Professional Documents

Culture Documents

Ijciet 08 04 102 PDF

Uploaded by

Lemuel TeopeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijciet 08 04 102 PDF

Uploaded by

Lemuel TeopeCopyright:

Available Formats

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 4, April 2017, pp. 868–883 Article ID: IJCIET_08_04_102

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=4

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

BEHAVIOR OF REINFORCED CONCRETE

BRACKETS STRENGTHENED WITH

DIFFERENT TECHNIQUES

Dr. Hassanien M. Thiyab

College of Engineering/ University of Kufa, Iraq

ABSTRACT

This study includes strengthening and testing of eight reinforced concrete brackets

with different techniques. The experimental variables considered in the test program

include strengthening type (external, internal, and repair), plate type (Carbon Fiber

Reinforced Plate (CFRP), CFRP bar, and steel plate), plate orientation, and plate

dimensions. The greatest load and the deflection of samples are compared to the control

sample. The cracking and mode of failure under static loading are studied. It was found

that (CFRP) plate is an effective strategy for strengthening reinforced concrete bracket.

The greatest load carrying capacity is increased from 32% to 124%. Strengthening the

samples by preparing C4 sample gives the best outcomes. This may be according to the

alignment of the CFRP plate being orthogonal with respect to the prepared cracks.

Key words: Strengthening, Bracket, CFRP Plate, CFRP bar, Behavior.

Cite this Article: Dr. Hassanien M. Thiyab, Behavior of Reinforced Concrete Brackets

Strengthened with Different Techniques. International Journal of Civil Engineering

and Technology, 8(4), 2017, pp. 868–883.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=4

1. INTRODUCTIOIN

Bracket is a structural member cast with column or wall at the same time. It is used mostly in

pre-cast buildings to transfer load from beam or slab to column or concrete wall. Bracket is a

short cantilever has the ratio of effective depth to shear span less than unity (ACI 318-11, 2011).

Figure (1) shows the bracket, column, beam, and slab system. The location of neutral axis limits

the compression and the tension region. In bracket, the region above neutral axis represents

tension region, and the region lower neutral axis represents compression region, and at the same

time concrete is known with its good resistance in compression and poor resistance in tension,

so that the steel bar should be used in the tension region to increase the load carrying capacity.

The behavior of reinforced concrete bracket likes the behavior of deep beam in mostly fails by

shear failure. Reinforced concrete bracket needs shear strengthening. Many different methods

of shear strengthening are available such as shear strengthening by external strengthening (strip

and plate) and internal strengthening (bar and plate). Many different researches have adopted

these methods. Every one of these methods has different parametric studies depending upon

http://www.iaeme.com/IJCIET/index.asp 868 editor@iaeme.com

Dr. Hassanien M. Thiyab

length, width, thickness of plate or diameter of bar, direction, and other technicals of bond with

concrete . This research is studying shear strengthening of reinforced concrete bracket by CFRP

plate with different locations, steel plate, near surface mounted CFRP bar and repair after 60%

loading to exam which methods are more effective. While an important variety of studies had

been created on common reinforced concrete brackets, a much less variety was created for

strengthening brackets using FRP blend components (Elgwady et al, 1999; Corry and Dolan,

2001;Erfan et al.,2010; Abed Attiah, 2010;Ahmed et al.,2013; Shadhan et al., 2o15). This trial

research concentrates on improving and repairing the R. C. B. with CFRP laminated.

(a) (b)

Figure (1) (a) Bracket, Column and Beam System, (b) Bracket, Column, Beam and Slab System.

2. EXPERIMENTAL TECHNIQUE

When a structure performance reduced due to accidents (earthquake, explosions), change in

loading, change in configuration, change in use, errors in design or construction the structure

needs to be strengthened or repaired. The objective of this study is to increase the load carrying

capacity of the structure.

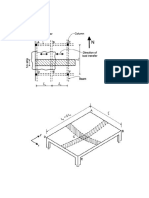

2.1. TEST SPECIMENS DIMENSIONS AND REINFORCEMENT

The test specimen had double brackets each in a rectangular shape with length of 200 mm,

width of 150 mm, and depth of 150 mm. The flexural reinforcement consisted of two steel bars,

each of diameter of 12 mm, and no stirrups were reinforced. The total length of column is 450

mm. the reinforcement of column included four longitudinal bars, each is 12mm in dia., and

four closed stirrups of diameter of 6 mm were used. All steel bars of diameter 12 mm and 6

mm had tensile strengthes of 590 MPa and 560MPa respectively, and the yield stresses of 430

MPa and 410 MPa, respectively. All specimens had the same dimensions and reinforcement as

shown in Figure (2).

http://www.iaeme.com/IJCIET/index.asp 869 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

Figure (2): Bracket Dimensions and Reinforcement

2.2. CONCRETE MIX

The eight specimens of brackets were cast in wooden forms in the concrete laboratory in Kufa

university. The cement: sand: gravel: water/cement rate ratios in the concrete mix were

1:2:4:0.53 by weight. The greatest size of gravel was 12.5 mm. Three concrete cubic 100mm,

and three concrete cylinders 100 mm ×200 mm were cast and are tested when each bracket

specimen is tested to determine the compressive strength and tensile strength of concrete. The

compressive strength ranges between 21 MPa to 23 MPa and the tensile strength ranges

between 1.9 MPa to 2.2 MPa.

