Professional Documents

Culture Documents

Modeling and Control of 2-DOF Robot Arm: November 2018

Uploaded by

Lavinia CuldaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling and Control of 2-DOF Robot Arm: November 2018

Uploaded by

Lavinia CuldaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/348509388

Modeling and Control of 2-DOF Robot Arm

Article · November 2018

CITATIONS READS

0 85

2 authors:

Nasr Ghaleb Ayman A. Aly

Taif University Taif University

2 PUBLICATIONS 0 CITATIONS 89 PUBLICATIONS 837 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Artificial neural network model for evaluation of the plowing process performance View project

Artificial neural network models for depicting mass flow rate of R22, R407C and R410A through electronic expansion valves View project

All content following this page was uploaded by Nasr Ghaleb on 15 January 2021.

The user has requested enhancement of the downloaded file.

International Journal of Emerging Engineering Research and Technology

Volume 6, Issue 11, 2018, PP 24-31

ISSN 2349-4395 (Print) & ISSN 2349-4409 (Online)

Modeling and Control of 2-DOF Robot Arm

Nasr M. Ghaleb1 and Ayman A. Aly1, 2

1

Mechanical Engineering Department, College of Engineering, Taif University, PO Box 888, Taif,

Saudi Arabia

2

Mechanical Engineering Department, Faculty of Engineering, Assiut University, PO Box 71516,

Assiut, Egypt

*Corresponding Author: Nasr M. Ghaleb, Mechanical Engineering Department, College of

Engineering, Taif University, PO Box 888, Taif, Saudi Arabia

ABSTRACT

This paper presents a Modeling, Simulation and Control of a Two Degree of Freedom (2-DOF) robot

arm.This Work is taken from the Final Year capstone project. First The Robot specifications , Robot

Kinematics with Denavit-Hartenberg parameters (DH)for Forward kinematics and Inverse Kinematicsof 2-

DOF robot armwere presented. Then The dynamics of the 2-DOF robot arm was studied to derive the

equations of motion based on Eular-Lagrange Equation of motion. A Control Design was performed using

PID controller for the modeling and control Technique. The models has been done based on

Matlab/Simulink software.

Keywords: Robotics, 2-DOF Robot arm, Kinematic, Dynamic, PID Control and Modeling.

INTRODUCTION most of industrial processes. Most robot

manipulators found in industrial operations are

Robotics is defined practically as the study, controlled by PID algorithms independently at

design and use of robot systems for

each joint.

manufacturing and generally are used to

perform highly repetitive, unsafe, hazardous, There are many control techniques used for

and unpleasant tasks. Robotics many different controlling the robot arm.

functions that used either in industry and The most familiar control techniques are the

manufacture or in complex, clatter and changing PID control, adaptive control, optimal control

environment such as pick and place, assembly, and robust control. As the final goal is to design

drilling, welding, machine tool load and unload and manufacturing real robots, it's helpful doing

functions, painting, spraying, etc. or in A the simulation before the investigations with

delivery in a hospital and Hotels, Discovering real robots, to enhance the final real robot

the space As a results of these different tasks performance and behavior.

there are different robot arm configuration such

as rectangular, spherical, cylindrical, revolute ROBOT SPECIFICATION AND KINEMATICS

and prismatic jointed. Robot Specification

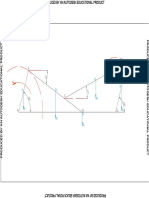

A pick and place robot arm is used to ease A two degree of freedom robot arm is described

process of moving materials and supplying the in Figure(1)

motion required in the manufacturing processes.

The transfer process of the materials is usually which consists primarily of two links with the

being accomplished, using man power and as following specifications in OXY coordinates:

the transfer process is repeated for a period of 𝐿1 = 1 m is the length of the first link.

time, it can cause injuries to the operator. the 𝐿2 = 1 m is the length of the second link.

robot arm preventing injuries and increasing the

efficiency of the work, with reducing the human 𝑚1 = 1 kg is the mass of the first link.

being errors that cost highly time and martial. 𝑚2 = 1 kg is the link of the second link.

The proportional-integral-derivative (PID) 𝜃1 = the rotation angel of the first link.

control has simple structure for its three gains.

𝜃2 = is the rotation angel of the second link.

The control performances are acceptable in the

International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018 24

Modeling and Control of 2-DOF Robot Arm

Robot Kinematics

Forward Kinematics

The Forward kinematics of a robotic arm is

determined a group of parameters called

Denavit-Hartenberg (DH) parameters which

used for deriving the homogenous

transformation matrices between the different

frames assigned on the robot arm structure. The

DH parameters for a two degree of freedom

robotic arm are defined as follows:

Figure 1. Two degree of freedom Robot Arm

Table 1. DH-parameters for the 2-DOF robotic arm

Link ai αi di 𝜽𝒊

1 L1 0 0 𝜃1

2 L2 0 0 𝜃2

The homogenous transformation matrices for the 2-DOF robotic arm shown in Figure(1) are derived

as follows:

cos 𝜃1 − sin 𝜃1 0 𝐿1 cos 𝜃1

𝟎 sin 𝜃1 cos 𝜃1 0 𝐿1 sin 𝜃1

𝟏𝑻 = (1)

0 0 1 0

0 0 0 1

cos 𝜃2 − sin 𝜃2 0 𝐿2 cos 𝜃2

𝟏 sin 𝜃2 cos 𝜃2 0 𝐿2 sin 𝜃2 (2)

