Professional Documents

Culture Documents

To Study Comparison Between Conventional Slab and Bubble Deck Slab

Uploaded by

Noor KhreisatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

To Study Comparison Between Conventional Slab and Bubble Deck Slab

Uploaded by

Noor KhreisatCopyright:

Available Formats

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

To study Comparison between Conventional Slab

and Bubble Deck Slab

Nagma Fatma1, Vinaysingh Chandrakar2

M.Tech, Department, Patel Institute of Technology and Science, Bhopal, India1

Professor, Department, Patel Institute of Technology and Science, Bhopal, India 2

Abstract: Bubble deck slab is a method of virtually eliminating all concrete from the middle of a floor slab, which is

not performing any structural function, thereby dramatically reducing structural dead weight. High density polyethylene

hollow spheres replace the in-effective concrete in the center of the slab, thus decreasing the dead weight and

increasing the efficiency of the floor. The advantages are less energy consumption - both in production, transport and

carrying out, less emission - exhaust gases from production and transport, especially CO2 and reduce the material, the

load, lower the cost and it is also a green technology.

In the bubble deck technology reduce the concrete volume by replacing the spherical bubbles, these are locally

available which is called as PEPSI balls, these balls are made up of HDPE (High Density polyethylene). In this

experimental program conventional slab and bubble deck slab are cast with various bubbles arrangement which is

continuous arrangement of bubbles within whole slab and two types of alternative bubbles arrangement in the slab. And

trying to enhance the increasing strength of that slab. This implies the realization of a monolithic slab element, which

will be subjected to static gravitational loadings in order to determine the load carrying capacity of the slab,

deformation (deflection), cracking and failing characteristics. The resultant conclusions will be used in defining the

failing mechanisms and advantages of the bubble deck slab are highlighted.

Keywords: Bubble Deck slab, conventional slab, HDPE.

I. INTRODUCTION

In a general way, the slab was designed only to resist vertical load. Now a days people recently wants residential

environment on which vibration & noise of the slab getting main role. The main moto of concrete construction that is

horizontal slab is having large weight which should be limits the span. Due to this major development of the reinforced

concrete must focus on developing the span, by reduction in weight or overbear concrete nature weakness in tension. In

early stages many attempts had made to manufacture biaxial slab which have hollow cavities to minimize the weight.

Many attempts had done before to prepare blocks having light weight material which is polystyrene used on top &

bottom reinforcement and other type’s grid & waffles slab. All these types only waffle slabs are used in the market.

But, the use of waffle slab is limited due to low resistance of shear, fire & local punching. The idea of using many

blocks of very light material in slab from same flaws, so that the use of this system had not gained any acceptance and

they are only used in a very specific number of projects.

BUBBLE DECK SLAB

It is geometry of Bubble Deck slab which defines by the spheres of specific size, placed in a reinforcement

grid for a particular overall deck thickness. Bubble deck slab produces 20% faster floors with beams and limited

formwork, which minimize the construction costs by 12% and agrees with 32% minimization in concrete use.

(a) Hollow spherical balls (b) Hollow elliptical balls

Fig. 1.1 Bubble Deck samples

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 70

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

Technology of Bubble Deck is that which allows for stronger, and often thicker, slabs of concrete that span

larger areas, and also gives the opportunity to architecturally design larger cantilevers. Bubble Deck is designed to be

an efficient solution to decrease quantity of concrete used in a building’s construction, greatly strengthen the overall

frame, and better distribute weight of concrete that is actually used.

This technology will be used to manufacture lighter weight bridge deck since a significant portion of the stress

applied to a bridge comes from its own self-weight. By using the knowledge collected during behavioural analysis, a

modular deck component for pedestrian bridges that is notably lighter but comparable in strength to typical reinforced

of concrete sections will be designed. For this investigation, the structural behaviour of Bubble Deck at different

conditions will be studied to gain an understanding on this new technique and to compare it to the current slab systems.

The difference between solid slab & voided slab of shear resistance. Due to minimizations of concrete volume, the

shear resistance gets reduced. The shear capacity should be measured in the range of 72-91% of shear capacity of solid

deck.

TYPES OF BALLS

(a) Plastic Balls (b) Hollow Plastic Balls (c) Polyurethane Balls

(d) Rubber Balls (e) Steel Balls (f) Phenolic Balls

TERMINOLOGIES USED

1. Conventional slab: This is a slab with specifications prepared to analyze experimentally with normal concrete

of grade M30 by adopting conventional methods of design according IS 456:2000 & IS 10262:2009.

2. Bubble deck slab: This is a slab with specifications prepared to analyze experimentally with normal concrete

of grade M30 by using Hollow strong plastic balls (HDPE- High density polyethylene) with the help of design

according to DIN 1045 (1988) or DIN 1045 (2001) code (Germen code)

3.2.1 There are three types of bubble deck slab are casted:

a) Continuous bubble deck slab

b) Alternative bubble deck slab (type I)

c) Alternative bubble deck slab (type II)

3.3 PROBLEM STATEMENT

A conventional slab of size 1mx1mx0.125m is casted, Bubble deck slab also casted of size same as

conventional slab 1mx1mx0.125m & study of various aspect and structural parameters.

CONVENTIONAL SLAB

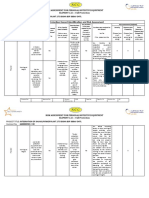

3.5.1 Conventional (M30) Concrete Mix Design

The conventional concrete i.e. M30 grade concrete is having mix design according to the IS 456:2000 &

IS10262:2009 is explained in this section.

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 71

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

1. Design constant

a) Grade Designation = M30

b) Type of Cement = OPC 53 grade

c) Maximum Nominal Aggregate Size = 20 mm

d) Minimum Cement Content =320 kg/m3

e) Maximum Water Cement Ratio = 0.45

f) Workability = 50-75 mm (Slump)

g) Exposure Condition = Severe

h) Degree of Supervision = Good

i) Type of Aggregate = Crushed Angular

j) Chemical admixture = No admixture use

2. Test Data for Materials

a) Cement Used Birla super OPC 53 grade

b) Sp. Gravity of Cement = 3.15

c) Sp. Gravity of Water = 1.00

d) Sp. Gravity of Coarse Aggregate = 2.77

e) Sp. Gravity of Fine Aggregate = 2.60

f) Water Absorption of Coarse Aggregate = 1.24%

g) Water Absorption of Fine Aggregate = 2.80%

h) Free (Surface) Moisture of 10 mm Aggregate = nil

i) Free (Surface) Moisture of crushed Sand = nil

3. Target Mean Strength

a) Target Mean Strength = 38.25N/mm2

b) Characteristic Strength @ 28 days = 30N/mm2

4. Selection of water cement ratio

a) Maximum Water Cement Ratio =0.45

b) Adopted Water Cement Ratio=0.43

5. Selection of water content

a) Maximum Water content (10262-table-2) =186 Lit.

b) Estimated Water content for 50-75 mm Slump=192 Lit.

6. Selection of cement content

a) Water Cement Ratio=0.43

b) Cement Content (192/0.43)=446.5 kg/m3

Which is greater than 320 kg/m3

7. Proportion of volume of coarse Aggregate & Fine Aggregate Content

a) Vol. of C.A. as per table 3 of IS 10262 = 62%

b) Adopted Vol. of coarse Aggregate = 55%

c) Adopted Vol. of Fine Aggregate = 45%

8. Mix Calculations

a) Volume of Concrete in m3 = 1.00

b) Volume of Cement in m3 = 0.142

(Mass of Cement) / (Sp. Gravity of Cement) x1000

c) Volume of Water in m3 = 0.192

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 72

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

(Mass of Water) / (Sp. Gravity of Water) x1000

d) Volume of All in Aggregate in m3 = 0.67

e) Volume of Coarse Aggregate in m3 = 0.55

f) Volume of Fine Aggregate in m3 = 0.45

9. Mix Calculations

a) Mass of Cement in kg/m3 = 446.5

b) Mass of Water in kg/m3 = 192

c) Mass of Fine Aggregate in kg/m3 = 784

d) Mass of Coarse Aggregate in kg/m3 = 1021

e) Water Cement Ratio = 0.43

3.6 BUBBLE DECK SLAB

3.6.1 Continuous bubble deck slab (M 30) Concrete Mixture Design

1. Design constant

a) Grade Designation = M30

b) Type of Cement = OPC 53 grade

c) Maximum Nominal Aggregate Size = 10 mm

d) Minimum Cement Content =320 kg/m3

e) Maximum Water Cement Ratio = 0.45

f) Workability = 50-75 mm (Slump)

g) Exposure Condition = Severe

h) Degree of Supervision = Good

i) Type of Aggregate = Crushed Angular

j) Chemical admixture = No admixture use

2. Test Data for Materials

a) Cement Used Birla super OPC 53 grade

b) Sp. Gravity of Cement = 3.15

c) Sp. Gravity of Water = 1.00

d) Sp. Gravity of Coarse Aggregate = 2.77

e) Sp. Gravity of Fine Aggregate = 2.60

f) Water Absorption of Coarse Aggregate = 1.24%

g) Water Absorption of Fine Aggregate = 2.80%

h) Free (Surface) Moisture of 10 mm Aggregate = nil

i) Free (Surface) Moisture of crushed Sand = nil

3. Target Mean Strength

a) Target Mean Strength = 38.25N/mm2

b) Characteristic Strength @ 28 days = 30N/mm2

4. Selection of water cement ratio

a) Maximum Water Cement Ratio =0.45

b) Adopted Water Cement Ratio=0.43

5. Selection of water content

a) Maximum Water content (10262-table-2) =208 Lit.

b) Estimated Water content for 50-75 mm Slump=214 Lit.

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 73

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

6. Selection of cement content

a) Water Cement Ratio=0.43

b) Cement Content (214/0.43)=497.67 kg/m3

Which is greater than 320 kg/m3

7. Proportion of volume of coarse Aggregate & Fine Aggregate Content

a) Vol. of C.A. as per table 3 of IS 10262 = 62%

b) Adopted Vol. of coarse Aggregate = 55%

c) Adopted Vol. of Fine Aggregate = 45%

8. Mix Calculations

a) Volume of Concrete in m3 = 1.00

b) Volume of Cement in m3 = 0.142

(Mass of Cement) / (Sp. Gravity of Cement) x1000

c) Volume of Water in m3 = 0.214

(Mass of Water) / (Sp. Gravity of Water) x1000

d) Volume of All in Aggregate in m3 = 0.644

e) Volume of Coarse Aggregate in m3 = 0.55

f) Volume of Fine Aggregate in m3 = 0.45

9. Mix Calculations

a) Mass of Cement in kg/m3 = 497.67

b) Mass of Water in kg/m3 = 214

c) Mass of Fine Aggregate in kg/m3 = 753

d) Mass of Coarse Aggregate in kg/m3 = 981

e) Mass of 10mm Aggregate in kg/m3 = 981

f) Water Cement Ratio = 0.43

Alternative bubble deck slab (type I) (M 30) Concrete Mixture Design

Design of Alternative bubble deck slab (type I)

In Alternative bubble deck slab (type I) bubbles are arranged in X and Y direction alternatively throughout the

slab.

Reinforcement of alternative bubble deck slab will be same as continuous bubble deck slab.

In the alternative bubble deck slab we reducing the bubbles volume and increase the concrete volume and

analyse the effect on strength.

The bonding between concrete and bubbles how efficiently effect on slab strength, for that reason alternative

bubble deck slab analysed.

Alternative bubble deck slab (type II) (M 30) Concrete

Design of Alternative bubble deck slab (type II)

In Alternative bubble deck slab (type II) bubbles are arranged in anyone of the direction alternatively

throughout the slab.

Reinforcement of alternative bubble deck slabs same as continuous bubble deck slab.

In the alternative bubble deck slab we reducing the bubbles volume and increase the concrete volume and

analyse the effect on strength.

The bonding between concrete and bubbles how efficiently effect on slab strength, for that reason alternative

bubble deck slab is analyse.

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 74

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

Conventional slab Reinforcement of continuous bubble deck slab

Crack pattern during testing on slab

cracks on conventional slab cracks on continuous bubble deck slab

CONCLUSION

In that experiment found that the bubble deck (continuous) is reduced the concrete volume so that slab of weight

ultimately decrease.

Simultaneously the load on the bubble deck slab (continuous) has also 23% increases as compare to conventional

slab.

But the arrangement of the balls are effect on load carrying capacity of slab, in alternative arrangement of bubbles

are 11% & 6% increasing the loaded carrying capacity than conventional slab but less than continuous bubble

deck of slab.

Simultaneously, slab of bubble deck has improve the elasticity property of slab, such as conventional slab is 6%

less deflect than bubble deck, and quantity of bubbles in slab also affect on the this elasticity property.

Weight reduction is the important factor is found in slab of bubble deck. Conventional slabs weight is 33% more

than the bubble deck.

Cost and time saving by using bubbles in slab like weight of slab, concrete volume indirectly load on the beam and

walls also decrease/ less so that building foundations is designed for smaller dead loads.

It is concluded that Load, deflection and weight parameters gives better result for bubble deck slab as compared to

conventional slab.

REFERENCES

[1] Shetkar A, Hanche N (2015) “An Experimental Study On bubble deck slab system with elliptical balls”. NCRIET-2015 & Indian Journal

science of research 12(1):021-027.

[2] Harishma KR, Reshmi KN (2015) “A study on Bubble Deck slab”. International Journal of Advanced Research Trends in Engineering and

Technology (IJARTET) Vol. II, Special Issue X

[3] Subramanian K, Bhuvaneshwari P (2015) “Finite Element Analysis of Voided Slab with High Density Polypropylene Void Formers”.

International Journal of Chem Tech Research, CODEN (USA): IJCRGG ISSN: 0974-4290, Vol.8, No.2, pp. 746-753

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 75

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 1, January 2018

[4] Bhagat S, Parikh KB (2014) “Comparative Study of Voided Flat Plate Slab and Solid Flat Plate Slab”. ISSN 2278 – 0211, Vol. 3 Issue 3

[5] Shaimaa TS (2014) “Punching Shear in Voided Slab”. ISSN 2224-5790 , ISSN 2225-0514 , Vol.6, No.10

[6] Bhagat S, Parikh KB (2014) “Parametric Study of R.C.C Voided and Solid Flat Plate Slab using SAP 2000”. IOSR Journal of Mechanical and

Civil Engineering (IOSR-JMCE), e-ISSN: 2278-1684, p-ISSN: 2320-334X, Volume 11, Issue 2 Ver. VI, PP 12-16

[7] Churakov A. (2014) “Biaxial hollow slab with innovative types of voids”. ISSN 2304-6295.6 (21). 70-88

[8] Ibrahim AM, Nazar KA, Wissam DS (2013) “Flexural capacities of reinforced concrete two-way bubble deck slabs of plastic spherical voids”.

Diyala Journal of Engineering Sciences, ISSN 1999-8716, Vol. 06, No. 02

[9] Terec LR, Terec MA (2013) “The bubbledeck floor system: a brief presentation”. CS I, INCD URBAN-INCERC Branch of Cluj-Napoca,

CONSTRUCŢII – No. 2

[10] Wesley NM (2013) “Viscoelastic Analysis of Biaxial Hollow Deck Balls”. International Journal of Computer Aided Engineering, ISSN: 1071-

2317, Vol.23, Issue.1

[11] Mihai B, Raul Z, Zoltan K (2013) “Flat slabs with spherical voids. Part II: Experimental tests concerning shear strength”.

ActaTechnicaNapocensis: Civil Engineering & Architecture Vol. 56, No. 1

[12] Larus HL, Fischer G, Jonsson J (2013) “Prefabricated floor panels composed of fiber reinforced concrete and a steel substructure”. Elsevier

Science engineering. Structures 46, 104-115

[13] Calin S, Asavoaie C (2010) “Experimental program regarding “Bubble Deck” concrete slab with spherical gaps”. ISSN 1582-3024, Article

No.4, Intersections, Vol.7, No.1

[14] Lai T. (2010) “Structural Behavior of Bubble Deck Slabs and their application to Lightweight Bridge Decks”. Massachusetts Institute of

Technology

[15] Bubble Deck-UK (2008). “Bubble Deck structure solutions – Product introduction”. Part 1, Bubble Deck UK Ltd.

[16] Martina SH, Karsten P (2002) “Punching behaviour of biaxial hollow slabs”. Elsevier Science cement & concrete composites 24 (2002) 551-

556

Copyright to IARJSET DOI 10.17148/IARJSET.2018.5111 76

You might also like

- Delivery For OutSystems Specialization Sample Exam - enDocument8 pagesDelivery For OutSystems Specialization Sample Exam - enmahesh manchalaNo ratings yet

- Verilog Code For Traffic Light Control Using FSMDocument7 pagesVerilog Code For Traffic Light Control Using FSMEr Pradip PatelNo ratings yet

- Chapter 09 SolutionsDocument43 pagesChapter 09 SolutionsDwightLidstromNo ratings yet

- Nipcib 000036Document273 pagesNipcib 000036AlfoFS0% (1)

- Pasreform Hatchery GuideDocument182 pagesPasreform Hatchery Guidemasud farahad100% (5)

- Inception Report - Performance Management and Measurement Including Monitoring & EvaluationDocument16 pagesInception Report - Performance Management and Measurement Including Monitoring & EvaluationDepartment of Political Affairs, African Union CommissionNo ratings yet

- Interlocking Plastic Blocks (IPB)Document7 pagesInterlocking Plastic Blocks (IPB)IJRASETPublicationsNo ratings yet

- Design and Durability Analysis of Marine ConcreteDocument8 pagesDesign and Durability Analysis of Marine Concretemarlon lumanogNo ratings yet

- Comparative Study of Bubble Deck Slab With Conventional R.C.C SlabDocument7 pagesComparative Study of Bubble Deck Slab With Conventional R.C.C SlabIJRASETPublicationsNo ratings yet

- Comparative Study About AAC Block With Porotherm BrickDocument8 pagesComparative Study About AAC Block With Porotherm BrickIJRASETPublicationsNo ratings yet

- Modified Review IDocument17 pagesModified Review IShaik Asif AliNo ratings yet

- Stabilization of Soil Using Ground Granulated Blast Furnace Slag and Fly AshDocument6 pagesStabilization of Soil Using Ground Granulated Blast Furnace Slag and Fly AshTeja Roop ReddyNo ratings yet

- Effectof Waterand Admixtureon Foam Concrete PropertiesDocument12 pagesEffectof Waterand Admixtureon Foam Concrete PropertiesRakha AdinataNo ratings yet

- Study On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementDocument6 pagesStudy On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementIJRASETPublicationsNo ratings yet

- Fin Irjmets1639807704 PDFDocument6 pagesFin Irjmets1639807704 PDFAkhil RajasekaranNo ratings yet

- Structural Behaviorof High Strength Precast Reinforced Concrete Vierendeel TrussDocument13 pagesStructural Behaviorof High Strength Precast Reinforced Concrete Vierendeel Trussemad mohamedNo ratings yet

- A Structural Study On Bubble Deck Slab and Its Properties: Mir Shahed Ali, Dr. S. Amaresh BabuDocument6 pagesA Structural Study On Bubble Deck Slab and Its Properties: Mir Shahed Ali, Dr. S. Amaresh BabuGrace HerdiyantiNo ratings yet

- Glass Waste in Concrete: Effect On Workability and Compressive StrengthDocument9 pagesGlass Waste in Concrete: Effect On Workability and Compressive StrengthJenny ValderramaNo ratings yet

- Cellular Light Weight Concrete Using Glass FiberDocument5 pagesCellular Light Weight Concrete Using Glass Fibermidhila vkNo ratings yet

- Utilization of Scoria As Aggregate in Lightweight ConcreteDocument4 pagesUtilization of Scoria As Aggregate in Lightweight ConcreteInnovative Research PublicationsNo ratings yet

- 1 s2.0 S1875389214001126 MainDocument6 pages1 s2.0 S1875389214001126 MainMalek GolNo ratings yet

- Glass Waste in Concrete Effect On Workability andDocument10 pagesGlass Waste in Concrete Effect On Workability andimen.bourahlaNo ratings yet

- Analysis of Geotextile in Road Embankment Using Plaxis 2d: Ankit Atkole, Tanmay Gharat, Ajit Agale, Bhavesh AdkarDocument5 pagesAnalysis of Geotextile in Road Embankment Using Plaxis 2d: Ankit Atkole, Tanmay Gharat, Ajit Agale, Bhavesh AdkarVIVA-TECH IJRINo ratings yet

- GLASSDocument6 pagesGLASSMR. ESHAN GHARPURENo ratings yet

- Cellular Light Weight Concrete Using Glass Fiber: September 2020Document6 pagesCellular Light Weight Concrete Using Glass Fiber: September 2020kinley dorjeeNo ratings yet

- Effect Steel Plate of Shear Reinforced Wide Beam ConcreteDocument6 pagesEffect Steel Plate of Shear Reinforced Wide Beam ConcreteAbel MulugetaNo ratings yet

- Class NoteDocument67 pagesClass NoteSujan SinghNo ratings yet

- 192 Experimental Study On Voided Biaxial Slab and Its ApplicationDocument5 pages192 Experimental Study On Voided Biaxial Slab and Its Applicationbogdan.kukosNo ratings yet

- To Investigate The Properties of Concrete Having Partial Replacement of Fine Aggregate With Copper Slag and Coarse Aggregate With Ceramic Tile WasteDocument11 pagesTo Investigate The Properties of Concrete Having Partial Replacement of Fine Aggregate With Copper Slag and Coarse Aggregate With Ceramic Tile WasteIJRASETPublicationsNo ratings yet

- IJSRET V8 Issue2 277Document4 pagesIJSRET V8 Issue2 277Ananjana cNo ratings yet

- 80 Abrasion PDFDocument6 pages80 Abrasion PDFايات علي احمدNo ratings yet

- The Mechanical Properties of Steel Fibre Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateDocument7 pagesThe Mechanical Properties of Steel Fibre Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- 164 - Pragna PaperDocument16 pages164 - Pragna Paperucsproject2017No ratings yet

- Bamboo Reinforced ConcreteDocument7 pagesBamboo Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Geopolymer Concrete Preparation MethodologyDocument6 pagesGeopolymer Concrete Preparation MethodologyIJRASETPublicationsNo ratings yet

- An Experimental Analysis of Partial Replacement of Coarse Aggregate by Waste Ceramic Tile in ConcreteDocument12 pagesAn Experimental Analysis of Partial Replacement of Coarse Aggregate by Waste Ceramic Tile in Concreteshivanand hippargaNo ratings yet

- Experimental Investigation On Behaviour of Circular Footings Resting On Reinforced SandDocument12 pagesExperimental Investigation On Behaviour of Circular Footings Resting On Reinforced Sandindex PubNo ratings yet

- Retrofitting of RC Structure Using FRP Laminate: AbstractDocument10 pagesRetrofitting of RC Structure Using FRP Laminate: AbstractYo Yo AkNo ratings yet

- An Engineering Approach To Predict The Proportion of Fines (Document18 pagesAn Engineering Approach To Predict The Proportion of Fines (Thomas LawsonNo ratings yet

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Document12 pagesExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNo ratings yet

- Stabilization of Subgrade With Waste Plastic As Stabilizer in Flexible PavementsDocument6 pagesStabilization of Subgrade With Waste Plastic As Stabilizer in Flexible PavementsTime PassNo ratings yet

- Performance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaDocument6 pagesPerformance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaIJRASETPublicationsNo ratings yet

- Experimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Document11 pagesExperimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Shilpa ShiNo ratings yet

- Analysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureDocument33 pagesAnalysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureThe CiVil Engineering ESENo ratings yet

- Using GGBS, An Experimental Investigation of Concrete Characteristics Was Conducted (Ground Granulated Blast Furnace Slag)Document7 pagesUsing GGBS, An Experimental Investigation of Concrete Characteristics Was Conducted (Ground Granulated Blast Furnace Slag)IJRASETPublicationsNo ratings yet

- With Ataria 2019Document12 pagesWith Ataria 2019ashwinraj562No ratings yet

- Review On Experimental Study Work On Partial Replacement of Cement With Waste Glass in Flexible or CC PavementsDocument7 pagesReview On Experimental Study Work On Partial Replacement of Cement With Waste Glass in Flexible or CC PavementsIJRASETPublicationsNo ratings yet

- Evaluation of The Mechanical Properties of Translucent ConcreteDocument8 pagesEvaluation of The Mechanical Properties of Translucent ConcretesehunNo ratings yet

- Research Paper On Optimum Addition of Glass Powder in For Replacement of CementDocument5 pagesResearch Paper On Optimum Addition of Glass Powder in For Replacement of CementJain SourabhNo ratings yet

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocument4 pagesStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127No ratings yet

- 19.cellular Light Weight Concrete Using Glass FiberDocument6 pages19.cellular Light Weight Concrete Using Glass FiberNAAC CivilNo ratings yet

- Experimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFDocument9 pagesExperimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFSalman AghariyaNo ratings yet

- Experimental Investigation and Cost Analysis of Light Transmitting ConcreteDocument5 pagesExperimental Investigation and Cost Analysis of Light Transmitting ConcreteTECH MACNo ratings yet

- CE512 Exam PaperDocument22 pagesCE512 Exam Paperedmond nyakundiNo ratings yet

- A Review in High Early Strength Concrete and Local PDFDocument10 pagesA Review in High Early Strength Concrete and Local PDFAgikx ChabeNo ratings yet

- Experimental Study On Voided Biaxial Slab and Its ApplicationDocument5 pagesExperimental Study On Voided Biaxial Slab and Its ApplicationEditor IJTSRDNo ratings yet

- Lab Report U1 (Workability)Document11 pagesLab Report U1 (Workability)SYaz WAniNo ratings yet

- Index 2Document10 pagesIndex 2kirtiNo ratings yet

- One and Two Dimensional Chloride Ion Diffusion of Fly Ash Concrete Under Flexural StressDocument10 pagesOne and Two Dimensional Chloride Ion Diffusion of Fly Ash Concrete Under Flexural StressJHON WILMAR CARDENAS PULIDONo ratings yet

- Soil Stabilization Using Industrial Waste and Lime:, A.Maria RajeshDocument7 pagesSoil Stabilization Using Industrial Waste and Lime:, A.Maria RajeshRitikNo ratings yet

- U Boot BetonDocument23 pagesU Boot BetonMegha KallihalNo ratings yet

- The Potential of Laterite As Fine Aggregate in Foamed Concrete ProductionDocument10 pagesThe Potential of Laterite As Fine Aggregate in Foamed Concrete Productionaloys NdzieNo ratings yet

- Effect of Recycled Coarse Aggregate On Concrete PropertiesDocument9 pagesEffect of Recycled Coarse Aggregate On Concrete PropertiesJumah Musdif TheirNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Hadi2008 JO PhosphateDocument13 pagesHadi2008 JO PhosphateNoor KhreisatNo ratings yet

- Bas Sir 2012Document20 pagesBas Sir 2012Noor KhreisatNo ratings yet

- Field Investigations Into The Axial Loading Response of Displacement Piles in ChalkDocument9 pagesField Investigations Into The Axial Loading Response of Displacement Piles in ChalkNoor KhreisatNo ratings yet

- Minerals Engineering: A A A B ADocument10 pagesMinerals Engineering: A A A B ANoor KhreisatNo ratings yet

- FPM 08 Negm AbouzeidDocument12 pagesFPM 08 Negm AbouzeidNoor KhreisatNo ratings yet

- Use of Alumina Phosphate Waste To Produce Building MaterialsDocument6 pagesUse of Alumina Phosphate Waste To Produce Building MaterialsNoor KhreisatNo ratings yet

- Effective Stress Regime Around A Jacked Steel Pile DuringDocument15 pagesEffective Stress Regime Around A Jacked Steel Pile DuringNoor KhreisatNo ratings yet

- Stabilisation of Excavated Slopes in Strain-Softening Materials With PilesDocument14 pagesStabilisation of Excavated Slopes in Strain-Softening Materials With PilesNoor KhreisatNo ratings yet

- Minerals Engineering: A A A B ADocument10 pagesMinerals Engineering: A A A B ANoor KhreisatNo ratings yet

- Effective Stress Regime Around A Jacked Steel Pile DuringDocument15 pagesEffective Stress Regime Around A Jacked Steel Pile DuringNoor KhreisatNo ratings yet

- Stabilisation of Excavated Slopes in Strain-Softening Materials With PilesDocument14 pagesStabilisation of Excavated Slopes in Strain-Softening Materials With PilesNoor KhreisatNo ratings yet

- Review On Bubble Deck Slabs Technology and Their ApplicationsDocument6 pagesReview On Bubble Deck Slabs Technology and Their ApplicationsNoor KhreisatNo ratings yet

- Field Investigations Into The Axial Loading Response of Displacement Piles in ChalkDocument9 pagesField Investigations Into The Axial Loading Response of Displacement Piles in ChalkNoor KhreisatNo ratings yet

- Common Pitfalls of Pile Driving Resistance Analysis - A Case Study of The Wikinger Offshore WindfarmDocument9 pagesCommon Pitfalls of Pile Driving Resistance Analysis - A Case Study of The Wikinger Offshore WindfarmNoor KhreisatNo ratings yet

- Ageing and Cyclic Behaviour of Axially Loaded Piles Driven in ChalkDocument16 pagesAgeing and Cyclic Behaviour of Axially Loaded Piles Driven in ChalkNoor KhreisatNo ratings yet

- Irjet V5i2116 PDFDocument6 pagesIrjet V5i2116 PDFCharles Kyle CerezoNo ratings yet

- Mousa F. Attom, Ph.D. Assistant Professor Civil Engineering Department Jordan University of Science of Technology Irbld - JordanDocument11 pagesMousa F. Attom, Ph.D. Assistant Professor Civil Engineering Department Jordan University of Science of Technology Irbld - JordanNoor KhreisatNo ratings yet

- Sheet Pile WallsDocument26 pagesSheet Pile WallslaekemariyamNo ratings yet

- Sheet Pile Retaining Walls Design and Construction in Brown Fields EnvironmentDocument29 pagesSheet Pile Retaining Walls Design and Construction in Brown Fields EnvironmentOky Mahertwo SeptianNo ratings yet

- To Study Comparison Between Conventional Slab and Bubble Deck SlabDocument7 pagesTo Study Comparison Between Conventional Slab and Bubble Deck SlabNoor KhreisatNo ratings yet

- Comparative Studies of Conventional Slab and Bubble Deck Slab Based On Stiffness and EconomyDocument4 pagesComparative Studies of Conventional Slab and Bubble Deck Slab Based On Stiffness and EconomyNoor KhreisatNo ratings yet

- Technical Supplement 14R Design and Use of Sheet Pile Walls in Stream Restoration and Stabilization ProjectsDocument36 pagesTechnical Supplement 14R Design and Use of Sheet Pile Walls in Stream Restoration and Stabilization ProjectsThaung Myint OoNo ratings yet

- Week 4 - Vapor-Liquid Separation (Multicomponent Distillation)Document19 pagesWeek 4 - Vapor-Liquid Separation (Multicomponent Distillation)psychopassNo ratings yet

- IO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENDocument24 pagesIO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENFranco MolinaNo ratings yet

- 7diesel 2016Document118 pages7diesel 2016JoãoCarlosDaSilvaBrancoNo ratings yet

- 2.21 - Hazard Identification Form - Fall ProtectionDocument3 pages2.21 - Hazard Identification Form - Fall ProtectionSn AhsanNo ratings yet

- Kaizenvest Education Report IndiaDocument62 pagesKaizenvest Education Report IndiaSakshi SodhiNo ratings yet

- Metrobank (Strengths)Document6 pagesMetrobank (Strengths)Hera IgnatiusNo ratings yet

- Thesis HealthDocument5 pagesThesis Healthcreasimovel1987100% (1)

- Times Leader 06-13-2013Document42 pagesTimes Leader 06-13-2013The Times LeaderNo ratings yet

- Vanderbeck Solman ch01-10Document156 pagesVanderbeck Solman ch01-10Jelly AceNo ratings yet

- Tutorial 3Document2 pagesTutorial 3AmrinaAkmal0% (1)

- BOM For Solar Water PumpDocument11 pagesBOM For Solar Water PumpNirat PatelNo ratings yet

- Citigroup - A Case Study in Managerial and Regulatory FailuresDocument70 pagesCitigroup - A Case Study in Managerial and Regulatory FailuresJulius NatividadNo ratings yet

- CIMB-Financial Statement 2014 PDFDocument413 pagesCIMB-Financial Statement 2014 PDFEsplanadeNo ratings yet

- Class 10th IMO 5 Years EbookDocument71 pagesClass 10th IMO 5 Years EbookAdarsh Agrawal100% (1)

- TIDCP vs. Manalang-DemigilioDocument2 pagesTIDCP vs. Manalang-DemigilioDi ko alam100% (1)

- 08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBDocument1 page08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBChristian ParedesNo ratings yet

- Safety Data Sheet: Armohib Ci-28Document21 pagesSafety Data Sheet: Armohib Ci-28SJHEIK AbdullahNo ratings yet

- Ips M PM 330Document25 pagesIps M PM 330Deborah MalanumNo ratings yet

- Project On SpicesDocument96 pagesProject On Spicesamitmanisha50% (6)

- Security+ Guide To Network Security Fundamentals, Fifth EditionDocument52 pagesSecurity+ Guide To Network Security Fundamentals, Fifth EditionVitæ ÆgisNo ratings yet

- LSD - Job Description - LogisticsDocument2 pagesLSD - Job Description - LogisticsIjas AslamNo ratings yet

- CW 3 - Non-Profit Making Organisation Sekolah Harapan Bangsa ACADEMIC YEAR 2020/2021Document3 pagesCW 3 - Non-Profit Making Organisation Sekolah Harapan Bangsa ACADEMIC YEAR 2020/2021Adrian WensenNo ratings yet

- Ergonomics InvestmentDocument4 pagesErgonomics InvestmentLiliana Alejandra Rodriguez ZamoraNo ratings yet

- Kendra Penningroth 8-08Document2 pagesKendra Penningroth 8-08api-355965189No ratings yet