Professional Documents

Culture Documents

Objective Questions: Analysis and Design of Machine Elements

Objective Questions: Analysis and Design of Machine Elements

Uploaded by

zangue billy jamesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Objective Questions: Analysis and Design of Machine Elements

Objective Questions: Analysis and Design of Machine Elements

Uploaded by

zangue billy jamesCopyright:

Available Formats

166 Analysis and Design of Machine Elements

3 What factors affect the uniformity of chain speed transmission?

4 What lubrication methods are available for chain drives? How does one select a suit-

able method?

5 How could one improve operating conditions if wear occurs on a roller chain?

Objective Questions

1 A power transmission includes a belt drive, a chain drive and a gear drive. Which of

the following is the best arrangement between a motor and a working machine?

(a) belt drive gear drive chain drive

(b) chain drive gear drive belt drive

(c) belt drive chain drive gear drive

(d) chain drive belt drive gear drive

2 In a chain drive, reducing the number of teeth of driving sprocket will

cause________.

(a) the severity of speed unevenness of chain drive

(b) the chain to jump off the sprocket more easily after wear

(c) poor lubrication that may lead to gluing

(d) the increase of rotational speed of driving sprocket

3 At a constant rotational speed, if we want to reduce speed unevenness and dynamics

load of a chain drive, we can ___________.

(a) increase p and z1

(b) increase p and reduce z1

(c) reduce p and increase z1

(d) reduce p and z1

(where z1 is the number of teeth of driving sprocket, p is pitch)

4 The number of rows of a multiple-strand chain is generally no more than four to ___.

(a) facilitate installation

(b) limit axial width of chain drive

(c) ensure even loading on each row

(d) reduce the weight of chain

5 The purpose of limiting the maximum number of sprocket teeth is _________.

(a) to ensure the strength of chain

(b) to ensure the transmission stability of chain drive

(c) to ensure the speed ratio selection of chain drive

(d) to prevent the chain from jumping off the sprocket

Chain Drives 167

Calculation Questions

1 A chain drive with pitch p = 25.4 mm rotates at n1 = 750 rpm. The number of teeth

of driving sprocket is z1 = 23. Determine the average speed v, the maximum speed

vmax and the minimum speed vmin .

2 A single-strand roller chain is used to transmit power between a 23-tooth driving

sprocket and a 69-tooth driven sprocket. The rotational speed of driving sprocket

is 960 rpm. If the rotational speed of driven sprocket is reduced to 210 rpm:

(a) What is the number of teeth of driving sprocket if the teeth number of the

driven sprocket is kept unchanged? What will be the power transmitted?

(b) What is the number of teeth of a driven sprocket if the teeth number of the

driving sprocket is kept unchanged? What will be the power transmitted?

(c) Compare the two approaches: which one is better?

3 A single-strand 08A chain operates on a 20-tooth sprocket at 750 rpm. The small

sprocket is applied to the shaft of an electric motor and the output sprocket to a

conveyor. Determine the power rating for the single-strand chain. What would be

the rating for four strands?

4 A four strand 08A roller chain is proposed to transmit power from a 21-tooth driv-

ing sprocket that rotates at 1200 rpm. The driven sprocket is to rotate at one-third

the speed of the driving sprocket.

(a) Determine the power that can be transmitted by the chain drive;

(b) Estimate the centre distance if the chain length is 82 pitches;

(c) Describe the preferred method of lubrication.

Design Problems

1 Design a roller chain drive to transmit 10 kW. The rotational speed of motor is

n = 970 rpm. The speed ratio of the chain drive is i = 3, uniform power transmission

and centre distance no less than 550 mm.

2 A 5 kW 750 rpm electric motor is to drive an agitator at 325 rpm. The motor shaft

will be in approximately the same horizontal plane as the agitator shaft. Specify the

chain size, the sizes and number of teeth of sprockets, the number of chain pitches

and the centre distance.

3 A heavy conveyor is to be driven at 250 rpm by a 30 kW six-cylinder engine with an

input speed of 500 rpm. The centre distance is approximately 1000 mm. Moderate

shock loading is expected. Select a suitable roller chain and associated sprockets for

this application.

168 Analysis and Design of Machine Elements

4 A rock crusher is driven by a 75 kW hydraulic drive at a speed of 625 rpm. The rock

crusher is to operate at 225 rpm, subject to heavy service. A centre distance of from

1000 to 1500 mm will be acceptable. Design a roller chain drive.

Structure Design Problems

1 In the design of chain sprocket, the number of teeth of driving and driven sprockets

are limited by zmin = 9 and zmax = 120, respectively. Explain the reason.

2 In chain design, why the speed ratio has a limitation of less than 8?

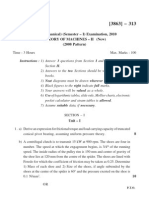

3 In Figure P7.1, the large sprocket is the driven sprocket. Decide on the rotational

direction of the small sprocket.

(a) (b) (c)

Figure P7.1 Illustration for Structure Design Problem 3.

4 In a chain drive design, two choices are available, that is, (1) p = 12.7 mm, z1 = 38;

(2) p = 25.4 mm, z1 = 19. Compare the two selections in respective of operating

smoothness and dynamic loads.

5 An electric motor at a speed of 1500 rpm is to drive a device at 15 rpm. A belt drive,

gear drive and chain drive can be used. Propose at least two layouts to transmit the

motion and compare them.

CAD Problems

1 Write a flow chart for the design process of a chain drive.

2 Develop a program to implement a user interface similar to Figure P7.2 and complete

the Example Problem 7.1.

You might also like

- Faulhaber DatasheetDocument5 pagesFaulhaber DatasheetMuhammad SharifNo ratings yet

- 11 Subnetting QuestionsDocument2 pages11 Subnetting QuestionsRaine CarrawayNo ratings yet

- Blanche-An Experimental in Guidance and Navigation of An Autonomous Robot VehicleDocument12 pagesBlanche-An Experimental in Guidance and Navigation of An Autonomous Robot VehiclemaysamshNo ratings yet

- 2018-11 FS9100 DatasheetDocument3 pages2018-11 FS9100 DatasheetNguyen Van HaiNo ratings yet

- Extra 330Document1 pageExtra 330nenoskaziNo ratings yet

- stm32f7 Reference ManualDocument1,709 pagesstm32f7 Reference ManualЕвгений ИвановNo ratings yet

- Problems s4Document4 pagesProblems s4zangue billy jamesNo ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- Final 222 2009 SolDocument6 pagesFinal 222 2009 SolNapsterNo ratings yet

- 56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFDocument7 pages56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFhecirlene vieiraNo ratings yet

- Problems: Analysis and Design of Machine ElementsDocument6 pagesProblems: Analysis and Design of Machine Elementszangue billy jamesNo ratings yet

- Ky Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDFDocument44 pagesKy Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDFwhaywhay whaywhayNo ratings yet

- Home Assignments #3Document2 pagesHome Assignments #3Pham Thanh0% (1)

- Home Assignment #6Document5 pagesHome Assignment #6Phạm Bùi Đình LộcNo ratings yet

- Advance Mechatronic - Machine Tools-2017 2Document43 pagesAdvance Mechatronic - Machine Tools-2017 2CôngHoàngNo ratings yet

- PLCDocument2 pagesPLCDarshan VoraNo ratings yet

- 1582887084-UI - 01 - 12. MechanismsDocument6 pages1582887084-UI - 01 - 12. MechanismsGeorgiana LazarNo ratings yet

- Total AutoDocument49 pagesTotal Automoba funnyNo ratings yet

- Maxon Re40 DC Motor 148866 Datasheet PDFDocument1 pageMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNo ratings yet

- Mini ProjectDocument11 pagesMini ProjectAthul John100% (1)

- Analysis of Bush Bearing Using Ansys 11Document5 pagesAnalysis of Bush Bearing Using Ansys 11engineersaabNo ratings yet

- 8 Alu DesignDocument3 pages8 Alu DesignSunilKumarReddy100% (1)

- OmniRoller Holonomic Drive TutorialDocument11 pagesOmniRoller Holonomic Drive TutorialYoussef AbbasNo ratings yet

- Stair Climbing Wheel ChairDocument4 pagesStair Climbing Wheel ChairMukesh Khairnar0% (1)

- Tutorial 5 On Memory Organization: A. RAM Chips 2k Bytes/256 Bytes 8, ROM 4k Bytes/1024 Bytes 4. BDocument3 pagesTutorial 5 On Memory Organization: A. RAM Chips 2k Bytes/256 Bytes 8, ROM 4k Bytes/1024 Bytes 4. BAgrim DewanNo ratings yet

- PIC16F877 and CCS-C LanguageDocument83 pagesPIC16F877 and CCS-C Language1726giangNo ratings yet

- ANSWERDocument10 pagesANSWERMuhammad Kamil Azman0% (1)

- (Exam) CAD-CAM-ThiCuoiKi (trắc nghiệm) - English (send)Document2 pages(Exam) CAD-CAM-ThiCuoiKi (trắc nghiệm) - English (send)Trường Nguyễn HuyNo ratings yet

- Employee Salary Prediction SlidesDocument21 pagesEmployee Salary Prediction SlidesrushipanchalNo ratings yet

- AXBB E ManualDocument29 pagesAXBB E ManualKenny HebertNo ratings yet

- Thiet Ke Vi Mach Cmos Vlsi Tap 1 Tong Van On, 322 Trang (Cuuduongthancong - Com)Document169 pagesThiet Ke Vi Mach Cmos Vlsi Tap 1 Tong Van On, 322 Trang (Cuuduongthancong - Com)Phạm Đức ThuậnNo ratings yet

- Hydraulic & Pneumatic MotorsDocument14 pagesHydraulic & Pneumatic MotorsJogi Oscar SinagaNo ratings yet

- Hướng Dẫn Lắp Đặt Và Cấu Hình Hệ Thống Dell Sc9000Document17 pagesHướng Dẫn Lắp Đặt Và Cấu Hình Hệ Thống Dell Sc9000Chien PhamNo ratings yet

- Auto Hybrid Electric Vehicle Maintenance and Repair CertificateDocument1 pageAuto Hybrid Electric Vehicle Maintenance and Repair CertificatespalomosNo ratings yet

- DENSO Robotics Datasheet HM-G SeriesDocument2 pagesDENSO Robotics Datasheet HM-G SeriesMarius Constantin100% (1)

- Study On The Embedded CAN Bus Control System in The Vehicle PDFDocument4 pagesStudy On The Embedded CAN Bus Control System in The Vehicle PDFsrcembeddedNo ratings yet

- Chapter 4 - Tutorial3Document6 pagesChapter 4 - Tutorial3Erwan Christo Shui 廖No ratings yet

- Chapter 36 DiffractionDocument36 pagesChapter 36 DiffractionMark ReyesNo ratings yet

- Prob Set #2Document2 pagesProb Set #2cookiepie21No ratings yet

- Cidm NotesDocument23 pagesCidm NotesPrajwal Jaiswal100% (1)

- Installation Guide: Tpsys SQL Interface SetupDocument16 pagesInstallation Guide: Tpsys SQL Interface Setupyin50% (2)

- Stepper Motor PDFDocument49 pagesStepper Motor PDFP HAMSA DATTANo ratings yet

- Max31910evkit Max31911evkitDocument13 pagesMax31910evkit Max31911evkitRody GCNo ratings yet

- Kinematics Modeling and Analyses of Articulated Rovers PDFDocument15 pagesKinematics Modeling and Analyses of Articulated Rovers PDFalokNo ratings yet

- Tran Quang Tho - KDDDocument46 pagesTran Quang Tho - KDDTuấn ĐặngNo ratings yet

- DC Motor Direction Control Using Power TriacDocument7 pagesDC Motor Direction Control Using Power TriacAshok KumarNo ratings yet

- Ed 4Document2 pagesEd 4Vaibhav KumarNo ratings yet

- Ee141 HW5 2Document3 pagesEe141 HW5 2Vidhya DsNo ratings yet

- ICARCV 2010 Conference GuideDocument154 pagesICARCV 2010 Conference GuidekamleshyadavmoneyNo ratings yet

- Topic 2. Computer ComponentsDocument17 pagesTopic 2. Computer ComponentsHiếu Bùi MinhNo ratings yet

- Gasoline Generator 800WDocument12 pagesGasoline Generator 800WRIcardo SotoNo ratings yet

- Test CCNADocument8 pagesTest CCNAquyentm2201No ratings yet

- Ho Vi Dieu Khien 8051 Tong Van OnDocument252 pagesHo Vi Dieu Khien 8051 Tong Van OnbuilenNo ratings yet

- Time: 3 Hours Total Marks: 70: Printed Pages: Sub Code: Paper Id: Roll NoDocument3 pagesTime: 3 Hours Total Marks: 70: Printed Pages: Sub Code: Paper Id: Roll NoAwanish SinghNo ratings yet

- Me-1352 Design of Transmission SystemDocument7 pagesMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.kr_padmavathiNo ratings yet

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Document3 pagesJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixNo ratings yet

- Publication 7 4677 752Document14 pagesPublication 7 4677 752Parth KumbhareNo ratings yet

- DTS Model PaperDocument3 pagesDTS Model PaperrajkumardotcomNo ratings yet

- Te 2008Document273 pagesTe 2008Smith KashidNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)PradeepNo ratings yet

- Problems s3Document3 pagesProblems s3zangue billy james67% (3)

- Problems s8Document4 pagesProblems s8zangue billy jamesNo ratings yet

- Problems s2Document6 pagesProblems s2zangue billy jamesNo ratings yet