Professional Documents

Culture Documents

Centrifugal Compressor Vs Reciprocating Compressor

Centrifugal Compressor Vs Reciprocating Compressor

Uploaded by

Juan Hernández GilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal Compressor Vs Reciprocating Compressor

Centrifugal Compressor Vs Reciprocating Compressor

Uploaded by

Juan Hernández GilCopyright:

Available Formats

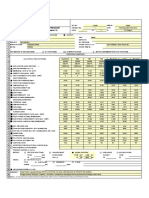

Comparison between Centrifugal Compressor and Reciprocating Compressor

Centrifugal Compressor Reciprocating Compressor

Working Principle It is rotodynamic type of compressor where the pressure rise is accomplished by dynamic It is positive displacement type of compressor, Certain volume of gas is drawn

& energy from the rotor to the gas. into the compression chamber where it is trapped, compressor and released.

compression process Rotating element Impeller imparts kinetic energy to gas and increase the velocity. Static Reciprocating motion of piston compress the gas inside the cylinder and deliver

diffuser controls the velocity of gas and convert it into pressure. it at higher pressure.

Maximum discharge pressure For Horizontal split case - Up to 100 bar Up to 3500 bar

For radially split case – Up to 1000 bar

Discharge Temperature range -46 C to 234 C (Lower or higher with special material) -40 C to 200 C (Lower or higher with special material)

Maximum Flow rate 8,50,000 Nm3/Hr 35,000 Nm3/Hr

Nature of flow Steady and continuous Pulsating and intermittent

Flow control / operating range Up to approx. 70% for fixed speed, Up to approx. 50% for VFD or Inlet Guide Vane Not possible for fixed speed. Up to 20% or lower through lower speed

Efficiency 70% to 85%, For axial it could go up to 90% 80% to 90%

Polytropic efficiency usually used except air compressors which use adiabatic efficiency Follow Adiabatic efficiency curve. Efficiency drops with compression ratio and

decreases with increased molecular weight

Reliability and availability Extremely reliable and availability is high Less reliable due to large number of parts and more rubbing seals that wear and

Due to a smaller number of rubbing parts and all rotating and critical parts are highly require more frequent replacement than any seal or part in a centrifugal

engineered, precision manufactured, tested and balanced. machine.

Maintenance cost Low High

Less number of replacement parts, repair or o/h interval is high. Large number of recurring parts, repair and O/h interval could be few months to

API 617, centrifugal compressor must be designed for at least five years of uninterrupted maximum 3-5 years.

service; they can operate continuously for 10 years or longer.

Noise and vibration Low High

Speed 1500-50,000 rpm 200-900 rpm

Initial cost High Low

Equipment protection Surge control Necessary Safety relief valve (Surge control is not required)

Applicable API standard API 617 API 618

Kirit Domadiya

You might also like

- Technical Data: - HA?DIDocument12 pagesTechnical Data: - HA?DIВладислав ЛеоновNo ratings yet

- Subaru Trouble Code InfoDocument16 pagesSubaru Trouble Code InfoKeven Cash100% (2)

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- Unit 8 Reciprocatng Compressors: StructureDocument26 pagesUnit 8 Reciprocatng Compressors: StructureRakeshKrNo ratings yet

- RT-flex-Introduction May13 Rev1Document96 pagesRT-flex-Introduction May13 Rev1NAGENDRA KUMAR D100% (1)

- 1 1515-30-S002 - Draft Specification For Reciprocating Compressors - Rev 4Document20 pages1 1515-30-S002 - Draft Specification For Reciprocating Compressors - Rev 4rutuja100% (1)

- F200bet Parts 2014Document100 pagesF200bet Parts 2014Anonymous Jw74aayApG100% (1)

- Frame Engine: EMS - Engine Management SystemDocument1 pageFrame Engine: EMS - Engine Management SystemAbner Souza100% (1)

- Centrifugal CompressorDocument5 pagesCentrifugal CompressorDeliaChiaNo ratings yet

- Caterpillar Air Intake Systems LEBW4969-04Document36 pagesCaterpillar Air Intake Systems LEBW4969-04mturri100% (1)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document4 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezNo ratings yet

- Fuel Supply SystemsDocument76 pagesFuel Supply SystemsTamil SelvanNo ratings yet

- 2103 G VD 101 013 - 1 Operation & Maintenance ManualDocument90 pages2103 G VD 101 013 - 1 Operation & Maintenance ManualArash SotoudehNo ratings yet

- Reciprocating CompressorDocument37 pagesReciprocating CompressorJithin DasNo ratings yet

- H2S PPM Into Mol % ConversionDocument1 pageH2S PPM Into Mol % ConversionYasir MumtazNo ratings yet

- Comparison of Types of EvaporatorDocument3 pagesComparison of Types of EvaporatorLon カンイェテNo ratings yet

