Professional Documents

Culture Documents

Operations Scheduling Techniques & Goals

Uploaded by

Asfawosen DingamaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operations Scheduling Techniques & Goals

Uploaded by

Asfawosen DingamaCopyright:

Available Formats

Chapter – 4 Operations Planning and Control –

Operations Scheduling

Scheduling Scheduling deals with the timing of operations

It is establishing the timing of the use of equipment, facilities and human activities in an

organization.

Scheduling It is the last stage of planning before production occurs 3 Capacity Planning (long

term; years) Changes in facilities Changes in equipment etc Aggregate Planning (intermediate

term; quarterly or monthly) Facility utilization Personnel changes Subcontracting etc Master

Schedule (intermediate term; weekly) Material Requirement Planning-MRP Disaggregating

aggregate plan Short term Scheduling (short term; days, hours, minutes) Work center loading Job

sequencing

Goals of Scheduling Efficient utilization of staf equipment facilities Minimization of

customer waiting time inventories processing time 4

5 Scheduling Operations Companies difer based on product volume and product variety which

afects how companies organizes their operations Each kind of company operation needs

diferent scheduling techniques Scheduling has specific definitions for routing, bottleneck, due

date, slack and queue

Scheduling Definitions Routing: The operations to be performed, their sequence, the work

centers, & the time standards Bottleneck: A resource whose capacity is less than the demand

placed on it Due date: When the job is supposed to be finished Slack: The time that a job can

be delayed & still finish by its due date Queue: A waiting line 6

Importance of Scheduling Scheduling executes a company’s strategic business plan

Scheduling afects functional areas Accounting relies on schedule information and completion

of customer orders to develop revenue projections Marketing uses schedule efectiveness

measurement to determine whether the company is using lead times for competitive advantage

Operations uses the schedule to maintain its priorities and to provide customer service by

finishing jobs on time 7

Type of Scheduling Forward scheduling Scheduling ahead, from some point in time

Forward scheduling starts as soon as the requirements are known or when a job is received

Frequently results in buildup of work-in-process inventory Backward scheduling Scheduling

by working backwards from the due date begin scheduling the job’s last activity so that the job

is finished on due date Due Due Date Now Now Due Due Date Date Now 8

Scheduling Operations Scheduling tasks are largely a function of the volume of system output

Diferent kinds of operations need diferent scheduling techniques Scheduling in High-Volume

Operations Scheduling in Intermediate-Volume Operations Scheduling in Low-Volume

Operations 9

10 High-Volume Operations Also known as flow operations (flow systems) Scheduling

encompasses allocating workloads to specific work centers and determining the sequence in

which operations are to be performed Characterized by standardized equipment and activities

that provide high-volume standard items Designed for high efficiency and high utilization of

labor and equipment

View document now

You might also like

- Om Group Assignment 1Document11 pagesOm Group Assignment 1motibtNo ratings yet

- Mb0044 Unit 13 SLMDocument22 pagesMb0044 Unit 13 SLMamit_idea1100% (2)

- Total Quality Management Short NoteDocument4 pagesTotal Quality Management Short NoteHazim IzzatNo ratings yet

- Scheduling Is An Important Tool For: Manufacturing EngineeringDocument4 pagesScheduling Is An Important Tool For: Manufacturing EngineeringSanghavee RajaramNo ratings yet

- Operations ManagementDocument12 pagesOperations ManagementkeerthiNo ratings yet

- Operations ManagementDocument15 pagesOperations ManagementJamil KamaraNo ratings yet

- Planning, Execution and Control Overview for Closed-Loop MPC SystemsDocument78 pagesPlanning, Execution and Control Overview for Closed-Loop MPC SystemsTerrelNo ratings yet

- Materials Planning: Unit IiDocument56 pagesMaterials Planning: Unit IiSownthariya T100% (1)

- OM0017-SLM-Unit-01 Operation Management SMUDocument19 pagesOM0017-SLM-Unit-01 Operation Management SMUpradeepjvsNo ratings yet

- Pom Chapter 10Document4 pagesPom Chapter 10keyt.riva.06No ratings yet

- Operations Planning and Scheduling SystemDocument5 pagesOperations Planning and Scheduling SystemAnn BautistaNo ratings yet

- Changing philosophy of operations managementDocument4 pagesChanging philosophy of operations managementslkizito100% (2)

- Production Planning and SchedulingDocument9 pagesProduction Planning and Schedulingsuriya kishoreNo ratings yet

- Week 11 & 12 (MRP - Information Technology & SCM, ERP)Document27 pagesWeek 11 & 12 (MRP - Information Technology & SCM, ERP)HAMNA SYEDNo ratings yet

- Operations Management: Production Planning & ControlDocument22 pagesOperations Management: Production Planning & ControlAnosh DoodhmalNo ratings yet

- Operations Scheduling: Maximize Resource UtilizationDocument14 pagesOperations Scheduling: Maximize Resource Utilizationbezawit mamuyeNo ratings yet

- Production Planning & ControlDocument43 pagesProduction Planning & ControlkunjammuNo ratings yet

- Definition of Production ControlDocument22 pagesDefinition of Production ControlNorIshamIsmailNo ratings yet

- Supply Chain ManagementDocument21 pagesSupply Chain ManagementMacy AndradeNo ratings yet

- SchedulingDocument20 pagesSchedulingShivansh SainiNo ratings yet

- Production and Operations Management Digital MaterialDocument220 pagesProduction and Operations Management Digital MaterialThe OpenstudioNo ratings yet

- GSPDocument41 pagesGSPHari PrasadNo ratings yet

- Aggregate Production Planning: Prepared By: Yonas KumsaDocument17 pagesAggregate Production Planning: Prepared By: Yonas Kumsa841388No ratings yet

- Week 11 & 12 (MRP - Information Technology & SCM, ERP)Document27 pagesWeek 11 & 12 (MRP - Information Technology & SCM, ERP)HAMNA SYEDNo ratings yet

- Business Process Reengineering: ERP-Lecture 16319Document6 pagesBusiness Process Reengineering: ERP-Lecture 16319neeraj sainiNo ratings yet

- Enterprise Resource Planning: Module: Production Planning and Manufacturing ProcessDocument10 pagesEnterprise Resource Planning: Module: Production Planning and Manufacturing ProcessAnurag RajwardhanNo ratings yet

- Om 0017Document194 pagesOm 0017praveen4_4No ratings yet

- Om 0017Document198 pagesOm 0017praveen4_40% (1)

- Scheduling v2Document51 pagesScheduling v2aryazynpkbkNo ratings yet

- By: Gerline Mae Ocampo PableoDocument6 pagesBy: Gerline Mae Ocampo PableoGerline MaeNo ratings yet

- Module-4: Material Requirement Planning (MRP)Document10 pagesModule-4: Material Requirement Planning (MRP)DhiyaneshNo ratings yet

- Chapter Four OmDocument20 pagesChapter Four Omkassahungedefaye312No ratings yet

- Aggregate Planning and MRP BenefitsDocument9 pagesAggregate Planning and MRP BenefitsKANISHK VARDHAN SINGHNo ratings yet

- SCM-Module-5-Resource Planning - MRP 1 & IIDocument24 pagesSCM-Module-5-Resource Planning - MRP 1 & IIMuhammed Husain MusaniNo ratings yet

- Process and production planning explainedDocument11 pagesProcess and production planning explainedLowEnd GamerNo ratings yet

- Scheduling Operations for Maximum EfficiencyDocument25 pagesScheduling Operations for Maximum EfficiencyMohammed Kazi100% (1)

- Scheduling OptimizationDocument11 pagesScheduling OptimizationClei UbandoNo ratings yet

- EMC 4512 Production SchedulingDocument6 pagesEMC 4512 Production Schedulingstephen mwendwaNo ratings yet

