Professional Documents

Culture Documents

LL1602 10184

Uploaded by

Amir HodzicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LL1602 10184

Uploaded by

Amir HodzicCopyright:

Available Formats

BETRIEBS-

ANLEITUNG

Operating Instructions · Manuel d’opération

Trouble-Shooting

Synchrospindle

• Synchrospindle mounting

• Locating- and indexing attachment adjustment

INDEX ABC

Control INDEX C 200 - 4

LL16 02.1 018 4

0998 STAND 0998/KR

Note on applicability

Some illustrations in this publication may deviate slightly from the product supplied, but this will not detract

from their instructional value.

The right of alteration by reason of technical progress is reserved by INDEX.

A word on copyright

This publication is protected by the law of copyright. The rights thereby established, particularly those of

translation, reprinting, extraction of illustrations, reproduction by photo-mechanical or similar means, and

storage in data processing installations, are strictly reserved, even for use as extracts.

Photo-copies for personal and other use of one’s own may only be made of individual sections or parts thereof

as single copies.

© Copyright by INDEX-Werke GmbH & Co. KG Esslingen 1997

Inhaltsverzeichnis

Preface ............................................................................................................................................................... 4

Synchrospindle mounting ............................................................................................................................... 5

Preparation for mounting ................................................................................................................................... 5

Machines without compressed air supply ................................................................................................... 6

Machines with compressed air supply ........................................................................................................ 6

Servicing unit ................................................................................................................................................. 6

Removing the old synchro spindle ................................................................................................................... 8

Mounting the new synchro spindle .................................................................................................................. 9

Synchro spindle adjustment .............................................................................................................................. 10

Locating- and Indexing Attachment Adjustment ........................................................................................ 12

Adjustment procedure ....................................................................................................................................... 12

Testing program for the locating- and indexing attachment ........................................................................... 15

Lubrication ......................................................................................................................................................... 16

Synchro spindle lubrication with oil .................................................................................................................. 16

Trouble-Shooting Synchrospindle - INDEX ABC

– 3 –

Preface

For carrying out the works described in this brochure, adequate knowledge of the operation of the control is required.

Pleaserefer to the brochure " Setting up and Operation of the Control INDEX C200-4 "

The adjustment dimensions and the tolerances mentioned are approximate values and are not binding. When more

accurate values are required we recommend to contact the INDEX service department.

For topics on the synchrospindle servicing please read the brochure "Servicing Instructions INDEX ABC".

• Always switch off the machine as follows before starting fitting, maintenance or inspection

work on the machine:

1. Set the isolating switch to OFF and secure against inadvertent switching on.

2. When working on the hydraulic system:

Depressurize the hydraulic system by opening the accumulator drain valve, or accumulator

drain valves.

Trouble-Shooting Synchrospindle - INDEX ABC

– 4 –

Synchrospindle mounting

Preparation for mounting

As from Mach. No.: 400500 the Index ABC synchrospindle is equipped with a

compressed air supply as standard. The compressed air is supplied through a system

of bores through the turret housing and the turret to the synchro spindle.

The pressure in the spindle housing improves the sealing of the synchro spindle

bearings against ingress of coolant.

On delivery of a new synchro spindle the following accessories are supplied:

1 hex. socket set-screw M6x6 ordering No.: 410156.0606

1 sealing ring (O-ring) ordering No.: 479103.0061

Furthermore the connecting bore on the synchro spindle is closed with a cheese head

screw (1). Please remove it.

L1601.10181/1

Trouble-Shooting Synchrospindle - INDEX ABC

– 5 –

Synchrospindle mounting

Machines without compressed air supply

On machines without compressed air supply the supplied set screw

2 must be glued into the connecting bore (2) of the synchro spindle.

Please use the adhesive "Loctite 542 (low strength)".

L1601.10181/2

Machines with compressed air supply

Sealing ring

On machines with compressed air supply the O-ring supplied must

be inserted into the counterbore of the connecting bore (3) before

➞

mounting the synchro spindle. This is in turret station 8.

3

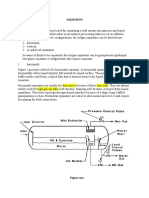

Servicing unit

L1601.10181/3

For the compressed air supply the machine is equipped with a se-

parate servicing unit. This is situated at the back of the machine.

The servicing unit is operated with unoiled air and is equipped with

an automatic water separator at the filter regulator for the operating

pressure and at the high performance compressed air filter each.

• A pressure switch will stop the machine as soon as the pressure

drops below 0,4 bar.

• Main line pressure max. ............................... 17 bar

• Pressure setting (preset by INDEX):

p1 = 1st Pressure reducing valve .................... 2 bar

p2 = 2nd Pressure reducing valve ................ 0,7 bar

In order to obtain an optimum sealing of the synchro

spindle the pressure of p2 0,7 bar must be absolutely

L1601.10181/4 maintained.

The water collecting containers must not be filled

with oil.

Trouble-Shooting Synchrospindle - INDEX ABC

– 6 –

Synchrospindle mounting

4 storing bore for the closing screw

5 oil infeed bore - synchro spindle

6 connecting bore

4 7 cover

8 clamping piece

5 9 pipe - oil infeed

10 adjusting screws

11 retaining screws

12 synchro spindle

6

13 spindle nopse cover

Fig: Turret 1 L1601.10181/6

10

11

12

13

L1601.10181/7

Fig: Synchro spindle

Trouble-Shooting Synchrospindle - INDEX ABC

– 7 –

Synchrospindle mounting

Removing the old synchro spindle

- Index turret to station 8

Only synchro spindle with locating and indexing attachment:

- Position synchro spindle to 0 degr.

Select operating mode "MDI-manual input":

100 1000

10 10000

1 Set NC-Mode selector switch to AUTOMATIK

( M ) -> Operating mode -> MDI-manual input

S125.2

Entries are posible only in key position "I SETTING UP".

Enter the following block for positioning the synchro spindle:

XXXXXXX

XXXXXXX

R10=0 L119

XXXXXXX

M17

Press softkey Select MDI TUR 1.

S120.1 Press key CYCLE START.

- Stop the machine and depressurize the hydraulic systems by opening the accumulator

draining valve.

- Slacken and unscrew the retaining screws (11)

- Loosen and pull out the clamping piece (8)

- Pull out the synchro spindle

- In order to avoid excessive loss of oil through the oil infeed (5), it can be closed

with the closing screw. This is found in the storing bore (4).

Trouble-Shooting Synchrospindle - INDEX ABC

– 8 –

Synchrospindle mounting

Mounting the new synchro spindle

(For operating instructions refer to brochure: "Settig up and Operation").

- Grease the driving gear.

- Possibly remove closing screw from oil infeed (5) and screw it into the storing

bore (4).

Only synchro spindle with locating - and indexing attachment:

- Turn the synchro spindle until the markings on the spindle and the housing

approximately coincide.

L1601.10051/7

- Mounting the synchro spindle.

Please observe that the markings are as close as possible after

mounting.

- Tighten the clamping piece (8) –> 20 Nm.

- Insert and tighten the retaining screws (11).

Check if the oil infeed pipe (9) can still be turned. In case this

should not be possible, the cover (7) must be slightly turned after

loosening the retaining screws.

Trouble-Shooting Synchrospindle - INDEX ABC

– 9 –

Synchrospindle mounting

Synchro spindle adjustment

A special adjusting arbor is used for adjusting the synchro spindlein

the INDEX works. Since this will rarely be vailable with the customers,

the dial indicator is set against the actual synchro spindle nose

diameter (refer to fig. "Dial indicator setting point")

- Switch on the hydraulic system (CYCLE START).

- Approach the reference points of all axes (CYCLE START).

- Traverse the compound slide 1 in operating mode JOG or INCREMENT in position

X120.

- Open the workpiece clamping of the synchro spindle.

- Dismantle the spindle nose front plate (13).

- Mount the dial indicator with 0,01 mm reading on the main spindle.

- Set the dial indicator against the actual synchro spindle nose diameter.

X1+

A B C

Z1+

M D

A Main spindle

B Dial indicator holder

C Dial indicator (0,01 mm reading)

D Synchro spindle

Fig. Dial indicator setting point L1601.10181/8

P1

P4

P3

P2

Fig. Measuring points L1601.10181/9

Trouble-Shooting Synchrospindle - INDEX ABC

– 10 –

Synchrospindle mounting

1. Evaluating the deviation between the measuring points P1 and P2␣ .

- Loosen and the slightly retighten the clamping piece (8.)

100 1000

10 10000 - Loosen the adjusting screws (10).

1

- Turn the NC-MODE SELECTOR SWITCH to INCREMENT 10 or 100.

S125.2

- Set the dial in dicator at the measuring point P2 to zero.

- Swing dial indicator to measuring point P1 and read the deviation.

- Equal out the deviation by traversing the X-axis (in small increments) until the

X+ X- indicator reading between P1 and P2 is less than 0,002 mm.

S121.7 S123.7

- Write down the reading, e.g. "X120.4000" (diameter display).

- Half of the written down value (60,2) is entered as X-tool geometry under the

␣ D-number T8.

1. Evaluating the deviation between the measuring points P3 and P4.

- Set the dial indicator at the measuring point P3 to zero.

- Swing dial indicator to measuring point P4 and read the deviation.

- Adjust the synchro spindle with the adjusting screws (10) until the indicator reading

between P3 and P4 is less than 0,002 mm.

- Lock the adjusting screws (10) with the nuts.

- Tighten the clamping piece (8) –> 20 Nm.

- Check the deviations again and correct if necessary.

- Mount the spindle nose plate (13).

Check if the oil infeed pipe (9) can still be turned. In case this

should not be possible, the cover (7) must be slightly turned after

loosening the retaining screws.

The position of the synchro spindle in relation to the rear end

drilling spindles must be checked and if necessary corrected after

the adjusting procedure.

Trouble-Shooting Synchrospindle - INDEX ABC

– 11 –

Locating- and Indexing Attachment Adjustment

After fitting of a new synchro spindle it is necessary to readjust the locating-

and indexing attachment.

Adjustment procedure

Switch on the machine and approach the reference points (see also brochure "Setting

up and Operation").

Select the picture " Synchro spindle" as follows:

( M ) -> Operate units -> Workpiece clampings -> Counter spindle

The following picture will be displayed:

L1602.10051/8

• Traverse the turret to a position in which indexing without collision is possible.

• Set FEED OVERRIDE to at least 1% and close sliding guard.

• Index turret 1 into pick-up position with softkey set synchron.

• Index turret 1 with softkey set synchron until the markings on the synchro

spindle coincide as closely as possible when the synchro spindle is in pick-up

position.

L1601.10051/7

• When this has been done the obtained position is confirmed with the softkey

store position.

Trouble-Shooting Synchrospindle - INDEX ABC

– 12 –

Locating- and Indexing Attachment Adjustment

Select the mode "MDI-manual input":

100 1000

10 10000

1 Set NC-Mode selector switch to AUTOMATIK

➤ ( M ) -> Operating mode -> MDI-manual input

S125.2 Entries are possible only at key switch position "I SETTING UP"

Enter the folowing block for adjusting the synchro spindle:

R10=0 L119

XXXXXXX

M17

XXXXXXX

XXXXXXX

XXXXXXX

Press softkey Select MDI TUR 1..

Turn synchro spindle by hand (≠ 0).

Press key CYCLE START.

S120.1

The synchro spindle will position to 0°. When no movement occurs

press the RESET-key and repeat the procedure.

S120.0

Press the key OPEN SLIDING GUARD and open the sliding guard.

Check by pushing in the latch pin if it engages in the notched disk. A thin hex.

S120.7

socket wrench may be used for this.

Latch pin

L1601.10181/5

Trouble-Shooting Synchrospindle - INDEX ABC

– 13 –

Locating- and Indexing Attachment Adjustment

When the latch pin does not engage, the synchro spindle must be slightly turned by

hand.

Watch the SPECIFIED/ACTUAL position display in the picture "synchro spindle" till

engagement of the latch pin.

L1601.10051/8 Write down the displayed difference value.

Select the picture "Spindle offset M19" as follows:

M -> -> Machine data -> Mecanic data -> M19 ref. offset

The following picturte will be displayed:

Spindle offset M19

Spindle offset

zero marker

S1 0

S2 0

S3 0

S4 0

S5 0

S6 0

Input 150 = 1.5 degrees

Entries are possible only at key switch position "I SETTING UP"

S122.7 Position the cursor to "S1" and enter the beforehand evaluated difference value under

"offset zero marker".

Entry value 150 = 1,5 degree

Possibly the password might be demanded)

The entries are transferred with INPUT.

To make correction values effective the following steps must be performed:

Press EMERCENCY STOP key and then unlock it again.

S122.3

Trouble-Shooting Synchrospindle - INDEX ABC

– 14 –

Locating- and Indexing Attachment Adjustment

Press both SPINDLE JOG MODE keys simultaneously for ca. 2 seconds.

S123.3 S124.5

Subsequently the hydraulic system must be switches-on again (by pressing CYCLE

START key)

Testing program for the locating- and indexing

attachment

A testing program is written for checking the function of the locating- and indexing

attachment. This can be started in the operating mode "MDI-manual input 1)".

1) For this refer to the brochure "Setting up and operation"

The program contents is as follows:

%SPF444

N005 L100 LF

N010 G0 G53 X280 Z350 LF

N015 M1=13 LF

N020 T8 LF

N025 R10=0 L119 LF

N030 M0 LF (Push in latch pin by hand)

N035 T3=5 LF

N030 M1=3 S1=200 LF

N045 G4 X1 LF

N050 R10=180 L119 LF

N055 M1=12 LF (Engage)

N060 M0 LF (Latch pin check*)

N065 M1=13 LF (Disengage)

N070 T3=4 LF

N075 M1=3 S1=200 LF

N080 G4 X1 LF

N085 R10=225 L119 LF

N090 M1=12 LF (Engage)

N095 M0 LF (Latch pin check*)

N100 M1=13 LF (Disengage)

N999 M17 LF

* Please check if the latch pin has actually engaged.

Trouble-Shooting Synchrospindle - INDEX ABC

– 15 –

Lubrication

Synchro spindle lubrication with oil

In delivered status, synchronized spindle bearings are filled with grease and sealed

against against intrusion of cooling lubricant by means of a packing.

This grease lubricaton is sufficient for the first 200 operating hours until the first oil

lubrication. After this the synchro spindle bearings and the bevel gears must be oiled

every 200 operatig hours.

The oiling nipple is situated on the side of the synchro spindle housing.

Procedure

• Set the main isolating switch to OFF and secure against inadvertent

switching on.

– Place greasing gun with oil cartridge against the oiling nipple.

– Actuate the gresing gun until oil starts penetrating at the front seal of the

synchrospindle.

The specification of the oil used is:

G68 ( ISO 3498 - 1979 )

CL68 ( DIN 8659 T2 )

Trouble-Shooting Synchrospindle - INDEX ABC

– 16 –

INDEX-Werke GmbH & Co. KG

Hahn & Tessky

Postfach 10 03 54

D-73726 Esslingen

Telefax (0711) 3191 - 587

You might also like

- Betriebs-Anleitung: Option For The ControlDocument40 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- Betriebs-Anleitung: Design and FunctionsDocument18 pagesBetriebs-Anleitung: Design and FunctionsAmir Hodzic100% (1)

- MEASUREMENT DATA REGISTRATIONDocument2 pagesMEASUREMENT DATA REGISTRATIONAmir Hodzic100% (1)

- LH1402 - 10013 MBLDocument48 pagesLH1402 - 10013 MBLSzaby Kalman100% (2)

- Betriebs-Anleitung: Option For The ControlDocument54 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- LL1302 - 10332-Functiile MasiniDocument16 pagesLL1302 - 10332-Functiile MasiniSzaby Kalman100% (1)

- ITNC 530 HSCI Service Manual - 02 - 2012 - enDocument654 pagesITNC 530 HSCI Service Manual - 02 - 2012 - enWaldemarNo ratings yet

- Ransport and Installation Instructions CTX 510 EcoDocument32 pagesRansport and Installation Instructions CTX 510 EcoMiliano FilhoNo ratings yet

- Heidenhain Ik 121v ManualDocument116 pagesHeidenhain Ik 121v ManualmasinemaNo ratings yet

- YCM500AW Operatin Manual - InglésDocument107 pagesYCM500AW Operatin Manual - InglésConociendoANuestraGenteNo ratings yet

- TM Functional Safety 04 2012 en PDFDocument275 pagesTM Functional Safety 04 2012 en PDFWaldemarNo ratings yet

- Siemense SM 06 04 23 76Document17 pagesSiemense SM 06 04 23 76skidamdnevnoNo ratings yet

- Manual FanucDocument6 pagesManual FanucWermeson SousaNo ratings yet

- M&H Probing ManualDocument52 pagesM&H Probing ManualWietse van der Steen100% (1)

- LL1302 40011-ProgramareDocument60 pagesLL1302 40011-ProgramareSzaby Kalman100% (1)

- Leadwell NV-Serie 2015 PDFDocument8 pagesLeadwell NV-Serie 2015 PDFLevi BriceñoNo ratings yet

- Easy Probing Renishaw PDFDocument29 pagesEasy Probing Renishaw PDFJesus MedinaNo ratings yet

- BA 296-36 CA, 2, en - GBDocument1,534 pagesBA 296-36 CA, 2, en - GBOiciruam Coatl ZiurNo ratings yet

- KellenbergerDocument44 pagesKellenbergerAminNo ratings yet

- V-20i Machine Instruction ManualDocument70 pagesV-20i Machine Instruction ManualsunhuynhNo ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument60 pagesBetriebs-Anleitung: Option For The MachineSzaby Kalman100% (2)

- Parameters 16i MADocument363 pagesParameters 16i MAGerardo AlcarazNo ratings yet

- Installation Manual for Extraction and Filter SystemsDocument42 pagesInstallation Manual for Extraction and Filter SystemsHannoun PartsNo ratings yet

- Emco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426Document282 pagesEmco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426AyoubNo ratings yet

- capto主轴标准Document87 pagescapto主轴标准中国心No ratings yet

- Parameter Manual Part 1Document474 pagesParameter Manual Part 1giuseppe abatiNo ratings yet

- 802Dsl AlarmesDocument438 pages802Dsl AlarmesWagner Rodolfo da SilvaNo ratings yet

- Fan Uc CNC Dual Check 01Document124 pagesFan Uc CNC Dual Check 01yogiboobooNo ratings yet

- Siemens Operator ManuelDocument64 pagesSiemens Operator ManuelFikret SönmezNo ratings yet

- Gls 150 SeriesDocument20 pagesGls 150 SeriesHâlid ŞenNo ratings yet

- FZ08 Fanuc Bed12 20Wz BA10 2000 ENDocument40 pagesFZ08 Fanuc Bed12 20Wz BA10 2000 ENCristian Gasca PatiñoNo ratings yet

- PLC Editor Manual enDocument43 pagesPLC Editor Manual enT FunnyNo ratings yet

- iTNC 530 Versatile Contouring ControlDocument60 pagesiTNC 530 Versatile Contouring ControlelumbNo ratings yet

- Manual de Instalacao Comando New990tdcaDocument100 pagesManual de Instalacao Comando New990tdcaAstrumosNo ratings yet

- TM Functional Safety 07 2011 enDocument229 pagesTM Functional Safety 07 2011 enWaldemarNo ratings yet

- HEIDENHAIN Absolute Encoder CNC ApplicationsDocument4 pagesHEIDENHAIN Absolute Encoder CNC ApplicationsocchityaNo ratings yet

- 21 Series Mill Controller Operation Manual: Date: 2013/11/08Document138 pages21 Series Mill Controller Operation Manual: Date: 2013/11/08Saif Uddin Ahmed100% (1)

- EP3 Use ManualDocument321 pagesEP3 Use Manualalejandro becerraNo ratings yet

- CNC Centurion 7 Programming Manual 179Document441 pagesCNC Centurion 7 Programming Manual 179Алексей ДоронинNo ratings yet

- VMC Maintenance Manual (Alarm) : (Mynx 6500/)Document156 pagesVMC Maintenance Manual (Alarm) : (Mynx 6500/)Sagar HankareNo ratings yet

- MVP 8040 Operators Manual Mveqth00 (Awea)Document224 pagesMVP 8040 Operators Manual Mveqth00 (Awea)Anonymous regHjENo ratings yet

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 pagesCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidNo ratings yet

- Siemense CNC 48SP2Document19 pagesSiemense CNC 48SP2Xaoc KabataNo ratings yet

- Operator'S Manual: HFA-250/250W/400/400WDocument174 pagesOperator'S Manual: HFA-250/250W/400/400WcoronaqcNo ratings yet

- Средства разработки макросовDocument42 pagesСредства разработки макросовAndrey VilchikNo ratings yet

- Gsk980tdb User Manual 20090901Document453 pagesGsk980tdb User Manual 20090901Sandrita Marisol Chasiluisa100% (2)

- Issues with ROBOCUT α-CiB Series Software UpdatesDocument2 pagesIssues with ROBOCUT α-CiB Series Software Updatesnhatnguyen101No ratings yet

- CNC MitshibushiDocument394 pagesCNC MitshibushiMathi AlaganNo ratings yet

- 1084-Apelio 5610 Parts List Rev (2) - 2Document662 pages1084-Apelio 5610 Parts List Rev (2) - 2李明泰No ratings yet

- DMU 70 Mechanik iTNC530Document74 pagesDMU 70 Mechanik iTNC530tolik19731No ratings yet

- MTB Tech BlogDocument41 pagesMTB Tech Blog이종훈No ratings yet

- User Manual v530 Bhe en v530 - 00fDocument128 pagesUser Manual v530 Bhe en v530 - 00fIonut-Daniel GeoNo ratings yet

- Operating Manual: LKHSP Self-Priming Centrifugal PumpDocument15 pagesOperating Manual: LKHSP Self-Priming Centrifugal Pumppablo ortizNo ratings yet

- Al Self Priming PumpDocument15 pagesAl Self Priming PumpHalley ElangovanNo ratings yet

- Husco PDFDocument70 pagesHusco PDFhamdaNo ratings yet

- Compact Hydraulic Directional Control ValveDocument34 pagesCompact Hydraulic Directional Control Valvebaskaranv100% (1)

- Bar Loading Magazine - Part 1: Operating InstructionsDocument50 pagesBar Loading Magazine - Part 1: Operating InstructionsAmir HodzicNo ratings yet

- Notes On Operating Materials: General InformationDocument18 pagesNotes On Operating Materials: General InformationAmir HodzicNo ratings yet

- Calibration Certificate Humidity SHTXX EDocument1 pageCalibration Certificate Humidity SHTXX EAmir HodzicNo ratings yet

- Safety Precautions: Operating InstructionsDocument34 pagesSafety Precautions: Operating InstructionsAmir HodzicNo ratings yet

- Salmson 2015-16 ENGDocument1,322 pagesSalmson 2015-16 ENGAmir Hodzic100% (1)

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- LL1602 10141Document100 pagesLL1602 10141Amir HodzicNo ratings yet

- Transportation, Installation, Commissioning: Operating InstructionsDocument32 pagesTransportation, Installation, Commissioning: Operating InstructionsAmir HodzicNo ratings yet

- Maintenance InstructionsDocument30 pagesMaintenance InstructionsAmir HodzicNo ratings yet

- Betriebs-Anleitung: Option To The MachineDocument8 pagesBetriebs-Anleitung: Option To The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Document28 pagesBetriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Amir HodzicNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- Notes On Operating Materials: General InformationDocument18 pagesNotes On Operating Materials: General InformationAmir HodzicNo ratings yet

- LL1602 10184Document18 pagesLL1602 10184Amir Hodzic100% (1)

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- Bar Loading Magazine - Part 1: Operating InstructionsDocument50 pagesBar Loading Magazine - Part 1: Operating InstructionsAmir HodzicNo ratings yet

- Safety Precautions: Operating InstructionsDocument34 pagesSafety Precautions: Operating InstructionsAmir HodzicNo ratings yet

- Betriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Document28 pagesBetriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Amir HodzicNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- Betriebs-Anleitung: Design and Functions of The MachineDocument14 pagesBetriebs-Anleitung: Design and Functions of The MachineAmir HodzicNo ratings yet

- Sulaiman Al Qudaibi Co.: Medium Term (1000 H) Hydrostatic Pressure Survival Test ProcedureDocument8 pagesSulaiman Al Qudaibi Co.: Medium Term (1000 H) Hydrostatic Pressure Survival Test ProcedureNADEEM AHMEDNo ratings yet

- Pearly Co Cleared Funds ForecastDocument8 pagesPearly Co Cleared Funds ForecastPutin Phy0% (1)

- 2.factory Price - Alarm Accessories-Complete 20150325Document15 pages2.factory Price - Alarm Accessories-Complete 20150325FREE BUSINESS INTELLIGENCENo ratings yet

- Separators: Figure OneDocument8 pagesSeparators: Figure OneMohamed Moder100% (1)

- Different Surgical Modalities For Management of Postburn FL Exion Contracture of The ElbowDocument6 pagesDifferent Surgical Modalities For Management of Postburn FL Exion Contracture of The ElbowMadhuchandra HirehalliNo ratings yet

- Envl 4300 Lab3Document9 pagesEnvl 4300 Lab3api-662867343No ratings yet

- S# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusDocument25 pagesS# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusahmedalishNo ratings yet

- Proper Application of Duff Phelps ERP Adjustment PDFDocument4 pagesProper Application of Duff Phelps ERP Adjustment PDFramsiva354No ratings yet

- (IJCST-V11I6P5) :A.E.E. El-Alfi, M. E. A. Awad, F. A. A. KhalilDocument9 pages(IJCST-V11I6P5) :A.E.E. El-Alfi, M. E. A. Awad, F. A. A. KhalilEighthSenseGroupNo ratings yet

- RESOLUTION 2022-08 Denial of Setback VarianceDocument5 pagesRESOLUTION 2022-08 Denial of Setback VarianceMatt McKinneyNo ratings yet

- Smoke Stratification - Understanding the DynamicsDocument3 pagesSmoke Stratification - Understanding the DynamicsGagan UpadhyayNo ratings yet

- Flashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelDocument37 pagesFlashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelTravel UnlimitedNo ratings yet

- Shrimp ReceipeDocument2 pagesShrimp Receipedonna blazoNo ratings yet

- Deliver VALUE and RENEWABLE FUTUREDocument30 pagesDeliver VALUE and RENEWABLE FUTUREAlexandru SuciuNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- Administrative Case ResolutionDocument2 pagesAdministrative Case ResolutionEunice Osam RamirezNo ratings yet

- 342Mass&HeatModule (3) Soln071118 OlefinPlantDocument12 pages342Mass&HeatModule (3) Soln071118 OlefinPlantmanuelNo ratings yet

- Cerberus PRO Product Catalog: Fire Safety Products and AccessoriesDocument253 pagesCerberus PRO Product Catalog: Fire Safety Products and AccessoriesleonardoleitealertaNo ratings yet

- SP-200 Advanced PumpDocument4 pagesSP-200 Advanced PumpOsvaldo BravoNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument2 pagesPolythionic Acid Stress Corrosion CrackingVajid MadathilNo ratings yet

- IRC Girl Shine Part 4 DigitalDocument124 pagesIRC Girl Shine Part 4 DigitalMónica SalesNo ratings yet

- WCDMA Optimization Case StudyDocument60 pagesWCDMA Optimization Case StudyRamesh Nikam100% (1)

- Color Me VeganDocument272 pagesColor Me VeganBela Luísa Novo100% (1)

- Aire Acondicionado Mazda 3 2006Document2 pagesAire Acondicionado Mazda 3 2006Jhon ConnorNo ratings yet

- Make Every Day Count: George Eliot's inspirational poemDocument3 pagesMake Every Day Count: George Eliot's inspirational poemRUTUJA KALENo ratings yet

- Pathology AIIMSDocument26 pagesPathology AIIMSvkNo ratings yet

- 01 Well Head ComponentsDocument46 pages01 Well Head ComponentsKhanh Pham Minh100% (7)

- Asia Pacific College of Advanced StudiesDocument4 pagesAsia Pacific College of Advanced StudiesRussel QuinonesNo ratings yet

- NCM 106 Acute Biologic CrisisDocument142 pagesNCM 106 Acute Biologic CrisisEllamae Chua88% (8)

- Automated Hematology Cell Counters 12-09-2023Document161 pagesAutomated Hematology Cell Counters 12-09-2023Tom JohnathanNo ratings yet