Professional Documents

Culture Documents

Effect Steel Plate of Shear Reinforced Wide Beam Concrete

Uploaded by

Abel MulugetaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect Steel Plate of Shear Reinforced Wide Beam Concrete

Uploaded by

Abel MulugetaCopyright:

Available Formats

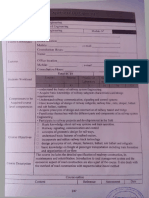

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Effect Steel Plate of Shear Reinforced Wide Beam

Concrete

Suhaib Jamal Al (1, 4), Prof (Dr) Amer M. Ibrahim2, Prof (Dr) V.C. Agarwal3

1

Student M.Tech Civil Eng. (Structure Engineering), SSET, SHIATS, ALLAHABAD-211007, Uttar Pradesh, India

2

Professor, College of Engineering, Diyala University (IRAQ)

3

Professor, Department of Civil Engineering, SSET, SHIATS, Allahabad, Uttar Pradesh, India

4

Republic of Iraq Governorate, Directorate of Baqubah Sewerage (IRAQ)

Abstract: Wide reinforced concrete beams have been used in buildings to reduce reinforcement congestion and floor heights for

required headroom. The beaming most of these cases is wider than that of the supporting columns. Consequently their shear capacity

might be effected and differ from that of conventional beams. This project report presents the test results of four wide beam specimens in

which their shear performances were studied. The influence of the support widths (100% of the beam width), the arrangement of

flexural reinforcement across the beam width, and the presence of shear reinforcement in the forms of third specimens consist of

concrete with steel plate and control beam conventional beam were investigated. The test setup was made similar for all the specimens,

one pointed load were on the beam width, the load put at distance column (300mm*300mm) from the center of support, therefore, the

specimen control failed in diagonal tension shear. But other specimens failed in flexural corporation. The results showed that wide

beam with plate has no effect on the shear strength of concrete and the influence of concentrating the flexural reinforcement within the

support width has no significant effect on the shear strength of concrete.

Keywords: wide beam, steel plate, Superplasticizer

1. Introduction 2. Literature Review

Reinforced concrete materials are widely accepted due to Kulkarni (2009) the study is performed to elucidate more

their strength, durability, reduced costs, quality, and easiness information and to understand the influence of critical

of formed into various shapes and sizes to make members parameters affecting the joint behavior such as column axial

like beams, slabs, columns, and shear walls. Concrete is load, beam anchorage ratio, and wide beam participation

strong in compression, but under tension it represents a poor

behavior. Thus, steel which is able to present a good tensile DYWANY (2010)the results showed that the narrow

behavior is added to concrete to improve the structural support has no effect on the shear strength of concrete and

behavior of concrete members. In a concrete structure, the influence of concentrating the flexural reinforcement

beams would adequately resist the ultimate bending within the support width has no significant effect on the

moments, shear force, and maybe torsion moments. shear strength of concrete.

Concrete slabs are mainly designed to withstand the most

unfavorable arrangements of loads, in the same manner as Bing and Sudhakar (2010)the studied behavior of the joints

beams. The use of reinforced concrete wide beams which in under the influence of critical influencing factors like

this study are shortly called wide beams is advantages column axial load, transverse beam, and beam bar anchorage

formany reasons. Wide beams, with the normal aspect ratio ratio were also analyzed through the parametric studies.

of width over thickness of larger than (2), are utilized in

buildings for the architectural gains, proportionally easy Bing and Qian (2011) this study demonstrates that the

formwork, and lower depth, Wide beams are horizontal repair of damaged RC beam-wide column joints by using

structural elements presenting multiple advantages when FRP can restore the performance of damaged RC joints with

using for multistory building having generally larger relative ease, suggesting that the repair of beam-column

openings and economical section, the disadvantages of wide joints is a cost-effective alternative to complete demolition

beams with respect to the regular ones multi-story building and replacement.