𝟐𝑻 =

0 0 1 0

0 0 0 1

Using the Eq. (1) and (2), the homogenous transformation matrix 02𝑇can be derived as follows:

cos(𝜃1 + 𝜃2 ) − sin(𝜃1 + 𝜃2 ) 0 𝐿1 cos 𝜃1 + 𝐿2 cos(𝜃1 + 𝜃2 )

𝟎 sin(𝜃1 + 𝜃2 ) cos(𝜃1 + 𝜃2 ) 0 𝐿1 sin 𝜃1 + 𝐿2 sin(𝜃1 + 𝜃2 )

𝟐𝑻 = ( 3)

0 0 1 0

0 0 0 1

Therefore, can be derived either algebraically or

𝑛𝑥 𝑜𝑥 𝑎𝑥 𝑝𝑥 geometrically. The geometrical approach is

𝑹

𝑛𝑦 𝑜𝑦𝑎𝑦 𝑝𝑦 considered to be much easier for robot arms of

𝑯𝑻 = 𝑛𝑧 𝑜𝑧 𝑎𝑧 𝑝𝑧 (4) high degrees of freedom. In our Case, we solved

0 0 0 1 the inverse kinematics equations for the 2-DOF

𝟎 𝑹

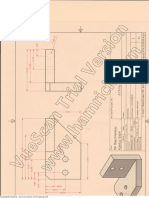

robotic arm shown in Figure(2) using the

𝟐𝑻 =𝑯 𝑻 (5) geometrical method.

From Eq. (5), the position coordinates of the

manipulator end-effector is given by:

𝑃𝑥 = 𝐿1 cos 𝜃1 + 𝐿2 cos(𝜃1 + 𝜃2 ) (6)

𝑃𝑦 = 𝐿1 sin 𝜃1 + 𝐿2 sin(𝜃1 + 𝜃2 ) (7)

And the end-effector's orientation matrix is

defined by the first three rows and three

columns of the transformation matrix in Eq.(3).

Inverse Kinematics

The inverse kinematics of a robotic arm is a

solution of finding the robot arm joint variables

of given the position Cartesian coordinates of Figure 2. Two degree of freedom Robot Arm Inverse

the end-effector. The mathematical equations Kinematic

used to solve the inverse kinematics problem From Figure2, a mathematical equation for

25 International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018

Modeling and Control of 2-DOF Robot Arm

solving the elbow joint angle 𝜽2 can be derived arm: Eular-Lagrange method and Newten-Eular

using Pythagoras theorem as follows: method. in this work , We used the Eular-

Lagrange method which depends on calculating

𝑝𝑥 2 + 𝑝𝑦 2 = 𝐿1 2 + 𝐿2 2 + 2𝐿1 𝐿2 cosθ2 (8) the total Kineatic and Potential Energies of the

1 robot arm to determine the Lagrangian (ℒ) of

cosθ2 = (𝑝𝑥 2 + 𝑝𝑦 2 − 𝐿1 2 − 𝐿2 2 ) (9)

2𝐿1 𝐿2 the whole system in order to calculate the force

or torque applied of each joint.With the

sinθ2 = ± 1 − cosθ2 2 (10) Lagrangianℒ, we can solve the Euler- Lagrange

equation which relies on the partial derivative of

Therefore, kinetic and potential energy properties of

sin θ2 mechanical systems to compute the equations of

𝜃2 = ± 𝑎𝑡𝑎𝑛 (11)

cos θ2 motion and is defined as follow:

For The joint variable 𝜃1 : 𝑑 𝜕ℒ 𝜕ℒ

F= − (21)

𝑑𝑡 𝜕 𝜃 𝜕𝜃

𝑝𝑥 = (𝐿1 + 𝐿2 cosθ2 ) cosθ1 − 𝐿2 sinθ1 sinθ2 (12)

where F is the external force acting on the

𝑝𝑦 = 𝐿2 sinθ2 cosθ1 + (𝐿1 + 𝐿2 cosθ2 )sinθ1 (13)

generalized coordinate, represents the torque

𝐿1 + 𝐿2 cosθ2 −𝐿2 sinθ2 applied to therobot and ℒ is the Lagrangian

∆= (14)

𝐿2 sinθ2 𝐿1 + 𝐿2 cosθ2 equation of the motion, given in Eq.(22)

𝑝𝑥 2 + 𝑝𝑦 2 = (𝐿1 + 𝐿2 cosθ2 )2 + (𝐿2 sinθ2 )2 (15) ℒ 𝑞 𝑡 ,𝑞 𝑡 = 𝐾𝐸 𝑞 𝑡 , 𝑞 𝑡 − 𝑃𝐸 𝑞 𝑡 (22)

𝐿1 + 𝐿2 cosθ2 𝑝𝑥 To solve the Lagrangian Eq.(22),we need first to

∆sinθ1 = (16)

𝐿2 sinθ2 𝑝𝑦 calculate the kinetic Energy 𝐾𝐸 and potential

Energy 𝑃𝐸 as follow:

