Professional Documents

Culture Documents

R (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling Cables

Uploaded by

Goran MladenovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling Cables

Uploaded by

Goran MladenovicCopyright:

Available Formats

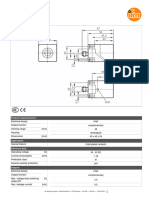

R(N)TSCGEWÖU 3,6/6 kV

based on DIN VDE 0250 p. 813

Medium Voltage Reeling Cables

CONSTRUCTION

Conductors Annealed flexible stranded tin coated class 5 to IEC 60228, HD 383

Separator Suitable semi-conductive tape between the conductor and insulation

Conductor screen Semi-conductive layer

Insulation Ethylene-propylene rubber (EPR) type IE4/ EI4 to IEC/HD

Insulation screen Semi-conductive layer Max. resistivity of semi-conductive layers - 200 x m

Internal layer of sheath A synthetic thermosetting compound type 5GM3 to DIN VDE 0207 part 21

Anti-torsion braid Braid of polyamide threads between internal and outer layer of sheath

Outer layer of sheath A synthetic thermosetting compound type 5GM5 to DIN VDE 0207 part 21

Colour of outer jacket Red or colours can be provided

FEATURES

▪ Excellent tear, impact and abrasion resistant

▪ Flame retardant

▪ Temperature range –25ºC to +90 ºC For fixed installation lowest temperature is -40 ºC

▪ UV, sunlight, ozone, oil resistant

▪ Embossing marking for easy identification

TELE-FONIKA Kable S.A

www.tfkable.com

R(N)TSCGEWOU 3,6/6kV 22.03.2018/JB

R(N)TSCGEWÖU 3,6/6 kV

based on DIN VDE 0250 p. 813

APPLICATIONS

▪ For connection of large material handling machines such as excavators, dumpers, crushers in open-cast

mines.

▪ Cables are suitable for high mechanical stresses in conjunction with mono spiral reels and cylindrical reels.

▪ Other industrial applications

Standard length cable packing 500 m on drums. Other forms of packing and delivery are available on request

Number of cores Nominal Approx. Approx. Current-currying

Cross-section Insulation O.D. Weight Capacity at 300C

Thickness

mm

mm2 mm kg/km A

3x16+3x10 3,0 42,3 2 515 -

3x25+3x10 3,0 45,3 2 985 132

3x25+3x16 3,0 45,3 3 110 132

3x35+3x16 3,0 47,0 3 550 161

3x50+3x10 3,0 52,9 4 350 202

3x50+3x16 3,0 52,9 4 475 202

3x70+3x16 3,0 56,4 5 310 251

3x95+3x16 3,0 61,0 6 315 301

3x120+3x16 3,0 65,7 7 285 351

3x120+3x35 3,0 65,7 8 042 351

3x150+3x25 3,0 69,6 8 990 405

3x150+3x35 3,0 69,6 9240 405

TELE-FONIKA Kable S.A

www.tfkable.com

R(N)TSCGEWOU 3,6/6kV 22.03.2018/JB

R(N)TSCGEWÖU 3,6/6 kV

based on DIN VDE 0250 p. 813

PHYSICAL PARAMETERS

Insulation:

Tensile tests for insulation shall values as follow :

Un aged test pieces : Tensile strength min, 6 N/mm2

Elongation at break min, 200%

Ageing in air oven : 1350C , 168 h

Change TS 30%

Change EB 30%

Internal sheath

Tensile tests shall values as follows :

Un aged test pieces : Tensile strength min , 10 N/mm2

Elongation at break min, 300%

Ageing in air oven : 1000C 168 h

Change TS 30% , EB 40%

After ageing in oil : 240C 168h

Change TS and EB 40 %

Outer sheath

Tensile tests shall values as follows :

Un aged test pieces : Tensile strength min , 15 N/mm2

TELE-FONIKA Kable S.A

www.tfkable.com

R(N)TSCGEWOU 3,6/6kV 22.03.2018/JB

R(N)TSCGEWÖU 3,6/6 kV

based on DIN VDE 0250 p. 813

Elongation at break min, 300%

Ageing in air oven : 1000C 168 h

Change TS 30% , EB 40%

After ageing in oil : 240C 168h

Change TS and EB 40 %

Tear resistance : Value of min, 30 N/mm

ELECTRICAL PARAMETERS:

Current –currying capacity: according to DIN VDE 0298 part 4

Conversion factor for current rating ambient temperatures deviating from 300C

Ambient temp, 0C 20 25 30 35 40 45 50

Conversion factor 1,09 1,05 1,0 0,92 0,88 0,83 0,78

Voltage tests : Cables shall be tested in air and withstand voltage test applied :

between power , earth conductors and screen in according DIN VDE 0250 part 813

Partial Discharge : max, 20 pC

THERMAL PARAMETERS

Ambient temperature: for fixed installation +800C/-400C

for mobile application +600C/-250C

Maximum permissible operating temp, of conductor 90 0C

Short-circuit temperature of conductor 250 0C

MECHANICAL PARAMETERS

TELE-FONIKA Kable S.A

www.tfkable.com

R(N)TSCGEWOU 3,6/6kV 22.03.2018/JB

R(N)TSCGEWÖU 3,6/6 kV

based on DIN VDE 0250 p. 813

Smallest admissible bending radius : according DIN VDE 0298 Part 3

The manufacturer recommend as below :

for fixed installation 6 D , D= cable diameter

for forced guidance with reeling operations 12 D

for forced guidance with sheaves 15 D

Torsion stress ± 100 0/m

Tensile load: Up to 20N/mm2

CHEMICAL PARAMETERS

Resistance to oil : DIN VDE ,Part 811-2-1 P, 10

Weather resistance : resistant to ozone , UV and moisture,

All the information contained in this document - including tables and diagrams - is given in good faith and believed to be correct at

the time of publication, The information does not constitute a warranty nor representation for which TELE-FONIKA Kable assumes

legal responsibility, TELE-FONIKA Kable reserves rights to introduce changes to the document at any time,

TELE-FONIKA Kable S.A

www.tfkable.com

R(N)TSCGEWOU 3,6/6kV 22.03.2018/JB

You might also like

- R (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling CablesDocument5 pagesR (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling CablesGoran MladenovicNo ratings yet

- Extremely torsionally stiff trailing cablesDocument1 pageExtremely torsionally stiff trailing cablesLuis AguilarNo ratings yet

- Tenax-Htt N-Tscgewoeu 6-10 KVDocument2 pagesTenax-Htt N-Tscgewoeu 6-10 KVbeycanNo ratings yet

- Medium Voltage Power CableDocument3 pagesMedium Voltage Power CableGuruh Panji SukardiNo ratings yet

- Traycontrol 600 C 2Document2 pagesTraycontrol 600 C 2ikuzma_1No ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnNo ratings yet

- Bahra WiresDocument12 pagesBahra WiresJoseph JoeNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument3 pagesCordaflex (SMK) (N) Shtoeufikri abu kassimNo ratings yet

- PC WireDocument7 pagesPC Wirejupe01No ratings yet

- TML Flat CableDocument2 pagesTML Flat CableMahmoud Al-SherbinyNo ratings yet

- Tauchflex-FL: 750 V, Blue, Submersible Pump CableDocument1 pageTauchflex-FL: 750 V, Blue, Submersible Pump Cabletees220510No ratings yet

- Resistor 10r0Document8 pagesResistor 10r0ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- SM Series: Aluminium Electrolytic CapacitorDocument2 pagesSM Series: Aluminium Electrolytic CapacitorStuxnetNo ratings yet

- J-Y (ST) y LG Rev004Document2 pagesJ-Y (ST) y LG Rev004Ruslan ValiakhmetovNo ratings yet

- N Tscgewã U 3 6 6kv and 6 10kv Submersible CableDocument3 pagesN Tscgewã U 3 6 6kv and 6 10kv Submersible Cableheri fauziNo ratings yet

- Helukabel F-Cy-JzDocument2 pagesHelukabel F-Cy-JzMikko MagtibayNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument4 pagesCordaflex (SMK) (N) ShtoeurachidNo ratings yet

- 3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws ArmouredDocument2 pages3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws Armouredgari_monsantoNo ratings yet

- Cable 07rn8-f 750v Epr-Cpe Blue-ElcosubDocument2 pagesCable 07rn8-f 750v Epr-Cpe Blue-ElcosubMiguel MontalvánNo ratings yet

- TT Control 600P 220SDocument4 pagesTT Control 600P 220Snanda09lvNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Optronics - Cat - 6 UUTP PVC CableDocument4 pagesOptronics - Cat - 6 UUTP PVC CableblegedesNo ratings yet

- DAHRENTRAD - DAMIDFIBRE - Przewody Emalia-SzkłoDocument4 pagesDAHRENTRAD - DAMIDFIBRE - Przewody Emalia-SzkłoSzymonNo ratings yet

- Vishay Dale ResistorsDocument8 pagesVishay Dale Resistorsalko123No ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- Wire - Building Al FanarDocument63 pagesWire - Building Al FanarKhaled BellegdyNo ratings yet

- HES KABLO POWERCABLE CATALOGUEDocument292 pagesHES KABLO POWERCABLE CATALOGUEحسن علي جاسمNo ratings yet

- FELTOFLEX NTMCWOEU 20kV - enDocument2 pagesFELTOFLEX NTMCWOEU 20kV - enPhilippe SingletonNo ratings yet

- Bahra Cable Building Wire CatalogDocument12 pagesBahra Cable Building Wire CatalognooruddinkhanNo ratings yet

- Flexidrum Nshtou 1Document3 pagesFlexidrum Nshtou 1Anonymous ItzBhUGoiNo ratings yet

- 2N6027Document9 pages2N6027mariogizziNo ratings yet

- 2.4 KV GENERAL CABLE PDFDocument2 pages2.4 KV GENERAL CABLE PDFjhernandezelNo ratings yet

- General Purpose Relays: SCHRACK Power PCB Relay RZDocument4 pagesGeneral Purpose Relays: SCHRACK Power PCB Relay RZBipmpNo ratings yet

- Medium Voltage Cables: Cable Structure: Technical DataDocument1 pageMedium Voltage Cables: Cable Structure: Technical Dataosvald97No ratings yet

- GORE Magnet Wires DataSheet OG - A4Document4 pagesGORE Magnet Wires DataSheet OG - A4terminatrixNo ratings yet

- Cable - Supershot - Protomont 241.1 3x120+3x70E+PilotDocument6 pagesCable - Supershot - Protomont 241.1 3x120+3x70E+PilotLong PhamNo ratings yet

- (N) Shtöu VDocument1 page(N) Shtöu VLuis AguilarNo ratings yet

- 15kv Phelps DodgeDocument4 pages15kv Phelps DodgeJuan E Torres M100% (1)

- WiresDocument17 pagesWiressureshisisisNo ratings yet

- STD H1Z2Z2-K Jembo Cable Solar Boom-1Document3 pagesSTD H1Z2Z2-K Jembo Cable Solar Boom-1kemasNo ratings yet

- FG7 (O) R Rev009Document3 pagesFG7 (O) R Rev009Armin HajdarovićNo ratings yet

- Raychem Spec 44Document8 pagesRaychem Spec 44zakariiNo ratings yet

- 11kV 3 Core PILC SWA BS6480 Cable SpecificationDocument3 pages11kV 3 Core PILC SWA BS6480 Cable SpecificationMuhammad TaufiqNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- 33kV BS7835 LSZH 3core Armoured Power CableDocument2 pages33kV BS7835 LSZH 3core Armoured Power Cablelafarge lafargeNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- SOLAR CABLE 0,6-1 KV PV1-F CharacteristicsDocument2 pagesSOLAR CABLE 0,6-1 KV PV1-F CharacteristicswagnerengNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- BS 7211 CableDocument22 pagesBS 7211 CablehanoiNo ratings yet

- na2xs2y-18-30-36-kv-cableDocument3 pagesna2xs2y-18-30-36-kv-cableElton MelecoNo ratings yet

- 3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty CwsDocument2 pages3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cwsgari_monsantoNo ratings yet

- ELETTRO SOLAR PV1-F Solar cables technical dataDocument1 pageELETTRO SOLAR PV1-F Solar cables technical dataPlacido León ValleNo ratings yet

- B Span 330m Silec Technical Offer Ref 5890636827terDocument9 pagesB Span 330m Silec Technical Offer Ref 5890636827terUdriste DanielNo ratings yet

- Weighbeam DWB40-200 TDocument4 pagesWeighbeam DWB40-200 TdassoumennNo ratings yet

- Datasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Document7 pagesDatasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Blendwerk AntikunstNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Lapp Pro261426enDocument4 pagesLapp Pro261426enLORIUNEANo ratings yet

- Lapp Pro481297enDocument4 pagesLapp Pro481297enGoran MladenovicNo ratings yet

- En Futura Data SheetDocument4 pagesEn Futura Data SheetGoran MladenovicNo ratings yet

- Etherline® PN Cat.5: Product InformationDocument4 pagesEtherline® PN Cat.5: Product InformationAchira DasanayakeNo ratings yet

- TeSys D contactor datasheetDocument6 pagesTeSys D contactor datasheetprasadNo ratings yet

- SchneiderDocument6 pagesSchneiderGoran MladenovicNo ratings yet

- Im511a 03 - en GBDocument3 pagesIm511a 03 - en GBGoran MladenovicNo ratings yet

- Dps Account Statement 20230828093145Document1 pageDps Account Statement 20230828093145Goran MladenovicNo ratings yet

- Data Sheet: Pro Eco 72W 24V 3ADocument5 pagesData Sheet: Pro Eco 72W 24V 3AArun KumarNo ratings yet

- YTONG - RS - PremiumDocument2 pagesYTONG - RS - PremiumGoran MladenovicNo ratings yet

- Dps Account Statement 20230828093145Document1 pageDps Account Statement 20230828093145Goran MladenovicNo ratings yet

- Schneider Electric Spacial-SM NSYSPS6200Document3 pagesSchneider Electric Spacial-SM NSYSPS6200Goran MladenovicNo ratings yet

- SINAMICS S120 Cabinet Modules Air Cooled en-USDocument710 pagesSINAMICS S120 Cabinet Modules Air Cooled en-USGoran MladenovicNo ratings yet

- MFL71675701 00 211130 WebDocument420 pagesMFL71675701 00 211130 WebGoran MladenovicNo ratings yet

- Confirmation of ConformityDocument4 pagesConfirmation of ConformityGoran MladenovicNo ratings yet

- G34296470024.q.eng-Dupline Universal Analog Input Module (4AI)Document3 pagesG34296470024.q.eng-Dupline Universal Analog Input Module (4AI)Goran MladenovicNo ratings yet

- ERI556660 DocumentDocument2 pagesERI556660 DocumentGoran MladenovicNo ratings yet

- Data Sheet 6ES7138-6AA01-0BA0: General InformationDocument4 pagesData Sheet 6ES7138-6AA01-0BA0: General InformationGoran MladenovicNo ratings yet

- Spacial SM - NSYSPCRDocument2 pagesSpacial SM - NSYSPCRGoran MladenovicNo ratings yet

- Altistart 48 - ATS48D75QDocument5 pagesAltistart 48 - ATS48D75QGoran MladenovicNo ratings yet

- Altistart 48 - ATS48D17QDocument5 pagesAltistart 48 - ATS48D17QHASTUNGKARA groupNo ratings yet

- Rittal WM Stainless Steel Enclosures 5 3078Document8 pagesRittal WM Stainless Steel Enclosures 5 3078tzuvela99No ratings yet

- Data Sheet 6XV1840-2AH10Document3 pagesData Sheet 6XV1840-2AH10Goran MladenovicNo ratings yet

- EMI Electrical Design GuideDocument34 pagesEMI Electrical Design GuideamardeepNo ratings yet

- TCSESU043F1N0: Product Data SheetDocument3 pagesTCSESU043F1N0: Product Data SheetGoran MladenovicNo ratings yet

- TeSys F - LC1F1000Document3 pagesTeSys F - LC1F1000Goran MladenovicNo ratings yet

- Altistart 48 - ATS48D75QDocument5 pagesAltistart 48 - ATS48D75QGoran MladenovicNo ratings yet

- Spacial CRN - NSYCRN106250Document2 pagesSpacial CRN - NSYCRN106250Goran MladenovicNo ratings yet

- 11KV MetalCladSwitchgear Protection Metering Panels 30 June 2010 2Document62 pages11KV MetalCladSwitchgear Protection Metering Panels 30 June 2010 2Rodolfo RodriguezNo ratings yet

- Uv 5x3 Manual PDFDocument91 pagesUv 5x3 Manual PDFChrisNo ratings yet

- 296 Clamp DMM User ManualDocument17 pages296 Clamp DMM User ManualBob JonesNo ratings yet

- CM-UFD.M31: Grid Feeding Monitoring According To VDE-AR-N 4105 and BDEWDocument17 pagesCM-UFD.M31: Grid Feeding Monitoring According To VDE-AR-N 4105 and BDEWZaharia MarianNo ratings yet

- Ysly Oz Ysly JZ EngDocument3 pagesYsly Oz Ysly JZ EngTrajkoNo ratings yet

- VINAYAKDocument27 pagesVINAYAKem1teamdNo ratings yet

- C1 - TQBM-D609017-Q172717DEI-65FT2v02Document2 pagesC1 - TQBM-D609017-Q172717DEI-65FT2v02carlosconstructor1No ratings yet

- As19 h1g PDFDocument12 pagesAs19 h1g PDFronald sosaNo ratings yet

- PDFDocument2 pagesPDFceca89No ratings yet

- AP Physics C: Electricity and Magnetism - Electrostatics ReviewDocument17 pagesAP Physics C: Electricity and Magnetism - Electrostatics ReviewDarkAgesGamerVNo ratings yet

- Mitsubishi Fx3u 20ssc H Sscnet Motion Users ManualDocument304 pagesMitsubishi Fx3u 20ssc H Sscnet Motion Users ManualCORTOCIRCUITANTENo ratings yet

- JDVP Learning MatrixDocument8 pagesJDVP Learning MatrixSCMCST IncNo ratings yet

- NEW I-LINE H CatalogueDocument60 pagesNEW I-LINE H CatalogueKenyDuyệtNo ratings yet

- CMOS Analog Circuit Design (Allen-2016)Document1,412 pagesCMOS Analog Circuit Design (Allen-2016)curliph0% (1)

- Synchronous Alternators: Three-Phase BrushlessDocument5 pagesSynchronous Alternators: Three-Phase BrushlessĐại DươngNo ratings yet

- Motion Mountain - Vol. 3 - Light, Charges and Brains - The Adventure of PhysicsDocument455 pagesMotion Mountain - Vol. 3 - Light, Charges and Brains - The Adventure of Physicsmotionmountain92% (12)

- ASR-3000 Service Manual PDFDocument23 pagesASR-3000 Service Manual PDFGencho VasilevNo ratings yet

- Load Cell (UTM)Document1 pageLoad Cell (UTM)José Rubén Ramos GarzaNo ratings yet

- Mk60 Wiring InstructionsDocument6 pagesMk60 Wiring InstructionsAnas KhalilNo ratings yet

- Chapter - 2 Transformers: 2.1 What Is A Transformer?Document23 pagesChapter - 2 Transformers: 2.1 What Is A Transformer?muralibeee2874No ratings yet

- PRC 119 (F) Student Guide v09 (1) .12.09Document143 pagesPRC 119 (F) Student Guide v09 (1) .12.09tomfriis0% (1)

- Transient Analysis: Jaesung JangDocument22 pagesTransient Analysis: Jaesung JangShivang LowanshiNo ratings yet

- Ficha Tecnica InversorDocument2 pagesFicha Tecnica InversorLissette Isabel E ANo ratings yet

- Chapter 4 Electronics and Thermionic EmissionDocument14 pagesChapter 4 Electronics and Thermionic EmissionNagmudiin AhmethNo ratings yet

- Three Phase Transformer 33/0.415kV DatasheetDocument1 pageThree Phase Transformer 33/0.415kV DatasheetTarik KhanNo ratings yet

- Power Supply Systems Spds Type 2: Dehnguard® Modular DG M TT 275 FMDocument2 pagesPower Supply Systems Spds Type 2: Dehnguard® Modular DG M TT 275 FMMohammad NasarNo ratings yet

- Installation Operation Maintenance: GVWF (R134a) GVWF-G (R1234ze)Document40 pagesInstallation Operation Maintenance: GVWF (R134a) GVWF-G (R1234ze)David PerisNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetDileep S NairNo ratings yet

- Safety and Statutory Information: Ar300 Series RouterDocument20 pagesSafety and Statutory Information: Ar300 Series RouterDavide SestiNo ratings yet

- Aircraft & Engine - Technical GeneralDocument16 pagesAircraft & Engine - Technical GeneralprachatNo ratings yet