having wide beams are used when complex optimization

parameters are imposed. We make compare between many Mohammadyanetal. (2012)the studied load carrying after

codes to find shear; first shear crack and displacement in wide beams using

independent bent-up bars becomes larger in comparison to

The following codes were used in the present study: beams using other type’s reinforcement that shows a gradual

1. ACI (318-11) failure and more ductility.

2. EN 1992[9]

3. Indian code IS 456-2000

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 596

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

3. Materials & Method 3.2 Experimental Program

3.1General The experimental program consists of testing four simply

supported wide beams. All beams have the same dimensions

Thischapter involves details of the experimental work and flexural reinforcement. They have an overall length of

carried out in these concerning specimen’s details, type and 1800 mm, a width of 560 mm and a height of 215 mm as

properties of used materials, mixes details, molds, fresh and shown in Figure 3.1 and they are designed to fail in shear.

hardened tests, test procedure and measurements.

Figure 3.1: Typical dimensions (mm) and details of tested wide beam

3.3 Materials 3.3.4 Superplasticizer

In this work, the superplasticizer used is known

3.3.1 Cement commercially as (GLENIUM51) it is a new generation of

Ordinary Portland cement (type I) of Tasluja Factory (Iraq) modified polycarboxylic ether. It is compatible with all

is used in the present study. Portland cements that meet recognized international

standards. Superplasticized concrete exhibits a large increase

3. 3. 2. Fine Aggregate in slump without segregation. However, this provides

Al-Ukhaider natural sand is used in concrete mix. enough period after mixing for casting and finishing the

concrete surface. Therefore, no retarders are required.

3.3.3 Coarse Aggregate (Gravel)

Crushed gravel of maximum size 10 mm brought from Al- 3.3.5 Steel Reinforcing Bars

Niba'ee region (Iraq). Before using it, the sieve analysis is

performed it, details are given below Table 3.2: Properties of reinforcing steel bars

Yield Ultimate Elongation at

Nominal bar Bar area

Table 3.1: Grading of coarse aggregate (gravel) stress stress ultimate stress

diameter (mm) (mm2)

Limits of the Iraqi (MPa) (MPa) (%)

Sieve size %Passing Limits of ASTM72

specification71 16 deformed 201 671 831 6.6

(mm) byweight C33-03 12 deformed 113 650 807 9.7

No.45/1984

12.5 100 100 100

9.5 87 85-100 85-100 3.3.6 Water

4.75 15 0-25 10-30 Clean tap water of Diaylawas used for mixing concrete.

2.36 4 0-5 0-10 However, no test was carried out on the water to be used.

1.18 0 - 0-5

3.3.7 Steel Plate

The steel plates used in this project are manufactured in Iraq

with thickness 4mm type gagger plate show in figure ( 3.2)

the purpose of using gagger steel plate to resist shear force .

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 597

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Figure 3.2: Steel plate (4mm)

3.4 Concrete Mixing and Placing In this study used four Specimens all ofSame dimension

(1800*560*215mm).

3.4.1Concrete Mixer The following observations were made.

The concrete is mixed by using a horizontal rotary mixer 1. Compressive strength.

with (0.1m) capacity available in the material construction 2. Splitting tensile strength

laboratory, College of Engineering, Diayla University.

All beams are tested in universal testing machine.

Table 3.3: Materials required

Water Gravel Sand Cement Superplasticizer

35 1680 840 100 130

Kg Kg Kg Kg Milliliter

0.35 16.8 8.4 1

Figure 3.2: Compression strength test cylinder specimens

Figure 3.3: Failure of cylindrical specimen due to splitting

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 598

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Figure 3.4: Preparation for loading test machine

