Professional Documents

Culture Documents

D5A High-Precision Switch

Uploaded by

Muhamad PriyatnaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D5A High-Precision Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

High-precision Switch

D5A

High-precision Switch for Detecting Micron-

unit Displacement

• Ideal for detecting and measuring wear of cutting tools or for

original point of work.

• Direct input possible to microprocessors and programmable

controllers.

• Types available with built-in operation indicator for ease of oper-

ation monitoring as well as a version with fiber optics remote op-

eration indicator.

• A version with screw-type cable connector available for easy in-

stallation and maintenance.

Ordering Information

■ List of Models

Contact Output Models (Without Operation Indicator)

Actuator Type Repeat Operating force Cable lead outlet Degree of Model

accuracy Type Length protection

Pin plunger M5 1 µm max. 0.29 N max. Pre-wired 1m IP40 D5A-1100

0.49 N max. D5A-1200

3 µm max. 0.29 N max. D5A-2100

0.49 N max. D5A-2200

M8 1 µm max. 0.49 N max. IP67 D5A-3200

0.98 N max. D5A-3300

M16 3 µm max. 2.45 N max. D5A-7400

Connector D5A-7403

Solid-state Output Models (With Operation Indicator)

Actuator Type Repeat Operating force Cable lead outlet Degree of Model

accuracy protection

Type Length

Pin plunger M8 1 µm max. 0.49 N max. Pre-wired 1m IP67 D5A-3210

0.98 N max. D5A-3310

Slim 0.49 N max. D5A-5210

0.98 N max. D5A-5310

M16 3 µm max. 2.45 N max. D5A-7410

Connector D5A-7413

Top plunger Limit 3 µm max. 3.92 N max. Pre-wired 3m D5A-8511

5m D5A-8512

Connector 3m D5A-8514

5m D5A-8515

Bevel plunger Pre-wired 3m D5A-9511

5m D5A-9512

Connector 3m D5A-9514

5m D5A-9515

High-precision Switch D5A 205

Specifications

■ Ratings

Contact output models 10 mA at 24 VAC, 10 mA at 12 VDC

Solid-state output models 100 mA at 5 to 24 VDC±10%

Leakage current: 0.15 mA max.

Residual voltage: 3 V max.

Power consumption: 3 mW max.

■ Characteristics

Degree of protection D5A-1@, D5A-2@: IP40

Other than the above models: IP67

Repeat accuracy (see note 2) M5 (D5A-1@@@ series), M8, slim type:1 µm max.

M5 (D5A-2@@@ series), M16, limit type:3 µm max.

Durability (see note 3) Mechanical: 10,000,000 operations min.

Electrical: 1,000,000 operations min. (10 mA at 24 VAC)

Deviation in electrical durability after M5, M8, M16, slim type: 10 µm max.

1,000,000 operations Limit type: 20 µm max.

Operating speed 1 µm to 0.5 m/s

Rated frequency 50/60 Hz

Insulation resistance 100 MΩ min. (at 250 VDC) between each terminal and ground

Contact resistance 800 mΩ max. (initial) with 1 m cable,

2.4 Ω max. (initial) with 3 m cable, 4 Ω max. (initial) with 5 m cable

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between each terminal and ground

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude

Shock resistance Mechanical: 1,000 m/s2 min.

Malfunction: 300 m/s2 min.

Temperature coefficient M5, M8, slim type: ±20 x 10–6/°C max.

(see note 4) M16 type: ±40 x 10–6/°C max.

Limit type: ±50 x 10–6/°C max.

Ambient temperature Operating: –20°C to 75°C (with no icing)

Ambient humidity Operating: 35% to 85% (35% to 95% with the seal rubber)

Note: 1. The above figures are initial values.

2. Contact your OMRON sales representative for measurement conditions of the repeat accuracy.

3. Durability values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your

OMRON sales representative for more detailed information on other operating environments.

4. The value indicates the operating position change rate for a change of 1°C in the ambient temperature.

The specifications depend on the model. Contact your OMRON sales representative for details.

Connections Output Circuit

■ Contact Form Solid-state Output Models

(PNP Transistor Output)

Contact Output Models HIC

Load +V

270 820 Ω Brown (White)

kΩ

ZD

LED

0V

Blue (Black)

Note: 1. HIC (hybrid integrated circuit)

2. An LED current limit resistor is incorporated.

3. The ZD absorbs surge.

4. The load can be connected to either the +V side

or 0V side.

