Professional Documents

Culture Documents

RCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)

RCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)

Uploaded by

jayapalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)

RCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)

Uploaded by

jayapalCopyright:

Available Formats

RCS-9626CN

Motor Management Relay

Instruction Manual

Nanjing Nari-Relays Electric Co., Ltd.

RCS-9626CN Motor Management Relay

Preface

Introduction

This guide and the relevant operating or service manual documentation for the equipment provide

full information on safe handling, commissioning and testing of this equipment.

Documentation for equipment ordered from NARI-RELAYS is dispatched separately from

manufactured goods and may not be received at the same time. Therefore this guide is provided

to ensure that printed information normally present on equipment is fully understood by the

recipient.

Before carrying out any work on the equipment the user should be familiar with the contents of this

manual, and read relevant chapter carefully.

This chapter describes the safety precautions recommended when using the equipment. Before

installing and using the equipment, this chapter must be thoroughly read and understood.

Health and Safety

The information in this chapter of the equipment documentation is intended to ensure that

equipment is properly installed and handled in order to maintain it in a safe condition.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of

the equipment. Failure to observe warning notices, incorrect use, or improper use may endanger

personnel and equipment and cause personal injury or physical damage.

Before working in the terminal strip area, the equipment must be isolated.

Proper and safe operation of the equipment depends on appropriate shipping and handling,

proper storage, installation and commissioning, and on careful operation, maintenance and

servicing. For this reason only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

l Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected;

l Are able to safely perform switching operations in accordance with accepted safety

engineering practices and are authorized to energize and de-energize equipment and to

isolate, ground, and label it;

l Are trained in the care and use of safety apparatus in accordance with safety engineering

practices;

l Are trained in emergency procedures (first aid).

NANJING NARI-RELAYS ELECTRIC CO., LTD i

RCS-9626CN Motor Management Relay

Instructions and Warnings

The following indicators and standard definitions are used:

DANGER means that death, severe personal injury, or considerable equipment damage will

occur if safety precautions are disregarded.

WARNING means that death, severe personal, or considerable equipment damage could occur

if safety precautions are disregarded.

CAUTION means that light personal injury or equipment damage may occur if safety

precautions are disregarded. This particularly applies to damage to the device and to

resulting damage of the protected equipment.

WARNING!

The firmware may be upgraded to add new features or enhance/modify existing features, please

make sure that the version of this manual is compatible with the product in your hand.

WARNING!

During operation of electrical equipment, certain parts of these devices are under high voltage.

Severe personal injury or significant equipment damage could result from improper behavior.

Only qualified personnel should work on this equipment or in the vicinity of this equipment. These

personnel must be familiar with all warnings and service procedures described in this manual, as

well as safety regulations.

In particular, the general facility and safety regulations for work with high-voltage equipment must

be observed. Noncompliance may result in death, injury, or significant equipment damage.

DANGER!

Never allow the current transformer (CT) secondary circuit connected to this equipment to be

opened while the primary system is live. Opening the CT circuit will produce a dangerously high

voltage.

WARNING!

l Exposed terminals

Do not touch the exposed terminals of this equipment while the power is on, as the high voltage

generated is dangerous

l Residual voltage

Hazardous voltage can be present in the DC circuit just after switching off the DC power supply. It

takes a few seconds for the voltage to discharge.

ii NANJING NARI-RELAYS ELECTRIC CO., LTD

RCS-9626CN Motor Management Relay

CAUTION!

l Earth

The earthing terminal of the equipment must be securely earthed

l Operating environment

The equipment must only be used within the range of ambient environment detailed in the

specification and in an environment free of abnormal vibration.

l Ratings

Before applying AC voltage and current or the DC power supply to the equipment, check that they

conform to the equipment ratings.

l Printed circuit board

Do not attach and remove printed circuit boards when DC power to the equipment is on, as this

may cause the equipment to malfunction.

l External circuit

When connecting the output contacts of the equipment to an external circuit, carefully check the

supply voltage used in order to prevent the connected circuit from overheating.

l Connection cable

Carefully handle the connection cable without applying excessive force.

Copyright

Version: RCS-9626CN V2.22.1.080191 NANJING NARI-RELAYS ELECTRIC CO., LTD.

Manual: V1.00 69 Suyuan Avenue. Jiangning, Nanjing 211102,China

P/N: EN_DYBH0443.0233.1101 Tel: 86-25-87178185, Fax: 86-25-87178208

Copyright © NR 2008. All rights reserved Website: www.nari-relays.com

Email: international@nari-relays.com

We reserve all rights to this document and to the information

contained herein. Improper use in particular reproduction and

dissemination to third parties is strictly forbidden except where

expressly authorized.

The information in this manual is carefully checked periodically,

and necessary corrections will be included in future editions. If

nevertheless any errors are detected, suggestions for correction or

improvement are greatly appreciated.

We reserve the rights to make technical improvements without

notice.

NANJING NARI-RELAYS ELECTRIC CO., LTD iii

RCS-9626CN Motor Management Relay

iv NANJING NARI-RELAYS ELECTRIC CO., LTD

RCS-9626CN Motor Management Relay

Table of Contents

Preface .............................................................................................................................................. i

Introduction............................................................................................................................... i

Health and Safety ..................................................................................................................... i

Instructions and Warnings ..................................................................................................... ii

Table of Contents............................................................................................................................ v

Chapter 1 Introduction ................................................................................................................... 1

1.1 Application .................................................................................................................... 1

1.2 Functions....................................................................................................................... 1

1.3 Features......................................................................................................................... 2

1.4 Ordering Options.......................................................................................................... 3

1.5 Warranty Conditions .................................................................................................... 3

Chapter 2 Technical Data ............................................................................................................... 5

2.1 General Specification................................................................................................... 5

2.1.1 Electrical Specifications ................................................................................... 5

2.1.1.1 Power Supply ............................................................................................... 5

2.1.1.2 Analog Current Input Ratings....................................................................... 5

2.1.1.3 Analog Voltage Input Ratings....................................................................... 5

2.1.1.4 Binary Input .................................................................................................. 6

2.1.1.5 Binary Output ............................................................................................... 6

2.1.1.6 Direct Current Output ................................................................................... 6

2.1.2 Mechanical Specifications................................................................................ 6

2.1.3 Ambient Temperature and Humidity................................................................ 7

2.1.4 Communication Interfaces ............................................................................... 7

2.1.5 Type Test............................................................................................................. 8

2.1.5.1 Environmental Tests ..................................................................................... 8

2.1.5.2 Mechanical Tests.......................................................................................... 8

2.1.5.3 Electrical Tests ............................................................................................. 8

2.1.5.4 Electromagnetic Compatibility...................................................................... 8

2.2 Protective Functions.................................................................................................... 9

2.2.1 Accurate Operating Scope ............................................................................... 9

NANJING NARI-RELAYS ELECTRIC CO., LTD v

RCS-9626CN Motor Management Relay

2.2.2 General Error of Analog Input Measurement ................................................. 9

2.2.3 Three Phase Overcurrent Protection .............................................................. 9

2.2.4 Inverse Time Characteristic ........................................................................... 10

2.2.5 Zero Sequence Overcurrent Protection ........................................................ 10

2.2.6 Overload Protection ........................................................................................ 10

2.2.7 Thermal Protection.......................................................................................... 10

2.3 Management Functions ............................................................................................. 10