4. Results and Discussions a reference beam of this group where in beam (B4), the

increase in shear reinforcement ratio is studied, while in

4.1 General beams (B4) the presence of failed in shear by diagonal. As

shown in figure (4.1) beams of this group failed in diagonal

In this study, four reinforced wide beam concrete specimens compression mode except beam (B4) by shear diagonal

are tested. These beams are identical in splitting mode. This different mode of failure was due to the

length(L=1800mm)and width (W=560mm)and (H=215mm), use of gagger plate (4 mm) instead of (12 mm) bars of

tension steel reinforcement area (As=2000mm2 ).but differ stirrups which have been used in other beams, where the

different in the shear reinforcement where(B1=steel plate in inclined cracks do not penetrate into the shear zone due to

length,B2=steel plate in length with circular holes,B3=steel the presence of this stiff gagger plate. Therefore, the

plate on width with circular holes,B4=reference )According crushing of concrete in the strut region is caused by reaching

to these variables, ultimate loads, load-deflection behavior, the compressive stress in concrete to its ultimate value

concrete compressive strain as well as crack patterns are before yielding or rupturing these gagger plates. This

different from each other, and these beam are divided into behavior is clear in figure (4.1) where the main crack does

four specimens. not penetrate into the top face of the beam while the

crushing takes place in the concrete strut especially at

4.2 Behavior and Strength of wide Beams regions near the support. This type of failure (diagonal

compression mode) makes the behavior more brittle. This

This test includes four beams designated as (BI, B2, B3, B4) means the necessity for determination of a maximum limit

which are similar in compressive strength (NSCC) and shear for shear reinforcement ratio to avoid brittle failure in wide

span to effective depth ratio (a/d = 0.31) but they differ in beams. Further studies are required to reach values and

their shear reinforcement design. Beam (Bl) is considered as equations to specify this limit.

Figure 4.1: Crack pattern after testing wide beam (B1.B2.B3, B4)

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 599

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

The presence of gagger plates contributes in delaying reduce in shear reinforcement ratio reduce the shear capacity

appearance of cracks and hampers their development. It is of beam leading to increment in deflection due to delay of

clear in figure (4.1) where the cracks are few and short failure which is governed by shear capacity of the beam.

especially at the midspan of beams (B1) and (B2) and(B3) in

comparison with crack pattern of beams (B4) .The results of From this figure, it can observe that the presence of steel

cracking load (PCr) and ultimate load (Pu) for each beam of plate enhances the Load - deflection curve characteristics.

this group are illustrated in figure (4.2, 4.3, 4.4) These The presence of steel plate increases the area under the load-

results indicate that the increase in the ultimate load from( deflection curve i.e. increases the energy absorption

420)kNto (620)kNand an increase in cracking load from ( capacity. Also at any load level, the deflection is smaller

60)kNto (70)kNand Reduce crack width from0.6mm in B4 when the steel plates are present. The advantage of steel

to 0.13mm in B1 and 0.13mm in B2 and 0.20mm in B3.It plate is more pronounced when used. This effectiveness of

was found that the ratio between crack width and ultimate steel plate is due to two positive actions:

load (PCr / Pu) is approximately constant in spite of the

change in shear reinforcement. 1) Increasing the tension zone capacity of beam section and

decreasing crack width and crack number in this region.

4.3 Load-Deflection Response of Wide Beams 2) Increasing the mechanical properties.

3) This will increase the compression zone depth depending

Testing procedure involves identifying the relation between on equilibrium of internal forces. This action causes an

the midspan deflection and the applied load for each beam. increase in moment of inertia of cracked section which

Figure 4.3 explains this relation for wide beams of Models. increases the rigidity of the beam, there by the deflection

It is clear that the relation is approximately linear throughout becomes smaller.

the entire path, but before failure the line slightly bends.

This behavior is observed in all beams due to controlling of 4.4 Concrete Compressive Strain of wide beam

shear rather than flexure in failure incidence especially small

values of shear span to effective depth ratio (a/d) as is the As shown in Figures (4.4) and, the solid wide beam (B1 and

case of these models. Also, the values of maximum B2 and B3) show decreasing concrete compressive strain in

deflection are generally small where they ranged between comparison with the reference beam (B4), where the study

(8.4 mm and 18.37 mm). The figure shows (4.3) that the observe that maximum strain in B1=(8*10−4 mm) at

increase in shear reinforcement does not affect the general ultimate load (471KN),and the maximum strain in

path of load deflection curve but increases the maximum B2=(7.3*10−4 mm)at ultimate load (420mm),and the

deflection accompanied by the ultimate load. maximum strain in B3=(11.7*10−4 mm) at ultimate load

(620KN), and the maximum strain in B3=(12*10−4 mm) at

This is because shear reinforcement has no effect on flexural ultimate load (460KN).

rigidity, before the deflection seems to be approximately

unaffected at all stages of loading. It can be noted that the

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 600

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

5. Conclusions Capacity of Concrete Wide Beams," Master Research

Report, Universiti Teknologi Malaysia, Johor, Malaysia,

The following conclusions are drawn from the present study: December.

1) Mid-depth of steel plate improves shear capacity of wide

beam a little in comparison to other ways of reinforcing

and the failure comes to be sudden failure under this kind

of reinforcement.

2) Using some steel plate causes increased shear capacity of

wide beams significantly that in combination with

stirrups there is increase in load capacity as well as

ductility.

3) Load carrying after first shear crack and displacement in

wide beams using independent steel plate becomes larger

in comparison to beams using other types of shear

reinforcement that shows a gradual failure and more

ductility.

4) Using independent steel plate in wide beams that need a

large number of flexural reinforcement provides

anchorage feasibility and is much easier than providing

stirrup legs in cross sectional area of these beams.

5) Increasing the tension of steel reinforcement area of wide

beam an increase of the ultimate load capacity by about

(30% to 40%) is observed.

6) The steel plate resistance to crack width where at load

(420 kN) observes the crack width in (B1, B2, B3) equal

to (0.12, 0.20, 0.16) mm respectively while (B1)

controller spacemen equal to (0.46) mm.

References

[1] 1.Abbas, A. A.; Pullen, A. D,and Cotsovos, D.

M,(2010),"Structural Response of RC Wide Beams

Under Low-Rate and Impact Loading," ‘Magazine of

Concrete Research,V.62,No. 10,723-740.

[2] ACI Committee 318, (2011)"Building Code

Requirements for Structural Concrete, (ACI 318M-11)

and commentary (318R-11)," American Concrete

Institute, Farmington Hills, Michigan, USA, 503 pp.

[3] Haidar.r.hashimal.dywany,(2010),"behaviour of wide

reinforced concrete beam in shear"

[4] Lubell, A. S.; Bentz, E. C ; andCollins, M. P, (2009),

“Shear reinforcement spacing in wide members," ACI

Structural Journal, V. 106, No. 2, March-April pp.

205-214.

[5] Mohammadyan-Yasouj,S. E., (2012), "The Influence of

Different Types and arrangements of Reinforcement on

Volume 4 Issue 2, February 2015

www.ijsr.net

Paper ID: SUB15741 601

Licensed Under Creative Commons Attribution CC BY

You might also like

- Study On Exterior Beam Column Joint With Basalt Fibre Under Cyclic LoadingDocument9 pagesStudy On Exterior Beam Column Joint With Basalt Fibre Under Cyclic LoadingAdithya J MallanNo ratings yet

- Jeas 0414 1070 PDFDocument6 pagesJeas 0414 1070 PDFVishvaa eswaranNo ratings yet

- Study On The Strength of Stainless-Steel Fiber Rein-Forcement ConcreteDocument6 pagesStudy On The Strength of Stainless-Steel Fiber Rein-Forcement ConcreteIJRASETPublicationsNo ratings yet

- Toughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessDocument4 pagesToughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessvitusstructuresNo ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- Shear Strength Compressive Strength and Workability Characteristics of Concretes Reinforced With Steel Fibres IJERTV8IS060035Document4 pagesShear Strength Compressive Strength and Workability Characteristics of Concretes Reinforced With Steel Fibres IJERTV8IS060035hasshosNo ratings yet

- Compare The Strength and Axial Displacement in All The Samples Using A Welded Wire Mesh On The Periphery of The Steel ReinforcementDocument3 pagesCompare The Strength and Axial Displacement in All The Samples Using A Welded Wire Mesh On The Periphery of The Steel ReinforcementEditor IJTSRDNo ratings yet

- Effect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteDocument6 pagesEffect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteIJSTENo ratings yet

- Concrete StrengthDocument4 pagesConcrete StrengthJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Ajassp 2017 436 446Document11 pagesAjassp 2017 436 446Prof. Dr. Adel Al-AzzawiNo ratings yet

- Etasr 3317Document9 pagesEtasr 3317Zatul IzattyNo ratings yet

- K501046775 PDFDocument9 pagesK501046775 PDFsahriNo ratings yet

- Engineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemDocument13 pagesEngineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemprasanthNo ratings yet

- Shear Strength of Composite Beams With Dual Concrete StrengthsDocument5 pagesShear Strength of Composite Beams With Dual Concrete StrengthsVitor Batista0% (1)

- Effect of Aggregate Size on Self-Compacting Concrete StrengthDocument6 pagesEffect of Aggregate Size on Self-Compacting Concrete StrengthvinothiniNo ratings yet

- Steel Fibre Reinforced ConcreteDocument16 pagesSteel Fibre Reinforced ConcreteRazzak MullaNo ratings yet

- Structural Behaviorof High Strength Precast Reinforced Concrete Vierendeel TrussDocument13 pagesStructural Behaviorof High Strength Precast Reinforced Concrete Vierendeel Trussemad mohamedNo ratings yet

- Flexural Behaviour of Hollow Reinforced Concrete T-BeamsDocument12 pagesFlexural Behaviour of Hollow Reinforced Concrete T-Beamsnagham tariqNo ratings yet

- Experimental Investigation of Steel Fibre Reinforced ConcreteDocument17 pagesExperimental Investigation of Steel Fibre Reinforced ConcreteCHEIF EDITORNo ratings yet

- Investigation On Properties of Steel Fibre Reinforced Concrete IJERTV9IS120220Document4 pagesInvestigation On Properties of Steel Fibre Reinforced Concrete IJERTV9IS120220Ricky RickxNo ratings yet

- Shear Strength Prediction of Reinforced Concrete Transfer BeamsDocument21 pagesShear Strength Prediction of Reinforced Concrete Transfer Beamsmohammed_fathelbabNo ratings yet

- Azad 2010Document11 pagesAzad 2010nndaksdnsdkasndakNo ratings yet

- Shear Behavior of Self Compacting R.C. I-BeamsDocument16 pagesShear Behavior of Self Compacting R.C. I-BeamsThomás LimaNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- 1179 FinalDocument21 pages1179 Finaltsitsi bizaNo ratings yet

- Experimental Study On The Steel Fiber Reinforcement ConcreteDocument6 pagesExperimental Study On The Steel Fiber Reinforcement ConcreteIJRASETPublicationsNo ratings yet

- Failure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationDocument14 pagesFailure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationkashifNo ratings yet

- Post-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDocument10 pagesPost-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDan MaceNo ratings yet

- Performance of Steel Fiber Reinforced Self Compacting ConcreteDocument5 pagesPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)No ratings yet

- 00 Estribos Inclinados 02Document13 pages00 Estribos Inclinados 02Juan CorvalánNo ratings yet

- Experimental study enhances concrete flexural strength with small steel fibersDocument9 pagesExperimental study enhances concrete flexural strength with small steel fibersSal SaadNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- An Experimental Investigation of Steel CDocument4 pagesAn Experimental Investigation of Steel CnomadiczapatoNo ratings yet

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysDocument12 pagesRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JNo ratings yet

- Ferrocement Column BehaviourDocument4 pagesFerrocement Column BehaviourPushpakaran PillaiNo ratings yet

- Fin Irjmets1639807704 PDFDocument6 pagesFin Irjmets1639807704 PDFAkhil RajasekaranNo ratings yet

- Studying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsDocument11 pagesStudying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsAarohiShirkeNo ratings yet

- Analysis of Strengthening RC Beams Using Stainless Steel Continuous Reinforcement Embedded at Ends Using ANSYSDocument6 pagesAnalysis of Strengthening RC Beams Using Stainless Steel Continuous Reinforcement Embedded at Ends Using ANSYSIJRASETPublicationsNo ratings yet

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Document12 pagesExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNo ratings yet

- Flexural Behavior of Hollow RC Beam Using Glass FiberDocument10 pagesFlexural Behavior of Hollow RC Beam Using Glass FiberIJSTENo ratings yet

- Crack Width in Partially Prestressed T-Beams Having Steel FibersDocument9 pagesCrack Width in Partially Prestressed T-Beams Having Steel FibersMishraq ul quraishNo ratings yet

- Strength of Concrete Chopped Glass Fibers Tiles and Effect of Glass FiberDocument5 pagesStrength of Concrete Chopped Glass Fibers Tiles and Effect of Glass FiberIJRASETPublicationsNo ratings yet

- 20174-Hzrina AIP1.5011494Document10 pages20174-Hzrina AIP1.5011494Ehsan WasimNo ratings yet

- Characteristic Strength of Concrete Using Steel Slag As A Fine AggregateDocument8 pagesCharacteristic Strength of Concrete Using Steel Slag As A Fine AggregateIJRASETPublicationsNo ratings yet

- Bond Strength of Concrete With The Reinforcement Bars Polluted With OilDocument18 pagesBond Strength of Concrete With The Reinforcement Bars Polluted With OilNadher Al-BaghdadiNo ratings yet

- Simulation of CFST Finite Element Models To Study Its BehaviourDocument6 pagesSimulation of CFST Finite Element Models To Study Its BehaviourNandeesh SreenivasappaNo ratings yet

- Experimental Study of Flexure and Impact On Ferrocement SlabsDocument5 pagesExperimental Study of Flexure and Impact On Ferrocement Slabsadwaid paloliNo ratings yet

- 1992 Yamada Nanni EndoDocument9 pages1992 Yamada Nanni EndoMarcus FreitasNo ratings yet

- Steel Fiber Reinforced Concrete - Shear Strength: K. Halvax, É. LublóyDocument18 pagesSteel Fiber Reinforced Concrete - Shear Strength: K. Halvax, É. LublóyAdrian SelisteanNo ratings yet

- J Jobe 2018 01 006Document23 pagesJ Jobe 2018 01 006noor ayaadNo ratings yet

- Slab Punching ShearDocument14 pagesSlab Punching Shearadnan-651358No ratings yet

- 4APM Islam Et Al 2011 CFRPDocument5 pages4APM Islam Et Al 2011 CFRPMashfiqul IslamNo ratings yet

- Effect of Lathe Waste in Concrete As ReinforcementDocument6 pagesEffect of Lathe Waste in Concrete As ReinforcementAnkit GuptaNo ratings yet

- Ijciet 08 04 102 PDFDocument16 pagesIjciet 08 04 102 PDFLemuel TeopeNo ratings yet

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteDocument8 pagesShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abNo ratings yet

- 169 328 1 SMDocument12 pages169 328 1 SMAbel MulugetaNo ratings yet

- One-Way Shear Strength of Thick Slabs and Wide BeamsDocument9 pagesOne-Way Shear Strength of Thick Slabs and Wide BeamsWasin WaiyasusriNo ratings yet

- Behavior of Steel Fiber Reinforced Concrete Beam Using Fly AshDocument11 pagesBehavior of Steel Fiber Reinforced Concrete Beam Using Fly AshAhmad YaniNo ratings yet

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDocument11 pagesAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridNo ratings yet

- Comparative study of flexural behavior of reinforced concrete and prestressed concrete beamsDocument4 pagesComparative study of flexural behavior of reinforced concrete and prestressed concrete beamsRahil QureshiNo ratings yet

- 2.etm Report b+g+8Document85 pages2.etm Report b+g+8Abel MulugetaNo ratings yet

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- Public Participation in EIA PeresentationDocument14 pagesPublic Participation in EIA PeresentationAbel MulugetaNo ratings yet

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- Buckling and Stability of ColumnsDocument61 pagesBuckling and Stability of ColumnsAbel MulugetaNo ratings yet

- Currency Exchange Table (US Dollar - USD) - X-RatesDocument4 pagesCurrency Exchange Table (US Dollar - USD) - X-RatesAbel MulugetaNo ratings yet

- Plastic Analysis (Surafel)Document22 pagesPlastic Analysis (Surafel)Abel MulugetaNo ratings yet

- Railway EngineeringDocument26 pagesRailway EngineeringAbel MulugetaNo ratings yet

- Chapter 1Document43 pagesChapter 1Abel MulugetaNo ratings yet

- Double TrackDocument10 pagesDouble TrackAbel MulugetaNo ratings yet

- Railway Course DescriptionDocument3 pagesRailway Course DescriptionAbel MulugetaNo ratings yet

- Free Structural SoftwareDocument16 pagesFree Structural SoftwareRaamkrishnanNo ratings yet

- TCC41 Continuous Beams A and DDocument14 pagesTCC41 Continuous Beams A and DAbdulrahman AlnagarNo ratings yet

- CHAPTER-4.8 FinishingDocument18 pagesCHAPTER-4.8 FinishingAbel Mulugeta100% (1)

- Analysis of earthquake loads in buildingsDocument4 pagesAnalysis of earthquake loads in buildingsAbel MulugetaNo ratings yet

- Chapter IIDocument25 pagesChapter IIAbel MulugetaNo ratings yet

- Chapter-2 Functional Planning of BuildingsDocument17 pagesChapter-2 Functional Planning of BuildingsAbel MulugetaNo ratings yet

- CH 3Document12 pagesCH 3Abel MulugetaNo ratings yet

- Software Shallow Foundation ThesisDocument133 pagesSoftware Shallow Foundation ThesisAbel MulugetaNo ratings yet

- Chapter-1 IntroductionDocument30 pagesChapter-1 IntroductionAbel MulugetaNo ratings yet

- Experimental Investigationof Shear Behaviorin Flexure MembersDocument7 pagesExperimental Investigationof Shear Behaviorin Flexure MembersAbel MulugetaNo ratings yet

- Shear Capacity of RC Beams With Different Patterns of Spiral ReinforcementsDocument3 pagesShear Capacity of RC Beams With Different Patterns of Spiral ReinforcementsAbel MulugetaNo ratings yet

- Experimental Investigation of Rectangular Spiral Reinforced Concrete BeamsDocument5 pagesExperimental Investigation of Rectangular Spiral Reinforced Concrete BeamsAbel MulugetaNo ratings yet

- E3145039520Document6 pagesE3145039520Abel MulugetaNo ratings yet

- Experimental Study On The Behaviour of Spirally Reinforced SCC BeamsDocument10 pagesExperimental Study On The Behaviour of Spirally Reinforced SCC BeamsAbel MulugetaNo ratings yet

- Chapter 4Document19 pagesChapter 4Abel MulugetaNo ratings yet

- Ajme 6 2 5Document10 pagesAjme 6 2 5Abel MulugetaNo ratings yet

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaNo ratings yet

- Static and Dynamic Analysis of Storage Tanks Considering Soil-Structure InteractionDocument18 pagesStatic and Dynamic Analysis of Storage Tanks Considering Soil-Structure InteractionRashma JomoNo ratings yet

- Unit 3 - Physics - WWW - Rgpvnotes.inDocument19 pagesUnit 3 - Physics - WWW - Rgpvnotes.inMayank SharmaNo ratings yet

- CHEMISTRY BOOK 2 ObjDocument44 pagesCHEMISTRY BOOK 2 ObjHaris AkhtarNo ratings yet

