Professional Documents

Culture Documents

Scheduled Inspection Program (Special) - Inspection/Check (LJ-1063 AND AFTER) 1. Scheduled Inspection Program (Special)

Uploaded by

alejandro0 ratings0% found this document useful (0 votes)

44 views6 pagesOriginal Title

ml-b-90-b90mm24

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views6 pagesScheduled Inspection Program (Special) - Inspection/Check (LJ-1063 AND AFTER) 1. Scheduled Inspection Program (Special)

Uploaded by

alejandroCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

SCHEDULED INSPECTION PROGRAM (SPECIAL) - INSPECTION/CHECK

(LJ-1063 AND AFTER)

1. Scheduled Inspection Program (Special)

Owner : LH Eng. S/N :

W/O Number : Total Time : Total Cycles :

Date In : Date Out : TSOH : Cycles SOH :

Serial No. : Reg. No. : TSHSI : Cycles SHSI :

Last Inspection : Phase : RH Eng. S/N :

Last Inspection Date : Total Time : Total Cycles :

Last Inspection Hours : TSOH : Cycles SOH :

Hourmeter : Total Time : TSHSI : Cycles SHSI :

Total Cycles : LH Prop S/N :

Researched By : LH Prop Total Time : TSOH :

RH Prop S/N :

RH Prop Total Time : TSOH :

In this chapter, ATA 20 references will be to the Standard Practices - Airframe Maintenance Manual, P/N 130-590031-487.

NOTE: If two inspection intervals are shown (i.e. 2,400 HRS OR 30 MONTHS) this indicates the inspection

requirement is due at whichever time frame occurs first.

A. Special Inspections

INSPECTION MECH INSP

INTERVAL

1. LEFT-HAND ENGINE

a. Perform hot section inspection as required, refer to

Pratt and Whitney Service Bulletin No. 1003 and/or P&W SB 1003, OR SB

Service Bulletin No. 1803 or subsequent for LJ-1 thru 1803, OR

LJ-1062, and Service Bulletin No. 1803 or subsequent SUBSEQUENT

for LJ-1063 and After and LW-1 and After.

b. Oil Filter, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

c. Chip Detector, refer to the appropriate Pratt and FIRST 100 HOURS OF

Whitney Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

d. Ignitor Box, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

e. Ignitor Plugs, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

f. P3 Filter, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

g. External Linkages, refer to the appropriate Pratt and FIRST 100 HOURS OF

Whitney Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

Copyright © Textron Aviation Inc. Page 1 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

2. LEFT-HAND ENGINE OIL FILTER - Replace filter. 1,000 HOURS

3. LEFT-HAND MAIN GEAR SHOCK ABSORBER 8,000 CYCLES OR 6

ASSEMBLY - Inspect for cracks, wear and corrosion interior YEARS

and exterior (Disassembly required).

4. LEFT-HAND MAIN GEAR DRAG BRACE ASSEMBLY - 8,000 CYCLES OR 6

Inspect for cracks, wear and corrosion interior and exterior YEARS

(Disassembly required).

5. LEFT-HAND MAIN GEAR AXLE ASSEMBLY and TORQUE

KNEES - Inspect for cracks, wear and corrosion interior and 8,000 CYCLES OR 6

exterior (Disassembly required) (Ref. Component YEARS

Maintenance Manual, 32-00-00).

6. LEFT-HAND MAIN GEAR ACTUATOR CLEVIS - Inspect

clevis hole for wear Maximum allowable wear of clevis hole is 1,000 CYCLES

not to exceed 0.3265 inch (Disassembly required).

7. LEFT-HAND MAIN LANDING GEAR WHEELS - Inspect

main wheels in accordance with manufacturer's instructions

(Ref. Component Maintenance Manual, 32-00-00).

8. LEFT-HAND FLAP FLEXIBLE SHAFT - Inspect for wear

and freedom of operation with both ends disconnected (Ref. 5,000 CYCLES

Chapter 27).

9. LEFT-HAND WING PANEL UPPER and LOWER MAIN

SPAR CAP - Check for corrosion. Inspect as outlined in the 5 YEAR INITIAL/ 1 YEAR

King Air Series Structural Inspection and Repair Manual RECURRING

(Ref. Chapter 57).