2.3. BONDING of CFRP to REINFORCED CONCRETE BRACKET

After casting and curing, the specimens must be cleaned and the bracket surfaces smoothed by

using a scraper machine as shown in Figure (3). The location of CFRP strips were washed by

water. As a primary stage in the CFRP put in place, the two-parts epoxy bond of (A and B)

were mixed in 3:1 amount by using power mixer until the color was green as shown in Figures

(4) and (5). The stick blender has been used to the outer cellular coating area of concrete at the

location of CFRP pieces to complete the cavities. Also, the stick blender was added on the area

of CFRP strips, and these pieces were used to the outer coating area of concrete. Figure (6)

shows specimens after removing all lousy materials. Tables (1) and (2) show the properties of

the resin and CFRP plate and CFRP bar, respectively.

Table (1) Properties of the Epoxy Resin

Mixing Compressive

Viscosity Pot life

Type Appearance ratio by strength Absorption

cps (minute)

weight (MPa)

Epoxy A:B 120min

Green 2475 71.7 12%

Bond 3:1 40min

http://www.iaeme.com/IJCIET/index.asp 870 editor@iaeme.com

Dr. Hassanien M. Thiyab

Table (2) Properties of Carbon Fiber Fabric Laminate, (Hughes Brothers, 2010).

Type of Tensile Strength Elasticity Ultimate

Cross Sectional Area (mm)2

CFRP (MPa) modulus (GPa) strain (%)

1.4 (Thickness)*50 (Width)

CFRP Plate 2400 165 1.35

CFRP Bar Pi 6 2 (Diameter) 2 2068 124 0.017

Figure (3) Cleaning by Scrape Device Figure (4) Epoxy Bonding Agent

Figure (5) Mixing by Electrical Machine Figure (6) Specimen after Cleaning

http://www.iaeme.com/IJCIET/index.asp 871 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

3. EXPERIMENTAL RESULTS

Tests were carried out by using universal testing machine with capacity of 2000kN.The

universal testing machine is a closed loop servo hydraulic testing system that controlled

manually. The experiments were executed in load control with manually data monitoring and

recording of both the load and mid span deflection. Whole of the specimens had statically

examined to fail in one cycle of loading. Load was slowly applied, the rate of loading equal to

0.5 kN/s, in successive increments up to failure. The load steps were initially 5 kN then they

were increased to 10 kN until specimen failure. The same method of failing happened for all

brackets. This mode was an angled shear crack leads to break of all carbon fiber reinforced

polymer plates in the shear region at the greatest load. Table (3) illustrates the sample

identification and strengthening schemes. The experimental results of each bracket sample

tested are shown in Table (4).The discussion of results for each sample is presented in the

following sections.

Table (3) Samples Identification and Strengthening Schemes.

C1 C2 C3

Front Project Front Project Front Project

C1 C2 C3

Back Project Front Project Back Project

C4 C5 C6 Repaired

(60%)

Front Project Front Project Front Project

C4 C5 C6 Repaired

(60%)

Back Project Back Project Back Project

http://www.iaeme.com/IJCIET/index.asp 872 editor@iaeme.com

Dr. Hassanien M. Thiyab

C7 CFRP Bar C8

(NSM) Steel Plate

Front Project Front Project

C7 CFRP Bar C8

(NSM) Steel Plate

Back Project

Back Project

Table (4) Experimental Results

First

Cracking Pu ((Pu-Po) Δu

Sample (a/d) Bracket type

Load (kN) /Po)% (mm)

(kN)

C1 0.8 Control 75 125 - 6.987

C2 0.8 Strengthened/CFRP Plate 100 165 32 4.54

C3 0.8 Strengthened/CFRP Plate 100 190 52 6.876

C4 0.8 Strengthened/CFRP Plate 100 280 124 6.584

C5 0.8 Strengthened/CFRP Plate 100 170 36 5.1

C6 0.8 Repaired 75 245 96 5.6

C7 0.8 Strengthened/CFRP bar 100 160 28 4.1

C8 0.8 Strengthened/Steel plate 85 150 20 5.8

*Pu: The ultimate load of the strengthened sample; Po: The ultimate load of control sample; Δu: The

ultimate deflection.