𝑝𝑥 −𝐿2 sinθ2

∆cosθ1 = (17) 1

𝑝𝑦 𝐿1 + 𝐿2 cosθ2 𝐾𝐸 = 𝑚𝑥 2

2

∆sin θ1 𝐿1 +𝐿2 cos θ2 𝑝 𝑦 −𝐿2 sin θ2 𝑝 𝑥

sinθ1 = = (18) 𝑃𝐸 = 𝑚𝑔𝑙

∆ 𝑃𝑥 2 +𝑝 𝑦 2

∆cos θ1 𝐿1 +𝐿2 cos θ2 𝑝 𝑥 +𝐿2 sin θ2 𝑝 𝑦 The velocity is determined by taking the

cosθ1 = = (19) derivative of the position respect to time. so the

∆ 𝑝 𝑥 2 +𝑝 𝑦 2

position in the end of the link is known using

sin θ1 𝐿1 +𝐿2 cos θ2 𝑝 𝑦 ±𝐿2 sin θ2 𝑝 𝑥

𝜃1 =𝑎𝑡𝑎𝑛 = 𝑎𝑡𝑎𝑛 (20) known familiar variables :

cos θ1 𝐿1 +𝐿2 cos θ2 𝑝 𝑥 ±𝐿2 sin θ2 𝑝 𝑦

𝑥1 = 𝐿1 𝑠𝑖𝑛𝜃1

ROBOT DYNAMICS

𝑦1 = 𝐿1 cos 𝜃1

The dynamic model of a robot is concerned with

the movement and the forces involved in the 𝑥2 = 𝐿1 𝑠𝑖𝑛𝜃1 + 𝐿2 sin

(𝜃1 + 𝜃2 ) (23)

robot arm and establishes a mathematical

𝑦2 = 𝐿1 cos 𝜃1 + 𝐿2 cos(𝜃1 + 𝜃2 )

relationship between the location of the robot

joint variables and the dimensional parameters Then substitute in the kinetic's energy equation:

of the robot. There are two methods for 1 1 1 1

𝐾𝐸 = 𝑚1 𝑥1 2 + 𝑚1 𝑦1 2 + 𝑚2 𝑥2 2 + 𝑚2 𝑦2 2 (24)

performing the dynamics equations of a robot 2 2 2 2

After simplification,

1 2 1 2 1 2 2

𝐾𝐸 = (𝑚1 + 𝑚2 )𝑙1 2 𝜃1 + 𝑚2 𝑙1 2 𝜃1 + 𝑚2 𝑙2 2 𝜃1 𝜃2 + 𝑚2 𝑙2 2 𝜃2 + 𝑚2 𝑙1 𝑙2 𝑐𝑜𝑠𝜃2 𝜃1 𝜃2 + 𝜃1 (25)

2 2 2

The Potential energy equation is defined as:

𝑃𝐸 = 𝑚1 𝑔𝑙1 cos 𝜃1 + 𝑚2 𝑔(𝑙1 cos 𝜃1 + 𝑙2 𝑐𝑜𝑠(𝜃1 + 𝜃2 )) (26)

Substitute Eq.(25) and(26) in Eq.(21) to form the lagrangian equation as:

1 2 1 2 1 2 2

ℒ = (𝑚1 + 𝑚2 )𝑙1 2 𝜃1 + 𝑚2 𝑙1 2 𝜃1 + 𝑚2 𝑙2 2 𝜃1 𝜃2 + 𝑚2 𝑙2 2 𝜃2 + 𝑚2 𝑙1 𝑙2 𝑐𝑜𝑠𝜃2 𝜃1 𝜃2 + 𝜃1 −

2 2 2

𝑚1 𝑔𝑙1 cos 𝜃1 + 𝑚2 𝑔 𝑙1 cos 𝜃1 + 𝑙2 𝑐𝑜𝑠 𝜃1 + 𝜃2 (27)

To calculate the force applied to the robot, we form the Lagrange-EularEq.(21)with the Lagrangian(ℒ)

𝑑 𝜕ℒ 𝜕ℒ

Fθ1,2 = −

𝑑𝑡 𝜕 𝜃 𝜕𝜃1,2

1,2

International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018 26

Modeling and Control of 2-DOF Robot Arm

After simplification, the force applied at joint 1is given by

𝐹𝜃1 =

𝑚1 + 𝑚2 𝑙1 2 + 𝑚2 𝑙2 2 + 2𝑚2 𝑙1 𝑙2 cos 𝜃2 ) θ1 + 𝑚2 𝑙2 2 − 𝑚2 𝑙1 𝑙2 cos 𝜃2 θ2 −

2

𝑚2 𝑙1 𝑙2 sin 𝜃2 ( 2𝜃1 𝜃2 + 𝜃2 ) − 𝑚1 + 𝑚2 l1 gsinθ1 − 𝑚2 𝑙2 𝑔𝑠𝑖𝑛(𝜃1 + 𝜃2 ) (28)

and the force applied at joint 2 is given by

𝐹𝜃2 = (𝑚2 𝑙2 2 + 𝑚2 𝑙1 𝑙2 cos 𝜃2 )θ1 + 𝑚2 𝑙2 2 θ2 − 𝑚2 𝑙1 𝑙2 sin 𝜃2 𝜃1 𝜃2 − 𝑚2 𝑙2 𝑔𝑠𝑖𝑛(𝜃1 + 𝜃2 ) (29)

The motion of the systemis given by the following formof a nonlinear equation:

𝐹 = 𝐵 𝑞 + 𝐶 𝑞, 𝑞 + 𝑔 𝑞 (30)

where,

F θ1

𝐹=

F θ2

( 𝑚1 + 𝑚2 𝑙1 2 + 𝑚2 𝑙2 2 + 2𝑚2 𝑙1 𝑙2 cos 𝜃2 ) (𝑚2 𝑙2 2 − 𝑚2 𝑙1 𝑙2 cos 𝜃2 )

𝐵 𝑞 =

𝑚2 𝑙2 2 + 𝑚2 𝑙1 𝑙2 cos 𝜃2 𝑚2 𝑙2

2

− 𝑚2 𝑙1 𝑙2 sin 𝜃2 ( 2𝜃1 𝜃2 + 𝜃2 )