10. RIGHT-HAND ENGINE

a. Perform hot section inspection as required, refer to P&W SB 1003, OR SB

Pratt and Whitney Service Bulletin No. 1003 and/or 1803, OR

Service Bulletin No. 1803 or subsequent. SUBSEQUENT

b. Oil Filter, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

c. Chip Detector, refer to the appropriate Pratt and FIRST 100 HOURS OF

Whitney Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

d. Ignitor Box, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

e. Ignitor Plugs, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

f. P3 Filter, refer to the appropriate Pratt and Whitney FIRST 100 HOURS OF

Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

g. External Linkages, refer to the appropriate Pratt and FIRST 100 HOURS OF

Whitney Maintenance Manual Section 72-00-00. OPERATION FOR A

NEW ENGINE

Copyright © Textron Aviation Inc. Page 2 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

11. RIGHT-HAND ENGINE OIL FILTER - Replace filter. 1,000 HOURS

12. RIGHT-HAND MAIN GEAR SHOCK ABSORBER 8,000 CYCLES OR 6

ASSEMBLY - Inspect for cracks, wear and corrosion interior YEARS

and exterior (Disassembly required).

13. RIGHT-HAND MAIN GEAR DRAG BRACE ASSEMBLY - 8,000 CYCLES OR 6

Inspect for cracks, wear and corrosion interior and exterior YEARS

(Disassembly required).

14. RIGHT-HAND MAIN GEAR AXLE ASSEMBLY and 8,000 CYCLES OR 6

TORQUE KNEES - Inspect for cracks, wear and corrosion YEARS

interior and exterior (Disassembly required).

15. RIGHT-HAND MAIN GEAR ACTUATOR CLEVIS - Inspect

clevis hole for excessive wear. Maximum allowable wear of 1,000 CYCLES

clevis hole is not to exceed 0.3265 inch (Disassembly

required).

16. RIGHT-HAND MAIN LANDING GEAR WHEELS - Inspect

main wheels in accordance with manufacturer's instructions

(Ref. Component Maintenance Manual, 32-00-00).

17. RIGHT-HAND FLAP FLEXIBLE SHAFT - Inspect for wear

and freedom of operation with both ends disconnected (Ref. 5,000 CYCLES

Chapter 27).

18. RIGHT-HAND WING PANEL UPPER and LOWER MAIN

SPAR CAP - Check for corrosion. Inspect as outlined in the 5 YEAR INITIAL/ 1 YEAR

King Air Series Structural Inspection and Repair Manual RECURRING

(Ref. Chapter 57).

19. EDGELIGHTED PANEL ASSEMBLIES - Inspect for 2,000 HOURS OR 4

condition (Ref. Chapter 33). YEARS

20. AIR-CONDITION COMPRESSOR DRIVE BELTS - Check

for proper tension (Ref. Chapter 21).

21. NOSE GEAR SHOCK ABSORBER ASSEMBLY - Inspect 8,000 CYCLES OR 6

for cracks, wear and corrosion interior and exterior YEARS

(Disassembly required).

22. NOSE GEAR DRAG BRACE ASSEMBLY - Inspect for 8,000 CYCLES OR 6

cracks, wear and corrosion interior and exterior YEARS

(Disassembly required).

23. NOSE GEAR AXLE ASSEMBLY and TORQUE KNEES - 8,000 CYCLES OR 6

Inspect for cracks, wear and corrosion interior and exterior YEARS

(Disassembly required).

24. NOSE GEAR ACTUATOR CLEVIS - Inspect clevis hole for

excessive wear (Disassembly required) (Ref. Component 1,000 CYCLES

Maintenance Manual, 32-00-00).

25. NOSE LANDING GEAR WHEEL - Inspect nose wheel in

accordance with manufacturer's instructions (Ref.

Component Maintenance Manual, 32-00-00).

Copyright © Textron Aviation Inc. Page 3 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

26. ALTIMETER and PITOT and STATIC SYSTEM - Inspect as

required by FAR 91.411 (Ref. Chapter 34 for system check 24 MONTHS

and leak test).

27. POWER LEVER DETENT PIN - Inspect for wear. Maximum 1,200 HOURS

allowable wear is 1/3 of pin diameter (Ref. Chapter 76).

28. FLIGHT COMPARTMENT FIRE EXTINGUISHER - 12 YEARS

Hydrostatically test extinguisher (Ref. Chapter 26).

29. CABIN FIRE EXTINGUISHER - Deleted, Moved to

Airworthiness Limitations Manual, 90-590024-187.

30. ENGINE FIRE EXTINGUISHER - Deleted, Moved to

Airworthiness Limitations Manual, 90-590024-187.

31. WING ATTACHMENT BOLTS

a. LJ-1063 thru LJ-1084, 1086 and LJ-1087 - Inspect the 1,000 HOURS OR 3

eight bolts as outlined in the King Air Series Structural YEARS

Inspection and Repair Manual (Ref. Chapter 57).

b. LJ-1085, LJ-1088 and After - Inspect the eight bolts as

outlined in the King Air Series Structural Inspection and 5 Years

Repair Manual (Ref. Chapter 57).

32. LANDING GEAR HYDRAULIC SYSTEM FILTER AND

PACKING - Replace filter and packings at first 200-hour

inspection and every 1,200 hours or 1,000 cycles thereafter,

whichever occurs first. In addition to these replacement 200 HOURS INITIAL/

frequencies, whenever a hydraulic component is replaced, 1,200 HOURS

this filter must be replaced after the system has been RECURRING

checked for operation. This filter must also be replaced at the

next inspection after component replacement was made

(Ref. Chapter 32).

33. FIRE EXTINGUISHER SQUIB CARTRIDGE (If Installed) -

Deleted, Moved to Airworthiness Limitations Manual, 90-

590024-187.

34. FLIGHT CONTROLS - Inspect all flight control pulley brackets 10,000 CYCLES

and castings for cracks, corrosion, wear and attachment INITIAL/5,000 CYCLES

(Ref. 20-04-00, 201). RECURRING

35. OXYGEN CYLINDER - DOT 3HT 1850 (Lightweight

composite) - Deleted, Moved to Airworthiness Limitations

Manual, 90-590024-187.

36. OXYGEN CYLINDER - DOT 3AA 1800 (Standard weight) -

Deleted, Moved to Airworthiness Limitations Manual, 90-

590024-187.

37. OXYGEN CYLINDER - DOT 3HT 1850 (Lightweight) -

Deleted, Moved to Airworthiness Limitations Manual, 90-

590024-187.

38. COCKPIT VOICE RECORDER UNDERWATER LOCATOR

BEACON (LJ-1353 and After) - Functional test unit and 24 MONTHS/ 6 YEARS

batteries for proper operation every 24 months. Replace

batteries every 6 years (Ref. Chapter 23).

Copyright © Textron Aviation Inc. Page 4 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

39. ENGINE MOUNT VIBRATION ISOLATORS - Inspect ENGINE TBO OR 4,000

vibration isolators for deterioration, damage and attachment HOURS

(Ref. Component Maintenance Manual, 71-00-00).

40. FUSELAGE INSPECTION - Perform inspection as outlined 6,000 CYCLES INITIAL/

in 53-10-00, 601. 3,000 CYCLES

RECURRING

41. WING STRUCTURE - Perform inspection as outlined in the

King Air Series Structural Inspection and Repair Manual

(Ref. Chapter 57).

42. LEAD ACID BATTERY (LJ-1534 and After) - A Battery 90 DAYS

stored in an airplane must be boost charged every 90 days.

43. BATTERY, EMERGENCY CAPACITY TEST (LJ-1534 and 12 MONTHS OR 600

After) - Perform initial test at 12 months or 600 hours HOURS INITIAL/ 12

whichever comes first and subsequent test at every 12 MONTHS OR 200

months or 200 hours whichever comes first. Replace Battery HOURS SUBSEQUENT

which does not pass capacity test.

44. DETAILED AILERON INSPECTION (Removal of aileron is 3,600 HRS INITIAL/ 800

required) HOURS SUBSEQUENT

a. Inspect the entire assembly for skin cracks and

evidence of corrosion.

b. Inspect under the hinge fittings for cracks and corrosion

using low power magnification. Pay particular attention

to the areas between the screw holes for cracks.

45. STANDBY POWER SUPPLY BATTERY (PS835) - Check,

load test, and recharge if necessary (Ref. Component 6 MONTHS

Maintenance Manual, 24-00-00).

46. CABIN ALTITUDE WARNING SYSTEM - Perform the CABIN

ALTITUDE WARNING PRESSURE SWITCH TEST 12 MONTHS

procedure (Ref. 21-30-11, 501).