3.1. Sample (C1)

To find the load-carrying capacity of squabby cantilever, this specimen was examined as a

control sample. The results in terms of total load compared to the net deflection are shown in

Figure (7). During loading sample C1, the first major crack showed at 75 kN. The first crack

was a vertical crack showing roughly at the bracket experience from the line side. The other

cracks were an inclined crack almost at an angel of 45°, angled shear cracks established at the

load of 100 kN. As load was increased, this crack began to grow and distribute resulting the

failure at load of 125 kN. Increasing the loading led to new angled cracks, and the angled cracks

spread rapidly until failure. The failure of this specimen occurred when a large crack started at

the intersection point of the bracket and the column face going to the point of load as shown in

Figure (7). Then the upper triangular reinforced concrete was divided. From this crack pattern

it can be concluded that this is a shear failure “beam type”.

http://www.iaeme.com/IJCIET/index.asp 873 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

Figure (7) Crack Pattern for Bracket C1.

Figure (8) Vertical Load Contra Def. Curve (C1)

3.2. Sample (C2)

This sample was improved with six vertical CFRP strips having 12.0 mm width and 1.4 mm

thickness for each face of the bracket. The first crack appeared during the loading was a flexural

crack like to that of a cantilever beam. While the second crack began at the keeping dish and

spread toward the cross of the column and face of the bracket. The sample failed at load of (165

kN) with a rise in resistance of about (32 %) in comparison to the control sample C1. From

Figure (9) it can be seen that the amount cracks was decreased considerably in comparison to

unstrengthened brackets, this linked to the existence of CFRP strips. Figure (10) reveals the

load in comparison to the deflection of the bracket samples C1 and C2.

http://www.iaeme.com/IJCIET/index.asp 874 editor@iaeme.com

Dr. Hassanien M. Thiyab

Figure (9) Crack Pattern for Bracket Sample C2.

Figure (10) Vertical Load Contra Def. Curves (C1) & (C2).

http://www.iaeme.com/IJCIET/index.asp 875 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

3.3. Sample (C3)

This sample was improved with eight vertical CFRP strips having 12.0mm width and 1.4 mm

thickness for each face of the corbel. Flexural cracks were observed first; at roughly the load

was 100kN, and then a few angled cracks had been noticed. With increasing load, the flexural

cracks improved way up and became broader. At the same time the angled cracks spread

towards the assisting point as shown in Figure (11). The first significant crack showed up at a

load of 130 kN. The sample failed at load of (190 kN) with a rise in resistance of about (52 %)

in comparison to the control bracket sample C1. The greatest load was greater than C2. At this

level there was no destruction in the concrete itself as those happened in the other samples.

Figure (12) reveals the load in comparison to deflection of brackets C1 and C3.

Figure (11) Crack Pattern for Bracket C3.

200

180

160

140

120

Load (kN)

100

80

60 C1

40 C3

20

0

0 2 4 6 8

Deflection (mm)

Figure (12) Vertical load contra def. curves (C1) & (C3).

3.4. Sample (C4)

To study the influence of strengthened reinforced concrete brackets with angled carbon fiber

plastic strips on the outside, bracket sample C4 was improved with four inclined CFRP strips

having 18.0 mm width and 1.4 mm thickness for front and back projects. The cracks pattern of

this bracket sample is shown in Figure (13). Shear cracks happened at a higher load than

http://www.iaeme.com/IJCIET/index.asp 876 editor@iaeme.com

Dr. Hassanien M. Thiyab

samples C1, C2, and C3, which was noticed at a used load of (100 kN). The bracket was failed

at the maximum load of (280 kN) with a rise in resistance of about (124 %) according to the

control bracket sample C1. This enhancement in strength is linked to the existence of CFRP

strips being orthogonal with respect to crack path. Also, the existence of CFRP gave another

advantage; it moved the cracking from several commonly spread and large size cracks to many

more carefully spread smaller cracks and reduced the bracket deflection. Figure (14) reveals

the load in comparison to deflection of bracket samples C1 and C4.

Figure (13) Crack Pattern for Bracket C4.

300

250

200

Load (kN)

150

100

C1

50

C4

0

0 2 4 6 8

Deflection (mm)

Figure (14) Vertical load contra def. curves (C1)&(C4).

http://www.iaeme.com/IJCIET/index.asp 877 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

3.5. Sample (C5)

To discover the influence of improving reinforced concrete brackets with an angled carbon

fiber plastic strips on the outside, bracket sample C5 was improved with six inclined CFRP

strips having 9.0 mm width and 1.4 mm thickness for front and back projects. The cracks

pattern of this bracket sample is shown in Fig.(15). Shear cracks happened at a higher load than

samples C1, C2 and C3 ,which was noticed at a used load of (100 kN). The bracket sample

failed at the maximum load of (170 kN) with a rise in resistance of (44 %) according to the

control bracket sample C1. This enhancement in strength is linked to the existence of CFRP

strips being orthogonal with respect to the crack path. Also, the existence of CFRP gave another

advantage; it moved the cracking from several commonly spread and large size cracks to many

more carefully spread smaller cracks and reduced the bracket deflection. Figure (16) illustrates

the load in comparison to deflection of bracket samples C1 and C5.

Figure (15) Crack Pattern for Bracket C5.

180

160

140

120

Load (kN)

100

80

60

40 C1

20 C5

0

0 2 4 6 8

Deflection (mm)

Figure (16) Vertical Load Contra Def. Curves (C1)&(C5).

http://www.iaeme.com/IJCIET/index.asp 878 editor@iaeme.com

Dr. Hassanien M. Thiyab

3.6. Sample (C6)

It is identified to load repaired bracket sample roughly to a lot of 75 kN (60% of the greatest

load) according to the control bracket C1, then strengthened by C6 technique because it is the

most effective technique of strengthening by four inclined CFRP pieces having 18.0 mm width

and 1.4 mm thickness for front and back projects. The experimental results of the sample gave

a similar behavior of sample C4, but less rigidity than the sample C4 due to pre-cracking as

shown in Figure (17). Figure (18) reveals the load in comparison to deflection of bracket

samples C1 and C6.

Figure (17) Crack Pattern for Bracket C6.

Figure (18) Vertical Load Contra Def. Curves (C1)&(C6).

3.7. Sample (C7)

To study the influence of strengthened reinforced concrete brackets with an angled near surface

mounted carbon fiber plastic bars technique, bracket sample C7 was improved with four

inclined CFRP bars having 6.0 mm diameter for front and back projects. The cracks pattern of

http://www.iaeme.com/IJCIET/index.asp 879 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

this bracket sample is shown in Figure (19). Shear cracks happened at a higher load than

samples C1, C2, and C3,which was noticed at a used load of (100 kN). The bracket sample

failed at a maximum load of (160 kN) with a rise in resistance of (28 %) according to the control

bracket sample C1. Also, the existence of CFRP bars gave another advantage; it moved the

cracking from several commonly spread and large size cracks to many more carefully spread

smaller cracks and reduced the bracket deflection. Figure (20) reveals the load in comparison

to deflection of bracket samples C1 and C4.

180

160

140

120

Load (kN)

100

80

60

40

C1

20

C7

0

0 2 4 6 8

Deflection (mm)

Figure (20) Vertical Load Contra Def. Curves (C1) & (C7).

http://www.iaeme.com/IJCIET/index.asp 880 editor@iaeme.com

Dr. Hassanien M. Thiyab

Figure (20) Crack Pattern for Bracket C7

3.8. Sample (C8)

To research the influence of strengthened reinforced concrete bracket with angled steel plate

strips on the outside, bracket sample C8 was improved with four inclined steel plates having

20.0 mm width and 1.4 mm thickness for front and back projects. The cracks pattern of this

bracket sample is shown in Figure (21). Shear cracks happened at load (85 kN). The sample

failed at a maximum load of (150 kN) with a rise in resistance of (20 %) according to the control

bracket sample C1. Figure (22) illustrates the load in comparison to the deflection of bracket

samples C1 and C8.

Figure (21) Crack Pattern for Bracket C8.

http://www.iaeme.com/IJCIET/index.asp 881 editor@iaeme.com

Behavior of Reinforced Concrete Brackets Strengthened with Different Techniques

160

140

120

100

Load (kN)

80

60

40

C1

20 C8

0

0 2 4 6 8

Deflection (mm)

Figure (22) Vertical Load Contra Def. Curves (C1) & (C8).

4. CONCLUSIONS

1. Using (CFRP) plates is an effective strategy for strengthening of reinforced concrete bracket.

The greatest load carrying capacity is increased from 32% to 124%.

2. The apportionment, place, alignment and quantity of CFRP strips perform an important part in

improving the damaged members; therefore, strengthening the samples by C4 sample gives the

best outcomes. This may be according to the alignment of the CFRP plate being orthogonal

with respect to the prepared cracks.

3. CFRP strips in most circumstances of improved bracket are neither jagged nor debonded, but

an eliminate of concrete breaking with CFRP items. It indicates that all strengthening

techniques used in the current research are effective in improving such members.

4. For the bracket repaired with CFRP strips in shear, the final load increased by (96%) based to

the greatest load of the control bracket.

5. Although the greatest load carrying capacity of strengthened samples were increased, all these

samples failed suddenly.

6. The deflection of strengthened samples is decreased significantly.

REFERENCES

[1] Abed Attiah M., (2010), Behavior of reinforced concrete corbels strengthened with carbon

fiber reinforced polymer strips, PhD thesis, Basrah University.

[2] Ahmad, S, Elahi, A, Kundi, S., and Haq, W., (2013), Investigation of shear behavior of

Corbel beams strengthened with CFRP, Life Science Journal 2013.

[3] American Concrete Institute, ACI Committee 318, (2011), Building code requirements for

structural concrete (ACI 318-11) and commentary, American Concrete Institute,

Farmington Hills, MI 48331.

[4] Corry, R. W. and Dolan, C. W. Strengthening and repair of a column bracket using a carbon

fibre reinforced polymer (CFRP) fabric, (2001), Journal of PCI Journal, pp. 54–63.

[5] Elgwady, M. A., Rabie, M., and Mosatafa, M. T., (1999), Strengthening of corbles using

CFRP, An Experimental Program, Cairo university, Giza, Egypt.

[6] Erfan, A. M., Abdel-Rahman, G. T., Nassifand, M. K. and Hammad, Y. H., (2010),

Behavior of reinforced concrete corbels strengthened with CFRP fabrics, Benha University.

http://www.iaeme.com/IJCIET/index.asp 882 editor@iaeme.com

Dr. Hassanien M. Thiyab

[7] Hughes Brothers, Inc., (2010), Carbon Fiber Reinforced Polymer (CFRP) Rebar Aslan 200,

Technical Data Sheet (Website: http://www.hughesbros.com).

[8] Ivanova, I., Assih, J., Li, A. and Delmas, Y., (2014), Influence of Fabrics Layers on

Strengthened Reinforced Concrete Short Corbels, International Journal of Civil

Engineering and Technology, 5(11), pp. 33–43.

[9] Shadhan, K. K. and Mohammad Kadhim, M. M., (2015), Use of CFRP Laminates for

Strengthening of Reinforced Concrete Corbels, International Journal of Civil Engineering

and Technology, 6(11), pp. 11-20.

http://www.iaeme.com/IJCIET/index.asp 883 editor@iaeme.com

You might also like

- Shear Strength of Composite Beams With Dual Concrete StrengthsDocument5 pagesShear Strength of Composite Beams With Dual Concrete StrengthsVitor Batista0% (1)

- MICROPILE CAP TEST REVEALS BEARING PLATES UNNECESSARYDocument11 pagesMICROPILE CAP TEST REVEALS BEARING PLATES UNNECESSARYrowatersNo ratings yet

- 3 PDFDocument14 pages3 PDFsakeriraq81No ratings yet

- Flexural Performance of Reinforced Concrete Beams With A Layer of Expansive SHCC-2012-Hae Jun YangDocument5 pagesFlexural Performance of Reinforced Concrete Beams With A Layer of Expansive SHCC-2012-Hae Jun YangsardarumersialNo ratings yet

- 7 Research Paper STRENGTH AND SERVICEABILITY OF FRP GRIDDocument10 pages7 Research Paper STRENGTH AND SERVICEABILITY OF FRP GRIDMuhammad DaniyalNo ratings yet

- Ijciet 06 10 003Document11 pagesIjciet 06 10 003IAEME PublicationNo ratings yet

- Effects - of - trapezoidal - cross-section - dimensions - on مفيد PDFDocument15 pagesEffects - of - trapezoidal - cross-section - dimensions - on مفيد PDFMajid AlzubadyNo ratings yet

- Study On FlexuralDocument8 pagesStudy On FlexuralRafael CuaNo ratings yet

- Behaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced PolymersDocument22 pagesBehaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced Polymersbariq89No ratings yet

- International Journal of Chemtech Research: Antony Salomy N, Gayathiri SDocument9 pagesInternational Journal of Chemtech Research: Antony Salomy N, Gayathiri Sci_balaNo ratings yet

- Strengthen Concrete Bridges with FRPDocument12 pagesStrengthen Concrete Bridges with FRPRaed alkronz Raed alkronzNo ratings yet

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysDocument12 pagesRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JNo ratings yet

- Energy Absorption Capacity of Composite BeamsDocument6 pagesEnergy Absorption Capacity of Composite BeamsvijayapandimNo ratings yet

- Case Studies in Construction Materials: Ra Fid Saeed AteaDocument8 pagesCase Studies in Construction Materials: Ra Fid Saeed Ateaviewer208No ratings yet

- Effects of Unconfined Concrete Strength On FRP Confinement of ConcreteDocument8 pagesEffects of Unconfined Concrete Strength On FRP Confinement of Concretecaojin259No ratings yet

- Experimental Study For Punching Shear Behavior in RC Flat Plate With Hybrid High Strength ConcreteDocument15 pagesExperimental Study For Punching Shear Behavior in RC Flat Plate With Hybrid High Strength ConcreteSelcuk CebeciNo ratings yet

- For FRP AbaqusDocument7 pagesFor FRP AbaqusnrtparNo ratings yet

- 20174-Hzrina AIP1.5011494Document10 pages20174-Hzrina AIP1.5011494Ehsan WasimNo ratings yet

- 1 Experiments Investigating Concrete Floor Punching PDFDocument17 pages1 Experiments Investigating Concrete Floor Punching PDFMelissa PungtilanNo ratings yet

- Aljanabi 2020 IOP Conf. Ser. Mater. Sci. Eng. 871 012004Document11 pagesAljanabi 2020 IOP Conf. Ser. Mater. Sci. Eng. 871 012004alaa hassoonNo ratings yet

- Serviceability Limit State ofDocument9 pagesServiceability Limit State ofnagham tariqNo ratings yet

- Shear Behavior of Self Compacting R.C. I-BeamsDocument16 pagesShear Behavior of Self Compacting R.C. I-BeamsThomás LimaNo ratings yet

- Failure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationDocument14 pagesFailure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationkashifNo ratings yet

- Pseudo-Dynamic Test of A Full-Scale CFT/BRB Frame: Part 2 - Construction and TestingDocument15 pagesPseudo-Dynamic Test of A Full-Scale CFT/BRB Frame: Part 2 - Construction and TestingDiego Matias Burgos FuentesNo ratings yet

- Fracture toughness of geopolymeric concretes reinforced with basalt fibersDocument6 pagesFracture toughness of geopolymeric concretes reinforced with basalt fibersSanjeeva YedavalliNo ratings yet

- Shear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetDocument6 pagesShear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetAzhar PLNo ratings yet

- Use of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningsDocument10 pagesUse of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningssuhagNo ratings yet

- Studying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsDocument11 pagesStudying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsAarohiShirkeNo ratings yet

- Strengthening of Reinforced Concrete Stepped Beam Using Cotton BeltDocument11 pagesStrengthening of Reinforced Concrete Stepped Beam Using Cotton BeltAbdulkhaliq AbdulyimahNo ratings yet

- Flexural Behavior of ECC Hollow Beams Incorporating Different Synthetic FibersDocument13 pagesFlexural Behavior of ECC Hollow Beams Incorporating Different Synthetic Fibersnagham tariqNo ratings yet

- The Effects of Partial Interaction Degree On Reinforced Concrete Arch BehaviorDocument8 pagesThe Effects of Partial Interaction Degree On Reinforced Concrete Arch BehaviorTJPRC PublicationsNo ratings yet

- Study On Flexural Behaviour of Ferrocement Slabs Reinforced With PVC-coated Weld MeshDocument8 pagesStudy On Flexural Behaviour of Ferrocement Slabs Reinforced With PVC-coated Weld MeshIJERDNo ratings yet

- 1994-High Strength Concrete Columnes Confined by Rectrangular TiesDocument22 pages1994-High Strength Concrete Columnes Confined by Rectrangular Tiesnedim.halebic1No ratings yet

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDocument11 pagesAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridNo ratings yet

- Shear Strength Prediction of Reinforced Concrete Transfer BeamsDocument21 pagesShear Strength Prediction of Reinforced Concrete Transfer Beamsmohammed_fathelbabNo ratings yet

- Smeared Crack Models of RC Beams With Externally Bonded CFRP PlatesDocument8 pagesSmeared Crack Models of RC Beams With Externally Bonded CFRP Platessmadireddy1No ratings yet

- Influence of ECC Mixture On The Structural Performance of Link Slabs in Bridge DecksDocument10 pagesInfluence of ECC Mixture On The Structural Performance of Link Slabs in Bridge DecksNavidNo ratings yet

- Strengthening of Reinforced Concrete Beams CarbonDocument6 pagesStrengthening of Reinforced Concrete Beams CarbonShabbar AbbasNo ratings yet

- Near Surface Mounted FRP MaterialDocument26 pagesNear Surface Mounted FRP MaterialMuhammad AjmalNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- The Retrofitting of Reinforced Concrete Column-To-Beam ConnectionsDocument9 pagesThe Retrofitting of Reinforced Concrete Column-To-Beam ConnectionssakthistructNo ratings yet

- Data Full Papers 112 DelDocument8 pagesData Full Papers 112 DelDBW Quality Control JVACCNo ratings yet

- Beam 1Document9 pagesBeam 1sakthistructNo ratings yet

- Cob03 0310Document11 pagesCob03 0310abdollahzadehNo ratings yet

- Behavior of AAC Infill Walls Under Lateral LoadsDocument7 pagesBehavior of AAC Infill Walls Under Lateral LoadsravirajNo ratings yet

- Numerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelDocument10 pagesNumerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelAnand RajNo ratings yet

- Ferrocement Column BehaviourDocument4 pagesFerrocement Column BehaviourPushpakaran PillaiNo ratings yet

- Effect Steel Plate of Shear Reinforced Wide Beam ConcreteDocument6 pagesEffect Steel Plate of Shear Reinforced Wide Beam ConcreteAbel MulugetaNo ratings yet

- CripplingDocument10 pagesCripplingaravindkarthiNo ratings yet

- 169 328 1 SMDocument12 pages169 328 1 SMAbel MulugetaNo ratings yet

- Script MCE181005Document3 pagesScript MCE181005Tariq MahmoodNo ratings yet

- Punching Shear Resistance of SlabDocument8 pagesPunching Shear Resistance of SlablinkgreencoldNo ratings yet

- Behaviour and Strength of Composite Slabs With Ribbed DeckingDocument19 pagesBehaviour and Strength of Composite Slabs With Ribbed DeckingRoberval PimentaNo ratings yet

- Behavior of Concrete and Ecc Structures Under Simulated Earthquake MotionDocument49 pagesBehavior of Concrete and Ecc Structures Under Simulated Earthquake Motionsreejithp104No ratings yet

