Professional Documents

Culture Documents

Nur Dayana - Ba2472a - Cross Words Puzzle

Uploaded by

YanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nur Dayana - Ba2472a - Cross Words Puzzle

Uploaded by

YanaCopyright:

Available Formats

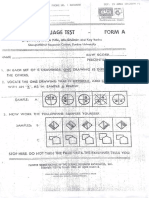

Name: NttR DAyAN A Date: I l+l3c,ll

Basics of Operations l\4anagement

,e

3elr u ':lp;

[E i a-E]

A

bK N- F!"

sfD .'

SqANTTCHART tl

T P lL j.

eu u,n

:n!D(

a '8{ eh N-

thDo LbEs

t4-e rlnoLrYE E 16u rw** eT

,orFqVg M3,

1fuqF1fuulEr. E T Y

l=

Pi 1o L Al NT

i9. Lr,

.Ilr Ir;.-Nkt t

,EEt

l "Elil_yl

Tyo h['-r]ilq4FEr.-:-u

3-

r. hl

!- hl

B

A

r.l

Across Down r',/

2. Six Sigma Technology was introduced by - 1. Spread or dispersion of dlta

3. Continuous lmproveilent is teehnique of "/ 4. Production flow analysis (PFA) is a method of '

6. Key to Chari is provided in -. identifying part families that uses data from ','

8. Un'evenness in the work is referred as z 5. First lndian steel company to win the Deming

10. Measure of Central Tendency V Award / ''

'r'i !: " ' '

12, Supply chain Management term was coined by 7. Nam_e associated with the phrase "Quality is

13. Staiisticalsampling was deveiopedby / free" r'

15. Also known as the vendor'z 9. Customer willing to pay is called as v'

17. Production leveling is l/ 11. PDCA is developed by r'

18. Standardization takes place in phrase r' 14. PERT/CPM was detreloped in the laboratory of

Y

19. Limiting factor in capacity planning system -/ which company

- 16. Mistake Proofing is called as /

20. Japanese word which is translated as "Card

you can see" ./

You might also like

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (4)

- Nur Dayana - Ba2472a - Cross Word PuzzleDocument1 pageNur Dayana - Ba2472a - Cross Word PuzzleYanaNo ratings yet

- Enll/ (-, 1.-I LL LLL ,: I L I (' J IDocument1 pageEnll/ (-, 1.-I LL LLL ,: I L I (' J ISalman KhanNo ratings yet

- R-R-Ofd07193: Nfier) .988Document2 pagesR-R-Ofd07193: Nfier) .988Cenyiqanita NurqanitaNo ratings yet

- United DC-6/7 Training MaterialDocument128 pagesUnited DC-6/7 Training Materialsimonduder85No ratings yet

- Absensi Safety MeetingDocument1 pageAbsensi Safety MeetingRusdi KoddengNo ratings yet

- Yugoslav COINTELPRO FilesDocument178 pagesYugoslav COINTELPRO FilesRobNo ratings yet

- 4 W % Q) 'Ff-Yt - Ffi AA: $atwroDocument2 pages4 W % Q) 'Ff-Yt - Ffi AA: $atwroAndriamos HutaurukNo ratings yet

- BMS34A142Document3 pagesBMS34A142Rohit Parmar (Computer Operator, Bangalore)No ratings yet

- Aircraft PerformanceDocument47 pagesAircraft PerformanceMedo KNo ratings yet

- Dun Bukit SelambauDocument29 pagesDun Bukit SelambaupialambkedahNo ratings yet

- Img 0020Document1 pageImg 0020Venkateshan VenuNo ratings yet

- Diams Opthalmology PDFDocument126 pagesDiams Opthalmology PDFSanjay OamNo ratings yet

- S L I A S 1Document4 pagesS L I A S 1jenann0702No ratings yet

- 2 09 PDFDocument77 pages2 09 PDFYu Zheng WuNo ratings yet

- Conflict of Laws Syllabus - Atty. QuibodDocument8 pagesConflict of Laws Syllabus - Atty. QuibodEzer Ivan Ria BacayoNo ratings yet

- U4Is) D: Iatstl$Lffirolh "Document3 pagesU4Is) D: Iatstl$Lffirolh "sushilNo ratings yet

- Instruction Booc For Electric Engine Telegraph Logger PDFDocument61 pagesInstruction Booc For Electric Engine Telegraph Logger PDFtoumassis_pNo ratings yet

- Standart Produksi Steel Pole (SPLN - 120 - 1996)Document27 pagesStandart Produksi Steel Pole (SPLN - 120 - 1996)ValentinoNo ratings yet

- Corporatiol/: H, S-:t-T++haDocument11 pagesCorporatiol/: H, S-:t-T++hagetachew negaNo ratings yet

- ,F,?O' Rflonrce Quc Jk. TH (-Iil,, I: LvsekgDocument2 pages,F,?O' Rflonrce Quc Jk. TH (-Iil,, I: Lvsekgjmjr30No ratings yet

- A Ttilck: Ttj. - S-./Rt8."..T.T:Tttt, Jlll,-K'Fli-C-N-UtmlDocument9 pagesA Ttilck: Ttj. - S-./Rt8."..T.T:Tttt, Jlll,-K'Fli-C-N-Utmlheavens indiaNo ratings yet

- UFO Files From The UK Government DEFE 24/2027Document280 pagesUFO Files From The UK Government DEFE 24/2027Exit ExitNo ratings yet

- P (LL"DL: Rcffiusrs LrefrmDocument2 pagesP (LL"DL: Rcffiusrs LrefrmAndriamos HutaurukNo ratings yet

- MMBC 3Document21 pagesMMBC 3suryaa ksNo ratings yet

- S, Fi..t:. I R: Itrtittll LTTTTDocument5 pagesS, Fi..t:. I R: Itrtittll LTTTTSixtus Okoro100% (1)

- Drawing Welding InspectionDocument9 pagesDrawing Welding InspectionEve ZimNo ratings yet

- Fisica Superiore Part1Document20 pagesFisica Superiore Part1alex831No ratings yet

- DLD FT Part 3 of 4Document18 pagesDLD FT Part 3 of 4Yasin ChowdhuryNo ratings yet

- Canadian National Railways System Timetables April 30, 1950Document85 pagesCanadian National Railways System Timetables April 30, 1950rivest266100% (1)

- '/:' (':.,''RL LZ: - 1t+n1,47't - N.TDocument8 pages'/:' (':.,''RL LZ: - 1t+n1,47't - N.TRadulian DanielNo ratings yet

- Maa Mangla Vc1Document1 pageMaa Mangla Vc1Sudarsan TuduNo ratings yet

- Img 20200429 0008 PDFDocument1 pageImg 20200429 0008 PDFPraise ChinoringaNo ratings yet

- Notulen Dan Daftar Hadir Rapat PMKP - 30 JuniDocument3 pagesNotulen Dan Daftar Hadir Rapat PMKP - 30 JuniklamasariNo ratings yet

- Wiązanka Melodii PopularnychDocument22 pagesWiązanka Melodii Popularnychczubak_pNo ratings yet

- 2.3.4 Ratio Student Mentor and Mentees With LogbookDocument30 pages2.3.4 Ratio Student Mentor and Mentees With LogbookRishabh BhandariNo ratings yet

- San NicolasDocument1 pageSan NicolasJerome GaliciaNo ratings yet

- Ffirrr RHT&,:, Fil, T '/irrt6o /YDocument14 pagesFfirrr RHT&,:, Fil, T '/irrt6o /Ypaulo_ramosNo ratings yet

- Neapolitan Tarantella PianoDocument10 pagesNeapolitan Tarantella PianomateuszNo ratings yet

- Piping Erection Estimating NormsDocument60 pagesPiping Erection Estimating NormsmehdiNo ratings yet

- Aprval 11Document11 pagesAprval 11Moses Iyekekpolor OtaborNo ratings yet

- CHP 4 Lec 1Document9 pagesCHP 4 Lec 1Fahad Hassan 1420607030No ratings yet

- Nov 2021 Board Exam PDFDocument76 pagesNov 2021 Board Exam PDFArnold HernandezNo ratings yet

- Paper 3 Section B No 4Document2 pagesPaper 3 Section B No 4Abdul ShariffNo ratings yet

- Still ReelingDocument2 pagesStill ReelingKarlīna ĪvāneNo ratings yet

- Gaspar SanzDocument7 pagesGaspar SanzAlvaro LuisNo ratings yet

- Cbs Coverage MapDocument1 pageCbs Coverage MappanditbhaiNo ratings yet

- PudueDocument3 pagesPudueHumanresource GoldshineNo ratings yet

- Marriage CertificateDocument1 pageMarriage CertificateJuarlito GomezNo ratings yet

- Img 20221212 0001Document7 pagesImg 20221212 0001Rohit KumarNo ratings yet

- Oh My Saviour by Sam MashDocument1 pageOh My Saviour by Sam MashSam MashNo ratings yet

- IMAGE0061Document1 pageIMAGE0061Rakesh PonnojuNo ratings yet

- AB ArK H 1956410167390 3 KANNAPPA PRO 001Document4 pagesAB ArK H 1956410167390 3 KANNAPPA PRO 001Vinod KumarNo ratings yet

- Wargames Illustrated #133Document64 pagesWargames Illustrated #133Анатолий Золотухин100% (1)

- Il :,TT W: Trhyffiffi W.F I RDocument1 pageIl :,TT W: Trhyffiffi W.F I RGilbert TanjutcoNo ratings yet

- Q'/"/ B) K, R Rfi : TLL LDocument1 pageQ'/"/ B) K, R Rfi : TLL Lscientia est potentiaNo ratings yet

- Konsep Keanekaragaman HayatiDocument1 pageKonsep Keanekaragaman HayatiErwin PerdanaNo ratings yet

- RMC No 96-2018Document1 pageRMC No 96-2018Randy PaderesNo ratings yet

- Nov 2011Document1 pageNov 2011alexander rereNo ratings yet

- Ransgai:, Ketr, G R, 4Rtf$ (/R (6Document1 pageRansgai:, Ketr, G R, 4Rtf$ (/R (6Deranie RidwanNo ratings yet

- Overview of Lean-ManagementDocument20 pagesOverview of Lean-ManagementKarthik ManianNo ratings yet

- Vizpcarshd v001Document10 pagesVizpcarshd v001Cliff OliveiraNo ratings yet

- Excel Professional Services, Inc.: Discussion QuestionsDocument5 pagesExcel Professional Services, Inc.: Discussion QuestionsRonna Mae MendozaNo ratings yet

- B2B Marketing PPT 21Document14 pagesB2B Marketing PPT 21Prashant patilNo ratings yet

- 2.JSA-Electrical Work Installation of Fire Alarm SystemDocument5 pages2.JSA-Electrical Work Installation of Fire Alarm SystemMuhammad Umar Gondal83% (6)

- Kunal Dengue ReportDocument1 pageKunal Dengue ReportSRK SRKNo ratings yet

- Isaac Kerich: Effects of Performance Management On Human Resource Output in Organizations-Case Safaricom Company-KenyaDocument69 pagesIsaac Kerich: Effects of Performance Management On Human Resource Output in Organizations-Case Safaricom Company-KenyaPeter DurbaNo ratings yet

- Guide To Selecting The Best JCT Main Contract - AveburyDocument1 pageGuide To Selecting The Best JCT Main Contract - Aveburyraymond1066No ratings yet

- Cambridge Bec4 Vantage4 Upper Intermediate Self Study Pack Sample Pages PDFDocument10 pagesCambridge Bec4 Vantage4 Upper Intermediate Self Study Pack Sample Pages PDFDanila YakushovNo ratings yet

- PMP ManualDocument638 pagesPMP ManualJavier100% (1)

- Artemis Medicare LTD (1) - 638163095219985066Document26 pagesArtemis Medicare LTD (1) - 638163095219985066Rahul NimmagaddaNo ratings yet

- Resume AbhyankDocument1 pageResume AbhyankvardhanreddyNo ratings yet

- The Brokerage Recruiting PlaybookDocument29 pagesThe Brokerage Recruiting PlaybookMonica StanciuNo ratings yet

- Ogl 321 Module 5 Paper 1Document6 pagesOgl 321 Module 5 Paper 1api-556515978No ratings yet

- Meeting 1Document4 pagesMeeting 1cristina valceaNo ratings yet

- Nakoda Publishers & Printers: Devi Ahilya University, Indore (DAVV)Document9 pagesNakoda Publishers & Printers: Devi Ahilya University, Indore (DAVV)Yukti KanungoNo ratings yet

- If You Are Looking For HighDocument6 pagesIf You Are Looking For HighSerap ErdoğanNo ratings yet

- V 6 o JDks 4Document3 pagesV 6 o JDks 4Noel JenningsNo ratings yet

- Norsok Standard R-003 Safe Use of Lifting EquipmentDocument58 pagesNorsok Standard R-003 Safe Use of Lifting EquipmentDing Liu100% (1)

- Project ProposalDocument4 pagesProject ProposalJayde GalopeNo ratings yet

- AI Sales Assistant 'Sellina' IntroDocument33 pagesAI Sales Assistant 'Sellina' IntrosurajcanonNo ratings yet

- Practical Handbook BPO Training Manual 2008Document28 pagesPractical Handbook BPO Training Manual 2008Tariq Hayat86% (7)

- Bonded Warehouse VS NonDocument3 pagesBonded Warehouse VS Nonphuong leNo ratings yet

- Understanding Japanese Management Practices: Parissa HaghirianDocument174 pagesUnderstanding Japanese Management Practices: Parissa HaghirianprabodhNo ratings yet

- Biodata Sheet - Vere Technical 2022-2023 FixedDocument7 pagesBiodata Sheet - Vere Technical 2022-2023 FixedjessyNo ratings yet

- Advertising ReportDocument4 pagesAdvertising ReportCeleste ErnNo ratings yet

- CVP NumericalsDocument12 pagesCVP NumericalsManmeet SinghNo ratings yet

- Enterprise Standards For Information SecurityDocument5 pagesEnterprise Standards For Information SecurityAnonymouse CTFNo ratings yet

- (KODE 05) - BI - CP (Kuantitatif) - Q1 - (Edited)Document9 pages(KODE 05) - BI - CP (Kuantitatif) - Q1 - (Edited)Arif Kathon SubhektiNo ratings yet

- Initiating The Inactive Employees Credit Card Process - SPDDocument5 pagesInitiating The Inactive Employees Credit Card Process - SPDFerasHamdanNo ratings yet