- Traditipn Production Planning and ControlDocument16 pagesTraditipn Production Planning and ControlpaulineNo ratings yet

- What Is Discrete ManufacturingDocument8 pagesWhat Is Discrete ManufacturingDhinakaran Veeman100% (1)

- P&OM Unit 3.1Document48 pagesP&OM Unit 3.1Tom CruiseNo ratings yet

- OM Chapter FourDocument58 pagesOM Chapter FourLakachew GetasewNo ratings yet

- Resource Management StrategiesDocument3 pagesResource Management StrategiesBao TranNo ratings yet

- Module 5 PDFDocument8 pagesModule 5 PDFMechanical EngineeringNo ratings yet

- Sche DullingDocument5 pagesSche Dullinganmol6237No ratings yet

- IEM-Module 3Document12 pagesIEM-Module 3Sunil Kumar KashyapNo ratings yet

- Chapter 4 OM Edited-1Document5 pagesChapter 4 OM Edited-1Seid KassawNo ratings yet

- Production-with-TQM-Chapter-4Document7 pagesProduction-with-TQM-Chapter-4Peter John Dela CruzNo ratings yet

- Capacity planning imp topicsDocument9 pagesCapacity planning imp topicsAryan RaiNo ratings yet

- CH - 08 - Production Planning-Exam PreDocument8 pagesCH - 08 - Production Planning-Exam PreK.M. Sabbir NomanNo ratings yet

- Short Term Scheduling: Mohammad Hashim Qureshi BBA-6 18/06/2011Document11 pagesShort Term Scheduling: Mohammad Hashim Qureshi BBA-6 18/06/2011Mohammad Hashim QureshiNo ratings yet

- Production Plnning & ControlDocument23 pagesProduction Plnning & ControlVivek VashisthaNo ratings yet

- Method of Operation Scheduling and Project ManagementDocument12 pagesMethod of Operation Scheduling and Project ManagementSurajit GoswamiNo ratings yet

- Functions of PPC - Planning, Timelines, ObjectivesDocument42 pagesFunctions of PPC - Planning, Timelines, ObjectivesSujit ThiruNo ratings yet

- Operations Management Course Scheduling and SequencingDocument12 pagesOperations Management Course Scheduling and SequencingSimantoPreeomNo ratings yet

- Production Planning and ControlDocument32 pagesProduction Planning and Controlsiddhi jainNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Ifrs Iyoha F (Acct) 3Document10 pagesIfrs Iyoha F (Acct) 3Asfawosen DingamaNo ratings yet

- HabteDocument5 pagesHabteAsfawosen DingamaNo ratings yet

- BooksDocument15 pagesBooksAsfawosen DingamaNo ratings yet

- Financial Acct For MBA - IfRS BasicsDocument75 pagesFinancial Acct For MBA - IfRS BasicsAsfawosen DingamaNo ratings yet

- Charles W. L. Hill / Gareth R. JonesDocument24 pagesCharles W. L. Hill / Gareth R. JonesAsfawosen DingamaNo ratings yet

- Ifrs MSL - 2019 - 277Document14 pagesIfrs MSL - 2019 - 277Asfawosen DingamaNo ratings yet

- Ifrs 947-1-926-1-10-20130410Document7 pagesIfrs 947-1-926-1-10-20130410Asfawosen DingamaNo ratings yet

- Ifrs AFC 2017 02 ParvathyDocument7 pagesIfrs AFC 2017 02 ParvathyAsfawosen DingamaNo ratings yet

- Benefits and Challenges of International FinancialDocument25 pagesBenefits and Challenges of International FinancialAsfawosen DingamaNo ratings yet

- Ifrs Article 9463Document6 pagesIfrs Article 9463Asfawosen DingamaNo ratings yet

- Ifrs The Challenges and Prospects of IFRS Adoption in Ethiopian Commercial BanksDocument20 pagesIfrs The Challenges and Prospects of IFRS Adoption in Ethiopian Commercial BanksAsfawosen DingamaNo ratings yet

- Ifrs D7105118419Document7 pagesIfrs D7105118419Asfawosen DingamaNo ratings yet

- Problem Set IIIDocument2 pagesProblem Set IIIAsfawosen DingamaNo ratings yet

- Section One 1.1 Backgroud of The StudyDocument10 pagesSection One 1.1 Backgroud of The StudyAsfawosen DingamaNo ratings yet

- Problem Set 2Document2 pagesProblem Set 2Asfawosen DingamaNo ratings yet

- Case Study 2.1 and 2.2Document3 pagesCase Study 2.1 and 2.2Asfawosen DingamaNo ratings yet

- School of Business and Economics ASTUDocument1 pageSchool of Business and Economics ASTUAsfawosen DingamaNo ratings yet

- Ifrs Literature ReviewDocument4 pagesIfrs Literature ReviewAsfawosen DingamaNo ratings yet

- Managerial Economics: Problem Set 1Document1 pageManagerial Economics: Problem Set 1Asfawosen Dingama100% (2)

- 1 Organizational Culture and Employees PerformanceDocument11 pages1 Organizational Culture and Employees PerformanceSyed Habib SultanNo ratings yet

- Managerial Economics: Problem Set 1Document1 pageManagerial Economics: Problem Set 1Asfawosen Dingama100% (2)

- Branson Airport ExperimentDocument10 pagesBranson Airport ExperimentAsfawosen DingamaNo ratings yet

- META ANALYSIS ON BPR APPROACHESDocument12 pagesMETA ANALYSIS ON BPR APPROACHESAsfawosen DingamaNo ratings yet

- School of Business and Economics ASTUDocument1 pageSchool of Business and Economics ASTUAsfawosen DingamaNo ratings yet

- Group II SolutionDocument4 pagesGroup II SolutionAsfawosen DingamaNo ratings yet

- Organizational Culture Impacts Employee PerformanceDocument17 pagesOrganizational Culture Impacts Employee PerformanceAsfawosen DingamaNo ratings yet

- Flexible UN treaty key to climate change progressDocument3 pagesFlexible UN treaty key to climate change progressAsfawosen DingamaNo ratings yet

- Bank Service Quality, Customer Satisfaction and Loyalty in Ethiopian Banking SectorDocument10 pagesBank Service Quality, Customer Satisfaction and Loyalty in Ethiopian Banking SectorAsfawosen DingamaNo ratings yet

- Measuring Service Quality in The Banking Industry: A Hong Kong Based StudyDocument20 pagesMeasuring Service Quality in The Banking Industry: A Hong Kong Based StudyJayD77No ratings yet

- Term Paper SolutionDocument27 pagesTerm Paper SolutionAsfawosen DingamaNo ratings yet

- G87.TEFRAprMay2013 - AFour Dayworkweek APolicyforImprovingEmploymentandEnvironmentalConditionsinEuropeDocument7 pagesG87.TEFRAprMay2013 - AFour Dayworkweek APolicyforImprovingEmploymentandEnvironmentalConditionsinEuropeอนรรฆ นิธิอิทธิไกรNo ratings yet

- It Is The Final Stage in The Strategic Management ProcessDocument66 pagesIt Is The Final Stage in The Strategic Management ProcessnathalieNo ratings yet

- Seminar 2 Presentation QuestionsDocument17 pagesSeminar 2 Presentation QuestionsJennifer YoshuaraNo ratings yet

- W4 TaxesDocument35 pagesW4 TaxesVanessa LeeNo ratings yet

- HBL-Vertical & Horizontal AnlyisDocument10 pagesHBL-Vertical & Horizontal AnlyismughalsairaNo ratings yet

- Chapter 1Document45 pagesChapter 1Genanew AbebeNo ratings yet

- Concepts of Logistics SystemDocument11 pagesConcepts of Logistics SystemVaibhav JaggiNo ratings yet

- Future Farming Policy Update1Document44 pagesFuture Farming Policy Update1aniNo ratings yet

- EIA1009 Take-Home Exam (30 Marks) (Vetted)Document4 pagesEIA1009 Take-Home Exam (30 Marks) (Vetted)Logan zhengNo ratings yet

- Week 9 - Appendix A - Pricing Products and ServicesDocument15 pagesWeek 9 - Appendix A - Pricing Products and ServicesAnh Thư PhạmNo ratings yet

- Framework For Mobile Money Implementation in NigerDocument9 pagesFramework For Mobile Money Implementation in Nigernocode pulseNo ratings yet

- Determinant Financial LeverageDocument19 pagesDeterminant Financial LeverageOdd BoyNo ratings yet

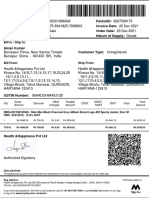

- Bill To / Ship To:: Qty Gross Amount Discount Other Charges Taxable Amount CGST SGST/ Ugst Igst Cess Total AmountDocument1 pageBill To / Ship To:: Qty Gross Amount Discount Other Charges Taxable Amount CGST SGST/ Ugst Igst Cess Total AmountAmanNo ratings yet

- Lista de beneficiários da previdênciaDocument9 pagesLista de beneficiários da previdênciaAllef Ferreira HillzNo ratings yet

- Local Merger 1. Overseas Filipino Bank (OFB) : 2. Allied Bank (Merged With Philippine National Bank)Document1 pageLocal Merger 1. Overseas Filipino Bank (OFB) : 2. Allied Bank (Merged With Philippine National Bank)hus wodgyNo ratings yet

- @afar - Complete (Oct2021-Dec2021)Document39 pages@afar - Complete (Oct2021-Dec2021)Violet BaudelaireNo ratings yet

- On Boundary Spanners and Interfirm Embeddedness - 2021 - Journal of PurchasingDocument11 pagesOn Boundary Spanners and Interfirm Embeddedness - 2021 - Journal of PurchasingRoshanNo ratings yet

- Fnbslw444 - Case StudyDocument5 pagesFnbslw444 - Case Studyinfobrains05No ratings yet

- Important Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruDocument7 pagesImportant Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruBoban RajkovicNo ratings yet

- Important Questions For CBSE Class 11 Business Studies Chapter 11Document23 pagesImportant Questions For CBSE Class 11 Business Studies Chapter 11Aishwarya100% (1)

- EJS With Portion SaleDocument3 pagesEJS With Portion SaleAidalyn Mendoza100% (1)

- Iii. in Both of The Above Cases, The Capitalist-Industrial Partner Shall Not Share in The Losses in His Capacity As Industrial PartnerDocument4 pagesIii. in Both of The Above Cases, The Capitalist-Industrial Partner Shall Not Share in The Losses in His Capacity As Industrial PartnerEsto, Cassandra Jill SumalbagNo ratings yet

- LangfieldSmith7e PPT Ch13Document33 pagesLangfieldSmith7e PPT Ch13Bành Đức HảiNo ratings yet

- Caso 1 - Airbnb in 2020 - Sobreviviendo A La Pandemia OriginalDocument18 pagesCaso 1 - Airbnb in 2020 - Sobreviviendo A La Pandemia OriginalArmando GarzaNo ratings yet

- Book Value Assets Total Unsecured Realizable ValueDocument9 pagesBook Value Assets Total Unsecured Realizable ValueJPNo ratings yet

- MealKit4U Stats Student-1Document14 pagesMealKit4U Stats Student-1s3976142No ratings yet

- McdonaldDocument4 pagesMcdonaldDwi KhonitanNo ratings yet

- Influence of Inflation On The Financial Challenges Faced by StudentsDocument4 pagesInfluence of Inflation On The Financial Challenges Faced by StudentsNobara AkatsukiNo ratings yet

- NayanaDocument40 pagesNayanaNitish KumarNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)