- TURBINESDocument44 pagesTURBINESESWARANM91No ratings yet

- Ninja 250 Part CatalogueDocument98 pagesNinja 250 Part CatalogueBapi Sarkar0% (1)

- Compressor Formula PDFDocument1 pageCompressor Formula PDFAli zeinabiNo ratings yet

- Comparison Between CompressorsDocument10 pagesComparison Between CompressorsMc Jason LaureteNo ratings yet

- Pump SkillsDocument1 pagePump SkillsSaleem ChohanNo ratings yet

- PumpWorks Broshure API 610 OH2Document6 pagesPumpWorks Broshure API 610 OH2cavillalobosbNo ratings yet

- Stepless Clearance Pocket: Oil & GasDocument4 pagesStepless Clearance Pocket: Oil & Gasshank100No ratings yet

- Centrifugal PumpsDocument14 pagesCentrifugal PumpsAshishAgarwalNo ratings yet

- NGL PumpsDocument4 pagesNGL Pumpsamol patkiNo ratings yet

- Centrifugal Pump and Seal Cooling TechnolDocument50 pagesCentrifugal Pump and Seal Cooling TechnolTaifurNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurearvind pillaiNo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApDocument39 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApAnonymous JtYvKt5XENo ratings yet

- T23195-201-Royce N Brown PDFDocument8 pagesT23195-201-Royce N Brown PDFAnonymous dGzE1FUSTLNo ratings yet

- 03 FundamentalsDocument32 pages03 FundamentalsKavi BhandariNo ratings yet

- Anti FoamDocument7 pagesAnti FoamMohammad MohseniNo ratings yet

- Inspection of Compressors: OISD-120 Amended EditionDocument20 pagesInspection of Compressors: OISD-120 Amended EditionNanu PatelNo ratings yet

- Parts Manual: B30D & B25D 6X6 MKV AdtDocument150 pagesParts Manual: B30D & B25D 6X6 MKV AdtTeknik MakinaNo ratings yet

- Reciprocating Compressor Cooloing ConsoleDocument22 pagesReciprocating Compressor Cooloing ConsolerutujaNo ratings yet

- Materials Used For Construction: 1. Reciprocating CompressorDocument6 pagesMaterials Used For Construction: 1. Reciprocating CompressorEdemNo ratings yet

- Manual de Partes Lister GW4Document75 pagesManual de Partes Lister GW4Shane Nelson100% (1)

- Mechanical Data Sheet For Fuel Gas FiltersDocument4 pagesMechanical Data Sheet For Fuel Gas FilterssudjonoNo ratings yet

- Open Vs Closed Impeller PDFDocument3 pagesOpen Vs Closed Impeller PDFucb2_ntpcNo ratings yet

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocument3 pagesTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasNo ratings yet

- Report On Gass CompresorDocument35 pagesReport On Gass CompresorPooyan Hasan Poor100% (2)

- RIKT Isothermal Turbocompressors PDFDocument6 pagesRIKT Isothermal Turbocompressors PDFJaswindersingh BhatiaNo ratings yet

- Accenture Silicon Valley Tech Innovation Ecosystem Infographic PDFDocument2 pagesAccenture Silicon Valley Tech Innovation Ecosystem Infographic PDFAli zeinabiNo ratings yet

- Wartsila O E W 38 TRDocument12 pagesWartsila O E W 38 TRbunguiaoNo ratings yet

- Gas Compressor AvanceDocument36 pagesGas Compressor AvanceLina VargasNo ratings yet

- Engro Fertilizer ReportDocument46 pagesEngro Fertilizer ReportSher Muhammad100% (1)

- BB1 Vs BB2Document1 pageBB1 Vs BB2bomthanhphuNo ratings yet

- Job Spec - Package - B224-114-80-43-SP-7204Document11 pagesJob Spec - Package - B224-114-80-43-SP-7204Esakki muthuNo ratings yet

- How To Calculate Polytropic EfficiencyDocument2 pagesHow To Calculate Polytropic Efficiencysevero97No ratings yet

- Mid-Term Training EvaluationDocument26 pagesMid-Term Training EvaluationVishalSharmaNo ratings yet

- AgitatorDocument8 pagesAgitatorMugesh KannaNo ratings yet

- BHEL ASh Handling Equp QA RequiremntDocument27 pagesBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- 14 Draw Off Nozzle Hydraulics PDFDocument12 pages14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNo ratings yet

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 pagesA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDNo ratings yet

- Data Sheet WB RU VDocument5 pagesData Sheet WB RU VMaharani Putri IndrianurNo ratings yet

- DE-magnetising-Gausing of Rotor IFFCODocument13 pagesDE-magnetising-Gausing of Rotor IFFCOManoj SinghNo ratings yet

- 254624-400-DS-PRO-310, Rev F - Datasheet of VRUDocument18 pages254624-400-DS-PRO-310, Rev F - Datasheet of VRURamesh SharmaNo ratings yet

- The Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChlorideDocument2 pagesThe Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChloriderawadNo ratings yet

- Self Priming PumpDocument3 pagesSelf Priming Pumpmoejamal80No ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- Low NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFDocument12 pagesLow NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFMuhammad ImranNo ratings yet

- Ash Handling SystemDocument16 pagesAsh Handling SystemashokNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Ppi CL PDFDocument3 pagesPpi CL PDFMaxflowNo ratings yet

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- Ppppu: Pressure Powered Pump Package Unit With IJ and CRM485RDocument4 pagesPpppu: Pressure Powered Pump Package Unit With IJ and CRM485Rnemi90No ratings yet

- GT Tray Tower1 PDFDocument12 pagesGT Tray Tower1 PDFJose Christian Viladegut GuzmanNo ratings yet

- Presentación de Normas de BombasDocument18 pagesPresentación de Normas de BombasP_I_P_HNo ratings yet

- Sundyne Pinnacle Centrifugal Compressor Data SheetDocument2 pagesSundyne Pinnacle Centrifugal Compressor Data SheethamedfazelmNo ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- Quick Reference - HVAC (Part-1) : DECEMBER 1, 2019Document18 pagesQuick Reference - HVAC (Part-1) : DECEMBER 1, 2019shrawan kumarNo ratings yet

- 100M SpecDocument2 pages100M SpecJerNo ratings yet

- Basic Comparison For PumpsDocument4 pagesBasic Comparison For PumpsFery HartantoNo ratings yet

- Azmun HaDocument4 pagesAzmun HaAli zeinabiNo ratings yet

- Power Generation: Full Air Flow Half Air Flow IGV Position ForDocument1 pagePower Generation: Full Air Flow Half Air Flow IGV Position ForAli zeinabiNo ratings yet

- Archvie of SID: (HVOF)Document15 pagesArchvie of SID: (HVOF)Ali zeinabiNo ratings yet

- Def Kato Imer 12vxe enDocument16 pagesDef Kato Imer 12vxe enYew LimNo ratings yet

- 07 GRP02 All EnginesDocument64 pages07 GRP02 All Engineseurospeed2No ratings yet

- Cerrar SIS: Excavator 323D L Excavator Bym 323D L Excavator BYM00001-UP (MACHINE) POWERED BY C6.4 EngineDocument5 pagesCerrar SIS: Excavator 323D L Excavator Bym 323D L Excavator BYM00001-UP (MACHINE) POWERED BY C6.4 EngineErick Christopher Galeano 6-3No ratings yet

- 303-03 Engine Cooling 2.3L EcoBoost - SpecificationsDocument2 pages303-03 Engine Cooling 2.3L EcoBoost - SpecificationsCARLOS LIMADANo ratings yet

- New 5 - and 6-Cylinder VW Diesel EnginesDocument28 pagesNew 5 - and 6-Cylinder VW Diesel EnginesErick RodriguesNo ratings yet

- Spark Plugs Cross MSDDocument6 pagesSpark Plugs Cross MSDabelcardenNo ratings yet

- Maintenance SchduleDocument6 pagesMaintenance SchdulejairamvhpNo ratings yet

- 020 - Engine - System Too Lean (Fuel Trim) (Bank 1)Document5 pages020 - Engine - System Too Lean (Fuel Trim) (Bank 1)2791957No ratings yet

- Design, Analysis and Optimization of A 6 Cylinder Engine Crank ShaftDocument8 pagesDesign, Analysis and Optimization of A 6 Cylinder Engine Crank ShaftIJMERNo ratings yet

- Wa Engine CatDocument32 pagesWa Engine CatthailanNo ratings yet

- Solenoid ProjectDocument5 pagesSolenoid ProjectLovely KrishnaNo ratings yet

- Aerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaDocument8 pagesAerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaMasoud doskiNo ratings yet

- Electronic Unit Injector - Remove (KENR6081-15)Document10 pagesElectronic Unit Injector - Remove (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Board Diploma Examination, (C-20) MAY-2023 Dme - Fourth Semester ExaminationDocument3 pagesBoard Diploma Examination, (C-20) MAY-2023 Dme - Fourth Semester ExaminationRkrishna ANo ratings yet

- Shutdown: Product: Model: ConfigurationDocument3 pagesShutdown: Product: Model: ConfigurationchanlinNo ratings yet

- Engine: Section 1Document13 pagesEngine: Section 1LUIS ARCENo ratings yet

- 04 00 ThyssenKrupp MeuselDocument18 pages04 00 ThyssenKrupp Meuselsardhan.rajender84No ratings yet

- Stiga Havetraktor GARDEN 1000E 13-2328-14 0173Document25 pagesStiga Havetraktor GARDEN 1000E 13-2328-14 0173World AmusementNo ratings yet

- Lombardini LDW 442 CRS - GBDocument144 pagesLombardini LDW 442 CRS - GBAndrej ŠtirnNo ratings yet