- Mechanical and Bond Properties of New Generation CFRP Reinforcing BarsDocument23 pagesMechanical and Bond Properties of New Generation CFRP Reinforcing BarsAhmed AjelNo ratings yet

- Ajassp 2017 436 446Document11 pagesAjassp 2017 436 446Prof. Dr. Adel Al-AzzawiNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Phy12 Exit Exam ReviewDocument9 pagesPhy12 Exit Exam ReviewAngelo Joshua De LeonNo ratings yet

- OSH Standards 2017Document422 pagesOSH Standards 2017Kap LackNo ratings yet

- Questions With Answers G3Document2 pagesQuestions With Answers G3Lemuel TeopeNo ratings yet

- SFTY 100 - Questions With AnswersDocument5 pagesSFTY 100 - Questions With AnswersLemuel TeopeNo ratings yet

- Chapter 3Document5 pagesChapter 3Lemuel TeopeNo ratings yet

- Lecture 1 Introduction To EstimatingDocument13 pagesLecture 1 Introduction To EstimatingLemuel TeopeNo ratings yet

- Analytic Geometry 3Document2 pagesAnalytic Geometry 3Lemuel TeopeNo ratings yet

- Physics Exit 8Document2 pagesPhysics Exit 8Lemuel TeopeNo ratings yet

- HW EssayDocument1 pageHW EssayLemuel TeopeNo ratings yet

- Physics Formula (Basic)Document12 pagesPhysics Formula (Basic)GaiusChrisA.EvaNo ratings yet

- CE Board Nov 2021 - Hydraulics - Set 8Document3 pagesCE Board Nov 2021 - Hydraulics - Set 8Lemuel Teope100% (1)

- Physics Exit 9Document3 pagesPhysics Exit 9Lemuel TeopeNo ratings yet

- Civil Engineering November 2021 Review Innovations Concrete 4 AnalysisDocument3 pagesCivil Engineering November 2021 Review Innovations Concrete 4 AnalysisLemuel TeopeNo ratings yet

- Steel Design 5 Nov 2021Document3 pagesSteel Design 5 Nov 2021Lemuel Teope100% (1)

- CE Board Nov 2021 - Hydraulics - Set 6Document2 pagesCE Board Nov 2021 - Hydraulics - Set 6Lemuel TeopeNo ratings yet

- Review Innovations Measures of Central Tendency FRACTILES: Percentiles, Deciles, and QuartilesDocument1 pageReview Innovations Measures of Central Tendency FRACTILES: Percentiles, Deciles, and QuartilesLemuel TeopeNo ratings yet

- SMAT1 - Simple Stress - 2 PDFDocument9 pagesSMAT1 - Simple Stress - 2 PDFLemuel TeopeNo ratings yet

- CE Board Nov 2021 - Engineering Mechanics - Set 2 SolutionDocument5 pagesCE Board Nov 2021 - Engineering Mechanics - Set 2 SolutionLemuel TeopeNo ratings yet

- CE Board Nov 2021 - Geotechnical Engineering - Set 5Document2 pagesCE Board Nov 2021 - Geotechnical Engineering - Set 5Lemuel TeopeNo ratings yet

- Solid Geometry 2Q2021Document31 pagesSolid Geometry 2Q2021Lemuel TeopeNo ratings yet

- Analytic Geometry 1Document2 pagesAnalytic Geometry 1Lemuel TeopeNo ratings yet

- SMAT4a - Mechanical Properties of MaterialsDocument6 pagesSMAT4a - Mechanical Properties of MaterialsLemuel TeopeNo ratings yet

- Graph of Trigo Functions by Engr. JuneDocument6 pagesGraph of Trigo Functions by Engr. JuneLemuel TeopeNo ratings yet

- SMAT4b - Simple StrainDocument4 pagesSMAT4b - Simple StrainLemuel TeopeNo ratings yet

- Reinforced Concrete Column DesignThe following provides a concise title for the given document:DOCUMENT REINFORCED CONCRETE COLUMN DESIGN PRINCIPLESDocument26 pagesReinforced Concrete Column DesignThe following provides a concise title for the given document:DOCUMENT REINFORCED CONCRETE COLUMN DESIGN PRINCIPLESJohn Cedric GarganeraNo ratings yet

- Algebra: Wednesday, 25 November 2020 9:01 AMDocument20 pagesAlgebra: Wednesday, 25 November 2020 9:01 AMLemuel TeopeNo ratings yet

- Plane Geometry: CE Correlation 1Document16 pagesPlane Geometry: CE Correlation 1Lemuel TeopeNo ratings yet

- Shear Stress and Bearing Stress ExamplesDocument7 pagesShear Stress and Bearing Stress ExamplesLemuel TeopeNo ratings yet

- Reinforced Concrete Column DesignThe following provides a concise title for the given document:DOCUMENT REINFORCED CONCRETE COLUMN DESIGN PRINCIPLESDocument26 pagesReinforced Concrete Column DesignThe following provides a concise title for the given document:DOCUMENT REINFORCED CONCRETE COLUMN DESIGN PRINCIPLESJohn Cedric GarganeraNo ratings yet