- Envir Otect Power Cable Install ManualDocument49 pagesEnvir Otect Power Cable Install ManualRashi MrBRDNo ratings yet

- B.E./B.Tech. Course File: St. Xavier's Catholic College of EngineeringDocument25 pagesB.E./B.Tech. Course File: St. Xavier's Catholic College of EngineeringMICHEL RAJ MechNo ratings yet

- AHU-B01-04 All Day Dining-Heating PDFDocument1 pageAHU-B01-04 All Day Dining-Heating PDFNgoc Vũ TrầnNo ratings yet

- Physics Oscillator ReportDocument14 pagesPhysics Oscillator ReportarushiNo ratings yet

- Prepare Report On Gear and Its TerminologyDocument12 pagesPrepare Report On Gear and Its TerminologyMadhuri TelangeNo ratings yet

- Koordinasi Proteksi Saluran Udara TinggiDocument68 pagesKoordinasi Proteksi Saluran Udara TinggiHendy KurniawanNo ratings yet

- PN427448 Ansul Foam Manual PDFDocument342 pagesPN427448 Ansul Foam Manual PDFCHANDANNo ratings yet

- Silicon Zener Diodes for Stabilizing and Clipping CircuitsDocument4 pagesSilicon Zener Diodes for Stabilizing and Clipping CircuitsMohamad Toufan AkbarNo ratings yet

- Premium Industrial NDT SolutionsDocument16 pagesPremium Industrial NDT SolutionsSiva ShankarNo ratings yet

- Mechanical Professional ElectiveDocument310 pagesMechanical Professional ElectivearunrajNo ratings yet

- Problem Set #6 AnswersDocument3 pagesProblem Set #6 AnswersStefan BamNo ratings yet

- DC-to-AC Converter Guide: Inverters ExplainedDocument48 pagesDC-to-AC Converter Guide: Inverters ExplainedShanthu BiswasNo ratings yet

- New Toshiba VRF FCU: 1. FeatureDocument9 pagesNew Toshiba VRF FCU: 1. FeatureLê Văn HuânNo ratings yet

- De150103 BMDDocument3 pagesDe150103 BMDseve1No ratings yet

- AJSIR-3-5-277-282Document6 pagesAJSIR-3-5-277-282omf.informaticienNo ratings yet

- Allied DC Portable Aspirator User ManualDocument9 pagesAllied DC Portable Aspirator User ManualmiguelNo ratings yet

- 7 HPLC Ay2223s2Document31 pages7 HPLC Ay2223s2Matty JakeNo ratings yet

- CSTR ManualDocument11 pagesCSTR ManualMelly FulaNo ratings yet

- Magnetic Material: By: Mr. Darshan Anil Sharma M - S C - 2 Year Department of Physics Guid by Dr. Sarkar SirDocument17 pagesMagnetic Material: By: Mr. Darshan Anil Sharma M - S C - 2 Year Department of Physics Guid by Dr. Sarkar SirDarshan SharmaNo ratings yet

- Manitowoc Ice Makers Service ManualDocument172 pagesManitowoc Ice Makers Service ManualJason PaschkeNo ratings yet

- IECEx PRE 19.0093U 000Document5 pagesIECEx PRE 19.0093U 000Mangesh MohiteNo ratings yet

- 04 Observing The SunDocument3 pages04 Observing The SungarryhodgesonNo ratings yet

- JO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemDocument9 pagesJO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemHasan MustafaNo ratings yet

- Evsjv 'K M Ru: Iwr÷Vw© Bs WW G-1Document36 pagesEvsjv 'K M Ru: Iwr÷Vw© Bs WW G-1Mizanur RahamanNo ratings yet

- Balloon Powered Race Cars-1Document8 pagesBalloon Powered Race Cars-1Angelica CamilonNo ratings yet

- Module-2 Energy Systems & AnalysisDocument46 pagesModule-2 Energy Systems & Analysisrushi C SNo ratings yet

- 420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónDocument7 pages420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónRosa ChNo ratings yet