206 High-precision Switch D5A

Nomenclature

■ D5A-3200

Spring

Case

Seal rubber (NBR)

Nameplate

Spring

Bearing Contact Cable

Plunger Contactor (V-HKCVV)

Engineering Data

Repeat Accuracy Examples (Reference Data)

M5 Type (Contact Output) With M5 Type (Contact Output) With

Repeat Accuracy of 1 µm max. Repeat Accuracy of 3 µm max.

D5A-1@@@ Series D5A-2@@@ Series

+2 +2

(µm) (µm)

+1 +1 OP

1.2 µm RP

0 0.5 µm

0

OP

1.2 µm

0.6 µm RP

-1 -1

-2 -2

0 50 100 150 200 0 50 100 150 200

Number of repeated measurements Number of repeated measurements

M8 Type (Contact/Solid-state Output) M16 Type (Contact/Solid-state Output)

With Repeat Accuracy of 1 µm max. With Repeat Accuracy of 3 µm max.

D5A-3@@@ Series D5A-7@@@ Series

+2 +2

(µm) (µm)

+1 +1 OP

OP 1.2 µm

0.6 µm RP

0 0

RP 1.1 µm

0.6 µm

-1 -1

-2 -2

0 50 100 150 200 0 50 100 150 200

Number of repeated measurements Number of repeated measurements

Slim Type (Solid-state Output) With Limit Type (Solid-state Output) With

Repeat Accuracy of 1 µm max. Repeat Accuracy of 3 µm max.

D5A-5@@@ Series D5A-8@@@ Series, D5A-9@@@ Series

+2 +2

(µm) OP

+1 +1

OP

1.4 µm

0.6 µm

0 0

RP RP

1.2 µm

0.5 µm

-1 -1

-2 -2

0 50 100 150 200 0 50 100 150 200

Number of repeated measurements Number of repeated measurements

High-precision Switch D5A 207

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

M5 Type

(Contact Output) M5 × 0.5 S-FLEX V-HKCVV

D5A-1100, D5A-2100 (see note) equal level, 3 dia.

D5A-1200, D5A-2200 Two cores

0.6 2.5 0.08 mm2 1M

8

OP (FP)

1.3 dia. 3 dia.

10 dia. 3.7R

Note: The threads of the case are not

18 standard. Therefore, standard

Ceramic plunger tapping to the case is not possible

Toothed lock washer Two clamping nuts for mounting.

Use the provided nuts for mounting.

M8 Type

(Solid-state Output)

D5A-3210, D5A-3310 OP (FP)

Operation indicator fiber, 2 dia.

(see note) (approx. 450 mm)

2 dia. 3 dia.

Seal S-FLEX V-HKCVV equal level,

15 dia. rubber 3 dia. Two cores

Ceramic plunger 0.08 mm2 1M

Toothed lock washer Two clamping nuts Note: The threads of the case are not

standard. Therefore, standard

tapping to the case is not possible

for mounting.

Use the provided nuts for mounting.

M8 Type

(Contact Output) 0.8

OP (FP) S-FLEX V-HKCVV equal level,

D5A-3200, D5A-3300 13

2.5

3 dia. Two cores

0.08 mm2 1M

4.85R

2 dia. 3 dia.

Note: The threads of the case are not

standard. Therefore, standard

Seal

rubber M8 × 0.5 (see note) tapping to the case is not possible

for mounting.

15 dia. Ceramic 16.5

plunger Use the provided nuts for mounting.

Two clamping nuts

Toothed lock washer

Slim Type

(Solid-state Output) Operation indicator (LED)

Seal

D5A-5210, D5A-5310 rubber

S-FLEX V-HKCVV equal level,

Ceramic OP (FP) 3 dia. Two cores

8 plunger 0.08 mm2 1M

4

3 dia.

12 5

2 dia.

4.85R 4 12±0.2 Two, 2.7+0.1

-0 dia.

20

Model D5A-1100 D5A-1200 D5A-3200 D5A-3300 D5A-5210 D5A-5310

D5A-2100 D5A-2200 D5A-3210 D5A-3310 (see note 2) (see note 2)

(see note 2) (see note 2) (see note 2) (see note 2)

OF max. 0.29 N 0.49 N 0.49 N 0.98 N 0.49 N 0.98 N

OT min. 1.5 mm 1.5 mm 1.5 mm 1.5 mm 1.5 mm 1.5 mm

MD max. 5 µm 5 µm 5 µm 5 µm 5 µm 5 µm

OP (2 mm) (2 mm) (6.5 mm) (6.5 mm) 10.5±0.4 mm 10.5±0.4 mm

(see note 1)

Note: 1. The operating position of these types is the same as the free position because of high sensitivity (repeat accuracy: 1 µm max.). This does

not apply to M16 limit switch types.

2. Total movement is 1.9 to 2.1 mm. Set the appropriate stroke (plunging depth) to 1.0 to 1.5 mm from the FP.

208 High-precision Switch D5A

M16 Type

(Contact Output/Solid-state Output) 1.2 M16 × 0.5 (Length: 28.5)

D5A-7400, D5A-7410 (see note 2)

24 1/8-inch ultra- 4

Nameplate

hard ball Operation indicator

(LED) (see note 1)

8 dia. 3 dia.

37.5 S-FLEX V-HKCVV Note 1: Not available in the

26 dia. PT equal level, 3 dia. contact output type.

OP 45 Two cores 2: The threads of the case are not

0.08 mm2 1M standard. Therefore, standard

M16 Type Two clamping nuts Toothed lock washer tapping to the case is not possi-

ble for mounting.

(Contact Output/Solid-state Output) Use the provided number for

D5A-7403, D5A-7413 mounting.

(Connector type)

Note: The dimensions are the

same as the above model's.

20 Cables with connectors are not

sold separately.

Two, 4.2 dia. holes

Limit Type 8 dia. spot facing depth: 5

(Solid-state Output) PT OP

Nameplate

D5A-8511, D5A-8512 Two, M3 × 0.5 3

6

Operation indicator (LED)

20±0.2

30 20±0.2 15 20

dia.

8 dia.

3 dia.

S-FLEX V-HKCVV

5 equal level, 3 dia.

16 10 Two cores

37.5 0.08 mm2 3M/5M

Limit Type 45

(Solid-state Output)

D5A-8514, D5A-8515

(Connector type)

20 Note: The dimensions are the

same as the above model's.

Cables with connectors are not

sold separately.

Limit Type

(Solid-state Output) Two, 4.2 dia. holes

D5A-9511, D5A-9512 PT OP 8 dia. spot facing depth: 5

Two, M3 × 0.5

3 6 Operation indicator (LED)

Nameplate

20 15 8 3 20

30 ±0.2 dia. dia.

20±0.2 dia.

5 S-FLEX V-HKCVV equal level,

16 3 dia. Two cores

10 0.08 mm2 3M/5M

Limit Type 37.5

45

(Solid-state Output)

D5A-9514, D5A-9515

(Connector type)

Note: The dimensions are the

20 same as the above model's.

Cables with connectors are not

sold separately.

Model D5A-7400/-7410 D5A-8511/-8514 D5A-9511/-9514

D5A-7403/-7413 D5A-8512/-8515 D5A-9512/-9515

OF max. 2.45 N 3.93 N

PT max. 1 mm 1 mm

OT min. 2 mm 5 mm 4 mm

MD max. 5 µm 5 µm 5 µm

OP (4.4 mm) 21.0±0.4 mm 15.2±0.4 mm

FP (5 mm) (21.8 mm) (15.8 mm)

High-precision Switch D5A 209

Application Examples

Origin Position Control of an X-Y Table Checking Turret Indexing Position

Turret

Motor

D5A

D5A

Motor

Note: Origin can be set to a desired position and the origin

position can be controlled using the D5A. Note: Set the D5A on the turret indexing position to check if

the turret is engaged properly at the specified position.

Coaxiality Inspection

D5A

D5A

Note: The D5A can be mounted on a jig used for checking

deviation to inspect its coaxiality.

Precautions

Refer to the “Precautions for General-purpose Limit Switches (Including Multiple Limit Switches, Mechanical Touch Switches, High-precision

Switches, Touch Switches, On-site Flexible Switches; Not Including Safety Switches)” on page 17.

■ Correct Use Do not impose any force exceeding 29.42 N on the cord, otherwise

the cord may break. Make sure that the bending radius of the cord is

at least 20 mm.

Handling of Fiber Cable

Connection of Contact Output

Do not pull or impose any force exceeding 29.42 N on the fiber cable.

Load

Make sure that the bending radius of the fiber cable is as large as

12 VDC

possible and at least R25 mm. 10 mA

The 40-mm portion of the fiber cable on the connector end as shown D5A

below must not be bent.

40 mm min.

Load

24 VAC

10 mA

D5A

Consideration of polarity is not required.

R25 mm min.

Connection of Solid-state Output

Do not impose compressing loads on the fiber cable. Be sure to connect the load to the power source in series.

Fiber cable The operating state of the Switch can be checked by the LED opera-

tion indicator (illuminants when the Switch is in operation) incorpo-

Nylon clip rated in the solid-state output circuit.

The output residual voltage is approximately 3 V. Therefore, exercise

care when selecting the load and setting the supply voltage. The

Correct residual voltage, however, can be easily calculated because it is

almost constant and is free from the influence of fluctuation in the

load current.

100 mA max.

Incorrect Brown (White) 5 to 24 VDC

Blue (Black)

D5A

The core wire colors have been changed to meet new standards.

The fiber cable can be cut with OMRON’s E39-F4 Cutting Tool. Make sure that the wires are connected correctly.

210 High-precision Switch D5A

Example: Connection to Power Source

1. In the above circuit, suppose the MY relay rated at 12 VDC is Be sure to connect the Switch to the power source via the load. If

used as the load. Since the must operate voltage of the relay is directly connected to the power source, the internal elements of the

80% or less than the rated voltage, it is 12 x 0.8 = 9.6 V. The sup- Switch may be damaged.

ply voltage, in turn, is 3 + 9.6 = 12.6 V.

Therefore, the relay may not operate with a 12 V power source.

2. However, if the relay rated at 24 VDC is employed, the must oper-

ate voltage and supply voltage of the relay are respectively 19.2 V

Brown (White)

and 22.2 V. The relay therefore can operate with a 24 V power Incorrect

source. Blue (Black)

D5A

When a solid-state circuit is turned OFF, leakage current of 0.15 mA

(max.) flows, causing some voltages to remain in the load. For this

reason, be sure to check the must release voltage of the load before Correctly connect the white and black lead wires to the positive and

using it. negative sides, respectively, of the power source. Although the D5A

will not be damaged even if the polarity is reversed by mistake, if this

happens, the Switch maintains the ON state (i.e., the contact is kept

Series Connection of Switches open) regardless of the presence or absence of the object to be

detected.

The Solid-state Output-type Switches must not be connected in

series. To obtain the same effect as a series connection, form an

AND gate with a relay inserted between the Switch and load.

Load

Blue

Load

Brown (White) (Black) Always close Incorrect

circuit

Blue (Black) D5A

D5A

Brown (White)

Incorrect

The core wire colors have been changed to meet new standards.

Brown (White) Make sure that the wires are connected correctly.

Blue (Black)

D5A

Others

Adjust the mounting of the D5A until the stroke of the pin plunger and

top plunger is aligned with the stroke of the operating body. Special

X1 X2 Load

Brown Brown

attention should be paid to the ceramic pushbutton unit. It might be

(White) (White) damaged if undue shock is applied.

X1

Correct

Incorrect Incorrect Correct

D5A D5A

Blue Blue X2

(Black) (Black)

Parallel Connection of Switches

In principle, two or more D5A’s should not be used in an OR configu-

ration.

The harder the material for the dog and the more solidly the mount-

ing base is fitted, the more accurately a minute displacement is

Brown (White) Brown (White) detected.

Load

When a limit switch type (D5A-8@@@, D5A-9@@@) is used, apply

A B Incorrect grease to the dog to reduce friction between it and the plunger. Do

D5A D5A

not apply grease to pin plungers, otherwise the grease may stick to

the contacts or generate gas that may cause contact failures.

Blue (Black) Blue (Black)

Be sure to use dogs made of hard materials for bevel or top plungers

and apply grease to the surface of the dogs. The hardness (Hv) of a

However, they can be connected in parallel provided that both bevel plunger is 2,000 or over, for which it is recommended that a

switches A and B in the above figure do not operate at the same time dog that has an Hv value of 1,000 or less be used.

and that the load does not have to be kept energized. In this circuit,

Do not fail to provide a stopper so as to prevent the enclosure of the

however, the leakage current is increased, multiplied by the number

D5A from being used as the stoppers.

of Switches connected in parallel. Consequently, the Switch may not

release properly. To keep the load energized, connect a relay to each

of the Switches as shown below. Correct Incorrect

Dog

X1 X2

Brown Brown Load Dog

(White) (Black)

Correct

Stopper

D5A D5A Blue X1 X2 Stopper

Blue (White)

(Black)

Attach an appropriate cover for the protection of the D5A from

machining oil or cuttings. No protective cover is, however, provided

together with the Switch.

High-precision Switch D5A 211

Exercise care that excessive force is not applied to the ceramic Do not mount the Switch with its nameplate facing downwards (i.e.,

plunger of M5, M8, or slim type. in the direction of gravity), otherwise the oil drain hole will not work

If the possibility exists that strong shock may be applied to the effectively.

plunger when the Switch is being mounted, use a protective cap. The

plunger may not release if it is depressed with too great a force. Set Oil drain hole

its stroke by referring to the OT value indicated in Operating Charac- Incorrect

Switch

teristics.

M5, M8 Slim

Nameplate

Mounting

The screw sections of cases for M5, M8, and M16 types have special dimensions. Do not use the mounting dimensions specified for standard types.

For the mounting dimensions, refer to the following figures and tables.

Dimensions M5 M8 M16

Contact output Solid-state

B output

A Mounting hole 5.2±0.1 mm dia. 8.2±0.1 mm dia. 16.2±0.1 mm dia.

B Panel thickness 3 to 10 mm 5 to 8 mm 5 to 13 mm 10 to 17 mm

C Toothed lock washer 10 mm dia. 15 mm dia. 26 mm dia.

C A

Dimensions Slim Limit

A Mounting pitch 12±0.2 mm 20±0.2 mm

B Tapping M2.6 M4

Mounting hole 2.8 +0.2

−0 mm dia. 4.2 +0.2

−0 mm dia.

A B

Do not tighten the nut with too much force.

Be sure to apply the clamping torque shown in this table.

Type Clamping torque

M5 0.98 N·m max.

M8 2.94 N·m max.

M16 9.81 N·m max.

Slim 0.29 N·m max. (M2.6 screw)

Limit 1.47 N·m max. (M4 screw)

When mounting the Switch to a panel, be sure to use the toothed

lock washer attached as an accessory (to M5, M8, and M16 types

only). Use the washer on the panel surface opposite the object to be

detected by the Switch.

Nut

Object

Panel

to be

detected

Toothed lock washer

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C070-E1-06 In the interest of product improvement, specifications are subject to change without notice.

212 High-precision Switch D5A

You might also like

- High-Precision Switch For Detecting Micron-Unit DisplacementDocument8 pagesHigh-Precision Switch For Detecting Micron-Unit Displacementkasim leeNo ratings yet

- D5B Mechanical Touch SwitchDocument6 pagesD5B Mechanical Touch SwitchMuhamad PriyatnaNo ratings yet

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNo ratings yet

- Total ProteccionDocument8 pagesTotal ProteccionMark XavierNo ratings yet

- DS-BT RelaysDocument4 pagesDS-BT RelaysRick HunterNo ratings yet

- Contact Displacement Sensor: Ordering InformationDocument10 pagesContact Displacement Sensor: Ordering Informationวรพงษ์ กอชัชวาลNo ratings yet

- Date Tehnice Releu Buchholz-01 - MSafe - enDocument4 pagesDate Tehnice Releu Buchholz-01 - MSafe - ennicolae ratescuNo ratings yet

- d5c Ds e 4 2 csm59413-96637Document8 pagesd5c Ds e 4 2 csm59413-96637Can Kutay TuçNo ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- ALA2F24Document4 pagesALA2F24Waldek LipskiNo ratings yet

- RG-213 DatasheetDocument1 pageRG-213 DatasheetMochammad Rizal SNo ratings yet

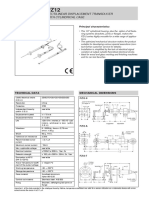

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Catalogo de Valvulas Solenoides Marca WaircomDocument15 pagesCatalogo de Valvulas Solenoides Marca WaircomNancy Del Pilar Gutierrez TaipeNo ratings yet

- Door Interlock Switch Offers 3mm Contact Gap SafetyDocument8 pagesDoor Interlock Switch Offers 3mm Contact Gap SafetyMuhamad PriyatnaNo ratings yet

- AMC3200DFV1 2 3 A4 enDocument4 pagesAMC3200DFV1 2 3 A4 enIbnu HasanNo ratings yet

- High Density D-Sub ConnectorsDocument5 pagesHigh Density D-Sub ConnectorsEdward FernandesNo ratings yet

- Door Interlock Switch D2TDocument4 pagesDoor Interlock Switch D2TMuhamad PriyatnaNo ratings yet

- Vergleichsliste Kapazitive SensorenDocument7 pagesVergleichsliste Kapazitive SensorenSerghei BotnaruNo ratings yet

- 915nm 976nm 10W Fiber Coupled Module Oclaro-1416083626Document5 pages915nm 976nm 10W Fiber Coupled Module Oclaro-1416083626thuyNo ratings yet

- Material Datasheets for Fire Resistant CablesDocument74 pagesMaterial Datasheets for Fire Resistant Cablesabdowais0% (1)

- HPML1370 Compact RCBO Flyer HRDocument2 pagesHPML1370 Compact RCBO Flyer HRPintea Ioan FlorinNo ratings yet

- Thiet Bi Bao Ve He Thong Dien PDFDocument215 pagesThiet Bi Bao Ve He Thong Dien PDFtranhuutuongNo ratings yet

- FTR F3aa012e PDFDocument5 pagesFTR F3aa012e PDFAhmad Noor HasanNo ratings yet

- M400 D4N 003Document19 pagesM400 D4N 003Mian FahimNo ratings yet

- Specification: DS980-24V-10mmDocument5 pagesSpecification: DS980-24V-10mmSALV2049No ratings yet

- Model 351 High Frequency Pulse Generator: DescriptionDocument2 pagesModel 351 High Frequency Pulse Generator: DescriptioncavendiNo ratings yet

- Datasheet Flame Detecor 2 or 4 Wired Fire AlarmDocument1 pageDatasheet Flame Detecor 2 or 4 Wired Fire AlarmhernanNo ratings yet

- Industrial Laser Module DC EllipticalDocument3 pagesIndustrial Laser Module DC EllipticalWendy SeegarNo ratings yet

- MP1 Series MagnetoPotDocument4 pagesMP1 Series MagnetoPotyayaNo ratings yet

- Pressure Relief Valves With Contacts t80 Flujo DirigidoDocument1 pagePressure Relief Valves With Contacts t80 Flujo DirigidoANGEL STRAGLIATINo ratings yet

- CM-MPN.72S: CM-MPN.72S Three-Phase Monitoring Relay 2c/o, 0,0.1-30s, L1-L2-L3 3x530-820VACDocument4 pagesCM-MPN.72S: CM-MPN.72S Three-Phase Monitoring Relay 2c/o, 0,0.1-30s, L1-L2-L3 3x530-820VACSSE ACCNo ratings yet

- AN2551 Aircraftplugs Technicalsheet 28VDC 3POLES 250316-3Document1 pageAN2551 Aircraftplugs Technicalsheet 28VDC 3POLES 250316-3andréNo ratings yet

- New S7 series high performance switch-disconnectorDocument6 pagesNew S7 series high performance switch-disconnectorMostafa ShannaNo ratings yet

- MS116-0.63 Manual Motor Starter Product DetailsDocument7 pagesMS116-0.63 Manual Motor Starter Product DetailsMary RoshmaNo ratings yet

- Huchez Winch 10 TonsDocument6 pagesHuchez Winch 10 TonsPhong DuongNo ratings yet

- Effective magnetic flowtube specificationsDocument4 pagesEffective magnetic flowtube specificationsFredy Martínez GonzaloNo ratings yet

- Sensor Catallogue HoneywellDocument8 pagesSensor Catallogue Honeywellfalah nihaNo ratings yet

- Av02 1508en - Ds - HFBR Rxxyyyz - 2016 02 18Document11 pagesAv02 1508en - Ds - HFBR Rxxyyyz - 2016 02 18Anonymous dGFqrw5vONo ratings yet

- MS116-32 Manual Motor Starter: General InformationDocument6 pagesMS116-32 Manual Motor Starter: General InformationCesar PerrusquiaNo ratings yet

- Safety Angle Transducer Type Series Contactless 533 400: Special FeaturesDocument4 pagesSafety Angle Transducer Type Series Contactless 533 400: Special FeaturesPatrick ByronNo ratings yet

