Professional Documents

Culture Documents

Mitsubishi Drive VFGL PDF

Mitsubishi Drive VFGL PDF

Uploaded by

prasad100%(1)100% found this document useful (1 vote)

1K views10 pagesOriginal Title

367648602 Mitsubishi Drive Vfgl PDF

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views10 pagesMitsubishi Drive VFGL PDF

Mitsubishi Drive VFGL PDF

Uploaded by

prasadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

ETAMELCO(UA, OA. OM, KW, SL TK ND; MD), SYSCON, LEVANT, MTS, MTULIF, MEGPT. MG-ROVO SAE MEUEIEED 95h MELA,

|NEMESA, SAN IAGUEL OOM, NELCOL, COHECD, GHENAE, FERAEWAOG, KWCH, A}, EMEC, UNE, AME MEUK. LAC. MEG, FAN ENNIS

FETE: ES MGR, ACEO WEN), NECITC EE, Fuk WIEE SPR EOE AE BUOOP NELSASA, 5D ST,

Dee, 12, 2008

NexWay-S (VFGL) Electric System Installation Manual

1. Goneralprocautons «

1-1 Precautions for safety

1-2 Precautions in handing the contol pane

2. Standard process of constuction

3. Preparaton for agustrent +

31 Tools

3-2 Instruments:

29 Ege cin ey

3-40thers

4 Preparation fr test run

41 Conta panel ,

442 Cleaning, inspection and ubication of Equipment in shaft

43 Cleaning and inspection of car surroundings

44 Load weighing device---~

45 Insulation test

46 Stow sequence test ~

47 Low speed operation

5. High-speed operation +

5+ Insalaon and adjustment ofthe devies

$52 Preparation fo high-speed operation

53 High-speed operation +

6. High-speed operation adjustment

6-1 Counterbalance +

{6-2 Confirmation of braking torque

6-3 Adjustment of ad weighing device

{6-4 Adjustment of ridng contort

{6-5 Adjustment for stop poston oo

6-6 Check of TSO .

6-7 Check or load futuation

68 Rowite of Fash-memory

{6-9 Magnetic pole acjusting operation

7. Operation check

1 Low-speed automatic operation

12 Aterion announcement basic

28ND ope Opi

8, Check before handing over

seeseesiaza

YG Hoaiga

(© 2003 MITSUBISHI ELECTRIC CORPORATION

Consction Maal

763200.)

r

lo

Pa

s

a) cmIL

@

8

&

€

a

=

g

38,388

Istataon Manual

acto machinelrake

car station

oe operator

weighing doce

CONTROL PANEL EXTERNAL WIRING DIAGRAM

ELECTRICAL LAVOUT EXTERNAL WIRING DIAGRAM

LANDING DEVICE INSTALLATION DWG

TERMINAL STOPPING DEVICE ATTACHMENT DWG

WEIGHING DEVICE ASSY

Consucton Nanyat

7.032028)

CHATO.I~, C4 ABO. ~ *

cra p321~

C18-09.428~

creRi~

Ye310¢100

‘YE3188350

yedoie4ss

Yedo1B447

‘YA030A222 (for 56 ropes)

‘YA039A223 (or 7 ropes)

YKARIVA

Meot RAR Se: C-7-C3200.1 @) EMC

Construction woe

7-03200.3 (3)

Doe, 12, 2008

1. General precautions,

‘This Construction manuals fo the electical system of Misubishi Compact Machine Room Elevator (Control name : VFGL).

14. Precautions for safety

1) Even after the power soutee is shut of andthe LED (OCV) on the PCB (Printed Circuit Board(KCR-945X) is tuned off, The

‘lectic charge ofthe main cuit capacitor salve fora while (1 to 2 minutes) andthe high voltage parts remain in each pat.

Therefore donot touch the main circuit ofthe inverter

Ifitis necessary to do so, check DC voltage atthe DC side of main converter diode module using the digtal volmeter after the

CVs tumed of to ensure thatthe cxcui is not ave

Even if MCB is shut of, do not touch carelessly because the common circuit i stil alive when the group control is possessed

(ACB having),

2} Note thatthe motor and the rageneratve resistance become hot by operating

{3} Excopt when rewriting Flash-memory using MC card, do nat place the RM-ANT:-FWR toggle swich in FWR postion. (When

‘ering parameter, set itn RIM and MNT postion.

4) Tum off the PIT switch when you enter the PIT.

Construction Many

6-7-0320. 4

Dee. 12, 003

12, Precautions in handing the contol panel

‘AS IGBT moduie is used in the inverter forthe contol panel, flow these precautions to prevent accidents from static elect

1A ar as possible, aot tauching the gators on GBT edule in the fgure shown below) and conducive pao the gate

cit! PCB KCR-48x Gant same fg)

2) In prince, IGBT module must be replaced, i necessary, as a part ofthe inverter unt assembly, as enclosed by chain line inthe

figure shown below.

3) Remove and throw away the font cover installation screws not fied by the snowman type hols, Never put the removed screws on

the top ofthe conto panel

4) Do not connect the power source wih the connectors EP and EP2 disconnected.

Inverter unit

GBT module

Gat creat

| Meat Ret: C7-032001 @ LAL

imatmaan se: C-7-c32001 EBL

Constn Mangal

7.03200. 4a 8)

Now 10,2004

1-3. Other Precautions

13+, Priory of NomaHhspection switch at inspection mode

‘$88}Safely Switch Box) on car > AUTO-Iaspecton switch in car > MSBMachine room Switch Box, PM-Gearless)

-AUTO-HAND switch on R1-PCB in C/P (Worm Gear)

That means:

Hthe $8 on cars Inspection mode, you can not operate inthe car and athe Machine room.

the AUTO-Inspeeton switch in caris Inspection made, you cannot operate atthe Machine oom,

senna: 07-3201 @ LAL

De. 12, 2008

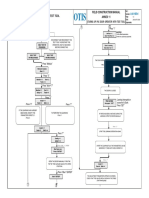

2, Standard process of constructon

(Construction Many

-7-03200. 51

Work item

Detal tem

Entry page

Preparation for test

un

(7) Clearing, inspection and lubrication of Equipment shaft

(2) Clearing and inspection of car surroundings

(9) Insuiation test

(4) Remove motor wires and BK wires

2

4

2 Testa

(0) Chek of power sore and conv volage

(2) Soquence test

(9) Hand operation

(@) Chock sat cut

{6} Cleaning, inspection and ubicaton of shalt

6

47

«0

50

50

Construction work for

‘hand operation

{(1) Adjustment of door operator

{2) Istalaton and adjustment of landing device

(6) Istalation and adjustment of terminal stopping device

ot

st

EA

‘Adustment of hgh

speed

(G) Confiomation ofrotary swich of printed crit board

(2) Writing foo height memory in hand operation

(9) High-speed operation

(4) Adjustment of counterbalance

(6) Confirmation of braking torque

(6) Adjustment of oad weighing device

(7) Witng too height memory in bigh-speed operation

(6) Adjustment of ide comfort and stop poston

(9) Check of Low-speed automate operation

(10) Check before handing-over

eeaesesea

ot

ORR AH: C-7-C3200.1 LIC

Constucton oa

6-7-0320. 6

Dec, 12, 2003

4. Preparation for adjustment

34, Tools

Use of improper tools may cause danger of fatal accident, Always make sure that proper tools are used,

1) Wrenches

One eachot 557, 7X8, 10x12, 10X13, 19% 17and 14x17

Two 1928

2) Screwdrivers

Ase of sorewerivers

M6 and M7 BOX screwdrivers

Minus chive for adjusting the rotary switches on PCB.

Mis driver for nger-protec terminal

3) Piers

acto pers and other pers

4) Short circuit wires

‘Two or more wires wit ligatorcippers at both ends.

5) Mini clippers (o be used fr trouble shooting)

a]

Mini. ciooar

{6 DYNAMIC contact cimper and pin remover (tobe used for alteration)

7) Seale

150mm Metal ruler

‘3.5m Convex measure

we rtneay se: C7-Ca000.1 @ ERI

“Grown

bec 2,208

22 atuners

1) ita voter or teste

Dal votnetrMrinum npg M histo be measurable vito 0

Teter Mente 20 hs

2)AC ammeter

‘AC 100 (A range, class 25 or above

Recommended too!

HIOK'-3264 (Note: Measure the current in FAST mode)

AC volmetor

‘AC. 300 (V range: The indicator tobe used shall have minimum input impedance 300 K ohms.

Recommended tol

Yokogawa 7990951

Dont use the folowing tools,

Yokogawa 2013-SPFB (mobi iron ype) _: Because input impedance isto low,

Yokogawa 2052-07 (mobile iron-stp type) _: Because the influence of induction noise i too high

4) Megger

High-votage megger:500V battery contained, minimum intemal resistance 200 K ohms. Do not use manval tuming type.

Low-votage megger: 15 V battery contained.

‘tester wih minimum intemal esstance 200 K ohms may be substiuted as low-voltage megget.

5) Fier for measuring motor terminal votage

Use this fiter wen measuring the votage atthe terminal.

‘Note: ft must not be used for non-inverler elevators such as AC-2. its used for them, it wl eause the indicated valve to be lower

than actual votage by several percent

“Note2’: The instalation of is fiter onthe molr side must be at only measuring, remove the fier alter the measurement Moreover,

the measurement must not extnd fora longtime.

——— 4 S

Tothe motor z To the vatmeer

= eS

‘Motor voltage measuring fier (¥X4000846-02)

6) Maintenance computer

‘To be used for updating parameters of the Fash-memory, in case of design changes, and for touble shooting,

7) Mini writer

Watanabe-sokki WTR-7! or an equal tem, ad for tovble shooting,

‘ok REAR Se: C-7-3200.1 (BS) LIL

Construction Mansel

ao 7.03200.)

3-3, Equipment of rewriting Flash-memory

1" MC card (Yx9028883 G02)

2) "Pt eabl (YX302B833 G04) [Connect between MC card and Pt-Card]

83) Maintenance computer (Personal compute)

4)"Cable (with connector) (¥X3028833 Go4) [Connect between mainlenance computer and MC card]

5) Power source device (YX401B000 Got) [wrt into the MC card]

6)"Flash wit / readin sofware instalation floppy ask (YX400C886 GOt Lot)

Note)“t: Arrangement collectively of (1}(2(4) is (¥X302B8%3 G01)

2: Only necessary itis when installs wring / reading S/W in maintenance computer

3-4, The others

1) Drawings

Control panel wing diagrams, layout drawings, ladder drawings, specications, components lst, et.

2) Documents

Final tet report, final test result shoot, check sheet, et

3) Safety handbook

Construction | ve

7.03200 9

Deo. 12, 2003,

4. Preparation for test un

4-1. Control panel

+) Enoue thatthe contro panel is propely insted and wired and its components (PCB, relays, fuses, et.) are in good condition

[No objec shall be placed in vieinty of the]

regenerating resistor which willbe not

| Note that the regenerating resistor remains het

ater the power source is shut of

PCB relay unit

[Ihe DYNAMIC connectors are nol

designed to prevent wrong insertion

Special cae is required to insert them]

in correct positon

[Elecic wires and conductor cables]

shall be managed so that they wil ot

interfere opening of the PCB rela]

unt panels.

contol pane!

\Whon mutiple cas ae used, the conto pane shal contain optical bers,

[Bo rot bind the cable, # necessary]

[Do not apply sess to the cable wher [wth excessive force.

passing through flexible conductors.

Take care to prevent trom being entangled

by he duct cover, et.

smotnetn se: C-7-03200.1 @&) Em

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Monospace 21 SeriesDocument54 pagesMonospace 21 Seriesprasad100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Field Construction Manual Annex 11 Manual Learning Mode Using Test ToolDocument2 pagesField Construction Manual Annex 11 Manual Learning Mode Using Test ToolprasadNo ratings yet

- HD One X S User Guide PDFDocument19 pagesHD One X S User Guide PDFprasad100% (1)

- Manual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDocument70 pagesManual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDio ChanNo ratings yet

- LEDDocument7 pagesLEDprasadNo ratings yet

- MP EcogosoftwarepackageaDocument68 pagesMP EcogosoftwarepackageaprasadNo ratings yet

- F15 Centa LoadDocument56 pagesF15 Centa LoadprasadNo ratings yet

- Maniobra KONE MonoSpace 2.X Con V3F16L - Formacion Tecnica PDFDocument90 pagesManiobra KONE MonoSpace 2.X Con V3F16L - Formacion Tecnica PDFprasadNo ratings yet

- Manuel Instalation 2Document66 pagesManuel Instalation 2prasad100% (1)

- 4 595879312201928Document150 pages4 595879312201928prasadNo ratings yet

- Display - FloorDocument7 pagesDisplay - FloorprasadNo ratings yet

- 80-CD-03-2-03-4-1-1-1-0 Fuji With H ARD 2Document3 pages80-CD-03-2-03-4-1-1-1-0 Fuji With H ARD 2prasadNo ratings yet

- Triplex For MCTCDocument2 pagesTriplex For MCTCprasadNo ratings yet

- NullDocument24 pagesNullprasadNo ratings yet

- 三菱无机房ELENSSA调试Document25 pages三菱无机房ELENSSA调试prasadNo ratings yet

- ARL-300 User Manual V25Document120 pagesARL-300 User Manual V25prasad100% (3)

- Mitsubishi VFGLDocument189 pagesMitsubishi VFGLprasadNo ratings yet

- HD Driver User GuideDocument16 pagesHD Driver User GuideprasadNo ratings yet

- Sigma - SI210 Controller #3Document20 pagesSigma - SI210 Controller #3prasadNo ratings yet

- Kone Unidrive: Service ManualDocument56 pagesKone Unidrive: Service Manualprasad100% (1)