Professional Documents

Culture Documents

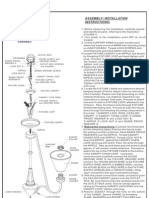

Drive Socket and Blade Assembly Replacement

Uploaded by

Annica MediciCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drive Socket and Blade Assembly Replacement

Uploaded by

Annica MediciCopyright:

Available Formats

3.

ROTATE THE DRIVE SOCKET UNTIL THE SCREW HEAD IS ALIGNED WITH

THE SLOT IN THE HOUSING; THEN LOOSEN IT USING A SMALL CROSS-

HEAD SCREWDRIVER. (TURN COUNTERCLOCKWISE, 4-5 COMPLETE

TURNS)

4. LEVER OFF THE DRIVE SOCKET USING 2 FLAT-HEAD SCREWDRIVERS OR 2

BLADE ASSEMBLY & DRIVE SOCKET REPLACEMENT RETAINER WRENCHES, APPLYING EQUAL PRESSURE TO BOTH SIDES.

5. LOCATE THE NEW DRIVE SOCKET ON TOP OF THE DRIVE SHAFT: ALIGN

I. TOOLS & BLENDER PARTS THE SQUARED BOTTOM OF THE SOCKET WITH THE SQUARED TOP OF

THE SHAFT, AND THEN PUSH STRAIGHT DOWN.

1. RETAINER WRENCH (X2) 2. FLAT-HEAD SCREWDRIVER (X2)

6. RE-TIGHTEN THE SCREW BENEATH THE DRIVE SOCKET (TURN CLOCKWISE

UNTIL THE SCREW HITS THE SHAFT OR STOPS GOING IN; THEN BACK OFF

¼ TURN.) DO NOT OVERTIGHTEN AS THIS WILL STRIP THE SCREW HEAD.

3. TWEEZERS 4. CROSS-HEAD SCREWDRIVER 7. REPLACE THE WATERPROOF RUBBER PAD, PUSHING IT GENTLY INTO

PLACE WITH A FINGER

8. REPLACE THE CONTAINER CUSHION.

5. JUG BASE PLATE 7. DRIVE SOCKET (MUSHROOM HEAD) REMOVE CONTAINER PULL OUT WATERPROOF ROTATE DRIVE SOCKET

CUSHION RUBBER TO ALIGN SCREWHEAD

PAD

6. RUBBER WATERPROOF

RUBBER PAD

CONTAINER

CUSHION SCREW

II. CHANGING THE BLADE ASSEMBLY RE-TIGHTEN SCREW

(CLOCKWISE)

LEVER OFF DRIVE SOCKET

1. USING THE WRENCH PUSH DOWN DRIVE SOCKET

OR FLAT-HEAD

SCREWDRIVER, TURN

THE UNIT

COUNTERCLOCKWISE

TO LOOSEN.

2. TURN CLOCKWISE

TO TIGHTEN. NOTE: TO TEST THE UNIT AFTER DRIVE SOCKET REPLACEMENT, TURN THE

MACHINE ON BRIEFLY WITH THE CONTAINER IN PLACE WHILE RESTING

YOUR HAND ON THE LID. IF THE CONTAINER VIBRATES EXCESSIVELY,

III. DRIVE SOCKET REPLACEMENT REMOVE THE DRIVE SOCKET FOLLOWING STEPS 1-4, ROTATE BY ¼ TURN

1. REMOVE THE CONTAINER CUSHION FROM THE BASE OF THE BLENDER. AND THEN RE-INSTALL FOLLOWING STEPS 5-8. IT MAY BE NECESSARY TO

2. USING TWEEZERS TAKE HOLD OF THE WATERPROOF RUBBER PAD AND TRY ALL 4 ¼-TURN ALIGNMENTS TO FIND THE BEST BALANCE.

PULL IT FREE FROM THE DRIVE SOCKET.

You might also like

- AISAN Carb DiagramDocument2 pagesAISAN Carb DiagramSolomon XI100% (1)

- Sked InstructionDocument6 pagesSked Instructionjr_mcmillinNo ratings yet

- Seal Installation Manual Seal Installation Manual: Required SpaceDocument3 pagesSeal Installation Manual Seal Installation Manual: Required SpacekiranNo ratings yet

- RL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Document2 pagesRL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Tuan TranNo ratings yet

- Master CylinderDocument2 pagesMaster CylinderamineNo ratings yet

- Manual Da Deslintadeira-200 SerrasDocument56 pagesManual Da Deslintadeira-200 SerrasAilson Silva AlvesNo ratings yet

- Speed Reducer.Document5 pagesSpeed Reducer.weldsaidiNo ratings yet

- KJ-M4 Manual: KjworksDocument16 pagesKJ-M4 Manual: KjworksЄвген ЗаліщукNo ratings yet

- RP554 ManualDocument3 pagesRP554 ManualAdolfo Angulo100% (1)

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document3 pagesAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- WWP 40 HDocument13 pagesWWP 40 HHEMANTKHERANo ratings yet