47. SKIN, EXTERIOR AIRFRAME - Inspect exterior skin

(including nose wheel well keels) for cracks and loose and 10,000 CYCLES

missing fasteners. If any repetitive damage is found, INITIAL/1,000 CYCLES

inspection on the internal structure for degradation in the RECURRING

local area is required.

48. AIRCONDITIONING MOTOR BRUSHES - Inspect 1,000 HOURS

airconditioning motor brushes for damage, wear and arcing. INITIAL/1,000 HOURS

RECURRING

49. WING ATTACH BOLTS - Check wing attach bolts for proper FIRST SCHEDULED

torque (Ref. King Air Series Structural Inspection and Repair INSPECTION/ FIRST

Manual, Chapter 57). SCHEDULED

INSPECTION AFTER

WING ADJUSTMENT

50. PILOT'S FUEL CONTROL PANEL and LOWER

EDGELIGHTED PANEL, COPILOT'S EDGELIGHTED

CIRCUIT BREAKER PANEL - Inspect for burned out bulbs, 12 MONTHS

delamination, corrosion, and evidence of moisture ingress

(Panel removal is required).

Copyright © Textron Aviation Inc. Page 5 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

King Air 90 Series Maintenance Manual (Rev D0)

05-25-05-6 (Rev D0)

51. NOSE AND MAIN LANDING GEAR TRUNNION BOLT 8,000 CYCLES OR 6

HOLES AND DRAG BRACE ATTACH HOLES (Airframe YEARS BUT NO LATER

Side) - Inspect for cracks, corrosion, damage, and THAN THE NEXT

elongation of holes. SCHEDULED 6 YEARS

GEAR INSPECTION

52. (LJ-1847, LJ-1853 and After) AUTOPILOT SERVO MOUNT

SLIP CLUTCH TEST - Perform the AUTOPILOT SERVO 12,000 HOURS

MOUNT SLIP CLUTCH TEST procedure (Ref. 22-13-19,

501).

53. (LJ-1847, LJ-1853 and After) Perform the ELECTRONIC

STANDBY INSTRUMENT SYSTEM (ESIS) BATTERY 3 TO 6 MONTHS

(PS835D) PERIODIC CHECK procedure (Ref. 34-23-07,

201).

54. (LJ-1847, LJ-1853 and After) Perform the ELECTRONIC

STANDBY INSTRUMENT SYSTEM (ESIS) BATTERY ANNUAL

(PS835D) CAPACITY TEST procedure (Ref. 34-23-07,

201).

55. ENGINES - Perform the ENGINE - INSPECTION (72-00-00, FIRST 100 HRS OF

Steps 1 through 7, including Table 602 titled Periodic OPERATION FOR A

Inspections, as detailed by the Pratt & Whitney Maintenance NEW ENGINE

Manual, Part No. 3043512, 03 April 2009 or subsequent.

56. Perform the Horizontal Stabilizer (Elevator) Structural 10,000 HOURS

Inspection Procedure as outlined in the King Air Series INITIAL/5,000 HOURS

Structural Inspection and Repair Manual (Ref. 55-00-13, RECURRING

201).

57. Perform the Vertical Stabilizer (Rudder) Structural Inspection 10,000 HOURS

Procedure as outlined in the King Air Series Structural INITIAL/5,000 HOURS

Inspection and Repair Manual (Ref. 55-00-14, 201). RECURRING

2. Inspection Completed

I certify that the Special Inspection was performed in accordance with the King Air 90 Inspection Program and that the

airplane is approved for return to service:

DATE:

MECHANIC:

CREW CHIEF:

QUALITY CONTROL INSPECTOR:

Copyright © Textron Aviation Inc. Page 6 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Feb 04 11:54:06 CST 2021

You might also like

- Precommissioning Procedures of Testing & CommissioningDocument96 pagesPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- NDTM Atr72 NR39 Jul18 Consult Tot PDFDocument1,258 pagesNDTM Atr72 NR39 Jul18 Consult Tot PDFZain HasanNo ratings yet

- Overhaul ManualDocument2,175 pagesOverhaul Manualernesto rodriguez100% (5)

- Specs DHC6-msn-846Document10 pagesSpecs DHC6-msn-846Bob DENARDNo ratings yet

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 pagesDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenNo ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- Temporary Revision 8Document38 pagesTemporary Revision 8Daniel Vásquez CabreraNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Passat No. 13/1: Comfort System, With Alarm SystemDocument16 pagesPassat No. 13/1: Comfort System, With Alarm SystemLuix TiradoNo ratings yet

- Komatsu PC200LC-6Document12 pagesKomatsu PC200LC-6Collin Corp100% (2)

- Enzymes and Effects of PHDocument4 pagesEnzymes and Effects of PHSeph Cordova50% (2)

- 5-25-05 - Scheduled Inspection Program (Special) - Inspectioncheck (LJ-1063 and After)Document6 pages5-25-05 - Scheduled Inspection Program (Special) - Inspectioncheck (LJ-1063 and After)Svtorrent SvtorrentNo ratings yet

- 04 - 03 - Annex C - Maintenance Plan - Ver03Document2 pages04 - 03 - Annex C - Maintenance Plan - Ver03ELILTANo ratings yet

- Nav Iii Phase 2Document30 pagesNav Iii Phase 2carl reevesNo ratings yet

- ML B 200 b200mm17Document18 pagesML B 200 b200mm17Angel Vieira MendezNo ratings yet

- Pwps Service Bulletin 96B03 Attachment A-1: Recommended Periodic Inspections For Ft8 UnitsDocument2 pagesPwps Service Bulletin 96B03 Attachment A-1: Recommended Periodic Inspections For Ft8 UnitsKarim KadriNo ratings yet

- ManualDocument29 pagesManualCleber SouzaNo ratings yet

- Pneumatic Control System of ZJ40DBT Drilling Rig User ManualDocument24 pagesPneumatic Control System of ZJ40DBT Drilling Rig User ManualJohn SimancaNo ratings yet

- 21H043-03 - 21H043 InstructionsDocument1 page21H043-03 - 21H043 InstructionsRaziel Postigo MezaNo ratings yet

- Type NBR/ Ata: 10W2 / 72: Engine - Preflight InspectionDocument20 pagesType NBR/ Ata: 10W2 / 72: Engine - Preflight InspectionArdyansyah Wahyu PrasojoNo ratings yet

- Buyer: OwnerDocument27 pagesBuyer: OwnerDaniel TostaNo ratings yet

- Gestion Mantenimiento Puente GruaDocument11 pagesGestion Mantenimiento Puente GruaBryan Esteban Casas ZapataNo ratings yet

- TC Operation ManualDocument49 pagesTC Operation ManualGleb Vospitanyuk100% (5)

- 22 February 84: LO 10-3930-243-12 Card 1 of 4Document10 pages22 February 84: LO 10-3930-243-12 Card 1 of 4Хелфор УкраинаNo ratings yet

- General Information 1 Using This Ipc 2 Contents 3 Materials and Symbols 4Document15 pagesGeneral Information 1 Using This Ipc 2 Contents 3 Materials and Symbols 4juanaNo ratings yet

- Choke 'E-S' MANUAL REL.1.1.15.03ADocument38 pagesChoke 'E-S' MANUAL REL.1.1.15.03AJulian Estaun100% (3)

- Nav Iii Phase 1Document20 pagesNav Iii Phase 1carl reevesNo ratings yet

- Doc2020060514191604-Exp 05-2020 PPT Anexo VDocument11 pagesDoc2020060514191604-Exp 05-2020 PPT Anexo VMarcos CedeñoNo ratings yet

- RT-258 - A1 - Inspection and Overhaul in - CleanedDocument13 pagesRT-258 - A1 - Inspection and Overhaul in - CleanedFaye BachtisNo ratings yet

- 72.00.00 Engine - Inspection - CheckDocument83 pages72.00.00 Engine - Inspection - CheckTimoteo Molina RomeroNo ratings yet

- A-4000 OElindikator GBDocument4 pagesA-4000 OElindikator GBmadiNo ratings yet

- Inspection Interval For Engine AuxiliariesDocument3 pagesInspection Interval For Engine Auxiliariesadeel ghouseNo ratings yet

- Dry MotorDocument6 pagesDry MotorIvan KryskoNo ratings yet

- Preventive Maintenance Inspection: Recommended Minimum FormDocument2 pagesPreventive Maintenance Inspection: Recommended Minimum FormJune AlapaNo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Is 4894 Standard PDFDocument21 pagesIs 4894 Standard PDFDharmendra PanchalNo ratings yet

- Service ProtocolDocument3 pagesService Protocolrudy oktaNo ratings yet

- PM Clinic 450-8Document7 pagesPM Clinic 450-8Naughty VongNo ratings yet

- Support: Maintenance Tracking ReportDocument13 pagesSupport: Maintenance Tracking ReportHuda LestraNo ratings yet

- 600 Hour InspectionDocument1 page600 Hour InspectionAdielNo ratings yet

- Emergency ShutingdownDocument11 pagesEmergency ShutingdownOsama OmayerNo ratings yet

- Air Pre HeaterDocument7 pagesAir Pre HeaterLakshminarayanNo ratings yet

- 024.5.120 Bài tập 1.2 MAN B&W 6S60MC-CDocument30 pages024.5.120 Bài tập 1.2 MAN B&W 6S60MC-CKhải Nguyễn MinhNo ratings yet

- AAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017Document21 pagesAAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017jerome chaussonNo ratings yet

- Safety Valve's Noise LevelDocument2 pagesSafety Valve's Noise Levelaravind grandhiNo ratings yet

- TFR MtnceDocument18 pagesTFR MtnceRajesh TKNo ratings yet

- Yancheng Control Panel For Choke Manifold - Operation Manual PDFDocument27 pagesYancheng Control Panel For Choke Manifold - Operation Manual PDFDaniel MedinaNo ratings yet

- LV HiluxDocument8 pagesLV HiluxAdie PranataNo ratings yet

- Previous Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyDocument41 pagesPrevious Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyKarina FloresNo ratings yet

- Aux HTDocument11 pagesAux HTsanjeevchhabraNo ratings yet

- TroubleShootingBendixRSA 1987Document21 pagesTroubleShootingBendixRSA 1987Ian WhitingNo ratings yet

- GAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Document15 pagesGAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Dipayan DasNo ratings yet

- Pm. Dozer d85ssDocument20 pagesPm. Dozer d85ssIqmal WahabNo ratings yet

- Lubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5Document6 pagesLubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5SteveNo ratings yet

- Faf OmDocument41 pagesFaf OmKRSRAMANNo ratings yet

- Serial No., Cast,: L5-FMT-046 Rev. 03Document3 pagesSerial No., Cast,: L5-FMT-046 Rev. 03Rahul MoottolikandyNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- Oil Pump Type T GEAR SIZES 2-3-4-5Document2 pagesOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- LPT Case Piping InspectionDocument7 pagesLPT Case Piping InspectionSonny RaymundoNo ratings yet

- Inspection Report No. 73Document3 pagesInspection Report No. 73Rahul MoottolikandyNo ratings yet

- C47B OmmDocument12 pagesC47B OmmturboshaftNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Helidosa Aviation Group FleetDocument13 pagesHelidosa Aviation Group FleetalejandroNo ratings yet

- The Developing Live Spiny Lobster Industry: NOAA Technical Memorandum NMFS-SEFSC-395Document11 pagesThe Developing Live Spiny Lobster Industry: NOAA Technical Memorandum NMFS-SEFSC-395alejandroNo ratings yet

- 1981 KINGAIR C90-1 S/NLJ-992: SPEED 270 MPH Passengers 7 Range (NM) 1,200Document9 pages1981 KINGAIR C90-1 S/NLJ-992: SPEED 270 MPH Passengers 7 Range (NM) 1,200alejandroNo ratings yet

- Wet and Dry LeasesDocument2 pagesWet and Dry LeasesSolo PeddamalliNo ratings yet

- Mil PRF 23699FDocument20 pagesMil PRF 23699FalejandroNo ratings yet

- 2014-02 Rev 1 Wing Bolt CoversDocument1 page2014-02 Rev 1 Wing Bolt CoversalejandroNo ratings yet

- Pilot's Operating Handbook Approved Airplane Flight Manual Supplement For Airplanes Equipped With KLNG Automatic Flight Control 1Document10 pagesPilot's Operating Handbook Approved Airplane Flight Manual Supplement For Airplanes Equipped With KLNG Automatic Flight Control 1alejandroNo ratings yet

