Professional Documents

Culture Documents

Mechanical Tube Plug Technology For High Pressure Heat Exchangers in Ammonia and Urea Plants

Mechanical Tube Plug Technology For High Pressure Heat Exchangers in Ammonia and Urea Plants

Uploaded by

moh ragehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Tube Plug Technology For High Pressure Heat Exchangers in Ammonia and Urea Plants

Mechanical Tube Plug Technology For High Pressure Heat Exchangers in Ammonia and Urea Plants

Uploaded by

moh ragehCopyright:

Available Formats

Mechanical Tube Plug Technology for High

Pressure Heat Exchangers in

Ammonia and Urea Plants

The Pop-A-Plug® system is a mechanical tube plug to seal leaking or degraded high-

pressure heat exchanger tubes. The design objective was to produce a fast and simple to

install mechanical tube plug with the same or better-installed stability than a welded

plug. This paper provides an update on the technical developments and successes of the

Pop-A-Plug® in Ammonia and Urea Plants.

A.G.C.M. de Rijk, EST Group B.V, The Netherlands

Introduction

S

Problem Description

KW STICKSTOFFWERKE

PIESTERITZ GMBH (SKW) is the Leaking tubes and some other tubes with cracks

largest producer of ammonia and urea in identified by eddy current examination required

Germany, domiciled at one of the best locations sealing off by plugging. Pitting corrosion due to

throughout Europe, in a largely agricultural caustic reaction resulted in tube leakage.

region of Germany. The company operates two

Kellogg ammonia plants, each with an output of The only known process for sealing the leaking

1,650 MTPD (1819 STPD) (first name plate: tubes was the installation of tube plugs with a

1,350 MTPD) (1488 STPD), three Stamicarbon thread. These plugs were welded into the tubes

CO2 stripping plants (all with a capacity of over with preheating and post heat treatment. This

4,000 MTPD) (4410 STPD), one Uhde nitric repair process is lengthy and could take up to a

acid plant and other plants for the production of total of 3 days to complete. Also subject welded

special products. plugs suffer from circumferential cracks after

the units have gone back into service and are

Ammonia Plants of SKW are designed by M. exposed to the temperature cycles of the waste

W. Kellogg, USA and engineered by Toyo heat boiler. (See Figure 1.)

Engineering Cooperation. The plants were

commissioned in 1973 and 1975. It is a

conventional steam reforming process. The

Capacity was enhanced to 1,650 MTPD (1819

STPD) in 1989.

This Kellogg Ammonia Plant operates a

secondary reformer 103-D followed by 2

primary waste heat boilers 101-CA/CB in

parallel, followed by one secondary waste heat

boiler 102-C. Figure 1. Example of welded plugs

2011 295 AMMONIA TECHNICAL MANUAL

2012 82 AMMONIA TECHNICAL MANUAL

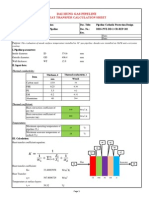

Applications Details Unit 102-C Tube side:

Pressure 320.0 BarG (4641 psig)

Temperature 345°C (653°F)

Fluid Process Gas

Shell side:

Pressure 115.0 BarG (1667 psig)

Temperature 330°C (626°F)

Fluid Boiler Feed Water

Figure 2. Tube to Tubesheet Welding drawing

102-C

The heat exchanger 102-C is a fixed tube

vertical heat exchanger with 1,101 tubes 25.4

mm (1.00 in) OD x 5.16 mm (.203 in) wall

(material of tubes and tube sheet: Pressure

hydrogen resistant steel 10 CrMo910 (ASTM A

182 F22). See Figure 2 for tube to tubesheet

configuration. Figure 3. Heat exchanger drawing 123-C1/C2

Process conditions are as follows:

Pop-A-Plug® Features

Tube side:

Pressure 35.5 BarG (515 psig)

Temperature (Low) 340°C (644°F)

Temperature (High) 450°C (842°F)

Fluid Process Gas

Shell side:

Pressure 118.0 BarG (1621 psig)

Temperature 330°C (626°F)

Fluid Steam Boiler Feed Water

Figure 4. EST Group Pop-A-Plug®

Applications Details Unit 123-C1/C2 The Pop-A-Plug® system eliminates the need

for welding tube plugs. The system is long

The heat exchanger 123-C1/C2 is a heat proven in fossil fuel and nuclear power

exchanger with tubes 19.05 mm (.75 in) x 3.10 generation stations. The Pop-A-Plug® heat

mm (.122 in) (material of tubes and tube sheet: exchanger tube plugging system is the only plug

10 CrMo910 (ASTM A 182 F22). See Figure 3 that features internally serrated rings designed to

for tube to tubesheet configuration. maintain a leak-tight seal under extreme thermal

and pressure cycling.

AMMONIA TECHNICAL MANUAL 296 2011

2012 83 AMMONIA TECHNICAL MANUAL

The Pop-A-Plug® is installed using a controlled Solution

force, which protects against damage to tube

sheet ligaments and the adjacent tube sheet

joints. Thus the life of the heat exchanger is SKW approached EST to find a solution to plug

extended and costs are reduced when you need these heat exchanger tubes without welding and

to re-tube. within a shorter timeframe with equal or

improved reliability.

Another advantage is the Pop-A-Plug® system

takes only minutes to install. The first step was for EST Group to investigate

the use of ASTM A 182 F22 Class 3 for

The system is available in a wide array of manufacturing POP-A-PLUGs®.

materials and can be matched to the tube or tube

sheet it is installed in. Matching the material For size selection it was decided for heat

eliminates differences in thermal expansion exchanger 102-C to have the plugs installed

rates and ensures a perfect seal is maintained inside the tube. A controlled surface and

during temperature cycles experienced by the tolerance was achieved by means of machining

heat exchanger. (reaming and brushing) the tube inside diameter

to a diameter of 16.0 mm (.63 in).

For size selection it was decided for heat

exchanger 123-C1/C2 to have the plugs installed

inside the tube sheet (tube section to be

removed). A controlled surface and tolerance

was achieved by means of machining (reaming

and brushing) the tube sheet inside diameter to a

diameter of 20.0 mm (.787 in)

EST Group engineered, manufactured and

qualified the appropriate POP-A-PLUG® made

from ASTM A182 F22 Class 3 for each heat

exchanger. The information below highlights

the plugs manufactured for SKW’s units.

Figure 5. Pop-A-Plug® installation inside tube

Heat Exchanger 102-C

EST Group Part #P2-630-CR-SP-0611

Max 413.6 BarG/537.8°C (6000 PSIG/1000oF)

Heat Exchanger 123-C1/C2

EST Group Part #P2-790-CR-SP-0611

Max 344.8 BarG/537.8°C (5000 PSIG)/1000°F)

2011 297 AMMONIA TECHNICAL MANUAL

2012 84 AMMONIA TECHNICAL MANUAL

Qualification Testing Increase from 22°C (72°F) to 350°C (662°F):

4 Hours

SKW provided 10CrMo9 10 bar stock material

for EST to manufacture test coupons in order to Holding Time at 350°C (662°F) : 2 Hours

install the plugs as per the installation

instructions and procedures supplied with the Cool down from 350°C to 22°C: Overnight

plugs.

Test Test Test Criteria Result

Coupon –

Number

1 P2-630- Bubble Leak Test Passed

CR-SP- with Air 0.5 BarG

0611 (7.25 psig)

2 P2-790- Bubble Leak Test Passed

CR-SP- with Air 0.5 BarG

0611 (7.25 psig)

3 P2-630- Withstand Passed

CR-SP- Pressure Test with

Figure 6. Test Coupon Figure 7. Test Coupon 0611 Air 1.1 x Tube

(10CrMo9.10) with (10CrMo9.10) with P2-790- Side Pressure =

P2-630-CR-SP-0611 CR-SP-0611 126.5 BarG (1835

psig)

4 P2-790- Withstand Passed

Thermal Heat Cycles CR-SP- Pressure Test with

0611 Air 1.1 x Tube

Test Coupons (10CrMo9.10) with P2-630- Side Pressure =

CR-SP-0611 (ASTM A182 F-22 Class 3) 352.0 BarG (5104

installed have been exposed to thermal heat psig)

cycles (Temperature selected was process gas 5 P2-630- 1 ½ to 1 Safety Passed

entry temperature) by SKW as below: CR-SP- Ratio Pressure

0611 Test with Water

Increase from 22°C (72°F) to 400°C (752°F) : 1.5 x Max

4 Hours Pressure POP-A-

PLUG® = 1.5 x

Holding Time at 400°C (752°F): 2 Hours 413.6 = 620.4

BarG (8996 psig)

Cool down from 400°C (752°F) to 22°C (72°F): 6 P2-790- 1 ½ to 1 Safety Passed

Overnight CR-SP- Ratio Pressure

0611 Test with Water

Test Coupon (10CrMo9.10) with P2-790-CR- 1.5 x Max

SP-0611 (ASTM A182 F-22 Class 3) installed Pressure POP-A-

have been exposed to thermal heat cycles PLUG® = 1.5 x

(Temperature selected by SKW) by SKW as 344.8 = 517.2

below: BarG (7499 psig)

AMMONIA TECHNICAL MANUAL 298 2011

2012 85 AMMONIA TECHNICAL MANUAL

Vickers hardness HV1

Nr. HV1

Hardness measurement

1 - 195

2 – 194

Following the successful completion of the 3 – 185

pressure tests, the coupons of both plug sizes 4 – 196

5 – 326

were sectioned and etched to review sealing 6 – 266

characteristics and perform a hardness test. 7 – 254

8 – 249

9 – 246

10 – 248

11 – 249

12 – 266

13 – 275

14 – 357

15 – 362

16 - 384

Figure 8. P2-630-CR-SP-0611 sectioned.

Figure 10. P2-630-CR-SP-0611 Detail

serration.

Conclusion

The POP-A-PLUG successfully passed all

qualification tests. And based upon the

Figure 9. P2-630-CR-SP-0611 detail of sealing

successful testing, SKW has approved the use of

ring.

POP-A-PLUG®’s in ASTM A 182 F22 Class 3

material in the Ammonia plant heat exchangers.

As a direct result significant reductions in repair

time will be accomplished.

POP-A-PLUG®’s can be installed in a matter of

hours compared to 3 days with welded tube

plugs.

2011 299 AMMONIA TECHNICAL MANUAL

2012 86 AMMONIA TECHNICAL MANUAL

EST Group will always review every

application for Pop-A-Plugs® in detail prior to

order and installation to ensure proper

application.

EST has experienced and certified POP-A-

PLUG® installation companies available.

Developments

Based on results, the next phase of this program

has started. This is to develop a suitable POP-

A-Plug® to plug tubes in High Pressure Heat

exchangers of a Urea Plant by using Safurex®

material and meeting the specific design criteria

applicable.

Pop-A-Plug® is a registered trademark of EST

Group, Hatfield, PA, USA.

Special thanks to Mr. Norbert Brett / SKW

STICKSTOFFWERKE PIESTERITZ GMBH

Germany for his support in the matter.

AMMONIA TECHNICAL MANUAL 300 2011

2012 87 AMMONIA TECHNICAL MANUAL

You might also like

- Coating & Painting Inspection ChecklistDocument3 pagesCoating & Painting Inspection Checklisthans100% (3)

- Daikin Packaged Unit UAYQ-C Series Engineering DataDocument58 pagesDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cracking and Repair of Closing Welds in 2.25 Cr1 Mo Steel Vessels Operating in High Temperature Synthesis GasDocument9 pagesCracking and Repair of Closing Welds in 2.25 Cr1 Mo Steel Vessels Operating in High Temperature Synthesis Gasvaratharajan g rNo ratings yet

- Indirect Water Bath HeaterDocument32 pagesIndirect Water Bath HeaterAhmedNo ratings yet

- Miller Big Blue 700X Spec Sheet April2013Document3 pagesMiller Big Blue 700X Spec Sheet April2013WaheedAhmedNo ratings yet

- Plug Process Repair Heat Exchangers PDFDocument6 pagesPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVANo ratings yet

- Heat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFDocument5 pagesHeat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFNomi A100% (1)

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNo ratings yet

- Ipc2022-87079 Squeeze The Crack Out of It - With Type A Compression SleevesDocument7 pagesIpc2022-87079 Squeeze The Crack Out of It - With Type A Compression SleevesOswaldo MontenegroNo ratings yet

- High Temperature Service Equipment and Piping Maintenance in PlantDocument22 pagesHigh Temperature Service Equipment and Piping Maintenance in Plantvaratharajan g rNo ratings yet

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 pagesGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedNo ratings yet

- Funke Shell Tube He eDocument24 pagesFunke Shell Tube He eSubrata DasNo ratings yet

- Boq Ductable AirconditionerDocument3 pagesBoq Ductable AirconditionerAPNIT MISHRANo ratings yet

- Specifications - FX 1502 - 7223Document4 pagesSpecifications - FX 1502 - 7223ridNo ratings yet

- 639 Rolling Thin Film OvenDocument1 page639 Rolling Thin Film OvenHuda MahdiNo ratings yet

- NK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Document14 pagesNK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Geovanni MZNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- Sanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerDocument2 pagesSanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerparsmessengerNo ratings yet

- Din 8075Document11 pagesDin 8075Marco Jorquera AguilarNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- Ac DefectsDocument5 pagesAc DefectsSAANO SOLOMENo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Technical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Document2 pagesTechnical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Chidiebere Samuel OkogwuNo ratings yet

- SPE-184102-MS (2 Technology For Cementation)Document14 pagesSPE-184102-MS (2 Technology For Cementation)Randy SooknananNo ratings yet

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- KCW EngDocument8 pagesKCW Engshahzad32552372No ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Replacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0Document12 pagesReplacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0David PierreNo ratings yet

- Designguide 4Document16 pagesDesignguide 4Adrian Flores GallardoNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- Cbe enDocument14 pagesCbe enStefanNo ratings yet

- PE Yellow Gas - WebDocument16 pagesPE Yellow Gas - WebGavin KwanNo ratings yet

- ELECTRIC DUCT HEATERS Catalogue EnglishDocument8 pagesELECTRIC DUCT HEATERS Catalogue EnglishHewa AkreyNo ratings yet

- Volume - 4Document72 pagesVolume - 4Arunkumar AdikesavanNo ratings yet

- MM, 63mm, 90mm, 125 MM, 180mm by Open Cut MethodDocument16 pagesMM, 63mm, 90mm, 125 MM, 180mm by Open Cut Methodhemant kumarNo ratings yet

- BR 1938 PDFDocument4 pagesBR 1938 PDFashok KumarNo ratings yet

- Brochure TG enDocument8 pagesBrochure TG enpascal_chinNo ratings yet

- Cat in 39g 1 Carrier AcDocument14 pagesCat in 39g 1 Carrier Acks aksNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- Trends in Insulation Systems For Generator Hv-WindingsDocument4 pagesTrends in Insulation Systems For Generator Hv-WindingsMaswady Bin MaskinNo ratings yet

- GE Quantum MV AC Induction Totally Enclosed Fan Cooled MotorsDocument4 pagesGE Quantum MV AC Induction Totally Enclosed Fan Cooled Motorslbk50No ratings yet

- Transformer Bushings, Type GOE and GOE (2) : Technical GuideDocument24 pagesTransformer Bushings, Type GOE and GOE (2) : Technical GuideTxavitoNo ratings yet

- RPI Heat Fusion Procedures 3Document10 pagesRPI Heat Fusion Procedures 3eru yoranda silalahiNo ratings yet

- Composite Coiled Tubing SolutionDocument7 pagesComposite Coiled Tubing Solutionarturo_partida_1No ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- PTFR Brochure en 2019 02 Grid PTR 0234Document8 pagesPTFR Brochure en 2019 02 Grid PTR 0234p m yadavNo ratings yet

- Da R Gewak Ks 10Document12 pagesDa R Gewak Ks 10rtrajan_mech5408No ratings yet

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 pagesInvestigation and Repair of H (1) - E.R Flange LeakriysallNo ratings yet

- Installation of Ammonia Pre-HeaterDocument24 pagesInstallation of Ammonia Pre-HeaterSAJIDSATTARNo ratings yet

- Attachment 1-Heat Transfer Calculation SheetDocument2 pagesAttachment 1-Heat Transfer Calculation SheetErica MartinNo ratings yet

- Data sheet-ROOF AM HTDocument3 pagesData sheet-ROOF AM HTUdhaya sankarNo ratings yet

- Acum +cadxDocument22 pagesAcum +cadxArumugam MurugesanNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- GEAKueba Katalog MarketSP enDocument12 pagesGEAKueba Katalog MarketSP enRodrigo GonçalvesNo ratings yet

- Air-Cooled Heat Exchanger Type ZBWDocument8 pagesAir-Cooled Heat Exchanger Type ZBWraja raniNo ratings yet

- Bioreactor QPM-126Document4 pagesBioreactor QPM-126upenderNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Recent Changes in Code Requirements For Repair of In-Service Pipelines by WeldingDocument7 pagesRecent Changes in Code Requirements For Repair of In-Service Pipelines by WeldingGuruchell ChellguruNo ratings yet

- ELECRODE STORAGeDocument4 pagesELECRODE STORAGeGuruchell ChellguruNo ratings yet

- Dashboard Starting ChecklistDocument2 pagesDashboard Starting ChecklistGuruchell ChellguruNo ratings yet

- Productivity Apps: Revenue CashDocument17 pagesProductivity Apps: Revenue CashGuruchell ChellguruNo ratings yet

- RT Film IntepretationDocument44 pagesRT Film Intepretationawong_911374100% (3)

- Turco 5351 TDSDocument3 pagesTurco 5351 TDSmiguelmosquerabNo ratings yet

- PTS-For-Industry AerocomDocument8 pagesPTS-For-Industry AerocomVano WardhanaNo ratings yet

- CPM Part ListDocument16 pagesCPM Part ListNeeraj gurungNo ratings yet

- L01 MBLC Con Fad Mat 006228 R00Document111 pagesL01 MBLC Con Fad Mat 006228 R00MOHAMEDNo ratings yet

- A 139 - A 139m - 00 Qtezos9bmtm5ts1sruqDocument9 pagesA 139 - A 139m - 00 Qtezos9bmtm5ts1sruqfadjarNo ratings yet

- ESAB ARC 400iDocument15 pagesESAB ARC 400ipm-kcpNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Form PQR 1 AsmeDocument6 pagesForm PQR 1 AsmeZam Zam NoorNo ratings yet

- Welding BrassDocument5 pagesWelding BrassMohammed NazeerNo ratings yet

- 18BT53 5X3 Box Trailer Drawings PDFDocument37 pages18BT53 5X3 Box Trailer Drawings PDFFelipe Maciel Del VecchioNo ratings yet

- Production Methods of Laminated Al Alloy Composites: Current Trends in Civil & Structural EngineeringDocument3 pagesProduction Methods of Laminated Al Alloy Composites: Current Trends in Civil & Structural EngineeringأبومحمدالزياتNo ratings yet

- ELOTOP 510 BrochureDocument1 pageELOTOP 510 BrochureVALERYA_LUPUNo ratings yet

- 21 Changes To PQR Essential Variables That Require WPS RequalificationDocument4 pages21 Changes To PQR Essential Variables That Require WPS RequalificationahmedNo ratings yet

- Models 2050 2055 2096 20khz Welding PressesDocument39 pagesModels 2050 2055 2096 20khz Welding PressesFernando CostaNo ratings yet

- Australian/New Zealand Standard: Welding Consumables For Build-Up and Wear ResistanceDocument7 pagesAustralian/New Zealand Standard: Welding Consumables For Build-Up and Wear ResistanceKavinNo ratings yet

- Fabrication and Erection Piping Procedure. - VT PDFDocument19 pagesFabrication and Erection Piping Procedure. - VT PDFLeonardo ManurungNo ratings yet

- Laser Micro Welding: Presented By: PAVAN PATEL (18BME082) & JIGAR MODI (18BME037)Document17 pagesLaser Micro Welding: Presented By: PAVAN PATEL (18BME082) & JIGAR MODI (18BME037)Pavan PatelNo ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- Stud Welding of Shear Conector PDFDocument13 pagesStud Welding of Shear Conector PDFramdacNo ratings yet

- Destructive TestingDocument2 pagesDestructive TestingErlinawati Bintu SupiyoNo ratings yet

- Sapa Friction Stir WeldingDocument6 pagesSapa Friction Stir WeldingvikramvasuNo ratings yet

- FMC Elevator BucketsDocument11 pagesFMC Elevator BucketscesarNo ratings yet

- 04 Limpiador-Torcha-Automatico 001 TorchWizard Brochure v2-8 WebDocument6 pages04 Limpiador-Torcha-Automatico 001 TorchWizard Brochure v2-8 Webalecandro_90No ratings yet

- MEP - Preform - UkDocument5 pagesMEP - Preform - UkLuiz HenriqueNo ratings yet

- A-CIV-SPE-000-30007 - Rev-0 - Specification For STR Steel Fab & Erection PDFDocument33 pagesA-CIV-SPE-000-30007 - Rev-0 - Specification For STR Steel Fab & Erection PDFHUSSEIN FNEISHNo ratings yet

- NEW Electroweld Pricelist - APR 25 2022Document7 pagesNEW Electroweld Pricelist - APR 25 2022ernst gencayaNo ratings yet

- Teaching Scheme For B.Tech "Industrial & Production Engineering"Document61 pagesTeaching Scheme For B.Tech "Industrial & Production Engineering"Sasank SaiNo ratings yet