𝐶 𝑞, 𝑞 =

− 𝑚2 𝑙1 𝑙2 sin 𝜃2 𝜃1 𝜃2

− 𝑚1 + 𝑚2 l1 gsinθ1 − 𝑚2 𝑙2 𝑔𝑠𝑖𝑛(𝜃1 + 𝜃2 ) )

𝑔 𝑞 =

−𝑚2 𝑙2 𝑔𝑠𝑖𝑛(𝜃1 + 𝜃2 )

θ1

𝑞=

θ2

1

MATHEMATICAL MODELING OF ACTUATING 𝜔 𝑠 = 𝐾𝑡 ∗ 𝐼𝑎 𝑠 ∗ (32)

(𝐽 𝑚 𝑠+𝑏𝑚 )

SYSTEM

The PMDC motor Transfer Function is derived,

The Permanent Magnet Direct Current PMDC Subtituting the electrical part characteristics

motor is used to actaute the system, which has Eq.(44) in Eq.(45), gives Eq.(46):

an Electrical part and a Mechanical part, as seen

1

in Eq.(44) and Eq.(45), Describing the Electrical 𝐾𝑡

𝐿𝑎 𝑠+𝑅𝑎

[𝑉𝑖𝑛 (𝑠) − 𝐾𝑏 𝜔𝑚 ] = 𝐽𝑚 𝑠𝜔 + 𝑏𝑚 𝜔 (33)

and Mechanical characteristics of PMDC motor,

respectively, Using Newton's law, Kirchhoff’s Rearranging Eq.(46), The PMDC motor open

law and Ohm’s law. loop transfer function is obtained, given by

1

Eq.(47), This equation shows that the PMDC

[𝑉𝑖𝑛 (𝑠) − 𝐾𝑏 𝜔𝑚 ] ∗ = 𝐼𝑎 𝑠 (31) motor is a second order system.

𝐿𝑎 𝑠+𝑅𝑎

(s ) Kt

G speed (s ) (34)

V in (s ) (La J m )s (R a J m bm La )s (R abm K t K b )

2

PIDCONTROLLER DESIGN where𝑒 = qd − q , qd is desired joint angle, Kp,

The nonlinear equation that are derived from Ki and Kd are proportional, integral and

Euler-Lagrange Eq. (30), where inputvariable F derivative gains of the PID controller,

which represents the torque applied to the robot respectively. This PID control law can be

is unknown, so it's requires a control in the expressed via the following equations.

Force applied of the joints to reach the final 𝐹 = 𝐾𝑃 𝑒 + 𝐾𝐷 𝑒 + 𝜉 (36)

position.In our case, we use the classical linear

PID, Particularly we need Two PID controls 𝜉 = 𝐾𝐼 𝑒 ; 𝜉 0 = 𝜉0

since the first arm motion is dependent from the where 𝜉 represents the additional state variable

second arm motion. In fact, still having a strong that is the integral action of the PID control law

interaction between the two arms. The classical formed and it's time derivative is 𝜉 = 𝐾𝐼 𝑒. The

linear PID law is performed; closed-loop equation is obtained by substituting

𝐹 = 𝐾𝑃 𝑒 + 𝐾𝐷 𝑒 + 𝐾𝐼 𝑒 𝑑𝑡 (35) the control action F from Eq.(32) into the robot

model Eq.(30), gives:

27 International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018

Modeling and Control of 2-DOF Robot Arm

𝐵 𝑞 + 𝐶 𝑞 , 𝑞 + 𝑔 𝑞 = 𝐾𝑃 𝑒 + 𝐾𝐷 𝑒 + 𝜉 (37) −π 2

θo = π

From the system'smodel Eq.(30), we can have 2

𝑞 = 𝐵(𝑞)−1 −𝐶 𝑞 , 𝑞 − 𝑔 𝑞 +𝐹 (38) so, in our case:

with 𝑓1 = 𝐾𝑃1 θ1𝑓 − θ1 + 𝐾𝐷1 𝜃1 + 𝐾𝐼1 𝑒(𝜃1 ) 𝑑𝑡

−1 𝑓2 = 𝐾𝑃2 θ2𝑓 − θ2 + 𝐾𝐷2 𝜃2 + 𝐾𝐼2 𝑒(𝜃2 ) 𝑑𝑡

𝐹=𝐵 𝑞 𝐹 ⇔ 𝐹=𝐵 𝑞 𝐹 (39)

so, we decoupled the system to have the new However, the complete system equations with

(non-physical)input control would be

𝑓 𝑞 = 𝐵(𝑞)−1 −𝐶 𝑞 , 𝑞 − 𝑔 𝑞 +𝐹 (43)

𝐹= 1 (40)

𝑓2 with

however, the physical torque inputs to the 𝑓1 𝐾𝑃1 θ1𝑓 − θ1 + 𝐾𝐷1 𝜃1 + 𝐾𝐼1 𝑒 𝜃1 𝑑𝑡

𝐹= = (44)

system are 𝑓2 𝐾𝑃2 θ2𝑓 − θ2 + 𝐾𝐷2 𝜃2 + 𝐾𝐼2 𝑒 𝜃2 𝑑𝑡

𝑓θ1 𝑓 recalling the physical actual torques

=𝐵 𝑞 1 (41)

𝑓θ2 𝑓2

𝐹θ1 𝑓

=𝐵 𝑞 1 (45)

The error signals of the system are 𝐹θ2 𝑓2

e θ1 = θ1𝑓 − θ1 RecallingEq.(32) and Eq.(38), gives:

e θ2 = θ2𝑓 − θ2 (42)

𝜉1 = 𝐾𝐼1 𝑒 𝜃1 𝑑𝑡 ⇔ 𝜉1 = 𝐾𝐼1 𝑒1

where θ𝑓 is the final positions. The final

position is given by 𝜉2 = 𝐾𝐼2 𝑒 𝜃2 𝑑𝑡 ⇔ 𝜉2 = 𝐾𝐼2 𝑒2 (46)

θ1𝑓 π So, the system equations are

= −π2

θ2𝑓 𝜉1 = 𝐾𝐼1 𝑒1

2

and the initial position is given by 𝜉2 = 𝐾𝐼2 𝑒2

θ1 𝐾𝑃1 θ1𝑓 − θ1 + 𝐾𝐷1 𝜃1 + 𝜉1

= 𝐵(𝑞)−1 −𝐶 𝑞 , 𝑞 − 𝑔 𝑞 + (47)

θ2 𝐾𝑃2 θ2𝑓 − θ2 + 𝐾𝐷2 𝜃2 + 𝜉2

SIMULATION AND RESULTS

Approximate mathematical models can be

obtained and then simulated in combination

with the designed control law, for providing a

more realistic validation of the system behavior

and control performance. First we made a

mathematical model of the PMDC motor to

determine the transfer function and then start the

simulation of the actuator system without

controller using MATLAB /Simulink as shown

in Figure (3)to study the system performance Figure3. Step Response of PMDC without controller.

and then improving the design by adding PID

Controller as shown in Figure(4)and(5) for a

more realistic validation of the system

performance.

The system reaches steady state value of 0.778

rad/s in 1.27 s, with small overshoot and the

system response is very fast as shown in

Figure(3), so we need to add controller to

improve the system behavior. PID controller

simulinkis built to control the angular speed at a

desired set point value (𝐾𝑎,𝑡 = 1)and improving

the system performance as illustrate in Figure4. Figure 4. Simulink model of the actuator

system(PMDC).

International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018 28

Modeling and Control of 2-DOF Robot Arm

We have noticed from Figure(5) and (6) that the After tuning by trial and error we got with the

system is second order system (Under damped) PID controller values :kp=40, ki=13,kd=5for the

and the values of the controller are getting with best performance, Also we have noticed from

PID tuning by trial and error with system Figure(8) that the position error reaches at a

characteristicsvalues for the best performance considerable time to zero steady-state of

and behavior:𝐾𝑝 =13, 𝐾𝑖 =39, 𝐾𝑑 =1.056, OS (%) constant input.

< 5, settling time < 2 sec, steady-state error <1%

and 𝐾𝐷𝐶 = 1.

Figure8. The position error.

Figure 5. System characteristics(With PID controller The force or torque applied can be shown in

tuning). Figure(9) is zero at steady state.

Figure6. Step response of the system with PID

controller.

Then we have built and studied the steady state

dynamic model with PID control of single link

by MATLAB simulation as illustrate in Figure 9. The torque error.

Figure(7). Then we have studied the two degree of

freedom with PID control as a whole system by

trial and error,

The PID parameters are manually tuned to get

the best performance of the system. The best

behavior and performance of the controller

parameters values are as follows :

𝐾𝑝1 = 250 𝐾𝑝2 = 250

𝐾𝑖1 = 200 𝐾𝑖2 = 200

𝐾𝑑1 = 30 𝐾𝑑2 = 30

By our approach trial and error, we have noticed

that 𝐾𝑝1 is related to direct error and to speed of

Figure7. PID Controller of One Single Link. evolution, 𝐾𝑝1 is related to speed of interaction

29 International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018

Modeling and Control of 2-DOF Robot Arm

with change in states and 𝐾𝑝1 is related to By the experiment, we got that the slightest

overall error cancellation. change in the controller parameters yields more

overshoots and oscillations due to highly

We have seen in the Figures (10) and (11) that sensitive to initial and final positions.

the position error reaches zero at a reasonably

fast time.

Figure13. Torque of Theta 1.

Figure10. Theta 1 error. CONCLUSION

The main topic of this paper is modeling,

simulation and control of two degree of freedom

robot arm.

The mathematical models of the actuator and

whole system are illustrated. Lagrangian and

Euler-Lagrange used to derive a dynamic model

that simulated the actual robot movement in real

life and obtain sufficient control over the robot

joint positions. The system was controlled in

order to reach a desired joint angle position

through simulation of PID controllers using

MATLAB/Simulink.

Also, the result showed that a slight changes in

initial joint angle positions of the robot arm

Figure11. Theta 2 error. resulted in different desired joint angle positions

and this necessitated that the gains of the PID

controllers need to be adjusted and turned at

every instant in order to prevent overshoot and

oscillation that associated with the change in

parameters values.

REFERENCES

[1] S. H. M. V. Mark W. Spong, Robot Modeling

and Control, WILEY, December 2005.

[2] N.Jazar, R. (2010). Theory of Applied

Robotics.

[3] Okubanjo, A. A., Modeling of 2-DOF Robot

Arm and Control. (FUTOJNLS, Volume-3 ,

December 2017 .

[4] David I. Robles G., PID control dynamics of a

Figure12. Torque of Theta 1. robotic arm manipulator with two degrees of

freedom, August 17, 2012.

And from Figures (12) and (13), we have seen [5] KhalilIbrahim, Ayman A. Aly and Ahmed Abo.

the force or torque applied slight overshot and Ismail ,”Position Control of A Single Flexible

quickly stabilize. Arm”, International Journal of Control,

International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018 30

Modeling and Control of 2-DOF Robot Arm

Automation and Systems, (IJCAS), Vol.2, Simulation and Control of 2-R Robot. Global

No.1, pp.12-18, 2013 Journal of Researches in Engineering, Volume

[6] Aalim M. Mustafa & A AL-SAIF, Modeling, 14, 2014.

Citation: Nasr M. Ghaleb and Ayman A. Aly, "Modeling and Control of 2-DOF Robot Arm", International

Journal of Emerging Engineering Research and Technology, 6(10), pp.24-31

Copyright: © 2018 Nasr M. Ghaleb. This is an open-access article distributed under the terms of the

Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in

any medium, provided the original author and source are credited.

31 International Journal of Emerging Engineering Research and Technology V6 ● I11 ● 2018

View publication stats

You might also like

- Gryphon EC Final ReportDocument12 pagesGryphon EC Final Reportsanjiv0909No ratings yet

- Robótica 1-3 Fotos2Document121 pagesRobótica 1-3 Fotos2Jesús Esquivel50% (2)

- Stair Climbing Wheel ChairDocument4 pagesStair Climbing Wheel ChairMukesh KhairnarNo ratings yet

- PID Controller With Feedforward Low Pass Filters For Permanent Magnet Stepper MotorsDocument4 pagesPID Controller With Feedforward Low Pass Filters For Permanent Magnet Stepper Motorsprateek agarwalNo ratings yet

- PID Control Dynamics of A Robotic Arm Manipulator PDFDocument7 pagesPID Control Dynamics of A Robotic Arm Manipulator PDFMourad KattassNo ratings yet

- Control System Design For An Autonomous Mobile Robot: Sathish K ShanmugasundaramDocument36 pagesControl System Design For An Autonomous Mobile Robot: Sathish K Shanmugasundaramteknikpembakaran2013No ratings yet

- Damping Hibrid Stepper MotorDocument8 pagesDamping Hibrid Stepper MotorMake_PicNo ratings yet

- Ambuj Gupta : I. D. No. 46671 ObjectiveDocument1 pageAmbuj Gupta : I. D. No. 46671 ObjectiveAmbujNo ratings yet

- PDFDocument24 pagesPDFOlga Joy Labajo GerastaNo ratings yet

- Abstract. The Balancing of An Inverted Pendulum byDocument5 pagesAbstract. The Balancing of An Inverted Pendulum byFariz AhdiatamaNo ratings yet

- Robust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton RobotDocument6 pagesRobust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton Robotabdelhamid.ghoul93No ratings yet

- High Gain ObserverDocument21 pagesHigh Gain ObserverGopakumarKodakkallingalNo ratings yet

- MechatronicsDocument1 pageMechatronicsHemant ModiNo ratings yet

- Self Balancing Inverted Pendulum Robot Shay Sackett S Project PortfolioDocument34 pagesSelf Balancing Inverted Pendulum Robot Shay Sackett S Project PortfolioAlejandro Nuñez VelasquezNo ratings yet

- 5.control of Manipulator by CPM2 Series PLCDocument5 pages5.control of Manipulator by CPM2 Series PLCIlija Petkovic0% (1)

- 00 Robotics F16MTE PLO CLO IntroductionDocument14 pages00 Robotics F16MTE PLO CLO IntroductionasadNo ratings yet

- Sliding Mode Observers Tutorial PDFDocument3 pagesSliding Mode Observers Tutorial PDFVicente Borja JaimesNo ratings yet

- Mechatronics (2015) Unit IIDocument38 pagesMechatronics (2015) Unit IIkishan100% (1)

- Chapter 2Document19 pagesChapter 2Aung ThikeNo ratings yet

- A Review of Models and Structures For Wheeled Mobile Robots - Four Case StudiesDocument6 pagesA Review of Models and Structures For Wheeled Mobile Robots - Four Case StudiesThanh NguyenNo ratings yet

- Application of A PID Controller in A Speed Control of A CarDocument11 pagesApplication of A PID Controller in A Speed Control of A CarAtchyuth SontiNo ratings yet

- Robotics: Dynamic Model of ManipulatorsDocument20 pagesRobotics: Dynamic Model of ManipulatorsbalkyderNo ratings yet

- Ofwacoustics PDFDocument41 pagesOfwacoustics PDFMike BrynerNo ratings yet

- Adaptive ControlDocument27 pagesAdaptive ControlmettayugeshreddyNo ratings yet

- Inverted Pendulum On Cart SolutionDocument8 pagesInverted Pendulum On Cart SolutionMario R. KallabNo ratings yet

- Manual Yalmip ResumenDocument15 pagesManual Yalmip ResumenSebastián Geerling GamboaNo ratings yet

- B.E. / B.Tech Degree Examinations April / May 2021 Mechatronics EngineeringDocument2 pagesB.E. / B.Tech Degree Examinations April / May 2021 Mechatronics EngineeringAravinthNo ratings yet

- ICARCV 2010 Conference GuideDocument154 pagesICARCV 2010 Conference GuidekamleshyadavmoneyNo ratings yet

- Inverted PendulamDocument34 pagesInverted PendulamVi JayNo ratings yet

- Basu-Fem Notes Me623Document210 pagesBasu-Fem Notes Me623Subhradeep ChatterjeeNo ratings yet

- HW #3 Book ProblemsDocument5 pagesHW #3 Book Problemsjackalscream910% (1)

- Project Report Hexapod RobotDocument3 pagesProject Report Hexapod RobotJunaid JahangirNo ratings yet

- Stepper Motor PDFDocument49 pagesStepper Motor PDFP HAMSA DATTANo ratings yet

- IAT0922 Industrial Robotics Chapter2 Rev4Document79 pagesIAT0922 Industrial Robotics Chapter2 Rev4visionNo ratings yet

- ScaraDocument7 pagesScaraAnand Kumar MishraNo ratings yet

- Direct KinematicsDocument66 pagesDirect KinematicsMateen Qadri100% (2)

- An Intelligent Line-Following Robot Project For Introductory Robot CoursesDocument7 pagesAn Intelligent Line-Following Robot Project For Introductory Robot CoursesAmla SingNo ratings yet

- PIC16F877 and CCS-C LanguageDocument83 pagesPIC16F877 and CCS-C Language1726giangNo ratings yet

- MPMC Unit-1-Part-B PDFDocument23 pagesMPMC Unit-1-Part-B PDFSasi BhushanNo ratings yet

- LTCC and HTCC PDFDocument3 pagesLTCC and HTCC PDFPhan Xuân TuấnNo ratings yet

- My Thesis BOOKDocument7 pagesMy Thesis BOOKjaaduuNo ratings yet

- Balancing RobotDocument5 pagesBalancing RobotMilton MuñozNo ratings yet

- Mathematical Modelling of Linear Induction MotorDocument4 pagesMathematical Modelling of Linear Induction MotorNasser100% (1)

- LAB1 Report FileDocument4 pagesLAB1 Report FiletawandaNo ratings yet

- Lab BalanceDocument1 pageLab BalancephuceltnNo ratings yet

- Chapter 3 PG MetrologyDocument3 pagesChapter 3 PG MetrologyramptechNo ratings yet

- Passivity Based ControlDocument25 pagesPassivity Based ControlRan HaoNo ratings yet

- Walking Trajectory Control of A Biped RobotDocument18 pagesWalking Trajectory Control of A Biped RobotBogdan PopNo ratings yet

- SEC Mechatronics Lab Manual R2013 Shan PDFDocument93 pagesSEC Mechatronics Lab Manual R2013 Shan PDFMonish KumarNo ratings yet

- Robo3 2Document336 pagesRobo3 2Debabrata PaulNo ratings yet

- Introduction To Robot SoccerDocument94 pagesIntroduction To Robot Soccerdek0ne100% (1)

- Micro MouseDocument17 pagesMicro MouseFarshad yazdiNo ratings yet

- Kinematics Modeling and Analyses of Articulated Rovers PDFDocument15 pagesKinematics Modeling and Analyses of Articulated Rovers PDFalokNo ratings yet

- Differential Transformation Method for Mechanical Engineering ProblemsFrom EverandDifferential Transformation Method for Mechanical Engineering ProblemsNo ratings yet

- Modeling and Control of 2-DOF Robot ArmDocument8 pagesModeling and Control of 2-DOF Robot ArmOtter OttersNo ratings yet

- E6E3E5E4CFDocument10 pagesE6E3E5E4CFSanket ChaudharyNo ratings yet

- Kinematics Modeling of A 4-DOF Robotic Arm: 2015 International Conference On Control, Automation and RoboticsDocument5 pagesKinematics Modeling of A 4-DOF Robotic Arm: 2015 International Conference On Control, Automation and Roboticsanon_731929628No ratings yet

- Modelling and Simulation of 5 DOFDocument6 pagesModelling and Simulation of 5 DOFaditdharkarNo ratings yet

- Kinematics Analysis and Workspace Calculation of A 3-DOF ManipulatorDocument10 pagesKinematics Analysis and Workspace Calculation of A 3-DOF ManipulatorkranthiNo ratings yet

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- LEGO-based Robotics in Higher Education: 15 Years of Student CreativityDocument15 pagesLEGO-based Robotics in Higher Education: 15 Years of Student CreativityLavinia CuldaNo ratings yet

- 8 NR 8 13 VasilescuDocument4 pages8 NR 8 13 VasilescuLavinia CuldaNo ratings yet

- 015 MANUELA AVADANEI - Industria Textila 5 - 2020Document9 pages015 MANUELA AVADANEI - Industria Textila 5 - 2020Lavinia CuldaNo ratings yet

- 5-Nr 1-2019 Lucrarea 5 Lucrare - Alin PopDocument5 pages5-Nr 1-2019 Lucrarea 5 Lucrare - Alin PopLavinia CuldaNo ratings yet

- 9 - Gheorghe PopDocument6 pages9 - Gheorghe PopLavinia CuldaNo ratings yet

- 13 - Moisescu R - Titu A M 19.01Document8 pages13 - Moisescu R - Titu A M 19.01Lavinia CuldaNo ratings yet

- Modeling and Control of 2-DOF Robot Arm: November 2018Document9 pagesModeling and Control of 2-DOF Robot Arm: November 2018Lavinia CuldaNo ratings yet

- Analysis of The Industry 4.0 Key Elements and Technologies Implementation in The Festo Didactic Educational Systems MPS 203 I4.0Document14 pagesAnalysis of The Industry 4.0 Key Elements and Technologies Implementation in The Festo Didactic Educational Systems MPS 203 I4.0Lavinia CuldaNo ratings yet

- Produced by An Autodesk Educational Product: C C C CDocument1 pageProduced by An Autodesk Educational Product: C C C CLavinia CuldaNo ratings yet

- Elementul 4 PDFDocument1 pageElementul 4 PDFLavinia CuldaNo ratings yet

- Elementul 2 PDFDocument1 pageElementul 2 PDFLavinia CuldaNo ratings yet

- PT 4Document1 pagePT 4Lavinia CuldaNo ratings yet

- Elementul 1 PDFDocument1 pageElementul 1 PDFLavinia CuldaNo ratings yet

- Elementul 5 PDFDocument1 pageElementul 5 PDFLavinia CuldaNo ratings yet

- Laborator 1 PDFDocument1 pageLaborator 1 PDFLavinia CuldaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductLavinia CuldaNo ratings yet

- PT 2Document1 pagePT 2Lavinia CuldaNo ratings yet

- Piesa2 PDFDocument1 pagePiesa2 PDFLavinia CuldaNo ratings yet

- Piesa1 PDFDocument1 pagePiesa1 PDFLavinia CuldaNo ratings yet

- PT 3Document1 pagePT 3Lavinia CuldaNo ratings yet

- PT 5Document1 pagePT 5Lavinia CuldaNo ratings yet

- Piesa2 PDFDocument1 pagePiesa2 PDFLavinia CuldaNo ratings yet

- PT 1Document1 pagePT 1Lavinia CuldaNo ratings yet

- BHBPgmplatz enDocument48 pagesBHBPgmplatz enLavinia CuldaNo ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- Piesa1 PDFDocument1 pagePiesa1 PDFLavinia CuldaNo ratings yet

- Department of Mechanical Engineering, Amity School of Engineering Technology Amity University Uttar PradeshDocument12 pagesDepartment of Mechanical Engineering, Amity School of Engineering Technology Amity University Uttar PradeshPRASENJIT MUKHERJEENo ratings yet

- An Accurate Full Car Ride Model Using Model Reducing TechniquesDocument9 pagesAn Accurate Full Car Ride Model Using Model Reducing TechniquesSandor CleganeNo ratings yet

- PPTDocument49 pagesPPTyunimulia100% (1)

- Planar Kinematics of A Rigid BodyDocument13 pagesPlanar Kinematics of A Rigid BodyMagicWand2No ratings yet

- Development of Lightweight SteelDocument6 pagesDevelopment of Lightweight SteelJA55EENo ratings yet

- Dynamics of Rigid BodiesDocument14 pagesDynamics of Rigid BodiesFelichi Dacumos BalajadiaNo ratings yet

- Seismic Performance of Spherical Liquid Storage TanksDocument10 pagesSeismic Performance of Spherical Liquid Storage TanksALONSO GOMEZNo ratings yet

- Mode Convert For The RF Cold TestDocument4 pagesMode Convert For The RF Cold TestNarayan KarkiNo ratings yet

- Iv. Shear and Diagonal Tension in Beams: CHAPTER 6, Sections 1-3, 5Document8 pagesIv. Shear and Diagonal Tension in Beams: CHAPTER 6, Sections 1-3, 5BELAL ALSUBARINo ratings yet

- Fluid Friction in Pipes Laboratory ReportDocument6 pagesFluid Friction in Pipes Laboratory ReportABamishe0% (1)

- L1 - Heat and Mass TransferDocument13 pagesL1 - Heat and Mass Transfershamiul himelNo ratings yet

- Eurocode 7 Section 7 Pile FoundationsDocument20 pagesEurocode 7 Section 7 Pile FoundationsHoNo ratings yet

- Wa0010 PDFDocument8 pagesWa0010 PDFAnita PuspitasariNo ratings yet

- 5b864940926b0BSCBAMATH PDFDocument76 pages5b864940926b0BSCBAMATH PDFRishabh KaliaNo ratings yet

- Materials Science With AnswersDocument3 pagesMaterials Science With AnswersAhmed HashkarNo ratings yet

- Circular Motion ReviewDocument10 pagesCircular Motion ReviewKimberley OrozcoNo ratings yet

- Momentum Assignment Class 9Document4 pagesMomentum Assignment Class 9Apex Institute0% (1)

- Sphere Penetration Into GelatinDocument8 pagesSphere Penetration Into GelatinRhonda BushNo ratings yet

- Manual For Flow ControlDocument4 pagesManual For Flow ControlReeve Tang CsvNo ratings yet

- ForcesDocument4 pagesForcesAlizeh ShoaibNo ratings yet

- 3PNT L2Document34 pages3PNT L2arun aryaNo ratings yet

- CEE4476B Assignment 2Document2 pagesCEE4476B Assignment 2Karla Isabel Salgado SánchezNo ratings yet

- Week 3 - Bernoulli EquationDocument4 pagesWeek 3 - Bernoulli EquationWahedaNo ratings yet

- CIVL311 - CIVL 911 - 2020 - Week 5 - Design of Columns and Walls - 4 PDFDocument21 pagesCIVL311 - CIVL 911 - 2020 - Week 5 - Design of Columns and Walls - 4 PDFBurhan AhmadNo ratings yet

- Metamaterial ArticleDocument6 pagesMetamaterial ArticleThành LạNo ratings yet

- Astm D790-15Document12 pagesAstm D790-15Leonardo Boa Sorte100% (2)

- Schureman 1924 Manual of Harmonic Analysis and Prediction TidesDocument331 pagesSchureman 1924 Manual of Harmonic Analysis and Prediction TidesGustavo Gomes100% (1)

- KineticTheoryandTransportPhenomena RodrigoSoto ContentsDocument7 pagesKineticTheoryandTransportPhenomena RodrigoSoto ContentsHishan Crecencio Farfan BachilogluNo ratings yet

- Blank Sticker Tabs TemplateDocument3 pagesBlank Sticker Tabs TemplateHina OdaNo ratings yet

- Kaplan Turbines SlidesDocument28 pagesKaplan Turbines Slidesjonas61700700100% (2)