alunday100% (1)

- Leopold's Maneuvers - PPTMDocument26 pagesLeopold's Maneuvers - PPTMDencel BarramedaNo ratings yet

- R V Itturiligaq, 2020 NUCA 6Document23 pagesR V Itturiligaq, 2020 NUCA 6NunatsiaqNewsNo ratings yet