2.3.1 Metering Scope and Accuracy ....................................................................... 10

2.3.2 Control Performance....................................................................................... 11

2.3.3 Clock Performance.......................................................................................... 11

2.3.4 Disturbance Records ...................................................................................... 11

2.3.5 Telesignal ......................................................................................................... 11

2.4 Certification................................................................................................................. 11

Chapter 3 Operation Theory ........................................................................................................ 13

3.1 Fault Detectors ........................................................................................................... 13

3.2 Overcurrent Protection .............................................................................................. 14

3.3 Negative Sequence Overcurrent Protection............................................................ 15

3.4 Overload Protection ................................................................................................... 17

3.5 Motor Thermal Protection.......................................................................................... 17

3.6 Earth Fault Protection................................................................................................ 19

3.7 Undervoltage Protection............................................................................................ 19

3.8 Mechanical Protection ............................................................................................... 20

Chapter 4 Supervision, Metering and Control........................................................................... 23

4.1 Overview...................................................................................................................... 23

4.2 Relay Self-supervision............................................................................................... 23

4.2.1 Relay Hardware Supervision.......................................................................... 23

4.2.2 DC Supply Supervision................................................................................... 23

4.2.3 Output Tripping Circuit Supervision ............................................................. 23

4.2.4 Setting Supervision......................................................................................... 24

4.2.5 Control Circuit Supervision............................................................................ 24

vi NANJING NARI-RELAYS ELECTRIC CO., LTD

RCS-9626CN Motor Management Relay

4.2.6 TWJ (52b) Contact Supervision ..................................................................... 24

4.2.7 VT Circuit Supervision.................................................................................... 24

4.2.8 CT Failure Supervision ................................................................................... 25

4.2.9 System Frequency Supervision..................................................................... 25

4.3 Metering....................................................................................................................... 25

4.4 Remote Control........................................................................................................... 26

4.5 Signaling...................................................................................................................... 26

4.5.1 General Purpose Binary Input........................................................................ 26

4.5.2 Special Purpose Binary Input ........................................................................ 26

Chapter 5 Hardware Description................................................................................................. 29

5.1 Overview...................................................................................................................... 29

5.2 Basic Enclosure.......................................................................................................... 30

5.3 AC Module................................................................................................................... 31

5.4 CPU Module ................................................................................................................ 33

5.5 HMI Module.................................................................................................................. 34

5.6 DC Module................................................................................................................... 35

5.7 SWI Module ................................................................................................................. 37

5.8 ODI Module.................................................................................................................. 42

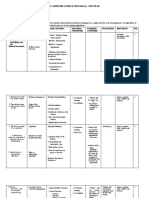

5.9 Module Configuration Scheme ................................................................................. 43

Chapter 6 HMI Operation Introduction ....................................................................................... 45

6.1 Human Machine Interface Overview......................................................................... 45

6.1.1 Design............................................................................................................... 45

6.1.2 Functionality .................................................................................................... 46

6.1.3 Keypad and keys ............................................................................................. 46

6.1.4 LED indications ............................................................................................... 46

6.2 Understand the HMI Menu Tree................................................................................. 47

6.2.1 OVERVIEW ....................................................................................................... 47

6.2.2 SETTINGS......................................................................................................... 49

6.2.3 VALUES............................................................................................................. 50

6.2.4 REPORT............................................................................................................ 50

NANJING NARI-RELAYS ELECTRIC CO., LTD vii

RCS-9626CN Motor Management Relay

6.2.5 PRINT ................................................................................................................ 51

6.2.6 SITE SET........................................................................................................... 52

6.2.7 TEST MODE...................................................................................................... 53

6.2.8 VERSION........................................................................................................... 53

6.2.9 PRESET ............................................................................................................ 54

6.2.10 LANGUAGE ...................................................................................................... 54

6.2.11 EXIT ................................................................................................................... 55

6.3 Understand the LCD Display..................................................................................... 55

6.3.1 Default Display under Normal Operation Condition.................................... 55

6.3.2 Display When Tripping.................................................................................... 56

6.3.3 Display under Abnormal Condition ............................................................... 57

6.4 View the Settings........................................................................................................ 59

6.5 View Status of Measured Value................................................................................. 61

6.5.1 Display Analogue Data.................................................................................... 61

6.5.2 Display the Status of Binary Inputs............................................................... 63

6.5.3 Display the Status of Virtual Enabling Binary Inputs .................................. 66

6.6 View Software Version ............................................................................................... 68

6.7 View Records .............................................................................................................. 69

6.7.1 General Description ........................................................................................ 69

6.7.2 View Reports through LCD............................................................................. 70

6.7.3 View Reports by Printing ................................................................................ 70

6.7.4 View Waveform by Printing ............................................................................ 71

6.8 Operation through Keypad........................................................................................ 73

6.8.1 Password Protection....................................................................................... 73

6.8.2 Change the Settings........................................................................................ 73

6.8.3 Switch Active Setting Group .......................................................................... 74

6.8.4 Print Records ................................................................................................... 75

6.8.5 Delete Records................................................................................................. 76

6.8.6 Clock Set .......................................................................................................... 77

6.9 Assistant Test Function ............................................................................................. 78

viii NANJING NARI-RELAYS ELECTRIC CO., LTD

RCS-9626CN Motor Management Relay

6.9.1 Overview........................................................................................................... 78

6.9.2 Check the Data-point....................................................................................... 78

6.9.3 Test the Tripping Output Circuit .................................................................... 79

6.9.4 Force a Metering Value ................................................................................... 79

6.10 Understand the Alarms .............................................................................................. 79

Chapter 7 Settings ........................................................................................................................ 81

7.1 Overview...................................................................................................................... 81

7.2 System Settings (SYS SETTINGS)............................................................................ 81

7.3 Protection Settings (PROT SETTINGS).................................................................... 82

7.4 Communication Settings (EQUIP SETTINGS) ......................................................... 84

7.5 Auxiliary Parameters (AUX SETTINGS) ................................................................... 86

7.6 VEBI Settings .............................................................................................................. 87

Chapter 8 Communication........................................................................................................... 89

8.1 General ........................................................................................................................ 89

8.2 Rear Communication Port Information.................................................................... 89

8.2.1 RS-485 Interface .............................................................................................. 89

8.2.1.1 EIA RS-485 Standardized Bus ................................................................... 89

8.2.1.2 Bus Termination ......................................................................................... 89

8.2.1.3 Bus Connections & Topologies .................................................................. 90

8.2.1.4 Biasing........................................................................................................ 90

8.2.2 Ethernet Interface ............................................................................................ 91

8.2.2.1 IP Address and Equipment Address of the Equipment.............................. 91

8.2.2.2 Ethernet Standardized Communication Cable........................................... 91

8.2.2.3 Connections and Topologies...................................................................... 92

8.2.3 IEC60870-5-103 Communication.................................................................... 92

8.3 IEC60870-5-103 Interface ........................................................................................... 92

8.3.1 Physical Connection and Link Layer ............................................................ 93

8.3.2 Initialization ...................................................................................................... 93

8.3.3 Time Synchronization ..................................................................................... 93

8.3.4 Spontaneous Events ....................................................................................... 94

8.3.5 General Interrogation ...................................................................................... 95

NANJING NARI-RELAYS ELECTRIC CO., LTD ix

RCS-9626CN Motor Management Relay

8.3.6 Cyclic Measurements...................................................................................... 95

8.3.7 General Commands......................................................................................... 96

8.3.8 Generic Functions ........................................................................................... 97

8.3.9 Disturbance Records ...................................................................................... 97

8.4 IEC60870-5-103 Interface over Ethernet .................................................................. 97

Chapter 9 Installation ................................................................................................................... 99

9.1 General ........................................................................................................................ 99

9.2 Safety Instructions ..................................................................................................... 99

9.3 Checking the Shipment ........................................................................................... 100

9.4 Material and Tools Required ................................................................................... 100

9.5 Device Location and Ambient Conditions ............................................................. 100

9.6 Mechanical Installation ............................................................................................ 101

9.7 Electrical Installation and Wiring............................................................................ 102

9.7.1 Grounding Guidelines................................................................................... 102

9.7.2 Cubicle Grounding ........................................................................................ 103

9.7.3 Ground Connection on the Device .............................................................. 103

9.7.4 Grounding Strips and their Installation....................................................... 104

9.7.5 Guidelines for Wiring .................................................................................... 104

9.7.6 Wiring for Electrical Cables.......................................................................... 105

9.8 Typical Wiring of the Relay...................................................................................... 105

Chapter 10 Commissioning ....................................................................................................... 107

10.1 General ...................................................................................................................... 107

10.2 Safety Instructions ................................................................................................... 107

10.3 Commission Tools.................................................................................................... 108

10.4 Setting Familiarization ............................................................................................. 108

10.5 Product Checks ........................................................................................................ 109

10.5.1 With the Relay De-energized ........................................................................ 109

10.5.1.1 Visual Inspection .................................................................................... 110

10.5.1.2 Insulation Test (if required)..................................................................... 110

10.5.1.3 Check the Jumpers .................................................................................111

10.5.1.4 External Wiring........................................................................................111

x NANJING NARI-RELAYS ELECTRIC CO., LTD

RCS-9626CN Motor Management Relay

10.5.1.5 Auxiliary Supply.......................................................................................111

10.5.2 With the Relay Energized.............................................................................. 112

10.5.2.1 Front Panel LCD Display ....................................................................... 112

10.5.2.2 Date and Time........................................................................................ 112

10.5.2.3 Light Emitting Diodes (LEDs)................................................................. 112

10.5.2.4 Testing the HEALTHY and ALARM LEDs .............................................. 112

10.5.2.5 Testing the TRIP LED............................................................................. 113

10.5.2.6 Testing the AC Current Inputs ................................................................ 113

10.5.2.7 Testing the AC Voltage Inputs ................................................................ 113

10.5.2.8 Testing the Binary Inputs........................................................................ 114

10.5.2.9 Testing the Binary Outputs..................................................................... 115

10.5.3 Protective Function Testing ......................................................................... 115

10.5.3.1 Demonstrate correct protection operation ............................................. 115

10.5.3.2 Overcurrent Protection Check................................................................ 115

10.5.3.3 Zero Sequence Overcurrent Protection Check...................................... 116

10.5.3.4 Negative Sequence Overcurrent Protection Check............................... 116

10.5.3.5 Overload Protection ............................................................................... 117

10.5.3.6 Motor thermal Protection........................................................................ 117

10.5.3.7 Undervoltage Protection ........................................................................ 118

10.5.3.8 Mechanical Protection............................................................................ 118

10.5.4 Print Fault Report .......................................................................................... 119

10.5.5 On-load Checks ............................................................................................. 119

10.5.6 Final Checks................................................................................................... 119

Chapter 11 Maintenance ............................................................................................................ 121

11.1 Maintenance Schedule............................................................................................. 121

11.2 Regular Testing......................................................................................................... 121

11.3 Failure Tracing and Repair ...................................................................................... 121

11.4 Replace Failed Modules........................................................................................... 121

Chapter 12 Decommissioning and Disposal ........................................................................... 123

12.1 Decommissioning..................................................................................................... 123

12.1.1 Switching off .................................................................................................. 123

12.1.2 Disconnecting cables.................................................................................... 123

12.1.3 Dismantling .................................................................................................... 123

12.2 Disposal..................................................................................................................... 123

NANJING NARI-RELAYS ELECTRIC CO., LTD xi

RCS-9626CN Motor Management Relay

xii NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 1 Introduction

Chapter 1 Introduction

1.1 Application

The RCS-9626CN relay is used for 3 ~10kV voltage level large/medium motor protection on solidly

grounded, impedance grounded, Peterson coil grounded and ungrounded system. The

RCS-9626CN relay is suited to be wall surface mounted indoors or outdoors or flush mounted into

a control panel.

Figure 1.1-1 Application of RCS-9626CN

1.2 Functions

Protective Functions

51P Definite time overcurrent protection

66 Starts per hour, time between starts

46 Negative sequence overcurrent protection

49 Thermal overload protection

51G Residual overcurrent protection

27 Undervoltage protection

MR Mechanical protection

AI Analog inputs

Voltage and current drift auto adjustment

Self supervision

VTS Voltage transformer supervision

NANJING NARI-RELAYS ELECTRIC CO., LTD 1

Chapter 1 Introduction

CTS Current transformer supervision

Binary input

Output relays

Rear communication ports: printer

Rear communication ports: RS-485/Ethernet

Time synchronization port

Relay Management Functions

Metering

Circuit breaker status monitoring

2 Circuit breaker control

TCS Trip coil supervision

Multiple setting groups

Control Inputs

64 Trip records

64 Self-check alarm records

64 Operating alarm records

64 User operating records

FR 8 Disturbance records

256 SOE records, latest records of following elements

state changing: operating abnormality alarm elements,

SOE

self-check alarm elements, protection elements and binary

input elements.

Circuit breaker operating time monitoring

Auxiliary Testing Functions

Virtual SOE records generation

Virtual measurement values generation

Virtual tripping reports generation

Virtual fault wave records generation

1.3 Features

l On the premise of 24 samples per cycle, all data measurement, calculation and logic

discrimination could be finished within one sampling period. The event recording and

protection logic calculation also can be finished simultaneously.

l The RCS-9626CN relay constantly measures and calculates a large mount of analog

quantities, such as phase voltage, phase-to-phase voltage, phase current, neutral current,

active power, reactive power, power factor and frequency.

l The relay can monitor and record the operating times of opening/closing circuit breakers.

2 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 1 Introduction

l Various methods of GPS clock synchronization, including message, pulse per second, and

IRIG-B synchronization.

l The HMI interface with a 160×80-dot LCD and a 9-button keypad on the front panel is very

friendly to the user.

l The relay is equipped with one EIA RS-485 standardized interfaces and two Ethernet

interfaces. The Ethernet interfaces are optional: electrical or optical.

l The relay can communication with SAS or RTU, the communication protocol of this device is

IEC60870-5-103.

l Maturity protection configuration, fast speed, security performance.

l Flexible configuration of operation circuit to suit for various circuit breakers.

l Strong function optional module to satisfy all kinds of requirement on site.

l High precision 14 bits A/D converter.

l Perfect fault and disturbance recording function: 64 latest fault reports, 8 latest fault wave (up

to 15s), 64 user operating records of users to equipment, and 256 records of time tagged

sequence of event can be recorded.

1.4 Ordering Options

l Two options are available for rated secondary current of CT inputs: 1A or 5A.

l Four options are available for rated auxiliary voltage: 250V, 220V, 125V, 110V.

l The rated current of target and seal-in relays in trip and closing circuit can be adaptive to 0.5 ~

4.0A automatically.

l The Ethernet interfaces are optional: electrical or optical.

1.5 Warranty Conditions

The warranty conditions are defined in the supply contract.

The manufacturers accept no responsibility for any damage resulting from improper use of the

RCS-9626CN.

Other special agreements are only valid if they are included in the contract.

NANJING NARI-RELAYS ELECTRIC CO., LTD 3

Chapter 1 Introduction

4 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 2 Technical Data

Chapter 2 Technical Data

2.1 General Specification

2.1.1 Electrical Specifications

2.1.1.1 Power Supply

Rated Voltage (Un) 24Vdc, 110Vdc, 125Vdc, 220Vdc, 250Vdc

Variation (80% ~ 120%)Un

Ripple in the DC

Max 15% of the DC value. Per IEC 60255-11

auxiliary voltage

Per IEC 61000-4-11, IEC 60255-11:1979

Voltage dips and voltage

20ms for interruption without de-energizing, dips 60% of Un without

short interruptions

reset up to 100ms

Quiescent

<15W

condition

Burden

Operating

<25W

condition

Backup battery type ML2032, 3V, 65mAh

2.1.1.2 Analog Current Input Ratings

Rated frequency 50Hz, 60Hz, ±10%

Phase rotation ABC

Rated Current (In) 1A 5A

Linear to (non-offset AC 20×In 20×In

current) 2×In (for metering) 2×In (for metering)

continuously 3×In 3×In

Thermal for 10s 30×In 30×In

withstand for 1s 100×In 100×In

capability for half

250×In 250×In

a cycle

Burden < 0.2 VA/phase @ In < 0.5 VA/phase @ In

2.1.1.3 Analog Voltage Input Ratings

Standard Per IEC 60255-6, IEC 60288

Rated Voltage (Un) 100V/√3, 110V/√3 100V, 110V 200V

linear to 100V 173 V 230V

Thermal continuously 120 120 V 200V

withstand 10s 200 200 V 350V

NANJING NARI-RELAYS ELECTRIC CO., LTD 5

Chapter 2 Technical Data

capability 1s 250 250 V 400V

Burden <0.2VA/phase @ Un <0.5VA/phase @ Un <2.5VA/phase @ Un

2.1.1.4 Binary Input

Rated Voltage 110Vdc 125Vdc 220Vdc 250Vdc

Pickup voltage 77.0Vdc 87.5Vdc 154Vdc 175.0Vdc

Dropout voltage 60.5Vdc 68.8Vdc 121Vdc 137.5Vdc

Maximum permitted

150Vdc 150Vdc 300Vdc 300Vdc

voltage

Withstand 2000Vac

Resolving time for

<1ms

logic input

2.1.1.5 Binary Output

Item Used for tripping contact Used for signal contact

Output model Potential-free contact

Max system voltage 250Vac/dc

Test voltage across

1000Vac rms fro 1min

open contact

Making Capacity >1000W at L/R=40ms

Breaking capacity 0.4A resistance 0.2A resistance

at 250Vdc 0.2A inductive(L/R=40ms) 0.05A inductive (L/R=40ms)

Continuous carry 8A 5A

Short duration current 50A for 200ms 50A for 200ms

Pickup time(Typical/Max) 5ms/10ms 10ms/15ms

Dropout time

8ms/10ms 4ms/10ms

(Typical/Max)

Bounce time 1ms 1ms

loaded

100,000 operations minimum 100,000 operations minimum

contact

Durability

unloaded

10,000,000 operations minimum 10,000,000 operations minimum

contact

2.1.1.6 Direct Current Output

Output range 4 ~ 20mA

Max load resistance 500ohm

Max output voltage 10V

2.1.2 Mechanical Specifications

Enclosure dimensions

142.4×266.0×203.0 (unit: mm)

(W×H×D)

Trepanning dimensions

154.0×268.0, M5 screw

(W×H)

6 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 2 Technical Data

Mounting Way Flush mounted

Weight per device Approx. 5kg

Small control module: 5 LED indicators, a 9-key keypad and a

Local control panel

160×80-dot LCD

Display language Optional: Chinese, English

Housing material Aluminum

Housing color Silver grey

Location of terminals Rear panel of the device

Front side: IP51

Protection class

Rear side, connection terminals: IP20

(per IEC60529:1989)

Other Sides: IP30

2.1.3 Ambient Temperature and Humidity

Operating temperature range -25°C ~ +55°C

Transport and storage temperature range -40°C ~ +70°C

Permissible humidity 5% ~ 95%, condensation not permissible

2.1.4 Communication Interfaces

Communication

Parameters

medium

Interfaces for communicating with RTU/SCADA

Port number 2

Baud rate 4800 ~ 38400bps

Transmission distance < 1000m@4800bps

RS-485 (EIA)

Maximal capacity 32

Protocol IEC60870-5-103:1997

Safety level Isolation to ELV level

Ethernet Port number 2~3

Connector type RJ-45

Transmission Rate 100Mbits/s

Electrical Transmission standard 100Base-TX

Transmission distance < 100m

Protocol IEC60870-5-103:1997 or IEC61850

Safety level Isolation to ELV level

Optical Port number 2~3

Connector type SC

Transmission Rate 100Mbits/s

Transmission standard 100Base-FX

Optical Fiber Type Multi-mode

Wavelength 1300nm

Transmission distance < 1500m

NANJING NARI-RELAYS ELECTRIC CO., LTD 7

Chapter 2 Technical Data

Protocol IEC60870-5-103:1997 or IEC61850

Safety level Isolation to ELV level

Interfaces for communicating with a printer

Port number 1

Baud rate 4800 ~ 38400bps

RS-232 (EIA)

Printer type EPSON® LQ-300K

Safety level Isolation to ELV level

Interfaces for clock synchronization

Port number 1

Transmission distance < 500m

RS-485 (EIA) Maximal capacity 32

Timing standard PPS, IRIG-B

Safety level Isolation to ELV level

2.1.5 Type Test

2.1.5.1 Environmental Tests

Dry heat test IEC60068-2-2:1974, 16 h at +55°C

Dry cold test IEC60068-2-1:1990, 16 h at -25°C

IEC60068-2-30:1980, two (12+12 hours) cycles, 95%RH,

Damp heat test, cyclic

low temperature +25°C, high temperature +55°C

2.1.5.2 Mechanical Tests

Vibration IEC60255-21-1:1988, Class I

Shock and bump IEC60255-21-2:1988, Class I

2.1.5.3 Electrical Tests

Dielectric tests IEC60255-5:2000, test voltage: 2kV, 50Hz, 1min

IEC60255-5:2000, test voltage: 5kV, unipolar

Impulse voltage tests

impulses, waveform 1.2/50μs, source energy 0.5J

Insulation

IEC60255-5:2000, insulation resistance >100MΩ, 500Vdc

measurement

2.1.5.4 Electromagnetic Compatibility

1MHz burst disturbance tests IEC60255-22-1:1988

(idt IEC61000-4-2:1995), Class III

- Common mode 2.5kV

- Differential mode 1.0kV

Electrostatic discharge tests IEC60255-22-2 :1996

(idt IEC 61000-4-2) Class IV

-For contact discharge 8.0kV

-For air discharge 15.0kV

Radio frequency interference tests IEC60255-22-3:2000

(idt IEC 61000-4-3:1995 ) class III

8 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 2 Technical Data

Frequency sweep

-Radiated amplitude-modulated 10V/m(rms), f=80…1000MHz

Spot frequency

-Radiated amplitude-modulated 10Vm(rms), f=80MHz/160MHz

/450MHz/900MHz

- Radiated pulse-modulated 10Vm(rms), f=900MHz

Fast transient disturbance tests IEC60255-22-4:2002

(idt IEC 61000-4-4)

- Power supply, I/O & Earth terminals Class IV, 4kV, 2.5kHz, 5/50ns

- Communication terminals Class IV, 2kV, 5.0kHz, 5/50ns

Surge immunity tests IEC60255-22-5:2002

(idt IEC 61000-4-5:1995) , Class III

- Power supply, AC inputs, I/O terminals 1.2/50us,

2kV, line to earth;

1kV, line to line

Conducted RF electromagnetic disturbance IEC60255-22-6, Class III

- Power supply, AC, I/O, Comm. terminal 10V(rms), 150kHz~80MHz

IEC61000-4-8:1993, Class V

Power frequency magnetic field immunity 100A/m for 1min

1000A/m for 3s

IEC61000-4-9:1993, Class V

Pulse magnetic field immunity 6.4/16 us

1000A/m for 3s

IEC61000-4-10:1993, Class V

Damped oscillatory magnetic field immunity

100kHz & 1MHz – 100A/m

2.2 Protective Functions

2.2.1 Accurate Operating Scope

Current 0.1×In ~ 20.0×In

Voltage 0.4V ~ 100.0V

Frequency 45Hz ~ 55Hz / 55Hz ~ 65Hz

Time delay 0s ~ 100s

2.2.2 General Error of Analog Input Measurement

Current ≤ 2.5% or 0.01×In, whichever is greater

Voltage ≤ 0.5%

Power frequency metering ≤ 0.01Hz

2.2.3 Three Phase Overcurrent Protection

Current setting 0.1×In ~ 20.0×In

Time setting 0s ~ 100s

NANJING NARI-RELAYS ELECTRIC CO., LTD 9

Chapter 2 Technical Data

Tolerance of current setting ≤ 2.5% or 0.01×In, whichever is greater

Tolerance of time setting ≤ 1% × Setting + 35 ms

2.2.4 Inverse Time Characteristic

Pickup threshold setting (Ip) scope 0.1×In ~ 4×In

Time multiplier setting scope 0.05 ~ 3.2

Tolerance of pickup threshold setting ≤ 2% or 0.01×In, which ever is greater

≤ 5% of reference (calculated) value +2%

Tolerance of trip time for 1.2<I/Ip<20

current tolerance, respectively 35ms

2.2.5 Zero Sequence Overcurrent Protection

Current setting 0.02A ~ 12.0A

Time setting 0s ~ 100s

Tolerance of current setting ≤ 2.5% or 0.01A, whichever is greater

Tolerance of time setting ≤ 1% × Setting + 35 ms

2.2.6 Overload Protection

Current setting 0.1×In ~ 20.0×In

Time setting 0s ~ 100s

Tolerance of current setting ≤ 2.5% or 0.01×In, whichever is greater

Tolerance of time setting ≤ 1% × Setting + 35 ms

2.2.7 Thermal Protection

Thermal alarm pick-up Calculated trip time ± 10%

Thermal overload pick-up Calculated trip time ± 10%

Cooling time accuracy 15% of theoretical

Repeatability <5%

2.3 Management Functions

2.3.1 Metering Scope and Accuracy

Current 0.05 ~ 1.4×In

Accuracy ≤ 0.2% of reading

Voltage 0.05 ~ 1.4×Vn

Accuracy ≤ 0.5% of reading

Power (W) 0.2 ~ 1.4×Vn, 0.05 ~ 1.4×In

Accuracy ≤ 0.5% of reading at unity power factor

Reactive Power (Vars) 0.2 ~ 1.4×Vn, 0.05 ~ 1.4×In

Accuracy ≤ 0.5% of reading at zero power factor

Apparent Power (VA) 0.2 ~ 1.4×Vn, 0.05 ~ 1.4×In

Accuracy ≤ 0.5% of reading

10 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 2 Technical Data

Energy (Wh) 0.2 ~ 1.4×Vn, 0.05 ~ 1.4×In

Accuracy ≤ 0.5% of reading at unity power factor

Energy (Varh) 0.2 ~ 1.4×Vn, 0.05 ~ 1.4×In

Accuracy ≤ 0.5% of reading at zero power factor

Phase range 0° ~ 360°

Accuracy ≤ 0.5% or ±1°

Frequency 45 ~ 55Hz

Accuracy ≤ 0.01Hz

2.3.2 Control Performance

Control mode Local or remote

Accuracy of local control ≤ 1s

Accuracy of remote control ≤ 3s

2.3.3 Clock Performance

Year 2000 Compliant

Real time clock accuracy ≤ 3 seconds/day

Accuracy of GPS synchronization ≤ 1ms

External clock synchronization IRIG-B (200-98), SNTP protocol etc.

2.3.4 Disturbance Records

Magnitude and relative phases ≤ 2.5% of applied quantities

Duration Up to 15000ms

Trigger position 3 cycles before pickup of the fault detector

2.3.5 Telesignal

Resolution of telesignals ≤ 2 ms

Input of telesignals Potential-free contact

Resolution of SOE ≤ 1ms

2.4 Certification

l ISO9001: 2000

l ISO14001:2004

l OHSAS18001: 1999

l CMMI L2

l EMC: 89/336/EEC, EN50263: 2000

l Products safety(PS): 73/23/EEC, EN61010-1: 2001, EN60950: 2002

NANJING NARI-RELAYS ELECTRIC CO., LTD 11

Chapter 2 Technical Data

12 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 3 Operation Theory

Chapter 3 Operation Theory

The RCS-9626CN motor protection relay is a microprocessor based relay designed for the

protection of large/medium motor. Some protective functions, fault diagnostic function and uplink

communication function are supported in this relay.

Voltage, current, frequency, power and energy metering functions are built into the relay as a

standard feature. Current parameters are available as total waveform RMS magnitude, or as

fundamental frequency only RMS magnitude and angle.

Diagnostic features include a sequence of records capable of storing 256 time-tagged events. The

disturbance records also can be captured during a system fault. The internal clock used for

time-tagging can be synchronized with a PPS signal and via the communication protocol over a

RS-485 port or an Ethernet port; it also can be synchronized with an IRIG-B signal. This precise

time stamping allows these records to be determined throughout the system. These tools

significantly reduce troubleshooting time and simplify report generation in the event of a system

fault.

Two rear RS-485 ports and two rear Ethernet ports allow independent access by operating and

engineering staff. All the ports use the IEC 60870-5-103 protocol. The RS-485 ports may be

connected to the supervisory system with baud rates up to 38.4 kbps, and the Ethernet ports has

100Mbit/s transmission rate. A rear RS-232 port is used to connect to an EPSON® LQ-300K serial

printer.

3.1 Fault Detectors

The fault detector operates if any of the following conditions is satisfied.

1. Any one of phase currents is in excess of the setting of the stage 1 overcurrent protection

multiplied by 0.95 on condition that the stage 1 overcurrent protection is enabled

(I>0.95×[I_OC1]).

2. Any one of phase currents is in excess of the setting of the stage 2 overcurrent protection

multiplied by 0.95 on condition that the stage 2 overcurrent protection is enabled

(I>0.95×[I_OC2]).

3. Any one of phase currents is in excess of the setting of the stage 3 overcurrent protection

multiplied by 0.95 on condition that the stage 3 overcurrent protection is enabled

(I>0.95×[I_OC3]).

4. Negative sequence current is in excess of the setting of stage 1 negative sequence

overcurrent protection multiplied by 0.95 on condition that the stage 1 negative sequence

overcurrent protection is enabled (I2>0.95×[I_NegOC1]).

5. Negative sequence current is in excess of the setting of stage 2 negative sequence

overcurrent protection multiplied by 0.95 on condition that the stage 2 negative sequence

NANJING NARI-RELAYS ELECTRIC CO., LTD 13

Chapter 3 Operation Theory

overcurrent protection is enabled (I2>0.95×[I_NegOC2]).

6. Any one of phase-to-phase voltage is in less than the setting of the undervoltage protection

multiplied by 1.05 on condition that the overload protection is enabled (UPP<1.05×[U_UV]).

7. Any one of phase currents is in excess of the current setting of the overload protection

multiplied by 0.95 on condition that the overload protection is enabled (I>0.95×[I_OvLd]).

8. Zero sequence current is in excess of the setting of the zero sequence overcurrent protection

multiplied by 0.95 on condition that the zero sequence overcurrent protection is enabled

(I0>0.95×[I_ROC]).

9. The thermal accumulation value is in excess of the motor thermal protection setting multiplied

by 0.95 on condition that the motor thermal protection is enabled (I>0.95×[A_MotorTherm]).

10. Any binary input of the mechanical protections is energized (BI_MR1=1, BI_MR2=1 or

BI_MR3=1), if the corresponding mechanical protection is enabled.

The FD (Fault Detectors) element will reset to normal operation status in 500ms after the last one

of the above items resets. The following figure shows the logic diagram of the fault detector of the

RCS-9626CN.

Figure 3.1-1 Logic diagram of the fault detector

3.2 Overcurrent Protection

The equipment provides three-stage definite time overcurrent protection. The stage 1 overcurrent

is similar to instantaneous overcurrent, the current setting should be higher than the pickup current

of the motor and the time-delay may be as zero or very short delay. The stage 2 and stage 3

overcurrent protections are usually set as definite time overcurrent protection.

The stage 1 overcurrent protection is mainly for short circuit fault of motor. The stage 2 overcurrent

protection is definite time overcurrent protection, and it will be enabled automatically after the

motor has started successfully and is working in normal situation. The stage 3 overcurrent

protection is provided for the stalling protection of the motor.

The functional logic diagram for the three-stage overcurrent protection is shown as bellow. The

overcurrent block is a level detector that detects that the current magnitude is above the threshold.

14 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 3 Operation Theory

Figure 3.2-1 Logical diagram of the overcurrent protection

Where:

[I_OC1] is the current setting of the stage 1 overcurrent protection;

[t_OC1] is the time-delay setting of the stage 1 overcurrent protection;

[En_OC1] is the logic setting of the stage 1 overcurrent protection;

[I_OC2] is the current setting of the stage 2 overcurrent protection;

[t_OC2] is the time-delay setting of the stage 2 overcurrent protection;

[En_OC2] is the logic setting of the stage 2 overcurrent protection;

[I_OC3] is the current setting of the stage 3 overcurrent protection;

[t_OC3] is the time-delay setting of the stage 3 overcurrent protection;

[En_OC3] is the logic setting of the stage 3 overcurrent protection;

[t_Start] is the time-delay setting of the starting process of the motor;

Flg_Motor_Start is a signal that means the motor is energized and starts working.

3.3 Negative Sequence Overcurrent Protection

When three phase current of motor is very asymmetrical, large negative current will appear and

two times power frequency current will generate in stator duo to appearance of negative current

thus lead excessive thermal to rotor and will endanger secure operating of motor.

The equipment provides two-stage definite time negative sequence overcurrent protection

separately for reverse-phase-failed, interturn fault and severe abnormal operation such as

asymmetrical voltage and so on. So the stage 2 negative sequence overcurrent as sensitive

unbalance overcurrent protection can be configured with definite time or inverse time

characteristic via the logical setting [En_InvNegOC].

NANJING NARI-RELAYS ELECTRIC CO., LTD 15

Chapter 3 Operation Theory

The stage 2 negative sequence overcurrent is also can be configured to issue an alarm signal

when it is configured with definite time characteristic through the logic setting [En_Trp_NegOC2].

The inverse time delayed characteristics comply with the following formula (based on IEC60255-4

standard).

80

t=

(I / I p )2 − 1 p

T

Where:

“Ip” is the current threshold setting; the current setting of stage 2 negative sequence

overcurrent (I_NegOV2) is used as the “Ip” in this relay. If the stage 2 negative sequence

protection of HV side is used as IDMT overcurrent protection, the range of the setting

[I_OC3_H] is 0.1×In to 4×In.

“Tp” is the time multiplier setting; the time-delay setting of the stage 2 negative sequence

overcurrent (t_NegOV2) is used as “Tp” in this relay. If the stage 2 negative sequence

protection of HV side is used as IDMT overcurrent protection, the range of the setting

[t_OC3_H] is 0.05s to 3.20s.

The functional logic diagram for the negative sequence overcurrent protection is shown as bellow.

The negative sequence overcurrent block is a level detector that detects that the negative

sequence current magnitude is above the threshold.

Figure 3.3-1 Logical diagram of the negative sequence overcurrent protection

Where:

[I_NegOC1] is the current setting of the stage 1 negative sequence overcurrent protection;

[t_NegOC1] is the time-delay setting of the stage 1 negative sequence overcurrent protection;

[En_NegOC1] is the logic setting of the stage 1 negative sequence overcurrent protection;

[I_NegOC2] is the current setting of the stage 2 negative sequence overcurrent protection;

[t_NegOC2] is the time-delay setting of the stage 2 negative sequence overcurrent protection;

[En_NegOC2] is the logic setting of the stage 2 negative sequence overcurrent protection;

16 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 3 Operation Theory

[En_Trp_NegOC2] is the logic setting which is used to enable the stage 2 negative sequence

overcurrent protection to issue a tripping signal;

[En_InvNegOC] is the logic setting which is used to configure the stage 2 negative sequence

overcurrent protection with IDMT characteristic.

3.4 Overload Protection

Overload reflects to quantity of the stator current. The equipment provides one stage definite

overload protection and can be configured to trip circuit breaker or issue an alarm signal.

Figure 3.4-1 Logical diagram of the overload protection

Where:

[I_OvLd] is the current setting of the overload protection;

[t_OvLd] is the time-delay setting of the overload protection;

[En_OvLd] is the logic setting of the overload protection;

[En_Trp_OvLd] is the logic setting which is used to enable the overload protection to issue a

tripping signal.

3.5 Motor Thermal Protection

Motor thermal protection is mainly used to protect against excessive heating of motor, in order to

realize this purpose, a “thermal replica” has been used in the protection design of this equipment.

Take account of combination heating of positive sequence current “I1” and negative sequence

current “I2”, the equivalent heating current “Ieq” will be used, and its expression is listed as below.

I eq2 = K1 × I12 + K 2 × I 22

Where:

I1 is the positive sequence current of the motor;

I2 is the negative sequence current of the motor;

K1 = 0.5, it is used to prevent maloperation in starting process;

K1 = 1.0, once the predefined time delay [t_Start] has elapsed, “I12” will not decrease

deliberately;

NANJING NARI-RELAYS ELECTRIC CO., LTD 17

Chapter 3 Operation Theory

K2 = 3 ~ 10, it is used to simulate enhanced heating effect of “I22”, 6 is a recommended value.

Protection operation equation is listed as below.

I eq 2

I − 1.05 × t ≥ τ

2

e

Where:

“Ieq” is the equivalent heating current;

“Ie” is the ratted current of the motor;

“ τ ” is the setting for accumulated heating thermal [A_MotorTherm];

When the thermal accumulation of the motor achieves the excessive thermal alarm level

([A_MotorTherm]×[K_Alm_MotorTherm]), [K_Alm_MotorTherm] is a coefficient for motor thermal

alarm, this relay will issue an alarm signal.

When the thermal accumulation achieves the excessive thermal trip level [A_MotorTherm], this

relay will issue a tripping command (if circuit breaker is not in open position, the relay will operate).

If power supply for motor is shunt off by the motor thermal protection, the motor can not start again

at once unless the temperature of motor is in permitted range after the heat elimination process. If

urgency starting is needed, the motor thermal state can be reset to “cool state” forcibly by

energizing the binary input [BI_RstTarg_Therm] (Terminal 328).

Figure 3.5-1 Logical diagram of the motor thermal protection

Where:

[A_MotorTherm] is the thermal accumulation setting of the motor;

[k_Alm_MotorTherm] is the motor thermal alarm coefficient setting of the motor;

[En_MotorThermAlm] is the logic setting which is used to enable the overload protection to

issue an alarm signal;

[En_MotorThermTrp] is the logic setting which is used to enable the overload protection to

issue a tripping signal;

“K1I12+K2I22” is the equation which is used to calculate the thermal accumulation of the motor;

“Flg_Fbd_ReStart” is the logic element which is used to forbid the motor restarting when the

18 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 3 Operation Theory

motor thermal protection is operated;

“MotorTherm Reset” and a button, which is used to input a reset signal to restore the thermal

accumulator in this relay.

3.6 Earth Fault Protection

One of the most common faults to occur on a motor is a stator winding fault. Whatever the initial

form of the fault (phase-to-phase, etc.) or the cause (cyclic overheating, etc.), the presence of the

surrounding metallic frame and casing will ensure that it rapidly develops into a fault involving

earth. Therefore, provision of earth fault protection is very important.

The equipment provides zero sequence overcurrent protection which is triggered by stator earth

fault of motor. It can be configured to trip circuit breaker or only issue alarm information via logical

setting in order to accommodate different condition.

The functional logic diagram for the zero sequence overcurrent protection is shown as bellow. The

zero sequence overcurrent block is a level detector that detects that the zero sequence current

magnitude is above the threshold.

Figure 3.6-1 Logical diagram of the zero sequence overcurrent protection

Where:

[I_ROC] is the current setting of the zero sequence overcurrent protection;

[t_ROC] is the time-delay setting of the zero sequence overcurrent protection;

[En_ROC] is the logic setting of the zero sequence overcurrent protection;

[En_Trp_ROC] is the logic setting which is used to enable the zero sequence protection to

issue a tripping signal.

3.7 Undervoltage Protection

The equipment provides undervoltage protection. When three phase-to-phase voltages all less

than undervoltage setting and the predefined time delay has elapsed, undervoltage protection will

operate. The undervoltage element is blocked by the open position state of the circuit breaker. The

VT circuit failure can be identified automatically by the equipment and the undervoltage element

will be blocked at once under such a condition.

The functional logic diagram for the undervoltage protection is shown as bellow. The undervoltage

block is a level detector that detects that the voltage magnitude is above the threshold.

NANJING NARI-RELAYS ELECTRIC CO., LTD 19

Chapter 3 Operation Theory

Figure 3.7-1 Logical diagram of the undervoltage protection

Where:

[V_UV] is the voltage setting of the undervoltage protection;

[t_UV] is the time-delay setting of the undervoltage protection;

[En_UV] is the logic setting of the undervoltage protection;

[EBI_UV] is the enabling binary input of the undervoltage protection;

[S_State_CB] is the position state of the circuit breaker.

3.8 Mechanical Protection

The equipment provides three independent mechanical protections, and one of the mechanical

protections used for tripping circuit breaker directly; another two can be configured to trip or alarm

via the logical setting. Time delay for first and second mechanical protections may reach up to 100

seconds; and time delay for third channel may reach up to 100 minutes. If the logical setting

[En_MR2] or [En_MR3] is disabled, it means the corresponding mechanical protection is only used

for alarm function.

Two of the mechanical protections can issue a tripping signal or an alarm signal, and another one

only can issue a tripping signal.

These special binary inputs and their functions are listed as below.

BI Name Relevant Function For tripping For alarming

BI_MR1 The No.1 mechanical protection YES NO

BI_MR2 The No.2 mechanical protection YES YES

BI_MR3 The No.3 mechanical protection YES YES

The circuit breaker position state is taken into account; only when the CB position state is closed,

the mechanical protections will be in service.

The logic diagram of the mechanical protection is shown in following figure.

20 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 3 Operation Theory

[S_State_CB]

[BI_MR1]

& [t_MR1] [Op_MR1]

[En_MR1]

[BI_MR2]

& [t_MR2] [Op_MR2]

[En_MR2]

& [t_MR2] [Alm_MR2]

[BI_MR2]

[BI_MR3]

& [t_MR3] [Op_MR3]

[En_MR3]

& [t_MR3] [Alm_MR3]

[BI_MR3]

Figure 3.8-1 Logical diagram of mechanical protection

Where:

[En_MR1] is the logic setting of the No.1 mechanical protection;

[En_MR2] is the logic setting of the No.2 mechanical protection;

[En_MR3] is the logic setting of the No.3 mechanical protection;

[t_MR1] is the time-delay setting of the No.1 mechanical protection;

[t_MR2] is the time-delay setting of the No.2 mechanical protection;

[t_MR3] is the time-delay setting of the No.3 mechanical protection;

[S_State_CB] is the position state of the circuit breaker.

NANJING NARI-RELAYS ELECTRIC CO., LTD 21

Chapter 3 Operation Theory

22 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 4 Supervision, Metering and Control

Chapter 4 Supervision, Metering and Control

4.1 Overview

Though the protection system is in non-operating state under normal conditions, it is waiting for a

power system fault to occur at any time and must operate for the fault without fail. When the

equipment is in energizing process before the LED “HEALTHY” is on, the equipment needs to be

checked to ensure there are no errors. Therefore, the automatic supervision function, which

checks the health of the protection system when startup and during normal operation, plays an

important role.

The numerical relay based on the microprocessor operations is suitable for implementing this

automatic supervision function of the protection system.

In case a fatal fault is detected during automatic supervision, the equipment will be blocked out. It

means that relay is out of service. Therefore you must re-energize the relay or even replace a

module to make relay back into service.

The relay also provides some auxiliary functions, such as disturbance data record, on-line data

metering, real-time power calculation etc. All these make the relay meet the demands of the

modern industrial requirements.

4.2 Relay Self-supervision

4.2.1 Relay Hardware Supervision

The DSP, RAM, ROM chips on the CPU module are monitored to ensure whether they are

damaged or have some errors. If any one of them is detected damaged or having error, the

equipment will be blocked and issues alarm signal [Alm_Fail]. The LED indicator “HEALTHY” will

be extinguished.

4.2.2 DC Supply Supervision

The secondary voltage level of the built-in DC/DC converter is monitored and checked whether the

DC voltage is within a prescribed range.

If a failure is detected in the DC power supply circuit, the alarm signal [Alm_Pwr_DC] will be

issued and the relay will be blocked. The LED indicator “HEALTHY” will be extinguished.

4.2.3 Output Tripping Circuit Supervision

Chips controlling the output relays in the output circuit are continually monitored. If any error or

damage is detected in these chips, the alarm signal [Alm_TrpOut] will be issued and the relay will

be blocked. The LED indicator “HEALTHY” will be extinguished.

NANJING NARI-RELAYS ELECTRIC CO., LTD 23

Chapter 4 Supervision, Metering and Control

4.2.4 Setting Supervision

This relay has several setting groups, while only one is active at the same time. The settings of

active setting group are checked to ensure they are reasonable. If the settings are checked to be

invalid, the alarm signal [Alm_Setting] will be issued and this equipment will be blocked at the

same time. The LED indicator “HEALTHY” will be extinguished.

4.2.5 Control Circuit Supervision

If the relay detects that the 52b (TWJ) contact position and the 52a (HWJ) contact position are off

at the same time for more than 3 seconds, the alarm signal [Alm_TCCS] will be issued and the

LED indicator “ALARM” will be lit.

4.2.6 TWJ (52b) Contact Supervision

If the relay detects that the TWJ (52b) contact position is on, i.e., the value of [BI_52b] is “1” in the

submenu “BI STATE”, meanwhile any phase current is more than 0.06In, and this condition lasts

more than 10 seconds, the alarm signal [Alm_52b] will be issued and the LED indicator “ALARM”

will be lit.

4.2.7 VT Circuit Supervision

The voltage transformer supervision (VTS) feature is used to detect failure of the AC voltage

inputs to the relay.

The VTS logic in the relay is designed to detect the voltage failure and automatically adjust the

configuration of protective elements whose stability would otherwise be compromised. A

time-delay alarm output is also available.

The VTS feature within the relay operates on detection of

(1) negative phase sequence (NPS) voltage is in excess of 8V or

(2) positive phase sequence (PPS) voltage is less than 30V with the presence of current of any

phase (I.e., any of the phase current is in excess of 0.06In ).

This gives operation for the loss of voltages. Stability of the VTS function is assured during system

fault conditions, by the presence of any pickup element.

Repeated here, the criteria of VTS Element:

(1) U1<30V and any of phase current is greater than 0.06In

(2) U2>8V

That any of these two conditions is satisfied means the VT is in abnormal status. Then the VT

alarm “Alm_VTS” is issued 10s later. When the VT status returns to normal condition, the alarm

will be restored automatically 1.25s later.

In case VT circuit is failure, protection elements dependent on voltage will be blocked.

The logic diagram of the VTS element is shown as below.

24 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 4 Supervision, Metering and Control

Figure 4.2-1 Logic diagram of the VTS element

4.2.8 CT Failure Supervision

The main purpose of the current transformer (CT) circuit failure supervision function is to detect

faults in the secondary circuits of CT and avoid influence on the operation of corresponding

protection functions. This CT failure supervision function will be processed all the time, whether

general fault detection picks up or not.

The criteria of CTS element are:

Time delay CT failure supervision executes in every sampling period. If any phase differential

current is in excess of 0.08In and this condition lasts for 10s, alarm information [Alm_CTS] will be

issued by the equipment. Under this condition, percentage differential current protection is not

blocked.

4.2.9 System Frequency Supervision

The frequency of the power system is supervised continually. When the phase-to-phase voltage is

greater than 40V, meanwhile the power system frequency is less than 49.5Hz, the LED indicator

“ALARM” will be lit and the alarm signal [Alm_Freq] will be issued 10s later.

In case system is abnormal, protection elements will not be blocked.

The logic diagram of the frequency supervision element is shown as below.

Figure 4.2-2 Logic diagram of the frequency supervision element

4.3 Metering

The relay produces a variety of both directly and calculated power system quantities. These

measurement values are updated on a per second basis and can be viewed in the submenu

“METERING” (in menu “VALUES”) of the relay or via relay communication.

This relay is able to measure and display the following quantities as summarized:

l phase voltage

l phase current

NANJING NARI-RELAYS ELECTRIC CO., LTD 25

Chapter 4 Supervision, Metering and Control

l zero sequence current (from zero sequence CT or derived)

l phase to phase voltage

l system frequency

l active and reactive power, power factor

l active energy and reactive energy

The measurands include IaM, IcM, I0, Ua, Ub, Uc, Uab, Ubc, Uca, f, P, Q and COSφ etc. These

measurands are got by real-time calculation and real-time summation locally. Active and reactive

power calculation eliminates error due to unbalance of the system voltage. This calculation is

independent with network.

All these measurands also can transmit to the SAS or RTU through communication. More

information about the communication and protocols, see Chapter 8 “Communication”.

4.4 Remote Control

The relay can receive the remote control commands to trip or close the circuit breaker. Up to three

groups telecontrol output relays can be configured.

Before executing a telecontrol command, it is necessary to put the telecontrol handle at the

“Remote” position and make the value of [EBI_TeleCtrl] as “1” in the submenu “BI STATE”.

The remote control commands include remote tripping command, remote closing command etc.

More information about the communication and protocols, see Chapter 8 “Communication”.

It is recommended that separate relay output contacts are allocated for remote circuit breaker

control and protection tripping. This enables the control outputs to be selected via a local/remote

selector switch. Where this feature is not required the same output contact(s) can be used for both

protection and remote tripping.

4.5 Signaling

4.5.1 General Purpose Binary Input

General purpose binary inputs are used to monitor the positions of up to ten contacts. They have a

common negative pole input. See Chapter 5 “Hardware Description” for the details about these

binary inputs.

The signal state change confirmation time of the BI_1 and BI_2 can be set respectively. Other

inputs (BI_3 ~ BI_10) have the same confirmation time, it is default 20ms and can be settable.

4.5.2 Special Purpose Binary Input

The BI_19 ~ BI_25 are used as special purpose binary inputs, such as protection logic calculation,

restoring signals etc.

26 NANJING NARI-RELAYS ELECTRIC CO., LTD

Chapter 4 Supervision, Metering and Control

These inputs (BI_19 ~ BI_25) have the same signal state change confirmation time, it is 10ms.

The following table lists these special inputs.

Binary Input Terminal number Description

BI_19 324 Binary input of the No.3 mechanical protection

BI_20 325 Binary input of the No.2 mechanical protection

BI_21 326 Binary input of the No.1 mechanical protection

BI_22 327 Enabling binary input of the undervoltage protection

BI_23 328 Binary input of the heat resetting signal

BI_24 329 Binary input of the signal resetting signal

BI_25 330 Binary input of the device maintenance signal

l The BI_19 is used to denote whether the No.3 mechanical protection has input signal to this

relay. If it’s energized, it means that this relay receives a mechanical protection signal. If the

state of BI_19 keeps for a relevant duration, this relay will issue a tripping or alarm signal.

l The BI_20 is used to denote whether the No.2 mechanical protection has input signal to this

relay. If it’s energized, it means that this relay receives a mechanical protection signal. If the

state of BI_20 keeps for a relevant duration, this relay will issue a tripping or alarm signal.