Professional Documents

Culture Documents

Field Construction Manual Annex 11 Manual Learning Mode Using Test Tool

Uploaded by

prasadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Construction Manual Annex 11 Manual Learning Mode Using Test Tool

Uploaded by

prasadCopyright:

Available Formats

Ref.

:

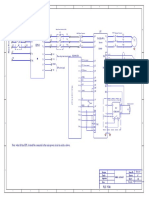

FIELD CONSTRUCTION MANUAL Number: A-A110Ev1

MANUAL LEARNING MODE USING TEST TOOL

OTIS ANNEX 11

STARING UP PAX DOOR OPERATOR WITH TEST TOOL

Page:

Date:

Supersedes:

1/2

JANUARY 2008

1 2

Press “1”

CONNECT THE POWER SUPPLY Learning:

Init Run = 1 1 With default parameters

TO DOOR OPERATOR CONTROL Door Para Run = 2 2 With the customized paramete

DISCONNECT AND RECONNECT THE

TEST TOOL THE RESTART THE

SELF TEST IN OPERATION. WAIT 20 SECONDS Door is running

PROGRESS BEFORE CONNECTING Stop Door run = 3

SELF TEST SELF TEST

OK-MECS-MODE OK-MP2/3-MODE

THE DOOR OPENS AND CLOSES IN STEPS OF 10 cm AT LOW

SPEED.

Press “Module” THE DOOR CLOSES AT LOW SPEED.

Welcome to Atxx

Atxx = 3

Press “3” Para run finish

Learning finished.

Monitor = 1 Test = 2 Press “ Funtkey” Press "FUNCTION"

Tools = 4

Press “blue”+”7”

Monitor = 1 Test = 2 THE DOOR IS CLOSED

Setup = 3 Tools = 4

Press “3”

Install = 1 Para run failed

Learning interrupted on

Field = 3 ENG = 4 Run again : “SET” account of a Daule.

Press “3” Press “1” Press “SET”

IF THE LEARNING HAS ALREADY

BEEN DONE, MODIFY THE TO PERFORM THE LEARNING IF THERE HAS BEEN A MISTAKE DURING THE

PARANETERS DIRECTLY. Press 1 LEARNING, OPEN THE DOOR MANUALLY

Press 3

"Press 1"

Install = 1

Field = 3 ENG = 4

START THE LEARNING OPERATION AGAIN

Press “1”

Config = 1

SetDef = 9

"Press Blue + ENTER" AFTER THE LEARNING RUN, THE PARAMETERS CAN BE

MODIFIED IF IT DOES NOT WORK CORRECTLY.

Start learn run

Press “ENTER”

"Press 3"

OPEN THE DOOR MANUALLY FRM THE

TOP OF THE CAR AND LEAVE IT IN OPEN Install = 1

POSITION. Field =3 ENG = 4

Press “ Blue” “ENTER”

Start “ENTER” THE ADJUSTMENT PARAMETERS APPEAR ON SCREEN;

CHECK THAT THE VALUES ARE AS SHOWN IN THE TABLE

(See following page)

1 2

Ref.:

Table of parameters FIELD CONSTRUCTION MANUAL Number: A-A110Ev1

% PARAM ETERS TLD

700

TLD

750

TLD

800

TLD

850

TLD

900

CLD

800

CLD

900

OTIS ANNEX 11

STARING UP PAX DOOR OPERATOR WITH TEST TOOL

Page:

Date:

2/2

MAY 2009

Supersedes: JANUARY 2008

START O PN DIST 50 50 50 50 50 50 50

10 10 10 10 20 20

O PEN CRP DIST 10

VERIFICATIONS AND CHECKS IN ORDER TO SOLVE POSSIBLE PROBLEMS

CLOSE CRP DIST 70 70 70 70 70 50 50

- Verify the parameter DOOR=12 in the LCB_II board (M-1-3-1-5) or parameters DOOR and REAR=13

START CLS DIST 20 20 20 20 20 20 20

ACCEL O PEN 40 40 40 40 40 40 40

in the GECB board (M-M-1-1-3-1-5).

DECEL O PEN 40 40 40 40 40 40 40

- Verify the addresses of the remote stations (Inputs and Outputs) which control the door operator,

ACCEL CLOSE 40 40 40 40 40 40 40 (LCB_II: M-1-3-2 or in GECB: M-M-1-1-3-2).

DECEL CLOSE 40 40 40 40 40 40 40 - Verify the addresses of each I/O in the programming list for the unit as there might be variations

REVERSAL O PEN 40 40 40 40 40 40 40 in the address.

REVERSAL CLOSE 40 40 40 40 40 40 40

69 69 69 69 69 69 ADDRESS ADDRESS

START O PEN SPEED 69 I/O FRONT I/O REAR

LCBII GECB LCBII GECB

O PEN CRP SPEED 46 46 46 46 46 46 46

CLOSE CRP SP EED 20 20 20 20 20 20 20 991 ST1 17.3 16.2 994 ST1 19.3 19.2

START CLOS E SP EED 30 30 30 30 30 30 30 992 ST2 17.4 16.3 995 ST2 19.4 19.3

M AX O PEN S PEED 62 62 62 62 62 54 54 993 ST3 16.3 16.4 996 ST3 00.0 19.4

M AX CLO SE SPEED 38 38 38 38 38 41 41

0 DOL 17.1 16.3 544 DOL 19.1 19.3

NUDG ING SPEED 47 47 47 47 47 47 47

605 DOS 17.4 16.2 606 DOS 19.4 19.2

O PEN TORQ UE 100 100 100 100 100 100 100

CLOSE TORQUE 50 50 50 50 50 50 50 607 LRD 17.3 16.4 608 LRD 19.3 19.4

CLOSE CRE EP 50 50 50 50 50 50 50 NOTE: Ignore the message «Double Adr/Pin» in the Test Tool and press «ENTER».

TORQ UE

- Check that all the inputs that are not used in the LCB_II board (M-1-1-2) or the GECB board

CLOSE IDLE TO RQUE 50 50 50 50 50 50 50

(M-M-1-1-1-2) are in small letters (deactivated).

O PEN LDLE TORQUE 50 50 50 50 50 50 50

CLOSE PUSH 100 100 100 100 100 100 100 CHECKING COMMUNICATION OF CONTROL SIGNALS ST1, ST2, ST3 WITH LCB_II

TORQ UE

NUDG ING TO RQUE 50 50 50 50 50 50 50

CONTROLLER.

STOP TO RQUE 255 255 255 255 255 255 255 - With the lift on INSPECTION and the stop not pressed, connect the Test Tool in the door operator

control and carry out a check of the interface M-3-2-4-1.

The main parameters in the above table are in dark grey. - It should show “Finish No Error” if the communication is correct. If not, consult the table of

To modify the parameters the door must be closed. test errors.

To check the door after each modification, follow the SVT Inte rfa c e OK Test completed successfully. Communication correct.

sequence below.

Press “ SET” ST1 shortcirc, ST1+2 shortcirc,

ST2 shortcirc, ST1+3 shortcirc,

Short-circuit with HL2 of one or more lines of command. Check the wiring.

Install = 1 ST3 shortcirc, ST2+3 shortcirc,

Field = 3 ENG = 4

ST1-3 shortcirc

ST1 broken, ST1+2 broken,

Press “ 4”

ST2 broken, ST1+3 broken,

Short-circuit at 24 V DC or broken wire in one or more lines of command.

Monitor = 1 Test = 2 ST3 broken, ST2+3 broken,

Setup = 3 Tools = 4

ST1-3 broken

Press “1” ST1 wrong connect,

Single Run = 1

ST2 wrong connect, Wiring sequence incorrect. Check the wiring between the junction box and DCSS.

Cont Run = 2 ST3 wrong connect,

The checking sequence is not detected in a period of 400 ms after request. Check the input

No response pin of the remote station and the voltage levels. In the checking sequence DOL and DOS are

Press “1” to open Open = 1 Close = 2 required in high logic status.

Stop = 3 Revels = 4

Press “2” to close

The DCSS was unable to interpret the commands received. The checking sequence was

Unknown error

possibly interrupted. Repeat the operation.

You might also like

- Scania DC12 Operator's ManualDocument65 pagesScania DC12 Operator's ManualAlex Renne Chambi100% (3)

- Dbss - HSDD - Startup Routine: Field Component ManualDocument25 pagesDbss - HSDD - Startup Routine: Field Component ManualМихаил100% (1)

- Make - Volume 13 - Volume 13Document212 pagesMake - Volume 13 - Volume 13Pedernal Lisiao100% (2)

- Esquema Electrico Acd2 ControllerDocument11 pagesEsquema Electrico Acd2 ControllerMoises PerelloNo ratings yet

- C U H Máy Kéo Sigma OtisDocument45 pagesC U H Máy Kéo Sigma OtisQuang Pham DuyNo ratings yet

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocument10 pagesOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNo ratings yet

- Mac Puarsa MRL SCHEMATICDocument28 pagesMac Puarsa MRL SCHEMATICthanggimme.phanNo ratings yet

- MRL E-Pack Assay Instructions For Tests and VerificationsDocument35 pagesMRL E-Pack Assay Instructions For Tests and VerificationsLe Huynh LongNo ratings yet

- PLC ProgrammingDocument116 pagesPLC ProgrammingVali Ene100% (4)

- GAA 24350 AW11 IVa PDFDocument31 pagesGAA 24350 AW11 IVa PDFEvgeniyNo ratings yet

- Otis Fo-VfDocument57 pagesOtis Fo-VffuhadNo ratings yet

- 8089SPL Doctaa26bjr PDFDocument56 pages8089SPL Doctaa26bjr PDFMichael AnodinNo ratings yet

- Monospace 21 SeriesDocument54 pagesMonospace 21 Seriesprasad100% (2)

- Monospace 21 SeriesDocument54 pagesMonospace 21 Seriesprasad100% (2)

- Monospace 21 SeriesDocument54 pagesMonospace 21 Seriesprasad100% (2)

- Playboard Iii: User ManualDocument88 pagesPlayboard Iii: User ManualAliRouyouNo ratings yet

- OTIS (Instruction Manual For TOMCB Converter Board)Document26 pagesOTIS (Instruction Manual For TOMCB Converter Board)Ariel LeonNo ratings yet

- List of Installation Parameters: Software Basic Data Mcs - LCB - IiDocument43 pagesList of Installation Parameters: Software Basic Data Mcs - LCB - IiBartz SantosNo ratings yet

- Triplex For MCTCDocument2 pagesTriplex For MCTCprasadNo ratings yet

- Errors SCH-1 PDFDocument946 pagesErrors SCH-1 PDFAshraful ShohagNo ratings yet

- DCSS BD Service Tool Manual GAA31064AAA 2007-01-19 10417955481260589056Document42 pagesDCSS BD Service Tool Manual GAA31064AAA 2007-01-19 10417955481260589056Ace Noah SomintacNo ratings yet

- GAA 24350 AW11 IVb PDFDocument11 pagesGAA 24350 AW11 IVb PDFDiego AguilarNo ratings yet

- WITTUR DOOR DRIVE - Supra Board PDFDocument30 pagesWITTUR DOOR DRIVE - Supra Board PDFkoustasd100% (4)

- Manual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDocument70 pagesManual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDio ChanNo ratings yet

- Manual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDocument70 pagesManual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDio ChanNo ratings yet

- Characteristics - Igtf Landing ArrangementDocument56 pagesCharacteristics - Igtf Landing ArrangementMAYESTON100% (1)

- Hh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdDocument3 pagesHh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdRebecca DangNo ratings yet

- Qatar OM PART C PDFDocument796 pagesQatar OM PART C PDFBobi Guau100% (3)

- Global Drive Operating Manual: DISTRIBUTION: Per Notification Document 53627Document155 pagesGlobal Drive Operating Manual: DISTRIBUTION: Per Notification Document 53627Ngangoum djiélé Roméo leveinardNo ratings yet

- HD One X S User Guide PDFDocument19 pagesHD One X S User Guide PDFprasad100% (1)

- Óleo Inglés K2 64230-002 R00Document31 pagesÓleo Inglés K2 64230-002 R00Elevateur ElevateurNo ratings yet

- Canny AntiguoDocument178 pagesCanny Antiguoguillermo Bueno100% (1)

- Kone Travelmaster™ (Ejv1.2) EscalatorDocument22 pagesKone Travelmaster™ (Ejv1.2) EscalatorChang ChangNo ratings yet

- Unpublished Work-© Otis Elevator Co. 2009Document33 pagesUnpublished Work-© Otis Elevator Co. 2009Quang Pham Duy100% (1)

- Si210 TS 02 1 - TCD070 079 (39 45)Document9 pagesSi210 TS 02 1 - TCD070 079 (39 45)FERNSNo ratings yet

- OTIS ACD RELEASE1 DAA21290AL电气原理图Document75 pagesOTIS ACD RELEASE1 DAA21290AL电气原理图Jms Quintero100% (1)

- Gba 26800 H II StartupDocument15 pagesGba 26800 H II StartupPeter100% (4)

- OH-CON4423 Adjust Training ManualDocument49 pagesOH-CON4423 Adjust Training ManualJuanmanuel Barroyeta100% (4)

- Xaa610bb GL enDocument24 pagesXaa610bb GL enchalogdNo ratings yet

- Lift Monitoring & Diagnostics: SystemDocument53 pagesLift Monitoring & Diagnostics: SystemMohd Abu AjajNo ratings yet

- Fuji-FRENIC-Lift LM2-Reference-Manual-INR-SI47-1909-E - Lift (LM2) - RM (E) - English PDFDocument246 pagesFuji-FRENIC-Lift LM2-Reference-Manual-INR-SI47-1909-E - Lift (LM2) - RM (E) - English PDFNaeem HussainNo ratings yet

- 3000 MRLDocument23 pages3000 MRLNguyễn Thân100% (1)

- Unidentified Alarm Occurrence / Run CPU Address Error: TCD-002 TCD - 003Document1 pageUnidentified Alarm Occurrence / Run CPU Address Error: TCD-002 TCD - 003NoahNo ratings yet

- Smart Board ManualDocument80 pagesSmart Board ManualAyra Elevator perkasaNo ratings yet

- Acd4 MRLDocument66 pagesAcd4 MRLRafael BrunoNo ratings yet

- Kone Unidrive: Service ManualDocument56 pagesKone Unidrive: Service Manualprasad100% (1)

- Apostila Eco Drive HydraPlus - Manual-1Document15 pagesApostila Eco Drive HydraPlus - Manual-1Edson Alessandro Caramite100% (3)

- Manual 40.10 PM-01.2016Document28 pagesManual 40.10 PM-01.2016Anonymous Mike100% (1)

- Acd2 Mrlxaa21310as - Santa AnitaDocument110 pagesAcd2 Mrlxaa21310as - Santa AnitaRafael BrunoNo ratings yet

- Electrical Wiring DiagramDocument46 pagesElectrical Wiring DiagramTùng Phạm xuânNo ratings yet

- Do3000x Oim enDocument38 pagesDo3000x Oim enAN NhiênNo ratings yet

- LBII ParametrosDocument37 pagesLBII ParametrosPolinho Donacimento100% (1)

- Electric Drawing-FR2000Document19 pagesElectric Drawing-FR2000MuMoMa100% (1)

- (PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17Document17 pages(PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17boneyNo ratings yet

- Parameter List MCS - RCB2Document34 pagesParameter List MCS - RCB2FazilNo ratings yet

- RL19560 Schematics XXDocument26 pagesRL19560 Schematics XXAsif AbbasovNo ratings yet

- MTELecoGO Pro-Eco H enDocument9 pagesMTELecoGO Pro-Eco H enRaja DuraiNo ratings yet

- Manual Sigma BG221Document29 pagesManual Sigma BG221Quang Pham DuyNo ratings yet

- Manuel Instalation 2Document66 pagesManuel Instalation 2prasad100% (1)

- Language - Introduction To The Integrated Language Arts CompetenciesDocument7 pagesLanguage - Introduction To The Integrated Language Arts CompetenciesHari Ng Sablay100% (1)

- Mesa Quirurgica Opt 70 Ec 02 PDFDocument36 pagesMesa Quirurgica Opt 70 Ec 02 PDFTEYLER BARBOZANo ratings yet

- Otis GeN2 Switch Gecb At120 Variador LV Diagramas TAA21310TDocument25 pagesOtis GeN2 Switch Gecb At120 Variador LV Diagramas TAA21310Tlucas100% (2)

- THYSSENKRUPP ElevatorDocument3 pagesTHYSSENKRUPP Elevatorhamid taher50% (2)

- Star-Up Lbii BD Component Start Up Gaa30163aaf - 2007!10!11Document17 pagesStar-Up Lbii BD Component Start Up Gaa30163aaf - 2007!10!11Polinho DonacimentoNo ratings yet

- 140VAT, OtisDocument12 pages140VAT, OtisRellim AugustoNo ratings yet

- Shorts DMG Controller Electrical SystemsDocument4 pagesShorts DMG Controller Electrical SystemsAnton LyakhovNo ratings yet

- Defeitos CMG S5500Document81 pagesDefeitos CMG S5500Douglas Da Silva Ribeiro100% (1)

- Controllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppDocument2 pagesControllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppMihai Lungu100% (1)

- Playboard V3 Iii PDFDocument90 pagesPlayboard V3 Iii PDFIván Sulbaran0% (1)

- MCS - LCB Ii, TCB, HCB, TCBCDocument77 pagesMCS - LCB Ii, TCB, HCB, TCBCHabboula MouradNo ratings yet

- The UML-51 / ELV-5R: Advance Elevator ControllerDocument25 pagesThe UML-51 / ELV-5R: Advance Elevator ControllerCristian Millan100% (1)

- Main Control Board User ManualDocument15 pagesMain Control Board User Manualmohammedalathwary100% (1)

- Iris1 NV: High Speed AdjustmentDocument3 pagesIris1 NV: High Speed AdjustmentgunawanNo ratings yet

- 1 BTN Remote - Eng Spa PDFDocument2 pages1 BTN Remote - Eng Spa PDFfmjmxNo ratings yet

- WD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualDocument36 pagesWD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualCarmelo EscribanoNo ratings yet

- T-Touch Ii User's Manual: AcknowledgementsDocument12 pagesT-Touch Ii User's Manual: AcknowledgementshafiziNo ratings yet

- MP EcogosoftwarepackageaDocument68 pagesMP EcogosoftwarepackageaprasadNo ratings yet

- Display - FloorDocument7 pagesDisplay - FloorprasadNo ratings yet

- Richard Feynman - The Hierarchy of ComplexityDocument3 pagesRichard Feynman - The Hierarchy of ComplexityjacquesyvescaruanaNo ratings yet

- IBEF Cement-February-2023Document26 pagesIBEF Cement-February-2023Gurnam SinghNo ratings yet

- Can We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsDocument15 pagesCan We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsKionara SarabellaNo ratings yet

- Āyāt Al-Aḥkām, Ayat Al-AhkamDocument6 pagesĀyāt Al-Aḥkām, Ayat Al-AhkamRasoul NamaziNo ratings yet

- Pertemuan Ke 12 - The Passive VoiceDocument5 pagesPertemuan Ke 12 - The Passive VoiceZarNo ratings yet

- Discovering JerusalemDocument134 pagesDiscovering JerusalemDzhel DezjayNo ratings yet

- New Criticism Hills Like White Elephants FinalDocument4 pagesNew Criticism Hills Like White Elephants Finalapi-313631761No ratings yet

- Brunswick Manual Preinstalacion GSXDocument33 pagesBrunswick Manual Preinstalacion GSXroberto dominguezNo ratings yet

- SN Quick Reference 2018Document6 pagesSN Quick Reference 2018pinakin4uNo ratings yet

- Kinetika Kimia Pada Laju ReaksiDocument25 pagesKinetika Kimia Pada Laju ReaksiWardahNo ratings yet

- QBM101Document37 pagesQBM101Shang BinNo ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- UNIT 5 Standard Costing - Variance AnalysisDocument50 pagesUNIT 5 Standard Costing - Variance AnalysisMohsin SheikhNo ratings yet

- Safelisting in Office 365Document5 pagesSafelisting in Office 365Brett ThomasNo ratings yet

- Capital MarketDocument5 pagesCapital MarketBalamanichalaBmcNo ratings yet

- Teacher Survey - Outdoor Classroom Feedback: Please Circle All That ApplyDocument3 pagesTeacher Survey - Outdoor Classroom Feedback: Please Circle All That ApplyBrooke Doran RoeNo ratings yet

- NS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710Document27 pagesNS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710PHAM PHI HUNGNo ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- 2.HVT Terminacion InstrDocument18 pages2.HVT Terminacion Instrelectrica3No ratings yet

- Additional Clinical Case Study TemplatesDocument4 pagesAdditional Clinical Case Study TemplatesMikhaela Andree MarianoNo ratings yet

- Chemistry Bridging Course Lecture NotesDocument3 pagesChemistry Bridging Course Lecture NotesNNo ratings yet

- ESET TechnologyDocument21 pagesESET TechnologyValentin SalcianuNo ratings yet

- Alup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENDocument2 pagesAlup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENBosznay ZoltánNo ratings yet

- Syeda Qirtas Zehra 14948 ObcDocument20 pagesSyeda Qirtas Zehra 14948 ObcSyeda ZehraNo ratings yet