Professional Documents

Culture Documents

One Direct Method Statement: Main Hazards Preventative Measures

Uploaded by

trravi1983Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

One Direct Method Statement: Main Hazards Preventative Measures

Uploaded by

trravi1983Copyright:

Available Formats

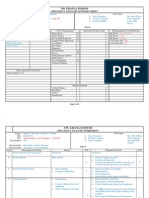

ONE DIRECT METHOD STATEMENT

NUMBER: MS0009

Start Date 01/05/2016

Task / Activity Glazing

Review Date 01/05/2018

SRA 0004, SRA 0016,

Accompanying Risk

Site Address /Location OHG Properties SRA 0017, SRA 0018,

Assessment

SRA 0019, SRA 0024

Personnel Involved One Direct Operatives Role /Trade Carpenters, Multi trade

Mark Bloxidge – H&S Manager Tel: 07900 160656

Health & Safety

Jessica Langley – H&S Advisor Tel: 07966 348804

Main Hazards Preventative Measures

yy Manual Handling yy Appropriate training and Supervision

yy Transporting Glass yy PPE

yy Working at Height yy Secure transportation

yy Working Near Overhead Cables yy Site survey prior to installation

yy Site Security yy Ensure site, tools and equipment are secured

yy Use of Hand Tools yy Cordon off work areas, including external areas

yy Glass removal below install

yy Glass Installation yy Safety Signage

yy Hazardous Substances yy COSHH Risk Assessments

Work Equipment Methods of Access

yy Hand Tools, glazers

and Egress to Work Area

points / pins, brush 7

yy Unknown

pan, hoover, putty, heat

gun / chemical, access

equipment, barriers,

signage, dust sheets,

bin / bucket

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

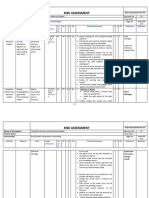

ONE DIRECT METHOD STATEMENT

NUMBER: MS0009

Sequence of Operations for Task

yy Wear appropriate PPE as identified external beads leaving the top until last

yy Survey site for any additional or to prevent the glass from falling forward

unidentified risks & implement additional yy Remove unit and place in bin/ bucket

control measures as required or report to

yy Carry out temporary repair if required/

supervisor

boarding up

yy Cordon of internal and external work area

yy Carry replacement glass to work area

as required

and securely store in vertical position

yy Erect appropriate access equipment as

ensuring the glass cannot fall or slide

required (ladder, mobile tower)

yy Lay down dust sheets/ floor protection as Install Glass (Single Pain and Putty)

required yy Primer or treat bare wood

yy Apply thin putty layer

Glass Removal (Single Pane & Putty) yy Insert correctly cut glass into frame and

yy If glass pane is holed, remove loose glass press firmly into place

with brush & pan or hoover, then remove yy Place glazers points/ pins into place and

larger pieces by hand, placing each piece secure into place with putty knife or pin

in the bin/ bucket prior to removing the hammer

next yy Apply putty into place and smooth with

yy If glass pane is cracked, place protective putty knife

film over glass and cut pane with glass Install Beaded Unit (Double Glazed Unit &

cutter leaving approximately 25mm Single Glazed)

around the edge, remove glass and place

yy Place unit into frame ensuring packers

into bin/ bucket

are in place

yy Cut away remaining small pieces with

yy Place hand on unit to prevent glass from

putty knife or break away with pliers

falling forward

yy Remove old putty with putty knife,

yy Replace beading (top first)

removing glazers points, pins as you go.

yy Replace gasket if required

Glass Removal for Beaded Units (Double Glazed

Units & Single Glazed) yy Check window for correct operation

yy Clean glass with window cleaner

yy If either pane is cracked or intact, place

protective film on glass

yy If either pane is holed, remove loose

glass with brush & pan or hoover, then

remove larger pieces by hand, placing

each piece in the bin/ bucket prior to

removing the next

yy For externally beaded units, remove

internal gasket (if fitted) then remove

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

ONE DIRECT METHOD STATEMENT

NUMBER: MS0009

PPE Required

HARD HAT HAND PROTECTION SAFETY VISOR

YES / If working YES/ Cut 5 Glass NO

below Gloves

HIGH VIZ SAFETY FOOTWEAR DUST MASK

YES YES YES

EYE PROTECTION EAR PROTECTION

YES Optional

Environmental Protection Measures

yy Dispose of all waste in designated area or skip provided for waste and in accordance with

manufactures instructions

Hazardous Substances

IRRITANT/ RESPIRATORY

FLAMMABLE

SENSITISER SENSITISER

YES / NO

YES / NO YES / NO

TOXIC CORROSIVE DANGEROUS TO

YES / NO YES / NO THE ENVIRONMENT

YES / NO

GAS UNDER PRESSURE

YES / NO

ONE DIRECT METHOD STATEMENT

NUMBER: MS0009

Emergency procedures

First Aid:

yy First Aid box provided on all vehicles

yy Local arrangements for contacting emergency services to be identified

yy Location or nearest hospital A&E must be known

yy In case of serious accident or injury requiring immediate medical attention call 999

yy Always inform supervisor or H&S Manager of all accidents, incidents and near misses

yy Ensure that accident, incident or near miss is logged

yy For severe cuts apply firm pressure to the wound and seek immediate medical attention

Fire:

yy Fire extinguisher on all vehicles

yy Only attempt to extinguisher fire if safe to do so

yy Local arrangements for contacting emergency services to be identified

yy Maintain adequate emergency access route in working location at all times

Training & Supervision Permit to work

yy All staff have received H&S Induction training yy No

yy Operatives carrying out glazing work to attend

Glazing TBT

yy All Operatives are supervised

Safety of Other Contractors Refuelling Procedure

or Members of the Public of Plant Machinery

yy Ensure that other contractors are aware

or Equipment

of hazards present

yy Fuel to be carried in appropriate fuel

yy Ensure that work area is secured containers and secured in vans. All plant

yy No works will be left in a dangerous and machinery to be refuelled away from

condition or with risk to themselves, the van, visitors and members of the

contractors, tenants or members of the public and any sources of ignition.

public yy Fuel is to be transferred from the

yy All tools and equipment will be securely proprietary containers by certified fuel

stored or removed from site at the end of transfer unit or through a funnel into the

each working day machine tank.

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

You might also like

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Mastic Sealing Method StatementDocument4 pagesMastic Sealing Method StatementFaisal RazaNo ratings yet

- ms0019 Dismantling of Non Load Bearing Wall-1Document4 pagesms0019 Dismantling of Non Load Bearing Wall-1SonukrishnaNo ratings yet

- One Direct Method Statement: Main Hazards Work EquipmentDocument4 pagesOne Direct Method Statement: Main Hazards Work EquipmentFaisal RazaNo ratings yet

- Electrical - Consumer Unit Method StatmentDocument4 pagesElectrical - Consumer Unit Method StatmentFaisal RazaNo ratings yet

- One Direct Method Statement: Main HazardsDocument4 pagesOne Direct Method Statement: Main HazardsAyu Wanda SaraswatiNo ratings yet

- Accessing Loft Spaces Method Statement PDFDocument3 pagesAccessing Loft Spaces Method Statement PDFFaisal RazaNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- ms0001 Ladders Step UpDocument4 pagesms0001 Ladders Step UpMD WARISNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Glass Breakage SOP-SatyaDocument5 pagesGlass Breakage SOP-SatyaSRI VYJAYANTHI QANo ratings yet

- What Type of Damage? What Aircraft Type? Where Was The Damage? Who Found It?Document1 pageWhat Type of Damage? What Aircraft Type? Where Was The Damage? Who Found It?mahhdyNo ratings yet

- JSA No 3 - Operate Dozer - Push ScraperDocument3 pagesJSA No 3 - Operate Dozer - Push ScraperBenjamin Fabin100% (1)

- AEG JSA 107 Milling MachineDocument2 pagesAEG JSA 107 Milling MachineAshok Suresh100% (1)

- Angle Grinder PDFDocument2 pagesAngle Grinder PDFcityofdarwingisNo ratings yet

- Safe Job Procedures SJPDocument49 pagesSafe Job Procedures SJPapi-317342021No ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- Application Manual: Heat Insulation Glass Coating Material GLC - 1 Cool in Summer, Warm in WinterDocument20 pagesApplication Manual: Heat Insulation Glass Coating Material GLC - 1 Cool in Summer, Warm in WinterLollipopNo ratings yet

- 10-TBT-07 Eye Injury Protection Week-7Document4 pages10-TBT-07 Eye Injury Protection Week-7saad aliNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- Disc Sander PDFDocument1 pageDisc Sander PDFcityofdarwingisNo ratings yet

- Craftsman Weed Eater 358.794773Document40 pagesCraftsman Weed Eater 358.794773carluchi47No ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- GW PDFDocument26 pagesGW PDFTony JenNo ratings yet

- 99MAH056A1Document120 pages99MAH056A1Okara666No ratings yet

- At 2190Document9 pagesAt 2190Hewa PCNo ratings yet

- Circular SawsDocument4 pagesCircular SawsVaisakhNambiarNo ratings yet

- Instruction Manual: Electromagnetic Clutch & BrakeDocument8 pagesInstruction Manual: Electromagnetic Clutch & BrakeangelNo ratings yet

- Instruction Manual: Electromagnetic Clutch & BrakeDocument8 pagesInstruction Manual: Electromagnetic Clutch & BrakeangelNo ratings yet

- Instruction Manual: Electromagnetic Clutch & BrakeDocument8 pagesInstruction Manual: Electromagnetic Clutch & BrakeangelNo ratings yet

- Instruction Manual: Electromagnetic Clutch & BrakeDocument6 pagesInstruction Manual: Electromagnetic Clutch & BrakeberkahharianNo ratings yet

- SOP001 - Milling MachineDocument3 pagesSOP001 - Milling MachineRaj SatoskerNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Methodology of Work and Sequence of ActivitiesDocument6 pagesMethodology of Work and Sequence of ActivitiesAmitNo ratings yet

- Installationguide 9144348Document4 pagesInstallationguide 9144348Mauro CNadruzNo ratings yet

- Greenhouse: Assembly and Safety AdviceDocument12 pagesGreenhouse: Assembly and Safety AdviceSztarszkiNo ratings yet

- Drop Saw PDFDocument1 pageDrop Saw PDFcityofdarwingisNo ratings yet

- GW PDFDocument24 pagesGW PDFCarlos Eduardo ZelidonNo ratings yet

- TDS - Pioneer Mighty Gasket Black - 022019Document2 pagesTDS - Pioneer Mighty Gasket Black - 022019wendel raguindinNo ratings yet

- For Work Site Activities: Safety Observation and Communication (Soc)Document2 pagesFor Work Site Activities: Safety Observation and Communication (Soc)Aung Pyae PhyoNo ratings yet

- Toolbox Talks Snow Thrower Safety EnglishDocument1 pageToolbox Talks Snow Thrower Safety EnglishAshpakNo ratings yet

- Fume Hood: Product Operation ManualDocument34 pagesFume Hood: Product Operation ManualDuong PhạmNo ratings yet

- Needle Scaler 96997Document12 pagesNeedle Scaler 96997Lawrence de RijkNo ratings yet

- Black & Decker Variable Speed Scroll Saw (Manual)Document39 pagesBlack & Decker Variable Speed Scroll Saw (Manual)Edward TowersNo ratings yet

- Publication Number 49702Document9 pagesPublication Number 49702Taha RdmanNo ratings yet

- GH 710Document37 pagesGH 710t_sebi20039559No ratings yet

- WSWP For Hamisa Cutting of ConcreateDocument8 pagesWSWP For Hamisa Cutting of ConcreateVictor Thembinkosi MakhubeleNo ratings yet

- Syncmaster 740Nw / 940 NW: Install Driver Install ProgramsDocument86 pagesSyncmaster 740Nw / 940 NW: Install Driver Install ProgramsHernanNo ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- SnowJoe-620 SnowthrowerDocument12 pagesSnowJoe-620 SnowthrowerHecsgt1991No ratings yet

- General Hazard Identification Form Sample ReportDocument10 pagesGeneral Hazard Identification Form Sample ReportJavanshir AkbariNo ratings yet

- RA-03-Using Disc Cutters and Abrasive WheelsDocument5 pagesRA-03-Using Disc Cutters and Abrasive Wheelsamritha n krishnaNo ratings yet

- New Sop & Maintenance Manual PDFDocument30 pagesNew Sop & Maintenance Manual PDFmukul royNo ratings yet

- Log Splitter Harbor Freight 96907Document20 pagesLog Splitter Harbor Freight 96907kdopsonNo ratings yet

- Installation Manual: Congratulations!Document22 pagesInstallation Manual: Congratulations!craig.stevens79No ratings yet

- Delta Model 31-080 1" Belt Sander ManualDocument12 pagesDelta Model 31-080 1" Belt Sander ManualRobert Steven Ciaccio0% (1)

- Eye Injuries: Worksafe Western AustraliaDocument5 pagesEye Injuries: Worksafe Western AustraliaaezeadNo ratings yet

- Lock-Out Tag-Out ReqDocument1 pageLock-Out Tag-Out Reqtrravi1983No ratings yet

- Work Permit Oil RefineryDocument83 pagesWork Permit Oil Refineryrvsreddy1972100% (5)

- Monthly Magazine - Effective Communication - April 2017Document6 pagesMonthly Magazine - Effective Communication - April 2017trravi1983No ratings yet

- Consent DirectionDocument4 pagesConsent Directiontrravi1983No ratings yet

- ERI Titles EnglishDocument2 pagesERI Titles Englishtrravi1983No ratings yet

- Sra0028 Stress ManagementDocument5 pagesSra0028 Stress ManagementRajesh gpNo ratings yet

- EHS Risk Assessment PDFDocument8 pagesEHS Risk Assessment PDFpoloNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Ambulance Check ListDocument1 pageAmbulance Check ListOkba TelNo ratings yet

- Management Programme (Hsmp/emp)Document1 pageManagement Programme (Hsmp/emp)midozotyNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Procedure For Jsa PDFDocument17 pagesProcedure For Jsa PDFHassan RazaNo ratings yet

- The University of Queensland: Confined Spaces Management PlanDocument27 pagesThe University of Queensland: Confined Spaces Management Plantrravi1983No ratings yet

- Portable Ladder Safety: The Importance ofDocument3 pagesPortable Ladder Safety: The Importance oftrravi1983No ratings yet

- Overhead CranesDocument52 pagesOverhead CranesSanthanu SukumaranNo ratings yet

- Overhead CranesDocument52 pagesOverhead CranesSanthanu SukumaranNo ratings yet

- Confined Spaces: Avoiding Common Mistakes in Gas DetectionDocument1 pageConfined Spaces: Avoiding Common Mistakes in Gas Detectiontrravi1983No ratings yet

- Safety Through Accountability & Recognition: OHSMS Management Commitment & Worker Participation ExplainedDocument6 pagesSafety Through Accountability & Recognition: OHSMS Management Commitment & Worker Participation Explainedtrravi1983No ratings yet

- Overhead CranesDocument52 pagesOverhead CranesSanthanu SukumaranNo ratings yet

- Event TreeDocument3 pagesEvent Treetrravi1983No ratings yet

- Introduction To The Management of Safety New ICAO Annex 19: Jean-Pierre ARNAUD R4.2 Rulemaking Officer 27 June 2012Document55 pagesIntroduction To The Management of Safety New ICAO Annex 19: Jean-Pierre ARNAUD R4.2 Rulemaking Officer 27 June 2012Kamaleshaiah MathavaraNo ratings yet

- Complete Guide CSP - 0718 PDFDocument36 pagesComplete Guide CSP - 0718 PDFWaleed MorsyNo ratings yet

- Tough Robust Safest Stacker by JostsDocument12 pagesTough Robust Safest Stacker by Joststrravi1983No ratings yet

- Covid 19 - Joint CMC Assessment Survey InfDocument10 pagesCovid 19 - Joint CMC Assessment Survey Inftrravi1983No ratings yet

- Denatured Spirit FP Rules1959Document87 pagesDenatured Spirit FP Rules1959trravi1983No ratings yet

- Lucas-TVS-Price List - 2nd May 2011Document188 pagesLucas-TVS-Price List - 2nd May 2011apalvora4u75% (12)

- RAMS For Pressure TestingDocument21 pagesRAMS For Pressure TestingAnandu AshokanNo ratings yet

- Method Statement: Installation of Fencing: N60 Balla To Claremorris Road Realignment at Heathlawn Scheme 0 12/5/14Document11 pagesMethod Statement: Installation of Fencing: N60 Balla To Claremorris Road Realignment at Heathlawn Scheme 0 12/5/14Stansilous Tatenda NyagomoNo ratings yet

- Health and Safety PresentationDocument16 pagesHealth and Safety Presentationbarnes method books international96% (27)

- Health & Safety Regulations: Control of Substances Hazardous To Health (Coshh)Document12 pagesHealth & Safety Regulations: Control of Substances Hazardous To Health (Coshh)Keron BretalNo ratings yet

- K-Othrine WG250 LabelDocument12 pagesK-Othrine WG250 LabelPham TuanNo ratings yet

- BSC Unit 2 AssignmentDocument17 pagesBSC Unit 2 AssignmentJamshar Kt89% (9)

- JE04 v1-0 16apr10 W505 MSDS For COSHH Exercise Process 2Document4 pagesJE04 v1-0 16apr10 W505 MSDS For COSHH Exercise Process 2golden abidemNo ratings yet

- Risk Assessment For PaintingDocument10 pagesRisk Assessment For PaintingTawrez KhatibNo ratings yet

- RA For Plumbing and HeatingDocument8 pagesRA For Plumbing and HeatingAngela DaveyNo ratings yet

- 8THL Balt ZZ ZZ HS X 22 0064Document13 pages8THL Balt ZZ ZZ HS X 22 0064georgemlcvpNo ratings yet

- Gold Anchor Criteria V1-2017Document101 pagesGold Anchor Criteria V1-2017Tawa CafeNo ratings yet

- Rig: Satti Date:: Job Risk Assessment JRA No: E-026 Revision:0 TaskDocument2 pagesRig: Satti Date:: Job Risk Assessment JRA No: E-026 Revision:0 Task121212No ratings yet

- Legal Register To UseDocument8 pagesLegal Register To UseKingsley Ahanonu67% (3)

- MSDS K100Document4 pagesMSDS K100Kerron RekhaNo ratings yet

- Coshh Quiz: Pass Mark 10 Out of 12 AnswersDocument1 pageCoshh Quiz: Pass Mark 10 Out of 12 AnswersMohamed Shabir100% (1)

- HSE Plan-TDDocument52 pagesHSE Plan-TDPeshteenNo ratings yet

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanNo ratings yet

- 048A COSHH Thinners-PaintDocument1 page048A COSHH Thinners-PaintanonNo ratings yet

- Greenstar Cdi Service Booklet For Engineers PDFDocument80 pagesGreenstar Cdi Service Booklet For Engineers PDFFabian Henao CalleNo ratings yet

- 3-WD 40 Spray (Anti Rust)Document2 pages3-WD 40 Spray (Anti Rust)MainrajNo ratings yet

- Risk Assessment FormDocument5 pagesRisk Assessment FormZeeshan AhmedNo ratings yet

- Pta MSDSDocument16 pagesPta MSDSSehry SyedNo ratings yet

- LY-HY5052 Safety Data SheetDocument12 pagesLY-HY5052 Safety Data SheetAnkit GuptaNo ratings yet

- Chemical Risk Assessment Presentation Feb 14Document64 pagesChemical Risk Assessment Presentation Feb 14PAUL LessiterNo ratings yet

- Blue Arrow CV Templates - A - Kitchen Porter and AssistantDocument3 pagesBlue Arrow CV Templates - A - Kitchen Porter and AssistantPhethego Caprivian MokgaloNo ratings yet

- Methode Statement For Albestos RemovalDocument59 pagesMethode Statement For Albestos RemovalHedi Ben MohamedNo ratings yet

- Cleaner CVDocument2 pagesCleaner CVAbdulfatai AbdulrasheedNo ratings yet

- Wa0019 PDFDocument59 pagesWa0019 PDFShafi AshrafNo ratings yet

- HSE ListDocument305 pagesHSE Listtcf2921No ratings yet

- Demolition Method Statement: ClientDocument86 pagesDemolition Method Statement: ClientEngr Nissar KakarNo ratings yet