- Certified Air Carrier Certificate #Oq9Ao51M, Being Your Best Choice When ItDocument4 pagesCertified Air Carrier Certificate #Oq9Ao51M, Being Your Best Choice When ItalejandroNo ratings yet

- Food Truck in Miami, Florida: 10 Licenses RequiredDocument95 pagesFood Truck in Miami, Florida: 10 Licenses RequiredalejandroNo ratings yet

- AW Limitations - LJ992Document6 pagesAW Limitations - LJ992alejandroNo ratings yet

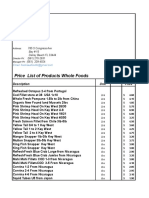

- Price List Whole FoodsDocument1 pagePrice List Whole FoodsalejandroNo ratings yet

- Hartzell Ovh ScheduleDocument26 pagesHartzell Ovh SchedulealejandroNo ratings yet

- Hartzell Maintenance ManualDocument286 pagesHartzell Maintenance ManualalejandroNo ratings yet

- Tbo S/B-33580-MDocument12 pagesTbo S/B-33580-MSawan Kumar SahaniNo ratings yet

- Nose Gear Shimmy Damper Nomenclature Effectivity Units PER Assy 1 2 3 4 5 6 7Document2 pagesNose Gear Shimmy Damper Nomenclature Effectivity Units PER Assy 1 2 3 4 5 6 7alejandroNo ratings yet

- Hartzell Ovh ScheduleDocument26 pagesHartzell Ovh SchedulealejandroNo ratings yet

- Hartzell Maintenance ManualDocument286 pagesHartzell Maintenance ManualalejandroNo ratings yet

- DASApplicationForm PDFDocument3 pagesDASApplicationForm PDFEngr.Hamid Ismail CheemaNo ratings yet

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesNo ratings yet

- MTK 1023-Material and ConsumableDocument13 pagesMTK 1023-Material and ConsumableGraceLamNo ratings yet

- Kubota Dual Fuel Series SpecificationDocument10 pagesKubota Dual Fuel Series Specificationפטריה מוזרNo ratings yet

- FP CLOCK - csproj.FileListAbsoluteDocument14 pagesFP CLOCK - csproj.FileListAbsolutePhi Huỳnh NgôNo ratings yet

- Croner PKE280 H35 Spec SheetDocument2 pagesCroner PKE280 H35 Spec Sheetvictor hugoNo ratings yet

- Roof Manual p10Document1 pageRoof Manual p10AllistairNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- Annex 1 - Air Dryer Duct DRG List - 140717Document1 pageAnnex 1 - Air Dryer Duct DRG List - 140717vemanreddy29No ratings yet

- Effect of Impurities On Freezing and Boiling PointsDocument6 pagesEffect of Impurities On Freezing and Boiling PointssakthivelNo ratings yet

- StoichiotryDocument57 pagesStoichiotryJezriel Theana SisonNo ratings yet

- SamplesDocument14 pagesSamplesSanjayNo ratings yet

- Analysis and Design of MOSFET Based Amplifier in Different ConfigurationsDocument8 pagesAnalysis and Design of MOSFET Based Amplifier in Different ConfigurationsPraveen KumarNo ratings yet

- ReleaseNotes MimicsMedical 21.0Document24 pagesReleaseNotes MimicsMedical 21.0陳司瀚No ratings yet

- 3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDDocument9 pages3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDaungyinmoeNo ratings yet

- Rainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesRainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing Engineers185412No ratings yet

- CI 1580A ENG User ManualDocument50 pagesCI 1580A ENG User ManualArdy KristianNo ratings yet

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 pagesProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranNo ratings yet

- Electrical ContactorDocument14 pagesElectrical ContactorRaphael212219No ratings yet

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Document3 pagesOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaNo ratings yet

- SZ 150.1 MergedDocument116 pagesSZ 150.1 MergedArif MamunNo ratings yet

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 pagesKSB KWP: Non-Clogging Centrifugal PumpsalfredNo ratings yet

- Reinforced Concrete Design BS 8110Document15 pagesReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- Find Serial Number of Computer in Windows 10Document2 pagesFind Serial Number of Computer in Windows 10GabbarNo ratings yet

- ASWipLL HW Installation Guide-V07-460Document322 pagesASWipLL HW Installation Guide-V07-460Fernando MartinNo ratings yet

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet