Professional Documents

Culture Documents

Summary of Cutting Data For Cylindrical Surface: Material Details

Uploaded by

Hugo Fernandez SanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary of Cutting Data For Cylindrical Surface: Material Details

Uploaded by

Hugo Fernandez SanchezCopyright:

Available Formats

Summary of cutting data for Cylindrical surface

Summary of cutting data for Cylindrical surface

Material details

MC, M1.0.Z.AQ, Hardness: 200 HB, Material group:M1.0.Z.AQ

Task details

Cylindrical surface

Machined diameter start (DMS) 16 mm

Machined diameter end (DME) 14 mm

Machined length (LM) 9.5 mm

Ra roughness value longitudinal (RRA) 0.8 µm

Operation type (CTPT) pre-machining and

finishing

Workpiece surface condition code (WKPSCC) Pre-machined

Cutting condition code (CUTCC) Continuous cut

Rotational speed maximum (RPMX) 4000 1/min

Recommended solution

C6-SDJCR-45065-11 DCMT 11 T3 12-MM 2025

Type (ASMTYPE) Indexable Tool Insert

Operation (SUBOPSEQ) Turning External only

Longitudinal

Tool (TOOL) C6-SDJCR-45065-11 DCMT 11 T3 12-MM 2025

No. of pieces (#) 1 1

Adaption type (ADINTMS) Capto (segment&bolt) -size C6

Grade (GRADE) 2025

Type of cooling (COOLSTL) Internal

Coolant (COOLT) Emulsion 10%

Machining time (TMF) min:s 00:00.828

No. of features (TLIFEC) 2050

CoroPak 21.1, Sandvik Coromant CoroPlus® 1 of 4 4/27/2021

ToolGuide (21.02.0.3732)

Summary of cutting data for Cylindrical surface

Cutting data

Legend

Finishing

Cutting speed (VC) 176 m/min

Feed per revolution (FN) 0.183 mm

Spindle speed (N) 4000 1/min

Number of passes in AP direction (NOPAP) 1

Machined diameter start (DMS) 16 mm

Machined diameter end (DME) 14 mm

Depth of cut (AP) 1 mm

Rotational speed maximum (RPM MAX) 4000 1/min

Maximum cutting power (PC MAX) 1.92 kW

Maximum cutting torque (MC MAX) 4.59 Nm

Tool life time (LIFETIME) 27 min

Tool life length (LIFELENGTH) 4688.81 m

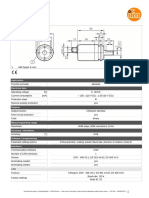

Produktinformation

CoroPak 21.1, Sandvik Coromant CoroPlus® 2 of 4 4/27/2021

ToolGuide (21.02.0.3732)

Summary of cutting data for Cylindrical surface

Beskrivning

CoroTurn® 107 cutting unit for turning

Beställningskod

ISO C6-SDJCR-45065-11

ANSI C6-SDJCR-45065-11

EDP

Streckkod 10768693

KAPR tool cutting edge angle 93 deg

PSIR tool lead angle -3 deg

MTP clamping type code S

CUTINTMASTER part 2 of cutting item interface identifiers DCMT 11T308

ADINTMS adaptive interface machine direction Coromant Capto (bolt and

segment clamping) -size C6

RMPX maximum ramping angle 27 deg

DMIN1 minimum bore diameter 140 mm

DMIN2 minimum bore diameter 190 mm

BAWS workpiece side body angle 0 deg

CDX cutting depth maximum mm

BAMS machine side body angle 0 deg

OHN minimum overhang mm

OHX maximum overhang 65 mm

LU usable length mm

HAND hand R

DPC damping property False

CNSC coolant entry style code 3: axial concentric and radial entry

CXSC coolant exit style code 6: decentral exit with nozzles,

adjustable

CNT coolant entry thread size

CP coolant pressure 40 bar

LOCAP location aid property

DCON connection diameter 63 mm

B shank width mm

H shank height mm

WSC clamping width mm

LPR protruding length mm

LF functional length 65 mm

WF functional width 45 mm

HF functional height 0 mm

HBL head bottom offset length mm

BD body diameter mm

WB body width mm

GAMO orthogonal rake angle 0 deg

LAMS inclination angle 0 deg

TQ torque 3 Nm

BMC body material code Steel

MIIDM master insert identification DCMT 11 T3 08

WT weight of item 1.054 kg

SEP Sensor embedded property 0

ValFrom20 Release date 1994-09-12

CoroPak 21.1, Sandvik Coromant CoroPlus® 3 of 4 4/27/2021

ToolGuide (21.02.0.3732)

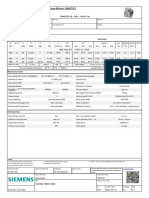

Summary of cutting data for Cylindrical surface

Beskrivning

CoroTurn® 107 insert for turning

Beställningskod

ISO DCMT 11 T3 12-MM 2025

ANSI DCMT 3(2.5)3-MM 2025

EDP

Streckkod 11147813

TMC1ISO Material classification level 1 M

IFS insert mounting style code 3

CUTINTSIZESHAPE insert size and shape DC11T3

CEDC cutting edge count 2

IC inscribed circle diameter 9.525 mm

W1 Insert width mm

SC insert shape code D

LE cutting edge effective length 10.4279 mm

RE Corner radius 1.1906 mm

WEP wiper edge property False

KRINS major cutting edge angle deg

BN face land width mm

GB face land angle deg

HAND hand N

GRADE grade 2025

SUBSTRATE Substrate HC

COATING coating CVD TICN+AL2O3+TIN

S insert thickness 3.9688 mm

AN clearance angle major 7 deg

WT weight of item 0.005 kg

SEP Sensor embedded property 0

ValFrom20 Release date 2000-08-14

Legal Notice

The data provided may be used at your own risk. AB Sandvik Coromant does not guarantee the applicability and functionality of the program, particularly the accuracy of the calculations. AB Sandvik Coromant will not accept any liability for trouble-free and

faultless use of the program. The user bears the entire risk of use.

In no event are Sandvik Coromant and its staff liable to the user for any damages, disadvantages and expenses, including any pecuniary damages, loss of data, etc., arising for the user or a third party out of, or in connection with, the use of, or inability to use,

the program. This exclusion of liability does not apply when and in as such as damages, disadvantages and expenses are caused intentionally or by gross negligence on the part of the staff of AB Sandvik Coromant.

You might also like

- ANEXEDocument16 pagesANEXERaul PopNo ratings yet

- Raport Cutit9797Document4 pagesRaport Cutit9797Catalin AirineiNo ratings yet

- CoroPlusToolGuide Report 2021-05-31Document4 pagesCoroPlusToolGuide Report 2021-05-31Dorin MacaruNo ratings yet

- Alegerea Sculei - Grafinariu Petru CiprianDocument4 pagesAlegerea Sculei - Grafinariu Petru CiprianAdrian-Dumitrel RaduNo ratings yet

- CoroPlusToolGuide Report 2023-12-02 Ins2 CatthoDocument9 pagesCoroPlusToolGuide Report 2023-12-02 Ins2 Catthonguyendangt740No ratings yet

- CoroPlusToolGuide Report 2022-01-12Document3 pagesCoroPlusToolGuide Report 2022-01-12Catalin AirineiNo ratings yet

- Summary of Cutting Data For Plain Surface: Material DetailsDocument5 pagesSummary of Cutting Data For Plain Surface: Material DetailsIorga AlexandruNo ratings yet

- CoroPlusToolGuide Report 2023-01-12Document5 pagesCoroPlusToolGuide Report 2023-01-12FEL EmpiresNo ratings yet

- Summary of Cutting Data For Hole in Rotation Component: Material DetailsDocument6 pagesSummary of Cutting Data For Hole in Rotation Component: Material DetailsdullecncNo ratings yet

- Summary of Cutting Data For Profile Surface - Ball Nose: Material DetailsDocument5 pagesSummary of Cutting Data For Profile Surface - Ball Nose: Material DetailsPalade LucianNo ratings yet

- Summary of Cutting Data For Plain Surface: Material DetailsDocument5 pagesSummary of Cutting Data For Plain Surface: Material DetailsIorga AlexandruNo ratings yet

- CoroPlusToolGuide Report 2023-01-25Document7 pagesCoroPlusToolGuide Report 2023-01-25FEL EmpiresNo ratings yet

- DTGNR 20 5DDocument2 pagesDTGNR 20 5DImam MulyonoNo ratings yet

- CoroPlusToolGuide Report 2019-12-01 PDFDocument5 pagesCoroPlusToolGuide Report 2019-12-01 PDFIorga AlexandruNo ratings yet

- DTFNR 3232P 27Document2 pagesDTFNR 3232P 27Imam MulyonoNo ratings yet

- Summary of Cutting Data For Widening and Finishing of Hole (No Demand On Shoulder)Document5 pagesSummary of Cutting Data For Widening and Finishing of Hole (No Demand On Shoulder)Iorga AlexandruNo ratings yet

- DTFNR 20 5D PDFDocument2 pagesDTFNR 20 5D PDFImam MulyonoNo ratings yet

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument6 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialIorga AlexandruNo ratings yet

- Coroguide Report 2016-05-26Document4 pagesCoroguide Report 2016-05-26Irwing MontenegroNo ratings yet

- PTFNL 3232P 27Document2 pagesPTFNL 3232P 27Imam MulyonoNo ratings yet

- GPS Report 2020-03-18Document3 pagesGPS Report 2020-03-18AlexNo ratings yet

- Summary of Cutting Data For Facing of Bar: Material DetailsDocument1 pageSummary of Cutting Data For Facing of Bar: Material DetailsPaul BuenañoNo ratings yet

- Shoulder: Material DetailsDocument5 pagesShoulder: Material DetailsDanielAileneiNo ratings yet

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDocument4 pagesSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiNo ratings yet

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDocument4 pagesSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiNo ratings yet

- Summary of Cutting Data For Thread in Through Hole: Material DetailsDocument5 pagesSummary of Cutting Data For Thread in Through Hole: Material DetailsIorga AlexandruNo ratings yet

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument5 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialIorga AlexandruNo ratings yet

- CSDNN 2525M 12-4 - Uso No Torneamento FofoDocument2 pagesCSDNN 2525M 12-4 - Uso No Torneamento FofoDennis CruzNo ratings yet

- AL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722Document9 pagesAL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722mehrdadgeminiNo ratings yet

- Summary of Cutting Data For Facing of Bar: Material DetailsDocument1 pageSummary of Cutting Data For Facing of Bar: Material DetailsPaul BuenañoNo ratings yet

- 1FK2204-5AK00-2MA0 Datasheet enDocument1 page1FK2204-5AK00-2MA0 Datasheet enGuilherme CompriNo ratings yet

- Summary of Cutting Data For Curve Slot With Two Open Ends: Frezare BuzunarDocument5 pagesSummary of Cutting Data For Curve Slot With Two Open Ends: Frezare BuzunarAndrei MihaiNo ratings yet

- A50U-PCLNR 16 Boring Bar Dia 50 MM SANDVIKDocument2 pagesA50U-PCLNR 16 Boring Bar Dia 50 MM SANDVIKsheldonNo ratings yet

- Summary of Cutting Data For Cylindrical Surface With ShoulderDocument1 pageSummary of Cutting Data For Cylindrical Surface With ShoulderPaul BuenañoNo ratings yet

- Coromill 316 + AdaptorDocument9 pagesCoromill 316 + AdaptorPalade LucianNo ratings yet

- Cutit CaneluraDocument3 pagesCutit CaneluraTurcanu ClaudiuNo ratings yet

- PTFNL 4040S 27Document2 pagesPTFNL 4040S 27Imam MulyonoNo ratings yet

- Summary of Cutting Data For Int. Cylindrical Surface: Material DetailsDocument3 pagesSummary of Cutting Data For Int. Cylindrical Surface: Material DetailsTurcanu ClaudiuNo ratings yet

- CXS-07T098-20-7240R 7014: Price Information Ordering CodeDocument2 pagesCXS-07T098-20-7240R 7014: Price Information Ordering CodePalade LucianNo ratings yet

- Summary of Cutting Data For Cylindrical Surface With Relief: Material DetailsDocument2 pagesSummary of Cutting Data For Cylindrical Surface With Relief: Material DetailsPaul BuenañoNo ratings yet

- CMR200T: Tuning Fork Crystal UnitDocument2 pagesCMR200T: Tuning Fork Crystal UnitAnoop GsNo ratings yet

- Summary of Cutting Data For Plain Surface: DegrosareDocument4 pagesSummary of Cutting Data For Plain Surface: DegrosareAndrei MihaiNo ratings yet

- CatalogueDocument41 pagesCatalogueiamtahn0281No ratings yet

- Gleason Kegelrad EnglischDocument4 pagesGleason Kegelrad EnglischRZW RNo ratings yet

- RM7012 00 - en UsDocument2 pagesRM7012 00 - en Ussylvainse1234No ratings yet

- MCR 370NDocument2 pagesMCR 370NMilo SorriNo ratings yet

- WalterGPS Report 2023-12-22Document4 pagesWalterGPS Report 2023-12-22lanhtraitim81No ratings yet

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument2 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialJosip ZrilićNo ratings yet

- Multiturn Solid Shaft Encoder: 1 M4 Depth 6 MMDocument2 pagesMultiturn Solid Shaft Encoder: 1 M4 Depth 6 MMSoha EzzaldenNo ratings yet

- Touch Panel MI0800CDP-CDocument19 pagesTouch Panel MI0800CDP-CStravik SudacaNo ratings yet

- Ftp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HDocument6 pagesFtp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HinfoNo ratings yet

- Drilling Bit 8.5 QD505XXDocument1 pageDrilling Bit 8.5 QD505XXRene Torres HinojosaNo ratings yet

- Datasheet ATM60-PAH13X13 1030015 enDocument7 pagesDatasheet ATM60-PAH13X13 1030015 enhebermarcussiNo ratings yet

- Plasma Cutting With MarkingDocument8 pagesPlasma Cutting With MarkingHidayat CharlesNo ratings yet

- 1LE1523-1EB43-4AA4 Datasheet enDocument1 page1LE1523-1EB43-4AA4 Datasheet enmuhammad nazmiNo ratings yet

- Cka6130 CNC Lathe: Detailed DescriptionDocument6 pagesCka6130 CNC Lathe: Detailed DescriptionIvona JovanovskaNo ratings yet

- Ftp-638Mcl401: Battery Driven, Ftp-608 Series 3" High Speed Thermal PrinterDocument6 pagesFtp-638Mcl401: Battery Driven, Ftp-608 Series 3" High Speed Thermal PrinterLaychoNo ratings yet

- IT6468 0911gbDocument24 pagesIT6468 0911gbmarcos lemosNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument2 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialHugo Fernandez SanchezNo ratings yet

- 2do Parcial HFS 149002Document4 pages2do Parcial HFS 149002Hugo Fernandez SanchezNo ratings yet

- Pre FresaDocument1 pagePre FresaHugo Fernandez SanchezNo ratings yet

- Pre TornoDocument1 pagePre TornoHugo Fernandez SanchezNo ratings yet

- Pre FresaDocument1 pagePre FresaHugo Fernandez SanchezNo ratings yet

- Pre TornoDocument1 pagePre TornoHugo Fernandez SanchezNo ratings yet

- Boxer EngineDocument84 pagesBoxer EngineTOONGA100% (7)

- Mahesh - Informatica DeveloperDocument5 pagesMahesh - Informatica DeveloperMadhav GarikapatiNo ratings yet

- Tablet Processing Problems and Their Remedies: Baharul IslamDocument16 pagesTablet Processing Problems and Their Remedies: Baharul IslamEspañola EloiseNo ratings yet

- ArticleDocument10 pagesArticlePrachiNo ratings yet

- How To Implement A Distributed CommonJ Work Manager ESDocument20 pagesHow To Implement A Distributed CommonJ Work Manager ESAbmel Salim LopessierNo ratings yet

- 3013 Thule Atlantis 780Document2 pages3013 Thule Atlantis 780Duarte MartinsNo ratings yet

- PugalenthiDocument7 pagesPugalenthiTHANI ORUVANNo ratings yet

- Dcs 2019 Questions PaperDocument14 pagesDcs 2019 Questions PaperDASHARATH VISHAWAKARMANo ratings yet

- Lampiran Uji Komparasi Ganda ScheffeDocument2 pagesLampiran Uji Komparasi Ganda ScheffeAhmad Safi'iNo ratings yet

- Edited C Spectra - APT and DEPTDocument4 pagesEdited C Spectra - APT and DEPTKasun RatnayakeNo ratings yet

- Aqa Byb1 W QP Jun07Document12 pagesAqa Byb1 W QP Jun07李超然No ratings yet

- Automatic Control Systems, 9th Edition: Chapter 9Document50 pagesAutomatic Control Systems, 9th Edition: Chapter 9physisisNo ratings yet

- 09 d01 Digsi 5 - Overview v1.1 En-UsDocument41 pages09 d01 Digsi 5 - Overview v1.1 En-UsAngie GinethNo ratings yet

- AristotleDocument126 pagesAristotlenda_naumNo ratings yet

- NTSE Stage - 1 Mock Test - 3Document16 pagesNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- RLC-circuits With Cobra4 Xpert-Link: (Item No.: P2440664)Document14 pagesRLC-circuits With Cobra4 Xpert-Link: (Item No.: P2440664)fatjonmusli2016100% (1)

- UACE BIO PAPER TWO SET 3 2023-JusanDocument3 pagesUACE BIO PAPER TWO SET 3 2023-JusanCampbell OGENRWOTNo ratings yet

- 3 772Document61 pages3 772D MNCNo ratings yet

- 17.alekhya Research ArticleDocument8 pages17.alekhya Research ArticleBaru Chandrasekhar RaoNo ratings yet

- AnovaDocument17 pagesAnovaIshan ShahNo ratings yet

- PRINCIPLES OF SURGERY (James R. Hupp Chapter 3 Notes) : 1. Develop A Surgical DiagnosisDocument5 pagesPRINCIPLES OF SURGERY (James R. Hupp Chapter 3 Notes) : 1. Develop A Surgical DiagnosisSonia LeeNo ratings yet

- ThinkSmart Hub SpecDocument5 pagesThinkSmart Hub SpecJose LopezNo ratings yet

- Product Data Sheet: Control Unit Micrologic 5.0 A, For Masterpact NT/ NW, LSI ProtectionsDocument3 pagesProduct Data Sheet: Control Unit Micrologic 5.0 A, For Masterpact NT/ NW, LSI ProtectionsEvandro PavesiNo ratings yet

- SSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Document14 pagesSSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Shrishanti Kale100% (1)

- A Proof of The Black and Scholes Formula: Claudio Pacati May 30, 2012Document3 pagesA Proof of The Black and Scholes Formula: Claudio Pacati May 30, 2012AndresC.MedinaSanhueza100% (1)

- EEMDocument17 pagesEEMSandaruwan සුජීවNo ratings yet

- Chloride LINEAR MK II - Service ManualDocument32 pagesChloride LINEAR MK II - Service Manualfabio.perazzoloNo ratings yet

- LAB REPORT BUCKLING OF STRUTS (Reference)Document13 pagesLAB REPORT BUCKLING OF STRUTS (Reference)jajenNo ratings yet

- LoadRunner BasicsDocument74 pagesLoadRunner BasicsmadhugangulaNo ratings yet

- IBM Data Science CapstoneDocument51 pagesIBM Data Science CapstonePeter Quoc88% (8)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- Tensor Technology Guide: Tensor Ring Benefits and UsesFrom EverandTensor Technology Guide: Tensor Ring Benefits and UsesRating: 5 out of 5 stars5/5 (2)

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismFrom EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo ratings yet

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersFrom EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersRating: 4 out of 5 stars4/5 (32)

- Epidemiology and Demography in Public HealthFrom EverandEpidemiology and Demography in Public HealthJaphet KillewoRating: 5 out of 5 stars5/5 (1)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Handbook of Hazardous Chemical PropertiesFrom EverandHandbook of Hazardous Chemical PropertiesRating: 5 out of 5 stars5/5 (1)

- Environmental and Health and Safety Management: A Guide to ComplianceFrom EverandEnvironmental and Health and Safety Management: A Guide to ComplianceRating: 4 out of 5 stars4/5 (2)