- Example 11 - One-Way Slab & SW InstructionsDocument9 pagesExample 11 - One-Way Slab & SW InstructionsLemuel TeopeNo ratings yet

- 3rd Quarter Mathematics Home Take Final Exam For Grade 10Document4 pages3rd Quarter Mathematics Home Take Final Exam For Grade 10John DejuNo ratings yet

- Multi-Hole Orifice CalculationDocument10 pagesMulti-Hole Orifice Calculationadrianrrcc100% (1)

- Maxwell's Equations ExplainedDocument347 pagesMaxwell's Equations ExplainedFabri ChevalierNo ratings yet

- Single Line SymbolsDocument26 pagesSingle Line SymbolsjoydeepNo ratings yet

- Sifat Bahan Pangan dan Hasil PertanianDocument39 pagesSifat Bahan Pangan dan Hasil PertanianStefanus Bayu Sindhu WijayaNo ratings yet

- Amp Question BankDocument14 pagesAmp Question BankdibyenindusNo ratings yet

- A Demonstration Lesson Plan Solutions and ColloidsDocument9 pagesA Demonstration Lesson Plan Solutions and ColloidsJenny Lynn dela Rosa100% (1)

- Design of Single Cylinder 4-Stroke Diesel EngineDocument10 pagesDesign of Single Cylinder 4-Stroke Diesel EngineNidishNo ratings yet

- CD Player State DiagramDocument14 pagesCD Player State DiagramCfhunSaatNo ratings yet

- Revamping Ammonia ConverterDocument5 pagesRevamping Ammonia ConverterHsein WangNo ratings yet

- XFOILDocument2 pagesXFOILbwwatsonNo ratings yet

- M.Sc. MATHEMATICS MODEL PAPERDocument22 pagesM.Sc. MATHEMATICS MODEL PAPERRatnesh RanjanNo ratings yet

- Accounting Management SystemDocument64 pagesAccounting Management Systemnilesh50% (2)

- Laguna Kosmetik MC1 PlusDocument2 pagesLaguna Kosmetik MC1 PlusLaguna Karaoke TarakanNo ratings yet

- The Van Der Pauw Method of Measurements in High-TcDocument12 pagesThe Van Der Pauw Method of Measurements in High-TcNolbert Renzo Umpire IncaNo ratings yet

- Geeks For Geeks - ArrayDocument33 pagesGeeks For Geeks - ArrayLove MehtaNo ratings yet

- Aashto Empirical Design MethodologyDocument76 pagesAashto Empirical Design MethodologyzainjoiyaNo ratings yet

- TARCOG Mathematical Models for Calculating Thermal Performance of Glazing SystemsDocument56 pagesTARCOG Mathematical Models for Calculating Thermal Performance of Glazing Systemsaaro_oraalNo ratings yet

- Shear Performance of Reinforced Expansive Concrete Beams Utilizing Aluminium WasteDocument16 pagesShear Performance of Reinforced Expansive Concrete Beams Utilizing Aluminium WasteShaker QaidiNo ratings yet

- Manual Aid 2Document136 pagesManual Aid 2Luis Chinchilla CruzNo ratings yet

- Genetic Change in EgyptDocument19 pagesGenetic Change in EgyptWesley MuhammadNo ratings yet

- MCCB - Disjuntores Modulados PVDocument67 pagesMCCB - Disjuntores Modulados PVJose mata IIINo ratings yet

- Three Dimensional Geometry - JEE Main 2023 January Chapter Wise Questions by MathonGoDocument43 pagesThree Dimensional Geometry - JEE Main 2023 January Chapter Wise Questions by MathonGoVansh ParasharNo ratings yet

- Activated Sludge Calculations With ExcelDocument22 pagesActivated Sludge Calculations With ExcelKaustav Patnaik88% (8)

- End Sem - Solution & Marking SchemeDocument41 pagesEnd Sem - Solution & Marking SchemeHaryanvi ChhoraNo ratings yet

- MOS-Construction of 132kv OHTL From Ad Darb To Looping PointDocument27 pagesMOS-Construction of 132kv OHTL From Ad Darb To Looping PointEngr Muhammad Azam ThaheemNo ratings yet

- IBM DB2 10.5 For Linux, UNIX, and Windows - Data Movement Utilities Guide and ReferenceDocument293 pagesIBM DB2 10.5 For Linux, UNIX, and Windows - Data Movement Utilities Guide and ReferenceBupBeChanhNo ratings yet

- IIT-JEE - 2020 - 2021: BY Referral CodeDocument31 pagesIIT-JEE - 2020 - 2021: BY Referral CodeBishwadeep RoyNo ratings yet

- Dimensions of The PantheonDocument3 pagesDimensions of The PantheonNerinel CoronadoNo ratings yet

- 80nva StatcomDocument1 page80nva StatcomIdriShh HaiNo ratings yet