Professional Documents

Culture Documents

Betriebs-Anleitung: Option For The Machine

Uploaded by

Amir HodzicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Betriebs-Anleitung: Option For The Machine

Uploaded by

Amir HodzicCopyright:

Available Formats

BETRIEBS-

ANLEITUNG

Operating Instructions · Manuel d’opération

Option for the Machine

Counterpressure attachment

INDEX G200

INDEX G300

INDEX ABC

Control INDEX C 200 - 4

LL13 02.1 046 1 - 02.99

0299/KR

Note on applicability

Some illustrations in this publication may deviate slightly from the product supplied, but this will not detract

from their instructional value.

The right of alteration by reason of technical progress is reserved by INDEX.

A word on copyright

This publication is protected by the law of copyright. The rights thereby established, particularly those of

translation, reprinting, extraction of illustrations, reproduction by photo-mechanical or similar means, and

storage in data processing installations, are strictly reserved, even for use as extracts.

Photo-copies for personal and other use of one’s own may only be made of individual sections or parts thereof

as single copies.

© Copyright by INDEX-Werke GmbH & Co. KG Esslingen 1999

Contents

General ............................................................................................................................................................... 4

General description ............................................................................................................................................ 4

Workpiece chucking with counterpressure ................................................................................................. 4

Workpiece chucking without counterpressure ............................................................................................ 5

Important machine functions (MAFU) ............................................................................................................... 5

M-Functions used ............................................................................................................................................... 6

Important description of errors ......................................................................................................................... 6

Setting the Chucking Pressure ...................................................................................................................... 7

Operating elements for pressure setting ......................................................................................................... 7

INDEX G200, G300 ....................................................................................................................................... 7

INDEX ABC .................................................................................................................................................... 8

Setting the chucking pressure and the chucking counterpressure ................................................................ 9

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 3 –

General

General description

Workpiece chucking with counterpressure

(M1=228 or MAFU 01/02 respectively)

Normal chucking cylinders do not function with a chucking pressure under 10 bar.

Therefore the chucking force, mainly for thin-walled workpieces, is still too high in

many cases.

With the counterpressure attachment, at two separate pressure regulating valves

,two different pressures are set which are effective on both sides of the piston

simultaneously.

The difference between both pressures results in the chucking force for the material

chucking system.

Example: Chucking pressure (high pressure)...............35 bar

Counterpressure (low pressure) ..................28 bar

Pressure difference.........................................7 bar

The following restrictions apply:

• The high pressure may be set between 20 and 40 bar only.

• The pressure difference must be at least 5 bar.

• The attachment is allowed only for chucking with a collet or an

expanding mandel, and a chucking stroke of 0,2 mm.

The counterpressure attachment can,

- be fitted to the main- and/or the counterspindle

- be applied for external- and internal chucking (expanding mandrel), while the above

mentioned restrictions apply.

- be operated as a single pressure-chucking attachment (refer to: ”Workpiece chucking

without counterpressure”).

Attention!

For safety reasons, the non-return valves fitted to the chucking

cylinder are without function when the counterpressure attachment

is used, i.e. at drop of the chucking pressure the workpiece may be

thrown out of the chucking means. For this reason chucking means

with a chucking stroke over 0,2 mm must not be used.

The use of power chucks in conjunction with the counterpressure

attachment is forbidden for this reason.

The hydraulic system must not switch off automatically when the

counterpressure attachment is used.

For this reason must be the MAFU 13/05 =1 (refer to description of

errors 81051 too).

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 4 –

General

Workpiece chucking without counterpressure

(M1=128)

This function correspons to the single-pressure chucking system, i.e. in this case all

types of chucking means, collets and power chucks as well, may be used.

The max. chucking pressure of 80 bar may be set.

The same pressure setting at both pressure regulating valves is

recommended.

Important machine functions (MAFU)

The following machine functions are required for the operation of the counterpressure

attachment. For the selection and operation of MAFUs refer to the brochure: ”Setting

up and operation INDEX C200-4).

• MAFU 01/01 Chucking cylinder 1 –> main spindle

• MAFU 03/01 Chucking cylinder 3 –> counterspindle1)

0 = clamped at rear (draw type chucking)

1 = clamped at front (thrust type chucking)

• MAFU 01/02 Multiple chucking pressure –> main spindle

• MAFU 03/02 Multiple chucking pressure –> counterspindle1)

0 = function chucking counterpressure contollable by Mx=y28

1 = function chucking counter pressure is continuously selected

• MAFU 01/03 Chucking travel monitoring –> main spindle

• MAFU 03/03 Chucking travel monitoring –> counterspindle1)

0 = disabled

1 = enabled

• MAFU 01/04 Start at open chucking system –> main spindle

• MAFU 03/04 Start at open chucking system –> counterspindle1)

0 = disabled

1 = enabled

• MAFU 13/05 Automatic auxiliary drive OFF

0 = enabled

1 = disabled

1) not applicable for INDEX ABC

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 5 –

General

M-Functions used

The following functions are required for the operation of the counterpressure chucking

attachment.

Mx = 68 chucking cylinder on

Mx = 69 chucking cylinder off

Mx = 25 checking the clamping means (refer to error No. 81311/81301)

Mx = 128 without counterpressure

Mx = 228 with counterpressure

1 = main spindle

3 = counterspindle1)

Important description of errors

The following description of errors contains additional information for the operation of

the counterpressure chucking attachment.

Error No. 81345

81346

81347

81348

81311

81301

81051

1) not applicable for INDEX ABC

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 6 –

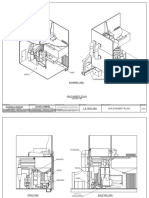

Setting the Chucking Pressure

Operating elements for pressure setting

INDEX G200, G300

Main spindle

L1301.10461_2

1 pressure gauge (for S20.0)

2 pressure regulating valve S20.0

3 pressure gauge (for S8.4)

4 pressure regulating valve S8.4

Counterspindle

L1301.10461_3

1 pressure gauge (for S20.1)

1 pressure gauge (for S12.4)

2 pressure regulating valve S20.1

4 pressure regulating valve S12.4

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 7 –

Setting the Chucking Pressure

INDEX ABC

Main spindle

L1301.10461_5

1 pressure gauge (for S20.0)

2 pressure regulating valve S20.0

3 pressure gauge (for S8.4)

4 pressure regulating valve S8.4

L1301.10461_4

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 8 –

Setting the Chucking Pressure

Setting the chucking pressure and the chucking

counterpressure

By reversing the chucking direction from ”clamped in back position” to ”clamped

when piston at the front” the function of the pressure regulating valves is reversed

as well.

In the following sketches is shown at which pressure regulating valve the respective

pressure is set.

,yy,y,y,y,y,y,y,

Main spindle

1. Case: Clamped when piston is at the back - e.g. Draw type chucking system

Chucking cylinder y,y,y,y, Chucking tube

Counterpressure Chucking pressure

pressure regulating valve (4) S8.4 pressure regulating valve (2) S20.0

pressure gauge (3) pressure gauge (1)

yy

, ,y,y,

2. Case: Clamped when piston is at the front - e.g. Thrust type chucking system

Chucking cylinder

,

y

,y

y ,

y

,y,

y

,y,

y

, Chucking tube

Chucking pressure Counterpressure

pressure regulating valve (4) S8.4 pressure regulating valve (2) S20.0

pressure gauge (3) pressure gauge (3)

L1301.10461_1

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 9 –

Setting the Chucking Pressure

Counterspindle1)

yyyy

,,,,

1. Case: Clamped when piston is at the back - e.g. Draw type chucking system

,,,,

yyyy

Chucking tube

,,,,

yyyy Chucking cylinder

Chucking pressure Counterpressure

pressure regulating valve (7) S20.1 pressure regulating valve (8) S12.4

pressure gauge (5) pressure gauge (6)

yyyy

,,,,

2. Case: Clamped when piston is at the front - e.g. Thrust type chucking system

,,,,

yyyy

,,,,

yyyy

Chucking tube Chucking cylinder

Counterpressure Chucking pressure

pressure regulating valve (7) S20.1 pressure regulating valve (8) S12.4

pressure gauge (5) pressure gauge (6)

L1301.10461_1

Chucking pressure -> 20 - 40 bar

Pressure difference -> minimum 5 bar

1) not applicable for INDEX ABC

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

– 10 –

INDEX-Werke GmbH & Co. KG

Hahn & Tessky

Postfach 10 03 54

D-73726 Esslingen

Telefax (0711) 3191 - 587

Verteiler für technische Dokumentation • Abt. TED

Titel: Gegenspanndruckeinrichtung Lit. Nr.: LL1302.1046 1 Ausgabe: 02.99

Maschine: G200 ,G300, ABC Steuerung: C200-4 Sprache: ENGLISCH

Datum: 22.02.99 Name: Krause ACROBAT PDF vorhanden? ja

Anmerkung: Der fertig ausgefüllte Verteiler ist die letzte Seite der elektronischen Datei und liegt auch den Druckvorlagen bei.

Anzahl Anzahl

KB 1/H.Großmann D-VTE/H. Ragab

KB 2/H.Faas D-VTM1/H.Beck MS…

KB 3/H.Trautmann D-TKD3/ H.Haidorfer/H.Huber MS…

KB 4/H.Hafla D-MON1/H.Schmid/H.Scheer MS…

TKD/H. Aigner D-MON/Mstr.Stürzl (Einrichterei) L3, L4

TKD4/H. Maier D-MON/Mstr.Traub (mech.) L3

VTK/H.Bader D-MON/Mstr.Schein/H. Frick (elektr.) L3

D-MON/Mstr.Reimer (elektr.) L4

D-MON/Mstr. Rachel (mech.) L4

MON/Mstr.Veit (Einrichterei) T6, T7, L6

MON/Mstr.Breymayer (mech.) T6, T7

Ausland

MON/Mstr.Henzler T6, T7, L6

VKA1/H.Stähle

6 (2x I.C., 2x Synergon, 2x Kingsbury) D-AVM/H.Specht (L3, L4)

AVM/H.Lehnig (L6, T6, T7)

VKA2/H.Jung

VFZ/H. Reutter

VID1/H.Spanbalch

(1x Springmann, 1x Liges) AVT/H.Kröner (L3, L4)

VID1/H.Götzenberger

(2x INDEX-France)

VID1/H.Götzenberger

(1x Prodeco, 1x H.Marks)

Summe der zusätzlich

6

zu druckenden Exemplare

Bemerkungen bzw. Änderungen zum Vorgänger

Änderung Seite 9 und 10 - Druckregelventile !!

Counterpressure attachment - INDEX G200, G300 und ABC; Control C200-4

Technische Dokumentation / Allg. Ablage / Formulare / Verteiler f. techn.Dok. / Ausgabe 25.11.98

– 11 –

You might also like

- LL1302 - 10332-Functiile MasiniDocument16 pagesLL1302 - 10332-Functiile MasiniSzaby Kalman100% (1)

- LL1602 10184Document18 pagesLL1602 10184Amir Hodzic100% (1)

- Betriebs-Anleitung: Option For The ControlDocument54 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- MEASUREMENT DATA REGISTRATIONDocument2 pagesMEASUREMENT DATA REGISTRATIONAmir Hodzic100% (1)

- Betriebs-Anleitung: Option For The ControlDocument40 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- LH1402 - 10013 MBLDocument48 pagesLH1402 - 10013 MBLSzaby Kalman100% (2)

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- Betriebs-Anleitung: Design and FunctionsDocument18 pagesBetriebs-Anleitung: Design and FunctionsAmir Hodzic100% (1)

- LL1302 40011-ProgramareDocument60 pagesLL1302 40011-ProgramareSzaby Kalman100% (1)

- Ransport and Installation Instructions CTX 510 EcoDocument32 pagesRansport and Installation Instructions CTX 510 EcoMiliano FilhoNo ratings yet

- The Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALDocument183 pagesThe Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALCONG TRAN NGOCNo ratings yet

- Parameters 16i MADocument363 pagesParameters 16i MAGerardo AlcarazNo ratings yet

- Manual FanucDocument6 pagesManual FanucWermeson SousaNo ratings yet

- Siemense SM 06 04 23 76Document17 pagesSiemense SM 06 04 23 76skidamdnevnoNo ratings yet

- VMC Maintenance Manual (Alarm) : (Mynx 6500/)Document156 pagesVMC Maintenance Manual (Alarm) : (Mynx 6500/)Sagar HankareNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument60 pagesBetriebs-Anleitung: Option For The MachineSzaby Kalman100% (2)

- 802Dsl AlarmesDocument438 pages802Dsl AlarmesWagner Rodolfo da SilvaNo ratings yet

- GENOS M460V-5AX Technical Information Booklet V1.01Document2 pagesGENOS M460V-5AX Technical Information Booklet V1.01frasorNo ratings yet

- MAZAK Centro Torneamento QT Compact - 99J195716E0se-1606Document12 pagesMAZAK Centro Torneamento QT Compact - 99J195716E0se-1606lcmengeNo ratings yet

- BA 296-36 CA, 2, en - GBDocument1,534 pagesBA 296-36 CA, 2, en - GBOiciruam Coatl ZiurNo ratings yet

- Vezérlőmüködtetése ANGOLDocument304 pagesVezérlőmüködtetése ANGOLKovacs Peter100% (1)

- ITNC 530 HSCI Service Manual - 02 - 2012 - enDocument654 pagesITNC 530 HSCI Service Manual - 02 - 2012 - enWaldemarNo ratings yet

- F400 Instruction Manual PDFDocument414 pagesF400 Instruction Manual PDFДТМ-Інжиніринг. Вестати з ЧПК, Південна КореяNo ratings yet

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- FZ08 Fanuc Bed12 20Wz BA10 2000 ENDocument40 pagesFZ08 Fanuc Bed12 20Wz BA10 2000 ENCristian Gasca PatiñoNo ratings yet

- HCN-5000 50 BrochureDocument3 pagesHCN-5000 50 Brochurevictor saenz100% (1)

- CNC MitshibushiDocument394 pagesCNC MitshibushiMathi AlaganNo ratings yet

- TM Functional Safety 04 2012 en PDFDocument275 pagesTM Functional Safety 04 2012 en PDFWaldemarNo ratings yet

- CNC - Sfy-Aem680atx-Im-M-0 M720XP 380VDocument211 pagesCNC - Sfy-Aem680atx-Im-M-0 M720XP 380VРоман ДупликNo ratings yet

- B-Axis Synchronization Function Work Program - 02Document2 pagesB-Axis Synchronization Function Work Program - 02Kamal KannanNo ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- HCN ElectricDocument414 pagesHCN ElectricroyNo ratings yet

- Leadwell NV-Serie 2015 PDFDocument8 pagesLeadwell NV-Serie 2015 PDFLevi BriceñoNo ratings yet

- AF 650 Operation Manual AFEQFI03Document152 pagesAF 650 Operation Manual AFEQFI03sunhuynh0% (1)

- Heidenhain Ik 121v ManualDocument116 pagesHeidenhain Ik 121v ManualmasinemaNo ratings yet

- Basic Parameter Setting Needs To Be Done To Run Two Servo and One Spindle - For 0i-FDocument6 pagesBasic Parameter Setting Needs To Be Done To Run Two Servo and One Spindle - For 0i-FAdvance CNC TechnologiesNo ratings yet

- Fan Uc CNC Dual Check 01Document124 pagesFan Uc CNC Dual Check 01yogiboobooNo ratings yet

- JIG Controller CPH ConnectionDocument26 pagesJIG Controller CPH ConnectionceginoNo ratings yet

- MACHINE TOOLS APPLICATION SUPPORT DOCUMENTDocument3 pagesMACHINE TOOLS APPLICATION SUPPORT DOCUMENTabelNo ratings yet

- CNC Lathe Operation ManualDocument39 pagesCNC Lathe Operation Manualfaqall0% (1)

- Sinumerik 810T Operating & ProgrammingDocument384 pagesSinumerik 810T Operating & ProgrammingGenes CristinelNo ratings yet

- Yasnac I80m Computer Cummunication InstructionsDocument42 pagesYasnac I80m Computer Cummunication InstructionssunhuynhNo ratings yet

- Mori Seiki ZLM Codes ListDocument3 pagesMori Seiki ZLM Codes ListDragosNo ratings yet

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- M300 M300-V Programming ManualDocument361 pagesM300 M300-V Programming ManualAndey RibalkoNo ratings yet

- How To Disassemble The Turret Clamp UnclampDocument13 pagesHow To Disassemble The Turret Clamp Unclampangeldorta2002No ratings yet

- Parametros rs232Document100 pagesParametros rs232Anel DominNo ratings yet

- Easy Probing Renishaw PDFDocument29 pagesEasy Probing Renishaw PDFJesus MedinaNo ratings yet

- Parameter Manual Part 1Document474 pagesParameter Manual Part 1giuseppe abatiNo ratings yet

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 pagesCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidNo ratings yet

- Mori Seiki ZT 1000 y enDocument16 pagesMori Seiki ZT 1000 y enOswald muñoz100% (1)

- Gls 150 SeriesDocument20 pagesGls 150 SeriesHâlid ŞenNo ratings yet

- 1084-Apelio 5610 Parts List Rev (2) - 2Document662 pages1084-Apelio 5610 Parts List Rev (2) - 2李明泰No ratings yet

- MVP 8040 Operators Manual Mveqth00 (Awea)Document224 pagesMVP 8040 Operators Manual Mveqth00 (Awea)Anonymous regHjENo ratings yet

- Ajuste Valvula Limitadora D6TDocument7 pagesAjuste Valvula Limitadora D6TDomingo Cruz GarciaNo ratings yet

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 pagesHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesNo ratings yet

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 pagesHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesNo ratings yet

- Adjust Valve Lash for 3116 Industrial EngineDocument5 pagesAdjust Valve Lash for 3116 Industrial EnginezeljkoNo ratings yet

- Valve Lash 1Document4 pagesValve Lash 1Daniel TekleNo ratings yet

- Vibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingFrom EverandVibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingNo ratings yet

- Bar Loading Magazine - Part 1: Operating InstructionsDocument50 pagesBar Loading Magazine - Part 1: Operating InstructionsAmir HodzicNo ratings yet

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- Notes On Operating Materials: General InformationDocument18 pagesNotes On Operating Materials: General InformationAmir HodzicNo ratings yet

- Salmson 2015-16 ENGDocument1,322 pagesSalmson 2015-16 ENGAmir Hodzic100% (1)

- Betriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Document28 pagesBetriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Amir HodzicNo ratings yet

- Safety Precautions: Operating InstructionsDocument34 pagesSafety Precautions: Operating InstructionsAmir HodzicNo ratings yet

- Maintenance InstructionsDocument30 pagesMaintenance InstructionsAmir HodzicNo ratings yet

- Calibration Certificate Humidity SHTXX EDocument1 pageCalibration Certificate Humidity SHTXX EAmir HodzicNo ratings yet

- Notes On Operating Materials: General InformationDocument18 pagesNotes On Operating Materials: General InformationAmir HodzicNo ratings yet

- LL1602 10141Document100 pagesLL1602 10141Amir HodzicNo ratings yet

- Betriebs-Anleitung: Design and FunctionsDocument18 pagesBetriebs-Anleitung: Design and FunctionsAmir Hodzic100% (1)

- Transportation, Installation, Commissioning: Operating InstructionsDocument32 pagesTransportation, Installation, Commissioning: Operating InstructionsAmir HodzicNo ratings yet

- Safety Precautions: Operating InstructionsDocument34 pagesSafety Precautions: Operating InstructionsAmir HodzicNo ratings yet

- Bar Loading Magazine - Part 1: Operating InstructionsDocument50 pagesBar Loading Magazine - Part 1: Operating InstructionsAmir HodzicNo ratings yet

- Betriebs-Anleitung: Option To The MachineDocument8 pagesBetriebs-Anleitung: Option To The MachineAmir HodzicNo ratings yet

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- Betriebs-Anleitung: Design and Functions of The MachineDocument14 pagesBetriebs-Anleitung: Design and Functions of The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Document28 pagesBetriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Amir HodzicNo ratings yet

- Betriebs-Anleitung: Design and FunctionsDocument18 pagesBetriebs-Anleitung: Design and FunctionsAmir Hodzic100% (1)

- Iecq 01-2003Document21 pagesIecq 01-2003שוהם בן טוביםNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Developing Enterprise ArchitectsDocument12 pagesDeveloping Enterprise ArchitectskikinjoNo ratings yet

- Coprative BankDocument4 pagesCoprative BankJasmandeep brarNo ratings yet

- Cordero ReflectionPaper I, RobotDocument1 pageCordero ReflectionPaper I, RobotCarmela Joy CorderoNo ratings yet

- Sheet Metal Design User Guide: Cadds 5i Release 12Document528 pagesSheet Metal Design User Guide: Cadds 5i Release 12kadam_nitsi2046No ratings yet

- Engineering Colleges in IndoreDocument1 pageEngineering Colleges in IndoreSanjiv ErryNo ratings yet

- Praktikum Akuntansi-BiayaDocument27 pagesPraktikum Akuntansi-BiayaK-AnggunYulianaNo ratings yet

- Asian Water Principles of Ion Exchange Neumann 03 09 PDFDocument6 pagesAsian Water Principles of Ion Exchange Neumann 03 09 PDFEmmaColladoArredondoNo ratings yet

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoNo ratings yet

- TOC - Table of Compliance Arsitek SimDocument40 pagesTOC - Table of Compliance Arsitek SimImran nasution0% (1)

- 601-620 Instruction ManualDocument120 pages601-620 Instruction ManualChinmayMaxNo ratings yet

- How To Make A Mini Milling Machine-Manual or CNC!Document31 pagesHow To Make A Mini Milling Machine-Manual or CNC!Cosmin Ionut100% (1)

- CLORIOUS - ControlsDocument4 pagesCLORIOUS - ControlsRM HaroonNo ratings yet

- Biotechnology 2018 Conference BrochureDocument6 pagesBiotechnology 2018 Conference BrochureJessica JordanNo ratings yet

- (1-01) Spesifikasi BTL-6000 High Intensity Laser 12 Watt (HIL 12 Watt)Document2 pages(1-01) Spesifikasi BTL-6000 High Intensity Laser 12 Watt (HIL 12 Watt)Fardiyan SyafriNo ratings yet

- Instructions To Connect Database in DerbyDocument17 pagesInstructions To Connect Database in DerbyRebekkaNo ratings yet

- Denis Wick PDFDocument2 pagesDenis Wick PDFvicentikooNo ratings yet

- Infinity SM 225Document2 pagesInfinity SM 225Bmwmotorsport GabriNo ratings yet

- Struxureware PME BrochureDocument2 pagesStruxureware PME BrochureSky BysNo ratings yet

- Ethernet Switch For Universal Multi-Service Aggregation: High Performance CarrierDocument4 pagesEthernet Switch For Universal Multi-Service Aggregation: High Performance Carriersalic2013No ratings yet

- Hse Documents-Portable Ladder Safety and TypesDocument6 pagesHse Documents-Portable Ladder Safety and Typesr2mgt28ssvNo ratings yet

- R-3 - C and T Rice MillDocument4 pagesR-3 - C and T Rice MillJonathan RodolfoNo ratings yet

- ABSTRACTDocument8 pagesABSTRACTMark Benecito BoñgolNo ratings yet

- Thesis Format Guidelines: 1. Thesis and Project Report ArrangementDocument29 pagesThesis Format Guidelines: 1. Thesis and Project Report ArrangementAakashMalhotraNo ratings yet

- Semi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerDocument7 pagesSemi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerdexiNo ratings yet

- tgv3m Drake Television Graphic Design AssignmentDocument2 pagestgv3m Drake Television Graphic Design Assignmentapi-308067286No ratings yet

- Steps To Generate AWR Report: 1. Log in To DatabaseDocument8 pagesSteps To Generate AWR Report: 1. Log in To DatabaseAnonymous 8RhRm6Eo7hNo ratings yet

- Fagor Bottle Cooler Equipment: Manual For Installation, Use and MaintenanceDocument18 pagesFagor Bottle Cooler Equipment: Manual For Installation, Use and MaintenancebaderaminvhrNo ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet