Professional Documents

Culture Documents

PTFE Material Property Sheet

Uploaded by

kdalavadi3905Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTFE Material Property Sheet

Uploaded by

kdalavadi3905Copyright:

Available Formats

Technical Data Sheet – TDS – Physical Properties of PTFE and Filled PTFE Products

Physical properties of Virgin PTFE & Filled Grade of PTFE are dependent upon many factors such as Grades of PTFE – Conventional, Modified PTFE or Fill ed PTFE, Particle size of r esin – Fine Cut or Coarse, Particle Shape of Resin – Spherical,

Flake, Irregular, Type & content of filler, Manufacturi ng Process – Compression Molding, Ram Extrusion, I sostatic, Paste Extrusion. Due to this – Physical Properties of PTFE & Filled PTFE Products – have the wide range of Values:-

25% Carbon / 35% Carbon /

Chemically 5% Glass 15% Glass 40% Bronze/ 40% Bronze 55% Bronze +

15% Glass 25% Glass 23% Carbon + 2% 33% Carbon + 15% Graphite 60% Bronze

Sr. Virgin PTFE Modified +5% MoS2 +5% MoS2 TSQ Filled + 5% MoS2 5% MoS2 Filled

Filled PTFE Filled PTFE Graphite Filled 2% Graphite Filled PTFE Filled PTFE

Property Unit Test Method PTFE Filled PTFE Filled PTFE PTFE Filled PTFE PTFE

PTFE Filled PTFE

No.

1 2 3 4 5 6 7 8 9 10 11 12 13

1 Density gm / cc ASTM D-792 2.1 – 2.2 2.15 – 2.2 2.15– 2.22 2.22– 2.25 2.20 – 2.24 2.20– 2.24 2.0 – 2.2 2.0 – 2.14 2.10– 2.16 3.0 – 3.2 3 – 3.2 3.8 – 4.0 3.8 – 4

2

2 Tensile Strength kgf/cm ASTM D-638 210 – 375 300 – 325 180– 260 125– 200 175– 250 150– 220 125–200 100– 175 150– 200 125– 225 125-225 100– 200 100-200

3 Elongation of Break % ASTM D-638 250 – 400 400 – 450 225-325 200-300 200-300 220-320 80–150 100-150 150-250 200-350 200-350 150-300 150-300

2

4 Compressive Strength kgf/cm ASTM D-695 40-50 45-55 65-75 75-85 60-70 65-75 75–85 80-90 65-75 85-100 80-95 115-125 115-125

5 Deformation under load (Max.)

0

a 2 Hrs. 23 C 113 kgf % 12 3.5 10 9 11 10 5 4 6 5 5 4 4

0

b 24 Hrs. 23 C 113 kgf ASTM D-621 15 5 12 11 13 12 7 6 8 6 6 5 5

c Permanent 8 2.5 7.5 7 8.5 7.5 3.5 3 4.5 3 3 2.5 2.5

0

d 2 Hrs. 150 C 113 kgf 55 40 52 50 52 50 35 30 43 42 42 40 40

6 Impact strength J/cm ASTM D-256 1.4 – 1.5 1.6 – 1.75 1.2 – 1.3 1.0 – 1.1 1.25 – 1.35 1.2 – 1.3 0.7 – 0.8 0.6 – 0.7 0.8 – 0.9 0.9 – 1.0 0.9 – 1.0 0.8 – 0.9 0.85 – 0.95

7 Hardness Shore D ASTM D-2240 58 – 62 56 – 62 58 – 62 58 – 63 60 – 65 60 – 65 60 – 65 60 – 65 60 – 65 62 – 66 62 – 66 64 – 68 64 – 68

8 Coefficient of Friction ASTM-D-1894 -

2

a DynamicP-7 kg/cm V-0.5 0.04-0.06 0.02-0.03 0.31-0.37 0.5-0.54 0.15-0.20 0.15-0.20 0.12-0.17 0.13-0.18 0.11-0.16 0.11-0.15 0.1-0.14 0.12-0.16 0.11-0.14

2

b Static P-35 kg/cm 0.05-0.08 0.04-0.06 0.01-0.12 0.11-0.13 0.08-0.01 0.08-0.01 0.09-0.11 0.01-0.12 0.08-0.10 0.08-0.10 0.075-0.09 0.08-0.10 0.07-0.09

9 Wear Rate (Max.) gm/s ASTM-G-137 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

10 Water Absorption (Max.) % ASTM D-570 0 0 0.015 0.013 0.015 0.015 0 0 0 0 0 0 0

0

11 Continuous Service Temperature C ASTM-D-648 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260

12 Heat Resistance (Max.) % ASTM-D-648 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

-6

13 Coefficient of Linear Thermal Expansion– 10 X % ASTM D-696 250 – 275 250 – 275 240 – 265 235 – 255 245 – 270 240 – 265 225 – 250 215 – 240 240 – 265 200 – 225 200 – 225 175 – 200 175 – 200

14 Linear Thermal Expansion (Max.) A R A R A R A R A R A R A R A R A R A R A R A R A R

0

a 30 – 150 C 1.5 1.5 1.5 1.5 1.5 1 1.5 0.7 1.5 1 1.5 1 1.2 1 1.1 0.9 1.3 1 1.15 0.95 1.15 0.95 1.1 0.9 1.1 0.9

% ASTM D-696

0

b 30 – 200 C 2.4 2.3 2.4 2.3 2.3 1.8 2.2 1 2.3 1.8 2.3 1.8 1.9 1.5 1.8 1.4 2 1.7 1.85 1.55 1.85 1.55 1.8 1.5 1.8 1.5

0

c 30 – 250 C 3.4 3.6 3.4 3.6 3.3 2.2 3.2 1.4 3.3 2.2 3.3 2.2 2.7 2.4 2.5 2.3 3 2.5 2.55 2.25 2.55 2.25 2.5 2.2 2.5 2.2

15 Dielectric Strength Kv/mm ASTM D-149 22 – 24 30 – 35 15 – 16 11 – 12 15 – 16 15 – 16 1–2 1–2 1–2 Conductive Conductive Conductive Conductive

16 Dimensional stability

a Length % ASTM-D-1710 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3 1.5 – 3

b Diameter % 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1 0.5 – 1

17 Chemical Resistance (Max.)

a Permeability % ASTM-D-543 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

b Dissolution % 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

PTFE is chemically inert & unaffected by all known chemicals except molten or dissolved alkali metals–Sodium; Potassium; Rubidium; Cesiurn; Francium & Fluorine gas, certain fluorine compounds & complexes at elevated temperatures. Filled PTFE has inferior chemical

c

resistance depending upon the particular filler.

The physical properties of Standard & Non-standard filled grade composition not mentioned in above table are to be referred on the basis of Material Test Certificate issued by Raw Material Supplier / Manufacturer. Data quoted are average values only & should not be used for designed

purpose.

Company has in-house test facility / Laboratory to test above properties. The testing equipments are calibrated as per procedures laid down in QMS-ISO-9001:2008, having traceability with NPL. The test procedures are self designed, similar to above referred ASTMs.

You might also like

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- Virgin and Filled PTFE (Teflon) PDFDocument1 pageVirgin and Filled PTFE (Teflon) PDFAnjani PrabhakarNo ratings yet

- Virgin and Filled PTFE (Teflon) New PDFDocument1 pageVirgin and Filled PTFE (Teflon) New PDFmohan115No ratings yet

- Virgin and Filled PTFE TeflonDocument1 pageVirgin and Filled PTFE TeflonRedzaNo ratings yet

- PTFE SammenligningstabellDocument2 pagesPTFE SammenligningstabellHardRockDiskNo ratings yet

- Armacell ArmaPET StructDocument4 pagesArmacell ArmaPET StructPeter Pumpkin EaterNo ratings yet

- Portland Limestone PCA Show 2014Document21 pagesPortland Limestone PCA Show 2014Agung PrasetyoNo ratings yet

- Threaded Ball Valves s51 PB en UsDocument2 pagesThreaded Ball Valves s51 PB en Usmahadeva1No ratings yet

- 228 706 TDDocument2 pages228 706 TDramiNo ratings yet

- Fluoroline ANSI 150 DataDocument31 pagesFluoroline ANSI 150 DataRanjani J DeepakNo ratings yet

- Isotech Etalon SondeDocument3 pagesIsotech Etalon SondeSinisaNo ratings yet

- 3-5 stage cement kiln comparison chartDocument1 page3-5 stage cement kiln comparison chartzementheadNo ratings yet

- Clinker IzationDocument30 pagesClinker Izationamaralinga chariNo ratings yet

- Value Bond VB NominalDocument4 pagesValue Bond VB NominaljessikaNo ratings yet

- Stuffing Box Packings: Sealing For A Safer and Greener TomorrowDocument4 pagesStuffing Box Packings: Sealing For A Safer and Greener TomorrowT. Sandy FajarNo ratings yet

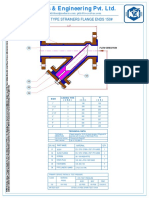

- Lined y Type Strainer 150Document1 pageLined y Type Strainer 150Su VicharNo ratings yet

- Protection Transformers Encapsulated in Resin: ReferencesDocument4 pagesProtection Transformers Encapsulated in Resin: ReferencesAlexander BakirovNo ratings yet

- REHOME CatalogueDocument36 pagesREHOME CatalogueNelson VielmaNo ratings yet

- Tabella Riassuntiva T.A. Di Precisione High Accuracy Cts Selection TableDocument27 pagesTabella Riassuntiva T.A. Di Precisione High Accuracy Cts Selection TableMEINARDONo ratings yet

- Especificação de GraxasDocument1 pageEspecificação de GraxasDouglas TondelloNo ratings yet

- 6996 TB 0102 Ground Granulated Blast Furnace Slag Its Chemistry and Use Chemical Admixtures Technical enDocument4 pages6996 TB 0102 Ground Granulated Blast Furnace Slag Its Chemistry and Use Chemical Admixtures Technical ensreeraj77No ratings yet

- Armacell - PET GR SeriesDocument4 pagesArmacell - PET GR SeriesJose Leandro AlvesNo ratings yet

- AFLAS Technical DatasheetDocument13 pagesAFLAS Technical DatasheetManual SourceNo ratings yet

- Outdoor unit specifications tableDocument2 pagesOutdoor unit specifications tableAhmed NajjarNo ratings yet

- SGL Datasheet SIGRAFLEX Graphite Rayons Yarns ENDocument2 pagesSGL Datasheet SIGRAFLEX Graphite Rayons Yarns ENTatyana MladenovaNo ratings yet

- Reciprocating CompressorsDocument1 pageReciprocating CompressorsSh.nasirpurNo ratings yet

- Kunst 3500Document3 pagesKunst 3500Ashish GondaneNo ratings yet

- Calcul GrinziDocument107 pagesCalcul GrinziAndriana DeacuNo ratings yet

- Fundamentals For Special Valves: Pressure Reducing Valve V82Document6 pagesFundamentals For Special Valves: Pressure Reducing Valve V82carlosNo ratings yet

- Ace Mersen Armylor - 2 Ptfe Pfa Lined Pipes Fittings AnsiDocument32 pagesAce Mersen Armylor - 2 Ptfe Pfa Lined Pipes Fittings AnsiClaire GrecoNo ratings yet

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDocument1 pageTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNo ratings yet

- Athabasca ConocoSurmont SAGDDocument258 pagesAthabasca ConocoSurmont SAGDosuna.osirisNo ratings yet

- Super TacDocument2 pagesSuper TacVelina MilevaNo ratings yet

- Comparison between Taiwan and Chinese CementDocument4 pagesComparison between Taiwan and Chinese CementNidDouNo ratings yet

- ASTM F1554 - Portland BoltDocument1 pageASTM F1554 - Portland BoltjacquesmayolNo ratings yet

- 5592F - Válvula de Bola (Roscada)Document1 page5592F - Válvula de Bola (Roscada)Rafael SalazarNo ratings yet

- Kavaata Ball Valves Seat Material Selection GuideDocument2 pagesKavaata Ball Valves Seat Material Selection GuideBibhu Ranjan MohantyNo ratings yet

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball ValvesBibhu Ranjan MohantyNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Cutsheet DixonDocument1 pageCutsheet Dixondcabrera600No ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- PT. Tekenomiks IndonesiaDocument4 pagesPT. Tekenomiks IndonesiaAhmat RamadaniNo ratings yet

- Envases para EnsaladasDocument11 pagesEnvases para EnsaladasJohan VargasNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- 3.4 Bituminous Materials: 3.4.1 DescriptionDocument5 pages3.4 Bituminous Materials: 3.4.1 DescriptionSujon AhmmedNo ratings yet

- TEFPASS Flexible HoseDocument12 pagesTEFPASS Flexible Hosegamil2No ratings yet

- Ace Mersen Armylor 2 Ptfe Pfa Lined Pipes DinDocument32 pagesAce Mersen Armylor 2 Ptfe Pfa Lined Pipes DinClaire GrecoNo ratings yet

- SPECIAL PIPES TORQUING TABLESDocument1 pageSPECIAL PIPES TORQUING TABLESdfz138No ratings yet

- Data Sheet Exxelor Maleic Anhydride Function Ali Zed PP PO 1020Document2 pagesData Sheet Exxelor Maleic Anhydride Function Ali Zed PP PO 1020maheshgupteNo ratings yet

- Te Lab RangesDocument4 pagesTe Lab Rangestangudusrikanth513gmNo ratings yet

- Manual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDocument2 pagesManual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDeivid Weber100% (1)

- 2023 EmaxDocument3 pages2023 EmaxYander Luis Hernández ArmasNo ratings yet

- Krylon - All Fast Dry Enamel PaintDocument4 pagesKrylon - All Fast Dry Enamel Paintjaredf@jfelectric.com100% (2)

- Hdpe PipeDocument7 pagesHdpe PipeAattakaariNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Ador Welding Cromoten D For c5 & f5 WeldingDocument1 pageAdor Welding Cromoten D For c5 & f5 WeldingShar MathewNo ratings yet

- Spiral Hose Guard: REF Length Wall ID OD Range Box WeightDocument2 pagesSpiral Hose Guard: REF Length Wall ID OD Range Box Weightviktor_gligorovNo ratings yet

- Glassfilled Ptfe Technical Data SheetDocument2 pagesGlassfilled Ptfe Technical Data Sheetseeralan_1986No ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Metals: Ffects of Different Parameters On Initiation andDocument18 pagesMetals: Ffects of Different Parameters On Initiation andFerdanish ShafiqNo ratings yet

- Stress Corrosion CrackingDocument16 pagesStress Corrosion CrackingzaxaderNo ratings yet

- Model: Series YS Model: Series YS: Flanged Stainless Steel Y-StrainerDocument3 pagesModel: Series YS Model: Series YS: Flanged Stainless Steel Y-Strainerkdalavadi3905No ratings yet

- Viton Selection GuideDocument18 pagesViton Selection GuideJohn MuellerNo ratings yet

- The Impact of Lee 534-8-3 On Control Valve Aerodynamic Noise PredictionDocument8 pagesThe Impact of Lee 534-8-3 On Control Valve Aerodynamic Noise Predictionkdalavadi3905No ratings yet

- Viton Selection GuideDocument18 pagesViton Selection GuideJohn MuellerNo ratings yet

- Solenoid Valve - BifoldDocument20 pagesSolenoid Valve - Bifoldkdalavadi3905No ratings yet

- Stress Corrosion CrackingDocument16 pagesStress Corrosion CrackingzaxaderNo ratings yet

- Soft Materials Temp-Pressure - GraphsDocument23 pagesSoft Materials Temp-Pressure - Graphsdevadoss kishoreNo ratings yet

- ASCO Symbols ValvesDocument2 pagesASCO Symbols ValvesPipe CastilloNo ratings yet

- ASCO Symbols ValvesDocument2 pagesASCO Symbols ValvesPipe CastilloNo ratings yet

- Evaluating Apparent Grain Size and Distribution of Cemented Tungsten CarbidesDocument4 pagesEvaluating Apparent Grain Size and Distribution of Cemented Tungsten Carbideskdalavadi3905No ratings yet

- Stepping Actuator Catalogue PDFDocument6 pagesStepping Actuator Catalogue PDFkdalavadi3905No ratings yet

- The Impact of Lee 534-8-3 On Control Valve Aerodynamic Noise PredictionDocument8 pagesThe Impact of Lee 534-8-3 On Control Valve Aerodynamic Noise Predictionkdalavadi3905No ratings yet

- Soft Materials Temp-Pressure - GraphsDocument23 pagesSoft Materials Temp-Pressure - Graphsdevadoss kishoreNo ratings yet

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- AWS A5.21-A5.21 M - 2011 SPC For Electrods & Rodes For SurfacingDocument12 pagesAWS A5.21-A5.21 M - 2011 SPC For Electrods & Rodes For Surfacingkdalavadi390550% (2)

- Axial Cylindrical Roller Bearings - Cages and Washers PDFDocument14 pagesAxial Cylindrical Roller Bearings - Cages and Washers PDFkdalavadi3905No ratings yet

- Vapour Pressure 2006Document6 pagesVapour Pressure 2006Sathish KumarNo ratings yet

- Model: Series YS Model: Series YS: Flanged Stainless Steel Y-StrainerDocument3 pagesModel: Series YS Model: Series YS: Flanged Stainless Steel Y-Strainerkdalavadi3905No ratings yet

- Model: Series YS Model: Series YS: Flanged Stainless Steel Y-StrainerDocument3 pagesModel: Series YS Model: Series YS: Flanged Stainless Steel Y-Strainerkdalavadi3905No ratings yet

- Cobalt Tungsten Carbide - Powder and HardmetalDocument180 pagesCobalt Tungsten Carbide - Powder and Hardmetalkdalavadi3905No ratings yet

- SKF Thrust BearingsDocument20 pagesSKF Thrust BearingsBùi Văn HợpNo ratings yet

- Datasheet For Steel Grades Tool Steel and Hard Alloy Stellite 6Document2 pagesDatasheet For Steel Grades Tool Steel and Hard Alloy Stellite 6kdalavadi3905No ratings yet

- Vapour Pressure 2006Document6 pagesVapour Pressure 2006Sathish KumarNo ratings yet

- SP-2154 - REV.1 Valves Technical Specification - 2014Document22 pagesSP-2154 - REV.1 Valves Technical Specification - 2014kdalavadi3905No ratings yet

- Vlave Stem Leack Tightness Method PDFDocument82 pagesVlave Stem Leack Tightness Method PDFkdalavadi3905No ratings yet

- Effect of Corrosion MaterialsDocument42 pagesEffect of Corrosion Materialskdalavadi3905No ratings yet

- Proposal For Mining Skill TrainingDocument31 pagesProposal For Mining Skill Trainingdwarka prasad100% (1)

- Lecture 10Document19 pagesLecture 10Sara AlwehrNo ratings yet

- Official All Things Turmeric PPT GuidebookDocument14 pagesOfficial All Things Turmeric PPT Guidebookapi-507527047No ratings yet

- Tle 9 DLL Q3 W1 1Document3 pagesTle 9 DLL Q3 W1 1Joanne GodezanoNo ratings yet

- Energy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneDocument25 pagesEnergy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneVỵ ĐặngNo ratings yet

- Acoustic Design For Call CenterDocument16 pagesAcoustic Design For Call CenteraliNo ratings yet

- String TheoryDocument12 pagesString TheoryYashvinder SinghNo ratings yet

- Creating A 3D-Map Using Reference Points: Cfr-19-Stm-CanadasatDocument14 pagesCreating A 3D-Map Using Reference Points: Cfr-19-Stm-Canadasattuguldur bayaraaNo ratings yet

- Dolphin Facts For Kids Ilovepdf CompressedDocument1 pageDolphin Facts For Kids Ilovepdf CompressedtechboostmrktgNo ratings yet

- HSE Report On Mooring IntegrityDocument313 pagesHSE Report On Mooring IntegritysanumajNo ratings yet

- Food DirectoryDocument20 pagesFood Directoryyugam kakaNo ratings yet

- Aeroacoustic and Aerodynamic Optimization of Propeller BladesDocument14 pagesAeroacoustic and Aerodynamic Optimization of Propeller BladesWouterr GNo ratings yet

- Paper1202169 2180 PDFDocument12 pagesPaper1202169 2180 PDFManish AnandNo ratings yet

- Deltopectoral Approach to the ShoulderDocument28 pagesDeltopectoral Approach to the ShoulderChrysi TsiouriNo ratings yet

- ABC Oilfield Services Emergency Drill RecordDocument1 pageABC Oilfield Services Emergency Drill RecordJaijeev PaliNo ratings yet

- Overview of Metal Forming ProcessesDocument19 pagesOverview of Metal Forming ProcessesAnonymous 7yN43wjlNo ratings yet

- Behavior of Connected and Unconnected Back-to-Back Walls For Bridge ApproachesDocument10 pagesBehavior of Connected and Unconnected Back-to-Back Walls For Bridge Approachessalar salarNo ratings yet

- Basic CourseDocument97 pagesBasic CourseAhmed KhairyNo ratings yet

- Water Transport Studies in Stone Masonry With Soil Cement MortarDocument10 pagesWater Transport Studies in Stone Masonry With Soil Cement MortarTJPRC PublicationsNo ratings yet

- 2021 SC Hurricane GuideDocument16 pages2021 SC Hurricane GuideWMBF News100% (1)

- Ashok M.tech CompleteDocument65 pagesAshok M.tech CompleteAshok BhatiaNo ratings yet

- Eating Healthily: People's Mixed ViewsDocument2 pagesEating Healthily: People's Mixed ViewsTbb GajahMada MagetanNo ratings yet

- Evaluation of Plant Extracts Against Two Spotted Spider MiteDocument7 pagesEvaluation of Plant Extracts Against Two Spotted Spider MiteAnkaranaRenvaNo ratings yet

- Chennai Public School: CH 3 Coordinate Geometry Multiple AssessmentDocument3 pagesChennai Public School: CH 3 Coordinate Geometry Multiple Assessment11F10 RUCHITA MAARANNo ratings yet

- Decline of Controversy and the Catholic ChurchDocument3 pagesDecline of Controversy and the Catholic ChurchEugenio PalandriNo ratings yet

- Special Report 205 Chemical Weekly 1 4-B PDFDocument7 pagesSpecial Report 205 Chemical Weekly 1 4-B PDFsifrmoroNo ratings yet

- Astm C1396 C1396M-17Document8 pagesAstm C1396 C1396M-17Stefano CamillucciNo ratings yet

- Datasheet GenDocument2 pagesDatasheet GenEdgar Bonilla MuñozNo ratings yet

- VIVI Ref Part 2 PDFDocument111 pagesVIVI Ref Part 2 PDFAaron OliverNo ratings yet

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet