Professional Documents

Culture Documents

PDF - Piano Technicians Guild

PDF - Piano Technicians Guild

Uploaded by

TuongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF - Piano Technicians Guild

PDF - Piano Technicians Guild

Uploaded by

TuongCopyright:

Available Formats

An International Non-Profit Organization of Registered Piano Technicians

Taylor Mackinnon, RPT

Plates in Focus

President

520 SE 29th Ave., Hillsboro, OR 97123

(503) 846-1501 Steve Brady, RPT

E-mail: pres@ptg.org Journal Editor

Richard Bittner, RPT

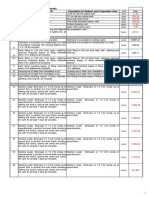

Vice President You may notice a special emphasis on piano plates in this issue; it’s no

519 Melody Ct., Royal Oak, MI 48073 accident. Some time ago the PTG Board of Directors approached me with a

(248) 398-8721

E-mail: vp@ptg.org special request: a “theme” issue dealing with plates. We had hoped to cover

Paul Monroe, RPT

plates from all angles, from raw materials, to design and manufacture, to

Secretary-Treasurer breakage and repair techniques. Of greatest concern, however, was the matter

5200 Irvine Blvd., Sp. 310, Irvine, CA 92620 of liability. When a plate breaks, whose fault is it?

(714) 730-3469

E-mail: sec@ptg.org

While an article on plate manufacture was not forthcoming, we’ve

David P. Durben, RPT covered most of the other bases. Don Galt’s excellent article gives as much

Immediate Past President

2310 E. Romneya Dr., Anaheim, CA 92806 detail about the raw materials – not just for plates but for many other iron

(714) 491-7392

E-mail: ipp@ptg.org

and steel piano parts as well – as most of us will ever need. Although Jim

Ellis analyzes a specific plate that broke because of poor design, he also

Ruth B. Phillips, RPT

Northeast Regional Vice President provides numerous insights into what constitutes a good plate design. From

3096 Bristol Rd., Warrington, PA 18976 Wilford Young comes a welding repair method that has proven effective over

(215) 491-3045

E-mail: nervp@ptg.org many, many years and retired engineer Richard Oliver Snelson describes a

hybrid restoration combining a mechanical repair with welded

Robert L. Mishkin, RPT

Southeast Regional Vice President reinforcements. Finally, we’ve addressed liability by relating a tale that

1240 NE 153rd St., N. Miami Beach, FL 33162 desperately needs to be told. As Marnie Squire’s story unfolds we see clearly

(305) 947-9030

E-mail: servp@ptg.org that the technical authorities are unanimous: tuning a piano cannot possibly

break a healthy plate.

Jack R. Wyatt Sr., RPT

South Central Regional Vice President Indeed, a healthy plate can withstand unspeakable acts. In “The Tuner’s

2027 15th St., Garland, TX 75041

(972) 276-2243 (H) Life,” Carman Gentile tells of one such experience. I can recall many other

(972) 278-9312 (W) instances myself. For example, a panicked piano owner called me after she

E-mail: scrvp@ptg.org

discovered that her 11-year-old son had industriously removed all the plate

Robert S. Bussell, RPT rim lags from her small Chickering grand. The piano was horrendously out

Central East Regional Vice President

224 West Banta Rd., Indianapolis, IN 46217 of tune. After replacing the lag screws, I found that the tuning had improved

(317) 782-4320 somewhat and was able to perform an uneventful tuning.

E-mail: cervp@ptg.org

In my shop, a concert-grand plate fell some four inches to a concrete

Richard E. West, RPT

Central West Regional Vice President floor when one of the hoist cables slipped. The plate didn’t break and,

1427 A St., Lincoln, NE 68502 although this happened nearly 20 years ago, the piano is still humming along

(913) 631-8227

E-mail: cwrvp@ptg.org happily.

Larry Joe Messerly, RPT The late Don Galt once related to me that he had seen a six-foot grand

Western Regional Vice President tumble end-over-end down a flight of 30 steps when a rope the movers were

2222 W. Montebello Ave., Phoenix, AZ 85015

(602) 433-9386 using suddenly broke as the piano approached the landing. Broken plate? No.

E-mail: wrvp@ptg.org “In fact,” Don said, “it was still pretty much in tune when we set it up

Keith Eugene Kopp, RPT afterward.” And that piano is still in service more than 25 years later.

Pacific NW Regional Vice President

61283 Killowan Lane, Bend, OR 97702

(541) 388-3741

E-mail: pnwrvp@ptg.org

2 Piano Technicians Journal / November 2000

Iron, Steel & Pianos

By Don Galt, RPT

(Reprinted from the Piano Technicians Journal, April, 1970.)

Editor’s Introduction

Don Galt served as Technical Editor of this publication from 1969 until 1977. One of the many special

things that Don brought to his work as a piano technician and his work with the Journal was his exten-

sive knowledge of iron and steel, gained over many years in his previous life as a re-bar engineer at

Bethlehem Steel. I am reprinting this article in its entirety, and in a sidebar I’ve included a brief question

and answer in which Don replies to a reader’s query on responsibility for plates broken while tuning.

This item appeared in the November, 1970 issue of PTJ, p.10. – SB

T

here is little in the appearance of a piano to Carbide System” and “Testing & Properties,” will probably

reveal the massive forces that its members exert make the greatest demands on the reader’s attention. The

on one another, without respite, through many author hopes that this attention will be rewarded with an

decades of time. It is only when the instrument enlarged understanding of how these materials do their

absorbs the energy of the musician, translates it and throws it work in the piano. If any reader gives up and jumps off

back as sound energy at small or great dynamic levels that during “The Iron-Iron Carbide System,” I hope he or she

the magnitude of these forces is hinted at. will climb back aboard for “Testing & Properties.”

Even so, the dynamism of the pianist and the stolidity of

the piano foster the illusion that the former, rather than the General Considerations

latter, is actually the source of the sound. Pure elemental metallic iron is a rare thing outside of the

So perhaps it is natural that piano users are ignorant of, laboratory and we never encounter it in pianos. The steel

and even piano technicians sometimes take for granted, the music wire and the gray cast-iron plates of pianos, as well as

highly stressed metallic members to which the modern other familiar iron products such as structural steel, wrought

piano largely owes its dynamic compass. iron, white cast iron and so on, are mixtures of iron and

To gain a little sympathetic understanding of these carbon, iron being by far the predominant ingredient. They

members, this paper attempts a short description of the are not chemical compounds, so their proportions and

important iron products used in piano building: their hence their properties can and do vary widely. If the carbon

manufacture, their physical properties, and their reactions to content is less than about two percent by weight, the

the loads they are asked to carry in the piano. material is called steel. If the carbon is more than two

For the reader’s convenience the article is divided into percent it is called cast iron. This two percent figure is not

the following sections: arbitrary, but we will not explore its significance at the

General Considerations moment.These terms illustrate the sort of paradox that can

Pig Iron — The Blast Furnace grow up on a subject when the usage develops gradually.

Gray Cast Iron — The Cupola Steel is defined as a mixture or alloy of iron and carbon, and

Steel — Making the Material yet what is called cast iron contains more carbon than steel

Steel — The Rolling Mill does.

Steel — Wire Drawing In practice, most steels have well less than two percent

The Iron - Iron Carbide System carbon, and most cast irons have well more than that

Testing & Properties amount. Gray cast iron, as used in piano plates, contains

The first five sections of the article, down through about 3.5 percent carbon, structural steel about 0.25

“Steel — The Rolling Mill,” are fairly general, but with percent, tool steels usually one percent or more, piano wire

occasional references to our special interests. about 0.90 percent.The properties of the material depend a

The section on “Steel – Wire Drawing” gives a very great deal on the percentage and form of the carbon

brief description of this procedure, leaving out more than it present.

tells (as does every part of the article).

The last two sections entitled “The Iron — Iron Continued on Next Page

November 2000 / Piano Technicians Journal 17

Iron, Steel & Pianos

Continued from Previous Page

All steels and cast irons also contain other elements and layers of coke, ore and limestone, which form a descending

materials. Some of these, such as sulphur and phosphorus, column. Air is forced in at the bottom, and the coke burns

are residual impurities which generally have been reduced partially to carbon monoxide, which in turn reduces the

in manufacture to the economic minimum. Others, such as iron oxide ore.The limestone forms a molten, fluid slag,

silicon and manganese, may be purposely left in in con- which, floating on the molten iron, accumulates and carries

trolled amounts, or be purposely added, to give the material off much of the waste matter. The blast furnace operates

special qualities. Examples are gray cast iron, containing continuously, with materials charged at the top and the slag

considerable silicon, and the many alloy steels containing and molten pig iron drawn off at the bottom.This is a hot

chromium, nickel, molybdenum and so on. process, with a temperature gradient in the furnace from a

The steel category includes a large spectrum of materi- few hundred degrees at the top to about 2,750 degrees F. at

als, classified by carbon content, as well as by the percentage the bottom.

ranges of other alloying elements. Music wire is generally Pig iron, the blast furnace product, contains fairly large

made from carbon steel, as distinguished from alloy steel, percentages (totaling seven percent or more) of impurities

which means that no deliberate alloy additions are used. such as silicon, manganese, sulphur, phosphorus and an

(Except manganese. Almost all steels, either carbon or alloy, excess of carbon. “Impurities” is a relative term, as some of

contain appreciable amounts of manganese.) these inclusions are impurities only as they are in excess for

Apart from the chemical distinction between steel and the purpose at hand.

cast iron, one of the most important differences is that the

various steels are generally ductile and malleable in varying Gray Cast Iron — The Cupola

degrees, while cast iron generally is not. (The amenability of If the end product is to be gray cast iron, the pig iron from

a material to plastic deformation under stress without the blast furnace is refined in an oxidizing furnace known as

fracture is called ductility or malleability, according as the a cupola. In foundry practice the cupola charge usually

stress is tensile or compressive.) includes cast iron and steel scrap and ferro-silicon, as well as

Wire could not be made from cast iron because the the pig iron. Coke for fuel and limestone for flux are also

manufacturing process and most wire usages demand a included. Because little or no chemical correction is possible

ductile material. On the other hand, piano plates could be in the cupola after melting, the charge must be carefully

made of steel by forging, casting or welding, but among planned as to proportions of entering materials, based on

other disadvantages they would be costly far beyond any the constitution of these materials and the desired constitu-

strength superiority they would have over plates of gray cast tion of the product. A typical melt for piano plates might

iron. contain 3.5 percent carbon and 2.4 percent silicon, about

We will return to some of the other properties and which more will be said later.

reactions of these materials after a short excursion into iron The molten “cast iron” is drawn off and poured into

and steel making. molds, usually of sand, in which it takes the shapes of the

The manufacture of steel divides rather naturally into patterns used in preparing the molds — piano plates, for

two stages: example.

1) making the material and 2) making the product from

the material (product meaning bars, structural shapes, sheets,

wire, etc.).With gray cast iron on the other hand, the Steel — Making the Material

material is generally turned out in product form, as we shall If the end material is to be steel, the pig iron from the blast

see. furnace is refined in one of various types of oxidizing

furnace permitting closer control than the cupola of the

iron foundry. The reader will have heard of the Bessemer

Pig Iron — The Blast Furnace converter and the open-hearth furnace, both long used in

The first step for either steel or cast iron is to recover iron in steel making. The electric furnace, once limited to special

usable form from iron ore, which is iron oxide (rust) in steel manufacture, is now used extensively in the production

varying mixtures with earth, sand and rock. This recovery is of more common grades. Steel music wire may be made of

mostly a process of getting rid of the oxygen by heating the either open hearth or electric furnace steel, never Bessemer.

ore in the presence of carbon and limestone. This takes place (The very fast Bessemer process is not deliberate enough to

in a blast furnace, which is a shaft, typically 25 feet or more allow the analysis and chemical corrections necessary to the

in diameter by 75 feet or more in height, charged with careful manufacture of high carbon steel.)

18 Piano Technicians Journal / November 2000

After various tests show that the desired constitution has elongates the grains or crystals, making the steel somewhat

been achieved in the furnace, the molten steel is poured fibrous in structure, with considerably increased longitudi-

into molds, where it cools and solidifies into ingots, oblong nal strength and toughness. (Steel should not be thought of,

in form and varying in size from a ton or less to many tons. however, as actually having fibers.) Flat rolled products, that

When the steel freezes in the ingot mold it has been in the is, sheets and wide plates, generally are cross-rolled early in

molten state for the last time and the steel making might be the rolling sequence, not only to gain width but also so that

said to be complete.The solid state processing which follows the improvement in properties will not be limited to the

does not change the constitution of the material, that is, the longitudinal direction.

proportions of its elemental ingredients. Steel destined for piano wire making is rolled on a rod

However, the various forming procedures and heat mill to a diameter of slightly over 1/4". It comes off of the

treatments do influence greatly the grain structure of the mill in a continuous coil instead of being straightened and

steel, and hence its physical properties such as strength and cut to length on the hot bed.

hardness. The special character of music wire depends as Up to this point in steel music-wire making, all of the

surely on the forming process as on the high temperature processing has been at high temperatures, beginning in the

chemistry of the steel furnace. So now let us examine some molten state in the blast furnace and the steel furnace where

of these forming processes in general and wire making in the temperatures approach 3,000 degrees F. The forming

particular. work on the rolling mill in the solid state requires tempera-

tures of the order of 2,000 degrees or more.

Steel — The Rolling Mill

The greatest tonnage of steel ingots goes next to the rolling Steel — Wire Drawing

mill (See Figure 1) in which a white-hot ingot is passed If the hot work of rolling added strength and toughness by

between rolls having appropriately shaped circumferencial elongating the grain structure, the cold work of the drawing

grooves. The ingot is thus elongated and reduced in cross- process which follows in wire manufacture has an even

section. greater effect on the properties of the steel.

After cleaning and coating, the rolled steel is drawn cold

through a fixed hole, or die (See Figure 2), which results in

elongation together with reduction of cross-section, and a

great increase in hardness, tensile strength and yield strength.

(This will be discussed in “Testing & Properties.”) As used

here, “cold” does not necessarily mean cold to the touch.

Work at any temperature below the recrystallization tem-

perature (several hundred degrees) is “cold work.”

Continued on Next Page

Figure 1 — Rolling Mill

Generally ingots are “broken down” into blooms, slabs

or billets in the “blooming mill,” etc. (These industry terms

identify the shape and size ranges of the products of the

initial rolling operations.) The blooms, slabs and billets go

on to smaller mills for rolling into various finished shapes.

Larger shapes may be rolled directly from ingots.

A sequence of many different roll passes is required to

reduce an 18” square by 6’ long ingot, for instance, to more

than 3/8 of a mile of 2” by 2” by 1/4” angles. Figure 2 — Wire Drawing

The “hot working” of the steel by rolling, squeezes and

November 2000 / Piano Technicians Journal 19

Iron, Steel & Pianos

Continued from Previous Page

A corollary result of the increase in

hardness is a reduction in ductility; that is,

some of the ductility is “used up.”The

fairly high carbon content of music wire

steel limits its ductility to a reduction in

area of about 30 percent or less per draft.

Obviously many drafts are required to

reduce a 1/4” rod to the diameter of music

wire and the ductility must be restored

between drafts. This is done by patent

annealing, which consists of reheating the

wire to a selected temperature, perhaps

1,500 degrees F., followed by slow cooling

in air or in a medium maintained at a

rather high temperature. The result is

recrystallization into a ductile grain

structure.The cycle of drawing and

patenting must be repeated several times.

The wire is finished on the final draft, with

no further heat treatment, so its strength

and hardness depends a great deal on the

amount of reduction after the last anneal. Figure 3 – Iron-Iron Carbide Equilibrium diagram

The traction for pulling the wire

through the die is supplied through the reel, or block, on The horizontal scale represents the percentage of

which it is wound. Since the tension is quite high, the wire, carbon by weight, and covers the range from pure iron (0

which comes through the die straight, is strained or cold percent carbon) to pure iron carbide (6.67 percent carbon).

worked to the curvature of the block’s circumference. A The vertical scale represents the temperature in degrees

technician struggling to untangle a small coil of recoiled Fahrenheit.We will not concern ourselves with the intrica-

piano wire that “got away” can readily estimate the diameter cies in the extremely low carbon area at the left side of the

of the draw block, unless, of course, the wire was straight- diagram.

ened before recoiling. The lightly cross-hatched area of Figure 3 represents a

At this point let us leave the solid-state processing of “mushy,” partly frozen state, bounded at the top by the line

steel, and look at the constitution and micro-structure of the marked “liquidus” and at the bottom by the line marked

various iron-carbon mixtures. “solidus.” Above the liquidus the material is completely

molten. Below the solidus it is completely frozen or solidi-

The Iron-Iron Carbide System fied. The mushy, partly frozen state between has an analogy

The molten metal which comes from the cupola or the steel in salt-water solutions, which are mushy through a consid-

furnace is largely a solution of iron carbide in iron, or more erable temperature range between the freezing point of pure

properly, a mutual solution of the two in each other. As water and the rather lower total freezing point of the

cooling proceeds, the metal undergoes a series of changes solution. The reader will note that, for both pure iron and

(reversible on reheating), of which freezing is merely the the eutectic cast iron (4.3 percent carbon) the liquidus and

first.The nature of these changes, and the temperatures at the solidus coincide — there is no mushy state, whereas at 2

which they occur, depend largely on the percentage of percent carbon the mushy state persists through a range of

carbon in the metal. about 450 Farenheit degrees.

Figure 3, which is a simple version of the Iron-Iron Below the solidus, solid state changes occur during

Carbide Equilibrium Diagram, will help to visualize the cooling, which, to simplify, consist of the separation of iron,

state of different iron-carbon mixtures at various tempera- carbon, and iron carbide in various forms as their mutual

tures, and some of the changes that occur during solidifica- solubility changes with falling temperature.These separa-

tion and cooling. tions are, of course, microscopic and result in changes in

crystalline structure.Volumes could be written analyzing

20 Piano Technicians Journal / November 2000

these changes and their practical significance.We will limit cementite increases the hardness and strength of the steel,

ourselves to a few observations relevant to this article. compared with that of steel which is lower in carbon.

To better understand Figure 3, one must realize that in It might be of interest to trace the cooling cycle of a

the solid state iron exists (at different temperatures) in at hyper-eutectoid steel of, say 1.25 percent carbon.This steel

least two allotropic forms. Below 1,333 degrees F. it is stable starts to freeze at about 2,650 degrees F. and freezing is

as alpha iron. Above 1,333 degrees it is stable as gamma iron. complete at about 2,350 degrees. It now remains solid

These forms have different crystalline structures and their austenite containing 1.25 percent carbon until it cools to

interest to us is in the fact that the solubility of carbon in gamma the Acm line at about 1,675 degrees. At this point the solu-

iron is fairly high, but in alpha iron it is extremely low. tion is saturated with carbon and the excess carbon starts to

With these facts before us we are ready for definitions precipitate in cementite. This precipitation of cementite

of some of the terms appearing in Figure 3. continues on down to 1,333 degrees, at which point the

Austenite: A solid solution of carbon in gamma iron. remaining austenite, which has now reached eutectoid

The maximum carbon in austenite varies composition, transforms to pearlite, and we have a mixture

between 2 percent at 2,065 degrees F. and of pearlite and Cementite grains as mentioned in the

0.8 percent at 1,333 degrees F. (See Acm preceding two paragraphs, and a rather hard steel.

line.) Austenite does not exist below 1,333 Hypo-eutectoid steel (less than 0.8 percent carbon),

degrees F. because gamma iron changes to after freezing, continues to cool as austenite down to the A1

alpha below that temperature. line, at which point it begins to cast out ferrite crystals. This

Ferrite: Almost carbon-less alpha iron. (Limited to continues on down to 1,333 degrees F. at which point again

about 0.02 percent carbon, as carbon is the remaining austenite has reached eutectoid composition,

virtually insoluble in alpha iron.) and transforms to pearlite, resulting in pearlite grains in a

Cementite: Iron carbide (Fe3C). An extremely hard and ferrite matrix. Ferrite is similar in properties to pure iron.

brittle compound, hard enough to scratch Hence steels low in carbon are relatively soft and of lower

glass. Contains 6.67 percent carbon by tensile strength than the high carbon steels.

weight. The temperature-related changes we have been discuss-

Pearlite: A low-temperature (below 1,333 degrees ing are also time-related. The equilibrium states represented

F.), rather homogenous laminar mixture of by the various areas of Figure 3 assume that the cooling

ferrite and cementite, containing about 0.8 metal has the necessary “leisure” for the changes to take

percent carbon. place. Sudden cooling may force non-equilibrium changes

Now, referring to Figure 3, let us follow a few iron- that alter the crystalline structure and the properties of the

carbon materials from the molten to the cold state. material.

Suppose we have molten steel of 0.8 percent carbon, These facts are the basis of the heat treatment of steel,

which is permitted to cool slowly. Freezing commences at which consists of slowing or speeding the cooling rate

about 2,690 degrees F. and is complete at about 2,520 through critical temperature ranges to facilitate or inhibit

degrees. The solid austenite then cools without change right change. Thus, in the wire-drawing process, ductility was

down to the 1,333-degree line. At this point the gamma restored between drafts by reheating the wire above the A3-

iron changes to alpha iron and the austenite transforms to Acm lines to the all-austenite condition, then cooling it

pearlite as the carbon is cast out of solution in iron carbide slowly to below the A1 line. A rapid quench cooling on the

laminae. This all-pearlite 0.8 percent carbon steel is said to other hand would have increased the hardness and reduced

have eutectoid composition. the ductility by forcing a non-equilibrium change into one

Pearlite actually retains its identity in non-eutectoid of the harder forms, as, for instance, Martensite (not defined

steels, but since its carbon content is uniform at 0.8 percent, in this article).

these non-eutectoid steels are necessarily not pure pearlite. Steel for piano wire, having about 0.85 to 0.90 percent

If the steel is hypo-eutectoid (less than 0.8 percent carbon) carbon, is near eutectoid composition and hence mostly

it consists of pearlite and ferrite grains mixed. If the steel is pearlite. It affords an excellent compromise between high

hypereutectoid (more than 0.8 percent carbon) it consists of tensile strength and high ductility.

pearlite and cementite grains mixed. Now let us look at the cast iron area of Figure 3.We see

The precipitated cementite in hyper-eutectoid steel at once that a cast iron of 4.3 percent carbon has the

forms at the pearlite grain boundaries, and this network of minimum freezing point of all the iron-carbon mixtures

Continued on Next Page

November 2000 / Piano Technicians Journal 21

(2,065 degrees F.).We see also that it has no mushy stage, percent) is precipitated as graphite flakes, interspersed with

since the liquidus and solidus lines coincide at that carbon the ferrite and cementite crystals, so that little cement-ite is

ratio. In foundry work this material would have the obvious present except in pearlite form.This formation of graphite

advantage of remaining fully fluid at a relatively low tem- is essential to the character of gray cast iron, and the silicon

perature, flowing freely in intricate molds such as those is the chief agent in its formation. Hence the great impor-

required for piano plates. Also, with almost no temperature tance of silicon in gray cast iron. (Figure 3 does not try to

change during freezing, shrinkage during freezing would be show this effect.)

minimal, resulting in sound castings free of shrinkage

defects. While the carbon in gray cast iron rarely exceeds 3.5 Testing & Properties

percent, the advantages named above are still partly retained Since the properties of a material determine its suitability

at this percentage. for a particular purpose, the testing of these properties is

In view of what we have said about the hardness of very important.

mixtures high in carbon (cementite), a 3.5 percent carbon Some vital properties of engineering materials are

cast iron might seem much too hard and brittle to be useful. toughness, hardness, and fatigue strength.Toughness is

Indeed it would be if all the carbon remained in combina- measured by the energy absorbed before fracture in a

tion as cementite. But the silicon present in the metal comes standardized impact test. Hardness is measured by the

to the rescue. As freezing and subsequent cooling progresses, penetration of a standardized indenting die. Fatigue strength

most of the carbon in excess of the eutectoid ratio (0.8 is measured as the maximum stress tolerable under indefi-

Broken Plate! Who Is Responsible?

A plea for advice about a distressing occurrence with no tuner within miles!

comes from New York State: It is safe to assert that a “healthy” plate, properly

“As a former member, retired, I am seeking some designed, properly fitted and secured in the piano,

information. I pulled up an old piano 1/2 note to 440 will not break under the ordinary stresses of the

pitch, informing the man it was risky to raise the pitch. In tuning process, even when the string tension is being

doing so, after the pull-up, the plate [cracked] in the treble raised back to standard after long neglect. It is de-

section. signed to stand much higher stresses than those set up

What I want to know is, who is responsible? by strings tuned to standard pitch.

This is the first time this has happened to me in 58 There is even some question whether such a

years tuning.” plate could be broken by deliberately over pulling the

Some [technicians] tune pianos for a lifetime strings or whether the strings would not break first.

without ever experiencing a broken plate. But it does But since the tuner does not do this, the question is

occur once in a while. It is always sudden and unpre- academic.

dictable, the result of some unseen internal strain in So there is no basis for considering the tuner to

the plate. It may be the result of metal fatigue in a be responsible for plate breakage that occurs during

plate that was never quite perfectly fitted to the heavy or after tuning. This fact is easier for customers to

wooden frame of the piano, but was forced to con- accept if they are forewarned that there is risk in-

form to it by the many bolts and screws. It may be the volved in raising the pitch of a piano. That this risk is

result of slight and gradual changes in the wooden extremely small is shown by the fact that our inquirer

frame itself, to which the cast-iron plate is not able to tuned for 58 years, including, I am sure, hundreds of

accommodate itself. It may be the result of a hidden pitch raises as drastic as this one, without ever experi-

weakness in the casting, which finally “lets go.” It is, as encing a broken plate.

I say, a rare thing, but it does occur. It has been known — Don Galt

to occur when the piano was sitting idle by itself,

22 Piano Technicians Journal / November 2000

nitely repeated cyclic loads. cross-section of the neck) is considerably greater than the tensile

The properties of steel most important to us in connec- strength (the maximum load achieved, divided by the

tion with piano wire are those called tensile properties. original cross-section). If one thinks of wire drawing as a

Because there are some striking similarities between wire sort of controlled tensile test, in which a “continuous neck”

drawing and the tensile testing of steel, we will examine the of uniform cross-section is formed, it is not hard to see how

latter in some detail. the drawn wire develops strength and hardness superior to

The tensile test consists of stretching a specimen of those of the hot rolled rod from which it is drawn. The

known cross sectional area to failure in a testing machine. drawn wire exhibits a new elastic limit and yield point,

The maximum tensile stress endured by the specimen higher than those of the steel in as-rolled condition, and is

before failure, divided by the original cross-sectional area, capable of elastic behavior within these limits.

gives the ultimate tensile strength per unit of area, usually It is imperative that the cold work of drawing not be

called simply the tensile strength. In countries using the overdone, lest the wire become too brittle.

English system, the tensile strength and the other tensile (The tensile test and the drawing process are not perfectly

properties, such as elastic limit and yield strength, are given analogous. In drawing, the lateral compression of the metal by the

in pounds per square inch. It is usual to use a specimen die is an effect similar to cold forging—an effect absent from the

accurately machined to a diameter of 0.505".This has a tensile test.)

cross-section of 0.2 square inch, which is a convenient What we have discussed is the testing of rolled steel.

divisor for converting the measured load on the specimen Wire can be tested similarly, though it is customary to quote

into the stress per square inch. the breaking strength of wire rather than the tensile

While the tensile strength is easily determined with strength.Tensile strength is a property of the material

proper equipment, it is not the most important tensile independent of size, whereas breaking strength is a property

property of steel. More important is the amount of stress it can of the specimen, depending on both tensile strength and

stand without permanent deformation. The specimen elongates sectional area.

as it undergoes constantly increasing loads in the testing Generally, smaller sizes of piano wire have higher tensile

machine. At first this elongation is elastic; that is, if the properties than larger sizes because of the additional drafting

tension is removed the original length will be recovered. As or cold work. Also, wire used for bass string cores generally

the load is further increased an elastic limit is reached, and is made with lower properties, in order to preserve enough

plastic, or permanent deformation begins. The precise elastic malleability so that the wire can be swedged, or flattened at

limit is seldom determined in practice, as the process is the start and finish of the winding. Moreover, some manu-

cumbersome. It requires the alternate application and release facturers make more than one grade of wire, for example,

of increasing loads, with measurement of the gauge length two grades of bass and two grades of treble wire. For the

each time to determine if the behavior is still elastic. most part these different grades and sizes come from the

The tensile property usually obtained instead of the same steel and owe the difference in their properties to the

elastic limit is the yield point, which, in steel, is only slightly amount of drafting and the spacing of annealings in the

above the elastic limit. This is the unit tensile stress at which manufacturing sequence.

the specimen continues to elongate for a period without The yield strength of the wire, which cannot be ex-

any increase in load. The term “yield” is quite descriptive of ceeded in piano stringing and tuning without serious

what takes place. At and above the yield point permanent damage, is determined by a rather arbitrary process known

slips occur along planes in the crystals, until they are arrested as the 0.2 percent offset method. It is generally found to be

by crystal boundaries and broken grains. At first, yielding is about 70 percent of the breaking strength. I do not mean to

distributed throughout the length of the specimen, but as pass lightly over the elastic limit and yield strength. The

the load rises a “neck” starts to develop in the specimen and non-determination of elastic limit, and the use of an

further elongation is concentrated at this neck. After arbitrary method for yield strength, are dictated by practical

necking starts, elongation continues under decreasing loads, considerations, not by any lack of importance of these

because the effective cross-section is decreasing, and this properties. Long and careful practice has shown that this

continues until fracture occurs at the neck. testing method for yield strength gives a valid measure of

The cold work of stretching actually hardens and the two properties in piano wire.

strengthens the stretched steel, so that the true unit stress on the In common with many other materials, steel under high

material at fracture (the load divided by the instantaneous

Continued on Next Page

November 2000 / Piano Technicians Journal 23

Iron, Steel & Pianos

Continued from Previous Page

tensile stress continues to elongate slightly for an indefinite any other means, and to excessively high tension. Remember

time.This elongation is called creep. In most steel uses creep that any tension approaching 70 percent of the breaking strength is

is considered negligible if the temperature is less than 40 dangerously close to the yield strength.

percent of the melting point on the absolute scale, i.e., less A few more words are in order about the properties of

than about 700 degrees F. With piano strings, whose pitch is gray cast iron, which is a more prosaic cousin of piano wire.

so sensitive to a very small change in tension, creep at Its eminent suitability from the standpoint of manufac-

ordinary temperatures is probably a factor in both the quick turing convenience in piano plate work has been mentioned.

loss of pitch in newly strung pianos (so-called primary Its low freezing point (compared with other iron-carbon

creep), and in the long-term loss of

pitch (secondary creep).

Fatigue in metal has been men-

tioned briefly, fatigue strength being the

tolerance of indefinitely repeated cyclic

loads.The high frequency reverse

bending that occurs constantly in a

highly tensioned vibrating string,

particularly at the ends where the

transverse waves are reflected, is surely

high stress cyclic loading, and many

string breaks in playing must be re-

garded as fatigue failures.

Whenever a string is placed in a

piano, it is necessarily cold worked at

several points, such as the bridge pins,

the agraffe, etc. Every non-elastic bend

that is put into the wire tends to harden

the wire by effectively cold working the

steel at that point.The fibers on the

convex side of any plastic bend have

probably been stretched beyond the

yield strength.This point will then be

slightly more brittle than other parts of

the string, and a likely candidate for

ultimate fracture. One such point is the

agraffe. Another is the point of tangency

where the string starts to wind around

the tuning pin. Repeated small tuning

changes subject a short section of the

string to alternate bending and straight-

ening, which, even though slight, tend

to work-harden the steel.This is

probably why so many “old age” string

breaks occur at the tuning pin.

It should be obvious that piano

strings are hard-working elements of

the musical structure of the piano and

we should be careful not to do anything

to make their lot harder. Specifically, we

should avoid subjecting them to

unnecessary plastic bends by kinking or

24 Piano Technicians Journal / November 2000

material), and the proximity to each other of its liquidus and permit use of a material of relatively low unit strength.

solidus temperatures combine to make for sound, uniform One of the properties of gray cast iron, which makes it

castings. particularly suitable for machinery bases, is also to its advan-

Gray cast iron also has about the same coefficient of tage in piano plates.This is its tendency toward internal self-

thermal expansion as steel music wire, which is a factor damping of vibrations.This property, largely due to the

favoring tuning stability. Lighter metals sometimes used for honeycombing with graphite carbon, means that plates of

piano plates have somewhat higher coefficients of thermal gray cast iron are not apt to show objectionable resonance.

expansion. They do not “ring.” Happily, the words “bell metal,” which we

Gray cast iron has good machinability, as anyone who has all have seen cast into some piano plates, are simply not true.

drilled a piano plate has observed.This characteristic is The graphite carbon of gray cast iron makes it very

enhanced by the presence of the carbon in graphite flake difficult to weld. Many piano technicians have had successful

form. experiences in repairing broken plates by welding. It must be

Gray cast iron has low tensile and compressive strength said, however, that the weldability of gray cast iron is poor, and

compared with steel, its ultimate tensile strength being about that these successful repairs are in spite of, not because of, the

25,000/30,000 pounds per square inch. Structural steel has a properties of the metal. After welding, the homogeneity of the

tensile strength about three times as high, and cold drawn casting is gone, and there is sure to be a zone of weakness

piano wire about ten times as high. In piano plates this relativesomewhere. Fortunately the plate is usually over-designed as

low strength is not a particular disadvantage.The plate needs far as structural strength is concerned and the weakness of the

to be heavy enough to afford a solid platform for the strings weld repair is not necessarily fatal. Sometimes there is no

to stand on while they are shaking the soundboard. Further- alternative to attempting repair by welding and it is not the

more, the parts of the plate must be large enough so that there author’s intent to write against it. But due to the micro-

will be little deflection under load.These two requirements structure of the material, welding cannot be thought of as a

reliable means of making broken gray

cast iron “as good as new.”

Of course, there are other iron

Pure Sound materials to be found in pianos in

smaller quantities.Tuning pins are made

Top quality Stainless of cold-drawn steel wire, not so hard,

considerably larger in diameter than

Steel Piano Wire piano wire.The many steel screws are

made of steel that is made brittle by the

WIRE DRAWING A.D. 1540

presence of sulphur, so that it will thread

from 1600 N/mm - mid 19th century

2 easily and cleanly. The leg plates of

to 2200 N/mm2 - modern pianos (short scaling) grand pianos are made of a tougher cast

iron than the gray cast iron of the string

Most versatile high tech piano wire based on latest plates.They are lower in carbon, much

developments in stainless steel processing. lower in silicon and higher in manga-

Tuning stability better than average. nese, and their carbon is not in graphite

Lower inharmonicity. Lovely sound! flake form.They exhibit a fair degree of

Prices in Euros: approx. 95¢ to the Euro at June 2000 malleability and less likelihood of

500 g - 15.00 250 g - 8.50 - 125 g - 5.50 (0.700 mm - 1.50 mm) fracture under shock than gray cast iron.

500 g - 21.00 250 g - 11.00 - 125 g - 7.00 (0.500 mm - 0.675 mm) But these two cousins in the iron

Complete list of breaking strengths, yield points family, steel music wire and gray cast

and other data available. iron plates, are the real backbone of the

modern piano.Without them it would

Pure Sound be, as it once was, a very different

Juan & Mary Más Cabré instrument.

Eline Verestraat 46 • 1183 KZ AMSTELVEEN, Netherland

Phone: +31.20.6418099 Fax: +31.20.6407621

E-mail: info@puresound-wire.com

November 2000 / Piano Technicians Journal 25

Piano Plate Breakage: A Case Stud

By Steve Brady, RPT

Journal Editor

T

he story I relate here is about an event, or series moving and resetting the plate, then that action may result in

of events, in the life of Marnie Squire, an plate failure.”

Associate member of the Cincinnati, OH, Sandy West, a later piano service manager for Baldwin, elabo-

chapter of PTG. She has been kind enough to rated:

provide the documentation from her case for use in this “It is my considered opinion that a broken plate cannot

issue of the Journal. “If it can help save someone else from be blamed or attributed to a typical tuning/service call. My

the kind of nightmare I went through,” she says, “I’m happy experience is that strings will break before the plate will. A

to share my story.” broken plate is usually the result of some major trauma, such

At about 10:30 a.m. on Friday, July 2, 1993, Marnie as the piano being dropped or the result of a defect in the

Squire arrived to tune a small Fischer grand piano at a home manufacture of the plate. In both such instances the actual

in Middletown, OH.The piano, an Aeolian product, had not crack or break may not show up for quite some time. It will

been tuned in 13 years. Squire played the piano briefly to develop over time as an eventual result of the continued pres-

evaluate its condition and found several keys not playing as sure on the fault by all the strings. Simply tuning the piano

well as some damper problems.The piano was 37 cents flat. would not cause such damage.”

After bringing the piano back to a condition of rough Dr.Albert Sanderson pointed out that Marnie Squire’s pitch-

playability, Squire began the process of raising pitch. Using a raising method had been entirely appropriate, then added:

Sanderson Accu-Tuner™, she completed a “normal” first pass “It has been my observation that plates that break under

and had nearly completed a second pass.Then, “I was about to normal tuning stress have a flaw in the casting that can be

tune the second or third string from the bottom of the bass seen when the break is examined. A flaw could be a bubble

section. I played the keys and a huge ‘bang!’ happened. I had in the casting or a crack that has been growing gradually over

no idea what had happened and was very shaken.” Looking the years owing to metal fatigue.”

over the piano she saw a crack in the second plate strut from Noted piano rebuilder Tony Geers reiterated the now-familiar

the top and another crack in the tuning pin area at the bass/ theme:

tenor break. Mortified, she called the owner of the piano, who “Based on the information we have at hand, most nota-

was at work and explained what had happened. bly the fact that the piano plate broke in both the tuning pin

The piano owner filed a lawsuit over the broken plate. area and treble bar, it would be our conclusion that faulty

The owner enlisted the aid of another piano technician in the installation of the plate during the manufacturing process is

area as an “expert” witness and this technician (whose name is the most likely cause for the breakage. It is impossible for a

omitted here) told the piano owner that Squire had brought tuner to break a plate by tuning alone. There must be other

the pitch up too fast, that she didn’t know what she was doing, circumstances present, i.e., faulty manufacturing, flaw in the

and that she had actually b ro kenthe plate! cast iron, piano dropped, etc.Tuning works against the strength

In September of 1993, Marnie Squire retained an attor- of the cast-iron plate. Over-tuning would cause string break-

ney to defend herself in the lawsuit and the long process of age long before any possible damage to the plate could oc-

gathering evidence began. Several PTG members sprang to cur.

Squire’s aid by examining the piano and writing opinions, “If the plate was improperly installed at the factory, plate

some even performing sophisticated analyses based on the breakage is a very real possibility. Improper installation could

physical evidence. From over two dozen written opinions be the bending of the plate over the pinblock or securing

placed at my disposal by Marnie Squire, I have excerpted a bolts or screws. When tension is added by tuning, extreme

number of relevant quotations. stress is focused on the bent portion of the plate; such as in

Willard Sims, piano service manager at Baldwin from 1946 to the area of the tuning pins and treble bars.”

1984, wrote on September 17, 1993: A letter from prominent piano technician and educator Jim

“The tuning of a piano by an experienced technician Geiger stated:

will not cause the string plate to fail.” In another letter dated “The conclusion is that a normal piano plate, designed

April 10, 1994, Sims reiterated this stance: “I repeat my state- to withstand 40 tons of pressure would not be broken by the

ment that the tuning of a piano will not cause plate failure. If tension from the piano strings regardless of the applied ten-

a rebuilder refurbished and perhaps rescaled the piano, re- sion, how fast the tension is applied and at what point of the

26 Piano Technicians Journal / November 2000

Case Study

scale the tension is applied. In the piano factories the tension “There are only two ways I know of that a tuner can

is applied as fast as the tuner can bring the strings up to pitch. break a piano plate that is not defective while servicing a

Indeed, it should not be possible to break a normal piano piano in the home. One way is to excessively tighten the

plate with string tension alone, because the strings would nose bolt that supports the plate in the center area of the

break first.There is just not enough margin between the ac- piano. This is an adjustment not normally made outside of a

tual string tension and the tension at which failure will occur piano rebuilding shop.The other way is to take a sledge ham-

for the piano wire to be able to produce the force necessary mer to it. In other words, it is virtually impossible for a piano

to cause a good piano plate to fracture.” tuner to break a plate during the normal tuning and pitch-

University technician Rolf von Walthausen added some back- raising of a piano unless the plate is already defective and

ground on the material, then pointed out that some piano models ready to break, in which case any tuner, regardless of skill or

frequently suffer cracked plates. In this particular case, it turned out method of tuning, will be the unwitting agent of such break-

that many Aeolian grands had suffered the same fate. von Walthausen age by fate alone. Even in a worst-case scenario, in which a

wrote: tuner sought to sabotage a piano by stretching all the strings

“Piano plates are made of cast iron, which is a material far above standard pitch, chances are that the strings would

that is extremely hard, but also brittle. Properly cast and in- break long before the plate would. Tuners are sometimes

stalled, it is capable of withstanding tremendous pressure from blamed for plate breakage by understandably distraught pi-

the strings, which are fastened to and held in tension by the ano owners, but in every such case the blame is misguided

plate. Improperly cast or installed, a cast-iron plate could eas- and completely unjustified.”

ily break or crack. Even if piano wire, which is a steel alloy In expectation that the lawsuit would come to trial,

with great tensile strength, is stretched quickly beyond a cer- Marnie Squire asked Jim Ellis to look at the piano and to

tain stiffness, the wire will break far, far before exerting a render an opinion from his background as an engineer. After

force on the piano plate that would cause breakage or any examining the piano, Ellis wrote a formal analysis (included in

type of damage to the plate. this issue of PTJ) proving that the plate was poorly designed.

“Some brands of pianos have frequent occurrence of plate “What I couldn’t understand,” he said,“is why the plate hadn’t

breakage or cracking. It is rare to find an old Bechstein grand broken when the piano was first strung in the factory.”

piano, for example, without a crack in the plate. Opinions Enter Paul Monachino, who had worked for the now-defunct

from experts differ as to why this is so (poor casting, design or Aeolian Corporation during the years when the subject piano was

installation), but o ne thing is never disputed: tuning or pitch manufactured. Delivering the death-blow to the plaintiff’’s case,

raising was never the cause.” Monachino wrote:

Nevin Essex, another highly regarded technician from the “This problem is nothing new in this style piano. I have

Cincinnati area, wrote: seen this particular plate cracked in the same place many, many

“I have been teaching piano tuning and technology times.The fault lies in the construction of the plate and not in

through the Guild, at universities and on my own since 1982. the tuning of the piano.” (Monachino’s emphases —SB)

I have researched teaching methods and developed my own. The night before the case was scheduled for trial, the

Nowhere have I ever seen or heard any scientific evidence piano owner’s “expert” witness backed out, leaving the

that suggests that a piano tuner can break a plate. My under- prosecution with no case at all.The shame of the whole story

standing is that plates are designed to withstand much more is that Marnie Squire had been placed in such a position to

tension than exists in any piano. I have never heard any cred- begin with. Besides having to spend hundreds of dollars in

ible account of a piano tuner breaking a plate. I was never attorney’s fees, she was “a nervous wreck” for the year that

taught nor do I teach any technique or method designed to passed before resolution.The silver lining to this cloud is that,

prevent a plate from breaking while tuning.Tuning methods because of what she went through, and the unanimous

that emphasize raising pitch evenly do so for the purpose of opinions provided by the real experts, this kind of nightmare

achieving a good tuning, not for preventing the plate from — a lawsuit obviously without basis in fact — should not

breaking. have to be suffered by any piano technician again.

The author of The Piano Book, Larry Fine, weighed in with

an opinion that even contributed a touch of humor to the situation:

November 2000 / Piano Technicians Journal 27

An Analysis of a Broken Plate

By Jim Ellis, RPT

Knoxville, TN Chapter

Background

W

hen Steve Brady called and asked me if I would surprised that that section of the capo bar had not broken

contribute an article about broken piano plates when the piano was first chipped at the factory. I was later

(to replace an article promised by someone else, told that some of them did.

but which had never actually materialized), his deadline was The following is the analysis that I presented to the

just five days away and I was leaving on a trip in three days. tuner-technician’s attorney and I was well aware that I

When I returned it would be too late. Because of the time might be called upon to present it in court later on. Fortu-

constraint Steve and I decided that I should just use an nately for everyone the suit was withdrawn the day before

analysis that I did back in May, 1994 for the Journal article. the hearing.This was such a no-winner! The design of the

The piano was a 1973 J&C Fischer that had been piano was, in my opinion, just asking for trouble.

neglected for several years and allowed to go 37 cents flat. The original analysis included four figures, which are

The scale design had only three major divisions, no agraffes, included here, and eight photographs — primarily for the

and the forward termination for the strings was a long education of the attorney — that do not appear here

curved capo bar that ran all the way from #1 in the bass to because they are no longer available.

#88 in the treble.The middle section spanned 32 triple-

string unisons without any additional support and the Tuning Procedure Used by Mrs. Squire

bearing angle of the strings against the bar was excessive. Mrs. Squire and I discussed the procedure she had used to

The dimensional cross section of the bar was minimal, and tune the piano just before the plate broke. The piano had

there were no shoulder (nose) bolts to secure the plate struts been neglected and not tuned for more than a decade. Mrs.

to any beams underneath. Immediately after the tuner- Squire measured its pitch and found it to be about 37 cents

technician brought the piano up to standard pitch and flat. In tonal nomenclature, a “cent” is 1/100 part of a

began to check the tuning, the middle section of the capo semitone; a “semitone” is 1/12 part of an octave; and an

bar broke. octave represents a ratio of 2:1 in frequency, or pitch. In

Another technician claimed that the plate broke going up the musical scale, each of the 12 semitones in an

because the tuner brought the piano back up to standard octave increases by the 12th root of 2, or 1.059463094

pitch in one tuning rather than in several small increments above the one below it.Therefore, being “37 cents flat”

spread out over a period of days, weeks or months.The means that the frequency (pitch) of the notes on the piano

owner filed a lawsuit against the tuner for an amount that, in was about 98 percent of what it should have been at stan-

my opinion, was far in excess of the actual worth of the dard pitch (A=440Hz).

piano. I was asked to be an “expert witness” for the tuner. When a piano is flat (low in pitch) by this much,

Although the piano was located in the Cincinnati area some current procedure calls for raising the pitch of each string

260 miles from where I live, I agreed to do it for net very, very slightly above its normal frequency so that when

expenses only. The intentions of the piano owner may have it settles after tuning it will be at, or very near, the desired

been perfectly honest, but his/her decision to sue was based pitch. It is well within the limits of good tuning practice to

upon an erroneous conclusion by another technician and raise the pitch of a piano by 37 cents at one time. Obviously,

the result could have set a precedent that would have been the tuner then repeats the tuning in order to obtain a finer

absolutely wrong! tuning, since the piano will always settle back some.This

After taking a good look at this particular piano I was procedure is accepted and recommended throughout the

28 Piano Technicians Journal / November 2000

industry. It is my understanding that Mrs. Squire had and brittle. Its properties depend upon the amount of

actually finished the tuning, and was playing chords to carbon and other impurities that it contains, and these can

evaluate the job, when the plate finally broke. vary widely. For these reasons, a quality grand piano is

Mrs. Squire was following a tuning procedure that was, designed so that the areas of high stress concentration in the

and is, appropriate for the occasion. I can find no fault at all plate are those that are under compression, not tension. For

with what she did. maximum stability and strength, piano plates are almost

always cast in one piece. They are usually finished with a

The Actual Cause of the Plate’s Failure bronze-lacquer-base paint.

In order to describe clearly what happened, and what For purposes of illustration, Photo 1 is a photograph of

caused this plate to break in this piano, I must first outline the tuning-pin area of a high-quality grand piano, not the

the most basic principles of cast-iron plates in grand pianos. piano with the broken plate. [E DITOR ’S N OTE : Remember

none of the photos referenced in this article are available for

publication. — SB] The photo shows the reinforcing bars

Basic Construction of a Piano Plate that are a part of the plate structure, tuning pins, agraffes,

The plate of a piano is the structure that provides a very capo bar and strings. The bars that run parallel to the strings

strong, rigid and stable framework inside which all the and carry the load of the tension of all the strings lie mostly

strings are strung. It is what makes the modern piano above the strings.The total tension can be anything from

capable of staying in tune for weeks and months at a time. 30,000 to 50,000 pounds, depending upon the size and

Piano plates are made of gray cast iron, and not “bell metal,” scaling of the piano. Because the strings are all pulling

as some people believe. inward on these bars in a plane that lies below their

Cast iron is chosen because it is economical, mechani- centerlines, the bars have a tendency to arch upward in the

cally stable and has a low coefficient of thermal expansion. middle (See Figure 1).

It is very strong under compression, but weak under tension, Continued on Next Page

Figure 1

November 2000 / Piano Technicians Journal 29

An Analysis of a Broken Plate

Continued from Previous Page

When a bar is bent, the material in the inner part of the Photos 5 and 6, taken at slightly different angles, are

bend is compressed, but that of the outer part of the curve is close-ups of the break at the right-hand end of the bar.

under tension and is elongated. Cast iron will not withstand Photo 7 shows the cracked plate at the left-hand end of

great bending forces because of its low tensile strength. the bar.

The tendency of a piano plate to bow upward in the Photos 5-6-7 clearly show that no agraffes are present.

middle is normally restrained by anchoring it to massive Instead, the treble capo bar has been extended all the way

wooden beams under the soundboard using shoulder bolts through the piano to act as a common forward termination

that extend through the soundboard.There are other

shoulder bolts in this piano, but they are not visible in the

photo.The outer perimeter of the plate is bolted to a very

rigid rim made of laminated hardwood to hold the plate

perfectly flat, and not allow it to bend under the tension of

all the strings. By anchoring the plate in this way, the only

major forces acting on it are compressive, not tensile.

The plate flange at the front of the piano, the bar that

extends across the width of the piano, and the bars that

connect A-B and C-D together, all form a very rigid

structure. Another part of the casting extends downward

from point X and attaches to a massive “cross-beam” that Pinblock

traverses across the width of the piano below the Figure 2

soundboard. The point where several of the plate bars

converge, is one of the regions of highest stress concentra-

tion in a grand piano.The part of the casting that ties this for all the strings.This appears to have been a cost-cutting

part of the plate to the cross-beam (sometimes referred to as measure by the manufacturer. Photos 5 and 6 show that the

the “horn” because of its shape), greatly improves the bar jumped upward and toward the rear of the piano when

strength and stability of the plate by securing it (out in the it broke. Judging from my first-hand observation of the

span across the piano) to the massive structure under the piano on May 2, 1994, and from the photographs I made,

piano. the angle of rise of the strings as they came forward from

Photo 2 is a close-up of the tuning-pin area of the under the bar must have been at least 30 to 35 degrees

piano shown in Photo 1. It clearly shows how the strings in before the bar broke. I consider this much bearing angle to

a grand piano extend through the agraffes, which form the be excessive. An angle of 16 to 18 degrees would have been

forward termination of the speaking lengths of the strings. more appropriate (See Figure 2).

Agraffes are made of machined brass, with threaded studs at Photo 8 is a view looking inside the action compart-

the bottom, which are screwed into threaded holes in the ment of the piano, with the keys and action removed. The

plate. In this division of the piano, they have three eyelets, sostenuto rod is in the lower foreground, and the damper

one for each of the three strings in each unison (note). flanges and wires are behind it. The bottoms of the dampers

Making and installing agraffes is time-consuming and costly can be seen above the wires. The “belly rail” (to which the

because it is detailed work. Nevertheless, this is the preferred front edge of the soundboard is glued) lies behind the

way to terminate the strings of a grand piano, except for the damper wires.The cross-beam is just under the belly rail.

high treble divisions, where a capo bar is usually used. The open space between the damper wires (middle of the

photo) under the cross-over between the bass and tenor

Construction of the Plate That Failed strings is where the “horn” (described earlier) would be, if

Photo 3 is a picture of the inside of the Fischer piano with there were one, but there is not. Neither are there any

the broken plate.The bar (H-J) in the foreground is broken shoulder bolts to secure the plate bars or string plate to a

at point J, and protrudes upward and slightly to the rear of massive under-structure.

the piano. The pinblock is the laminated hardwood plank that

Photo 4 is a closer view of the broken bar (H—J). A securely holds the tuning pins. It is normally fitted to, and

total of 30 three-string unisons can be seen in this division rests against, a flange on the under-side of the plate, behind

of the piano. the tuning pins, so that the pinblock cannot move under the

30 Piano Technicians Journal / November 2000

Figure 3

tension of the strings. In this Fischer piano, a wide gap exists strings in the piano. The length of line (O-G) represents the

between the pinblock and the plate flange, a condition that total tension in the speaking length of the strings. The

is considered poor construction by most piano builders and length of lines (O—A) and (O-B) represent the total

rebuilders. tension in the short lengths of the strings between the capo

bar and the plate bearing surface for the estimated bearing

Scenario of the Break angles of 30 and 35 degrees respectively.

There are 30 unisons (notes) in this middle division of the The original scale design of this piano is not available to

piano. Each unison has three strings. We may assume that me, therefore I am constrained to estimate what the total

the total tension of all the strings in this piano, when tuned tension of the piano, and of the strings in this division

to standard pitch, would be somewhere between 35,000 and would be. I believe that it is reasonable to assume an average

38,000 pounds, and that the average tension of each string tension of 155 lbs. for the strings in this division, as stated

in this division would be about 155 pounds. As I indicated above. The total string tension in this division would then

earlier in this report, I believe the bearing angle of the be 3 X 30 X 155 = 13950 pounds. I am also constrained to

strings at the capo bar was at least 30 degrees, and perhaps as assume that the tensions of the strings were all equalized

much as 35 degrees before the bar broke. It is impossible across the capo bar.The graphic analysis assumes this.

now to measure the angle, because the bar is broken, but if I However, because of the excessive bearing angle at the capo

imagine that it is intact in the right place, that is the ap- bar and therefore excessive friction, this may not be the case,

proximate number that I get. which would make the situation actually worse than what I

Therefore: have shown.

Tension of each string (pounds) = 155 If the string bearing-angle across the capo bar were only

Number of unisons in this division = 30 30 degrees, line (O-A) would represent that vector. Com-

Number of strings per unison =3 pleting the parallelogram (lines A-F and F-G), gives the

Estimated string bearing angle under capo = 30 resultant force represented by line (O-F), and indicates that

degrees minimum, 35 degrees maximum. the force was 7300 pounds upward at an angle of 15 degrees

Figure 3 is a vector analysis of the combined force of all toward the rear of the piano. This breaks down into compo-

the strings against the capo bar that broke. The force vectors nent forces of 7000 pounds straight up and 2000 lbs. toward

are taken from the origin (O), which represents the point of the rear. If, on the other hand, the bearing angle had been

contact of the strings against the capo bar in this division of 35 degrees, then the resultant would have been 8450

the piano. The horizontal axis represents the plane of the Continued on Next Page

November 2000 / Piano Technicians Journal 31

An Analysis of a Broken Plate

Continued from Previous Page

pounds upward at an angle break was complete; the

of 17.5 degrees to the rear. right end of the bar flew

The component forces on up an inch or two, and

the capo bar would then then fell back down to

have been 8000 pounds where it is now, as the

straight up and 2650 plate cracked at the other

pounds toward the rear. end of the bar due to the

Figure 4, attached, sudden prying action of

shows the general pattern the bar as its right end flew

of stress in this division of Figure 4 upward.

the capo bar. Forces In my opinion, the full

pressing upward and 88-note capo bar in this

outward against the curve of the bar would create “stress piano was an inexpensive and inferior substitute for much

risers” at the bottom of each end.Tensile strains (for which better construction.The long curved span of the capo bar

cast iron is weak) would then focus at these points and tend was unrestrained in the middle.The string bearing-angle

to tear the bar apart here. was excessive. In my opinion, this bar was strained to its

When the tensile strain exceeded the low elastic limit of limit as soon as the piano was tuned at the factory. It held

the casting at the right end of the bar, it broke.The fracture for the first few years, and then for the final decade of the

appears to have begun at the bottom, near the front, and piano’s life while the string tension slowly decreased as the

moved upward in a matter of a few microseconds until the piano was neglected and allowed to go flat.Then, when the

piano was finally tuned back up to

standard pitch, the weakened bar

broke.

Conclusion

In my opinion the plate in this piano

broke as a result of inferior and faulty

design. It would have broken, no

matter who tuned the piano. Fortu-

nately, piano plates rarely break, but

when one does, it is not uncommon

for it to do so some years after the

piano was built, and the cause is almost

always a fault of some sort in the plate.

Stress fatigue in metal does occur with

the passage of time, and microscopic

cracks do grow until the part finally

fails. In my opinion Marnie Squire was

not at fault in any way, and to con-

clude that the plate in this piano broke

because of any negligence or improper

technique on her part would be

utterly absurd.

32 Piano Technicians Journal / November 2000

Welding Cracked Plates:

A Proven Method

By Wilford Young, RPT

Salt Lake City, UT Chapter

A

broken plate can be welded if one wants to go and keybed. It will have pulled a nearby nosebolt out of its

to all the work. First, one must determine how supporting post — stripping the threads.

much the plate has warped or changed shape. It I use a jig to pull vertical plates back into their original

makes no sense to weld the plate in its broken shape. (See Figure 1) After releasing string tension and

configuration.That’s like tuning a low-pitched piano removing the strings in the break area I drill a 3/4" hole

“where it’s at.” The problem with welding a plate “where through the soundboard. Then I insert a long 3/4" continu-

it’s at” is that forevermore the piano will be in that same ous-threaded bolt

shape — the shape of “where it’s at.” through the hole and

In grands, the most common break results in the plate through blocks placed in

and pinblock dropping a few millimeters. Sometimes the the front and back of the

pinblock will make contact with the action. Removing the piano, and begin pulling

action when this has happened can be a real challenge, but the plate back to where

with persistence it can be done. Loosening the strings is a it belongs. The correct

must. position is determined

by checking the

Preliminaries downbearing of a string

To begin the repair, unhook the strings from their hitch pins laid across the bridge and

in the area to be worked on (about two octaves). Tie them fastened to its hitch pin.

to one side. This is required before grinding, drilling and In some cases it may not

welding begins. Once the action is removed, a small hydrau- be possible to bring the

lic jack can be used to raise the plate back to its original plate back that last one

position. or two millimeters

In vertical pianos, the most common break occurs mid- without danger of

section just behind the keybed. The plate will likely have breaking the plate in a View showing the completed weld and how the straps

moved forward to where it has lodged against the action different place. But don’t were placed across the break.

throw the piano away,

even if you are unable to achieve positive downbearing.

After all,Vladimir Horowitz’s Steinway had negative

downbearing during his later years of concertizing.

Just try closing the gap in the crack as much as possible.

One will find that a lot of force is required to move the

plate even a small amount. As the plate moves closer to

position, the nut on the jig will get so tight that it nearly

strips the threads of the 3/4" bolt, so don’t try using a

smaller bolt.

Preparation for the Weld

Proper procedure requires that a “V” groove be made where

the weld is to take place. Cast iron is easy to grind and drill.

A small hand-held, high-speed grinder works quickly. If

A typical break in a vertical piano. Straps of steel were used for reinforcement.

limited space prevents use of a grinder, then try a 3/8" drill

34 Piano Technicians Journal / November 2000

quickly peen the weld metal with a ball-peen hammer. This

causes the metal to “flow” as it shrinks during cooling, at the

same time adding strength to the weld and reducing the

chance of small cracks showing up. Before proceeding, let

the weld cool until you can place your hand on it. If you

Shows how a groove is cut into the broken strut to allow the weld to

bond the two broken parts together.

proceed faster, cracks will occur somewhere else in the plate,

maybe as far away as the opposite end. Do not try to speed

up the cooling process with a fan, or cold cloths or water. It

with various size bits (sharpened). will mean failure.

The ideal situation is to have the broken plate removed What happens if you get in a rush? A friend asked me to

from the piano and delivered to one’s shop where it is free weld his initials on the cast-iron lid of his Dutch oven. I

from encumbrances. Another advantage of this is that it asked him if he wanted it done in the manner I do piano

allows the plate to spring back into its original shape, plates (very slowly and costly) or a quick blacksmith job

eliminating the need for jigs, etc. Most of my welding, with cheap welding rod. He chose the fast method, where I

however, takes place in the customer’s living room. would weld continuously nonstop till finished. So I did it.

To protect the piano from sparks, get some old towels or When I finished, I observed that the lid was laced with

cloths at a thrift shop. Dampen them (but not dripping wet). spider-web cracks. I was surprised the lid did not shatter, but

Spread them out to protect the keybed from beads of hot Continued on Next Page

metal. Also, stuff damp cloth between the plate and the