- New Sked Instruction With Bleedv - 3 2022Document20 pagesNew Sked Instruction With Bleedv - 3 2022Rogelio Andrés DíazNo ratings yet

- SC5357Document3 pagesSC5357tzNo ratings yet

- Is Tfww2840Document3 pagesIs Tfww2840dayshift5No ratings yet

- SKEDCO Sked Manual EC 2016 05 31 v1Document20 pagesSKEDCO Sked Manual EC 2016 05 31 v1ersNo ratings yet

- T TH HE E S ST Tiin NG GR RA AY Y & & X XO OC CE ET T: Owner'S Manual Series 2 ModelsDocument10 pagesT TH HE E S ST Tiin NG GR RA AY Y & & X XO OC CE ET T: Owner'S Manual Series 2 ModelssaorspioradNo ratings yet

- Instructions User Manual: The Complete Rescue SystemDocument20 pagesInstructions User Manual: The Complete Rescue SystemangelNo ratings yet

- Parking LDocument1 pageParking LRoberoNo ratings yet

- Honda HRA214 Quick AdjustDocument1 pageHonda HRA214 Quick AdjusthicksdpNo ratings yet

- Changing The Spring: HOSE REEL SER. 883, 887, 888, 889, 890, 893Document2 pagesChanging The Spring: HOSE REEL SER. 883, 887, 888, 889, 890, 893Marcio SenaNo ratings yet

- Resilient Seated Wedge Gate Valve: Installation, Operation & Maintenance InstructionsDocument2 pagesResilient Seated Wedge Gate Valve: Installation, Operation & Maintenance InstructionsshahqazwsxNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- GM G Cool - SPM PDFDocument24 pagesGM G Cool - SPM PDFAugustoA.TosiNo ratings yet

- Orca Share Media1571233257950Document17 pagesOrca Share Media1571233257950Prince YapNo ratings yet

- Btr-V2-Shaftrockerkit-082522 1 1Document2 pagesBtr-V2-Shaftrockerkit-082522 1 1Dale ReidNo ratings yet

- Is WC1915Document1 pageIs WC1915dayshift5No ratings yet

- Nexusgears-390/250ktm Instruction ManualDocument1 pageNexusgears-390/250ktm Instruction ManualNexusGearsNo ratings yet

- Imo 004enDocument4 pagesImo 004enHASBUL AZIZI BIN MAHMUNNo ratings yet

- Toyota LC HZJ78 02 CL ClutchDocument4 pagesToyota LC HZJ78 02 CL Clutchyannis.spinnerNo ratings yet

- QB78 CO2 Air Rifle TuningDocument14 pagesQB78 CO2 Air Rifle Tuningaakk75100% (7)

- Is Q148KDocument1 pageIs Q148Kdayshift5No ratings yet

- Week 12Document6 pagesWeek 12Denmark CruzadoNo ratings yet

- Hydraulic Cylinder ServiceDocument8 pagesHydraulic Cylinder Servicehesham farouk86100% (1)

- Bathtub Shower ValveDocument2 pagesBathtub Shower ValvestudboyNo ratings yet

- Contoh Penampang Gambar Mesin PenggerakDocument8 pagesContoh Penampang Gambar Mesin Penggerakcv piramidhaNo ratings yet

- Mud Motor Hand BookDocument80 pagesMud Motor Hand BookHanaNo ratings yet

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document3 pagesAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- Rotochambers: DescriptionDocument4 pagesRotochambers: DescriptionPABLONo ratings yet

- Chapter 4: Installing PistonsDocument14 pagesChapter 4: Installing Pistonss swamiNo ratings yet

- Assembly / Installation Instructions:: Chain-Hung MountingDocument1 pageAssembly / Installation Instructions:: Chain-Hung MountingA_tenksNo ratings yet

- Chemical Cutter Assembly ProcedureDocument29 pagesChemical Cutter Assembly ProcedureFélix Manuel Cedeño AgredaNo ratings yet

- CyScan IV Engineers and Service Guide - v1Document11 pagesCyScan IV Engineers and Service Guide - v1Thang PhamNo ratings yet

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document1 pageAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- Valve/Tappet Clearance Valve/Tappet Clearance: ! CautionDocument2 pagesValve/Tappet Clearance Valve/Tappet Clearance: ! CautionVenkatNo ratings yet

- Is Tfad2841Document3 pagesIs Tfad2841dayshift5No ratings yet

- 6-1 Cautions For Disassembly and ReassemblyDocument4 pages6-1 Cautions For Disassembly and ReassemblysalvadorNo ratings yet

- kiểm tra twistlocks (khó gù)Document5 pageskiểm tra twistlocks (khó gù)Nguyễn Văn HùngNo ratings yet

- Briggs Riley Repair KitDocument2 pagesBriggs Riley Repair KitslithersilverNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- Assembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document1 pageAssembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- Life Saving EquipDocument5 pagesLife Saving EquipAbdul Hameed OmarNo ratings yet

- Crane Overhaul ProcedureDocument8 pagesCrane Overhaul ProcedureHưng ĐỗNo ratings yet

- Assembly / Installation Instructions: For Canadian Installations Please Refer To Page 2Document3 pagesAssembly / Installation Instructions: For Canadian Installations Please Refer To Page 2dayshift5No ratings yet

- 684 MK1 Technical Training Rev - 01Document96 pages684 MK1 Technical Training Rev - 01iqbal husseinNo ratings yet

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document1 pageAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- Engine: Cam TimingDocument86 pagesEngine: Cam TimingXimena Justiniano LeytonNo ratings yet

- How To Change A Watch Battery Author StarstruckllcDocument12 pagesHow To Change A Watch Battery Author StarstruckllcPredrag NedeljkovicNo ratings yet

- Competence 10Document18 pagesCompetence 10Mabel Albares100% (1)

- Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandAnalysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionRating: 5 out of 5 stars5/5 (1)

- ASTM D2105 Longitudinal Tensile FiberglassDocument6 pagesASTM D2105 Longitudinal Tensile FiberglassAngyMartinezNo ratings yet

- F1511 Data SheetDocument2 pagesF1511 Data SheetJV Balisi100% (1)

- Pharmaceutical EngineeringDocument284 pagesPharmaceutical EngineeringPankesh Agrawal100% (1)

- MOL Hyundai R330LC-9SDocument1 pageMOL Hyundai R330LC-9SApril SNo ratings yet

- ICC-ES Evaluation Report ESR-2347: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDocument6 pagesICC-ES Evaluation Report ESR-2347: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDaniel PulgarNo ratings yet

- Estimating Design Parameters in Propane Refrigerant Systems - Pumps & SystemsDocument6 pagesEstimating Design Parameters in Propane Refrigerant Systems - Pumps & Systemsm.shehreyar.khanNo ratings yet

- Capaliiry Flow MethodDocument3 pagesCapaliiry Flow MethodDinesh Kumar MehraNo ratings yet

- ZF ControlesDocument39 pagesZF Controlesmarcosluna68100% (6)

- Case Study MTPS Dr. Jagannath Munda DVCDocument21 pagesCase Study MTPS Dr. Jagannath Munda DVCLakshmi NarayanNo ratings yet

- Ns Series Sub Mers DewateringDocument8 pagesNs Series Sub Mers DewateringPrateekNo ratings yet

- c5 ManualDocument196 pagesc5 ManualRelu MateiNo ratings yet

- Shapes and Irregularities StructureDocument5 pagesShapes and Irregularities StructureZul FadhliNo ratings yet

- Manitou MRT 3255 & MRT-X 3255 FT (EN)Document4 pagesManitou MRT 3255 & MRT-X 3255 FT (EN)ManitouNo ratings yet

- ForensicEngineeringMay262015 LoadTestingDocument10 pagesForensicEngineeringMay262015 LoadTestingEli MatucadNo ratings yet

- MIT Ising ModelDocument43 pagesMIT Ising ModelAritra LahiriNo ratings yet

- Thrust BlocksDocument16 pagesThrust Blockshemantkle2uNo ratings yet

- Problem Sheet - 2 PDFDocument2 pagesProblem Sheet - 2 PDFJyotirmoy DekaNo ratings yet

- Integration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionDocument8 pagesIntegration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionNambi RajanNo ratings yet

- Pump Data SheetDocument1 pagePump Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Parts ListDocument17 pagesParts ListKrunal PatelNo ratings yet

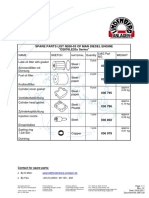

- Spare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Document1 pageSpare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Jezrell JaravataNo ratings yet

- BEMechanicalProduction Engineering2015SchemeDocument37 pagesBEMechanicalProduction Engineering2015SchemerajatjainkkjNo ratings yet

- Conexão Manômetro EN 837 PDFDocument4 pagesConexão Manômetro EN 837 PDFJoana MellerNo ratings yet

- HOW TO Design A Pump System PDFDocument17 pagesHOW TO Design A Pump System PDFwidhihartantoNo ratings yet

- Hawe PDFDocument262 pagesHawe PDFmadan mohan katta0% (1)

- Standard Style Stuffing BoxDocument4 pagesStandard Style Stuffing BoxAdelzon KinteroNo ratings yet

- Nippon Piston RingsDocument26 pagesNippon Piston Ringsadam_nell_1No ratings yet

- VOL 15-AWS Inspection Trends - 2012 - 01Document36 pagesVOL 15-AWS Inspection Trends - 2012 - 01Nguyen Duc DungNo ratings yet

- A New Development in Continuous Torque Monitoring CouplingsDocument13 pagesA New Development in Continuous Torque Monitoring CouplingsmlouredocasadoNo ratings yet

- 1sifat Fisik Mekanik Dan Kuat Tarik Batuan UtuhDocument13 pages1sifat Fisik Mekanik Dan Kuat Tarik Batuan UtuhChrlakhyarNo ratings yet