- 2608 Analog MultimeterDocument1 page2608 Analog Multimeterneurofuzzy7393No ratings yet

- TL W Datasheet en 201108Document10 pagesTL W Datasheet en 201108luis raymundo garcia ruiz esparzaNo ratings yet

- RK Engineering Earth Leakage RelayDocument1 pageRK Engineering Earth Leakage RelaySEO BDMNo ratings yet

- Magnalock Models M32, M62 and M82B Installation InstructionsDocument1 pageMagnalock Models M32, M62 and M82B Installation InstructionsMilos StoisavljevicNo ratings yet

- Omron TL-W Proximity SensorDocument8 pagesOmron TL-W Proximity SensorsaifulNo ratings yet

- LS03 Series Level Sensors: L S 0 3 - 0 X 0 0 - X X - 0 0 0 XDocument3 pagesLS03 Series Level Sensors: L S 0 3 - 0 X 0 0 - X X - 0 0 0 XmmNo ratings yet

- MrigargbDocument8 pagesMrigargbrizkifadlyNo ratings yet

- Datasheet RigaDocument8 pagesDatasheet RigaDenisAlexandreNo ratings yet

- AMC2100 V1.2.0.r 1.a4.enDocument4 pagesAMC2100 V1.2.0.r 1.a4.enDiradivo VakaikopNo ratings yet

- SPEC..600 Volt USE-2Document4 pagesSPEC..600 Volt USE-2quatudogonNo ratings yet

- Ats1000ats1200 Brochure enDocument1 pageAts1000ats1200 Brochure enAnoop Jacob KunnappuzhaNo ratings yet

- Sliver3000 Panel SpecificationsDocument5 pagesSliver3000 Panel SpecificationsembokoNo ratings yet

- DS8168GWWW 24V 10mmDocument6 pagesDS8168GWWW 24V 10mmSALV2049No ratings yet

- d10 Oxygen Probe Accessories GB 1104Document2 pagesd10 Oxygen Probe Accessories GB 1104JC AlemanNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- Simplex Fiber Optic Cordage: DescriptionDocument2 pagesSimplex Fiber Optic Cordage: DescriptionMuhamad Andri KurniawanNo ratings yet

- PV Isolators up to 1800A for Photovoltaic ApplicationsDocument21 pagesPV Isolators up to 1800A for Photovoltaic ApplicationsAnoop ChandranNo ratings yet

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionslaconte_No ratings yet

- Deetap ® Du: Off-Circuit Tap-ChangerDocument6 pagesDeetap ® Du: Off-Circuit Tap-ChangervitalstyleNo ratings yet

- A Series Miniature Control UnitsDocument44 pagesA Series Miniature Control UnitsMuhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- FB Series Plastic Control Boxes provide IP65 protectionDocument8 pagesFB Series Plastic Control Boxes provide IP65 protectionMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power Supplies Compact SizeDocument2 pagesPS5R-SB Switching Power Supplies Compact SizeMuhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- 30 MM XN Series Emergency Stop SwitchesDocument12 pages30 MM XN Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- 16 MM XA Series Emergency Stop Switches (Illuminated Type)Document4 pages16 MM XA Series Emergency Stop Switches (Illuminated Type)Muhamad PriyatnaNo ratings yet

- 1 Residual Current Circuit Breaker (RCCB) (ELCB)Document6 pages1 Residual Current Circuit Breaker (RCCB) (ELCB)Anirudh VN100% (1)

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- Photoelectric, Inductive & Capacitive SensorsDocument14 pagesPhotoelectric, Inductive & Capacitive SensorsMuhamad PriyatnaNo ratings yet

- Cutler-Hammer: Standards Global Third Party CertificationDocument45 pagesCutler-Hammer: Standards Global Third Party Certificationmenendez2050100% (1)

- Tynx10 Series: 10A SCRDocument6 pagesTynx10 Series: 10A SCRAAurelianNo ratings yet

- Se250sm CeDocument38 pagesSe250sm CejaviergmarNo ratings yet

- Diffusion: 2.3 C-V CharacteristicsDocument1 pageDiffusion: 2.3 C-V CharacteristicsCarlos SaavedraNo ratings yet

- E5x/E6x System Wiring DiagramsDocument221 pagesE5x/E6x System Wiring DiagramsKonstantin KozyuraNo ratings yet

- SYNCHRONOUS MOTORS AND POWER FACTOR CORRECTIONDocument21 pagesSYNCHRONOUS MOTORS AND POWER FACTOR CORRECTIONSaurav KafleNo ratings yet

- Service and Parts Manual Rexel Shredder S16Document43 pagesService and Parts Manual Rexel Shredder S16Raltec LtdNo ratings yet

- Dewa QuestionDocument16 pagesDewa Questionjayapal100% (2)

- Patient Care AreasDocument8 pagesPatient Care AreastemamNo ratings yet

- Unisonic Technologies Co., LTD: Bipolar Power General Purpose TransistorDocument4 pagesUnisonic Technologies Co., LTD: Bipolar Power General Purpose TransistorManuel SierraNo ratings yet

- 0100 Motor Start Cat enDocument190 pages0100 Motor Start Cat enVõ Thạch BảoNo ratings yet

- Always Leading The Pack: Unilab LaboratoryDocument30 pagesAlways Leading The Pack: Unilab LaboratoryMrsSohaibHannanNo ratings yet

- T6N 800 PR221DS-LS/I in 800 3p F FDocument3 pagesT6N 800 PR221DS-LS/I in 800 3p F FOliver CelestialNo ratings yet

- Battery Safety Fuse FailureDocument3 pagesBattery Safety Fuse FailureKhincho ayeNo ratings yet

- Maintaining Lightning Arresters with DisconnectorsDocument5 pagesMaintaining Lightning Arresters with DisconnectorsSSE/TRD DankuniNo ratings yet

- IRF630M IRF630MFP: N-CHANNEL 200V - 0.35 - 9A TO-220/TO-220FP Mesh Overlay™ MosfetDocument9 pagesIRF630M IRF630MFP: N-CHANNEL 200V - 0.35 - 9A TO-220/TO-220FP Mesh Overlay™ MosfetEduRoiNo ratings yet

- Protection Methods for AlternatorsDocument25 pagesProtection Methods for AlternatorsSoniya Mahida100% (1)

- Structure of Electrical Power SystemDocument13 pagesStructure of Electrical Power SystemBelayneh TadesseNo ratings yet

- CVV CVV SDocument8 pagesCVV CVV Spatootom5No ratings yet

- 1HSM 9543 23-03en DCB Application Guide Ed3 - 2013-09 - EnglishDocument60 pages1HSM 9543 23-03en DCB Application Guide Ed3 - 2013-09 - EnglishBelmin ŠabićNo ratings yet

- Susol Modular MDB - PR - ENG - V1Document15 pagesSusol Modular MDB - PR - ENG - V1Duc ManhNo ratings yet

- Remote Control for Home AppliancesDocument2 pagesRemote Control for Home Appliancesaa bbNo ratings yet

- Spaulding Lighting Olympia Floodlight Spec Sheet 4-86Document2 pagesSpaulding Lighting Olympia Floodlight Spec Sheet 4-86Alan MastersNo ratings yet

- 3-Phase Transformer Connections & ApplicationsDocument16 pages3-Phase Transformer Connections & ApplicationseeetistNo ratings yet

- HIP4081Document18 pagesHIP4081armin rahmatiNo ratings yet

- 150HP 380V 3Ø Y-D Duplex Sump Pump 240amp PanelDocument2 pages150HP 380V 3Ø Y-D Duplex Sump Pump 240amp PanelJose Lorenzo RefelinoNo ratings yet

- Transistor As Auto SwitchDocument2 pagesTransistor As Auto SwitchSalmizam IzamNo ratings yet

- AldoDocument3 pagesAldorobson lopes bezerraNo ratings yet

- CONVENTIONNAL UPS - 10kva To 120 - Tender Technical SpecificationsDocument8 pagesCONVENTIONNAL UPS - 10kva To 120 - Tender Technical SpecificationsMuhammad Qumar NazeerNo ratings yet

- LM2931 Series 100 Ma, Adjustable Output, LDO Voltage Regulator With 60 V Load Dump ProtectionDocument20 pagesLM2931 Series 100 Ma, Adjustable Output, LDO Voltage Regulator With 60 V Load Dump ProtectionВалерий ГрицкевичNo ratings yet

- Documentation System Cabling For CENTUM VP - CENTUM CS 3000 R3 and STARDOMDocument202 pagesDocumentation System Cabling For CENTUM VP - CENTUM CS 3000 R3 and STARDOMMatthew Daniel100% (1)