Professional Documents

Culture Documents

Kone Travelmaster™ (Ejv1.2) Escalator

Uploaded by

Chang ChangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kone Travelmaster™ (Ejv1.2) Escalator

Uploaded by

Chang ChangCopyright:

Available Formats

KONE TravelMaster™ (EJV1.

2) Escalator

Technical Information for Sales

KONE TRAVELMASTER™ ESCALATOR

KONE

Sales

©

DL1-02.56.210

All

(C)2006

rights

2007-01-29

Guide

TravelMaster™

KONE

reserved.

Corporation

(EJV1.2) Escalator

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 1 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

© 2006 KONE Corporation

Unpublished work. All rights reserved. No portion of this volume may be reproduced or used in any

manner without written permission from KONE Corporation.

Due to our policy of continuing improvement, we reserve the right to alter design and specification

without prior notice. The right to make changes to product design and material use, without notice, is

reserved. All hardware and software referenced in this publication and/or used in conjunction with

equipment described herein is the exclusive property of KONE Inc. whether or not protected by U.S.

and/or International Trademark, Copyright and/or Patent Laws.

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 2 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

TABLE OF CONTENTS

1 Basic design criteria and performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Theoretical transport capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Handrail type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Step width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Description of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Visual options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Balustrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Handrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.4 Step color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.5 Access cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.6 Comb segments and combplate . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.7 Skirt, decks, frontplate, and skirt brush . . . . . . . . . . . . . . . . . . . . 7

2.2 Electrification and control options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.1 Electrification platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.2 Control cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Remote stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.4 Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Mechanical and structural options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.2 Truss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.3 Intermediate support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.4 Chain lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.5 Hand winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.6 Auxiliary brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Semi-outdoor options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.1 Sprinkler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.2 Seismic support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Installation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Loading information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

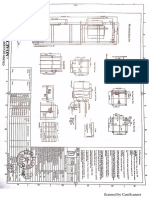

4.3 Structure dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Competitor comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Approvals and Version History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 3 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

1 BASIC DESIGN CRITERIA AND PERFORMANCE

Escalator type EJV - S

Application Retail, office, hotel, public access

Environment Indoor, semi-outdoor

Recommended duty cycle Up to 12 hr/day

800 mm

Step width

1000 mm

Minimum rise 2000 mm

Maximum rise 9500 mm

Inclination 30 degree and 35 degree

Horizontal step 2/2, 3/3

Speed 0.5 m/s

Worm gearbox (standard); Helical gearbox (optional); with duplex drive chain (only

Drive

available for power supply, 380v 50Hz)

Motor rating Worm gear: 7.5 KW, 8 kW, 11 kW, 15 kW; Helical gear: 7.5 kW, 9.2 KW, 11 kW.

Balustrade EJV S:10 mm glass with slim type handrail profile

Truss L angle. Truss deflection: 1/750

Rise: up to 6000 mm

= 1.0 (top) / 1.0 (bottom)

Transition radii

Rise: 6000 to 9500 mm

= 1.5 (top) / 1.0 (bottom)

1.1 Theoretical transport capacity

Step width Speed Theoretical maximum capacity

800 mm 0.5m/s 6750 passengers/hour

1000 mm 0.5m/s 9000 passengers/hour

1.2 Handrail type

The handrail is made of rubber in a C-type profile. The EJV-S type uses a slim handrail base profile.

1.3 Step width

Two step widths are available - 800 mm and 1000 mm for both 30 and 35 degree with rises up to 9500

mm (only 30 degree escalators can have rises greater than 6000 mm).

Step design

The steps are of a one-piece rigid design and are of high tensile die cast aluminium construction. To

reduce the risk of entrapment, thereby providing maximum passenger safety, the tread plates have

narrow grooves, which mesh with the combs at each landing.

Each step has two step rollers and two chain rollers of 75 mm diameters (rollers inside chain) giving

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 4 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

minimum rolling resistance and maximum life. All steps are interchangeable and can be easily

removed and replaced without removal of the chains, skirts or inside balustrades.

Step chain type

There are two different step chains available. The appropriate chain is selected to suit the construction

code, step width, step band speed and duty cycle, and the customers preferred lubrication method.

The step chains are of the precision roller type with heat-treated links. The pitch of the chains is 133.33

mm. They are fitted with seamless steel tube axles incorporating synthetic rollers, which are oil and

abrasion resistant. The axles are subject only to oscillating motion and only require minimal

maintenance.

Step width

Chain Type 800 mm 1000 mm Break load Lubrication

Escalator rise (mm)

Manually applied

during service visits

13KV-C 2000 - 9500 2000 - 7900 105 kN

(Option: automatic

lubrication)

Manually applied

during service visits

20KV-C - 7901 - 9500 173 kN

(Option: automatic

EJV-S

lubrication)

13KV-SF (for both

Sealed-for-life

indoor and semi- 2000 - 8000 2000 - 6500 88 kN

lubrication-free

outdoor use)

18KV-SF (for both

Sealed-for-life

indoor and semi- 8000 - 9500 6501 - 9500 173 kN

lubrication-free

outdoor use)

1.4 Noise level

The noise level is measured by “sound pressure level”, using A scale.

Noise level: Noise level is under 60dB(A), and the method for measuring is described as follows.

Method: Noise measurement is done at both ends of the escalator, at the position of 1.0 m from the

end of the newel of the balustrade and 1.5 m above the combplate on the centerline of the escalator.

The measurement is done by using a sound pressure level meter with back ground noise under

45dB(A).

7-000724 (2007-01)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 5 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2 DESCRIPTION OF COMPONENTS

2.1 Visual options

2.1.1 Balustrade

The standard glass balustrade height is 900 mm with slim handrail base profile. Balustrade height of

1000 mm and 1100 mm is available as an option.

The balustrade panels are of 10 mm thick clear tempered glass and are self-supporting without the

need of support mullions. The incline panels are separated into standard lengths and neatly butt up to

each other without cover strips. The joints of the glass are perpendicular to the truss.

The EJV-S standard balustrade profile/handrail guide profile is made of galvanized sheet steel with

black powder-coated finish.

Stainless steel handrail profile is available as an option.

2.1.2 Handrails

The C-type rubber handrails are pre-stretched and provided with high-grade linings. Handrails are

guided by the handrail base profile and are synchronized with the step band.

Plain black handrails are provided as standard. As an option, these can be fitted with white dots to help

partially sighted people see the moving handrail. Other optional colors are red, blue, green brown,

beige and grey (colour details defined by KONE).

2.1.3 Lighting

No lighting is fitted as standard, but various options are available to meet the customers aesthetic and

safety requirements. All of these lighting options illuminate automatically when the escalator is

switched on, or when the direction of travel is selected for an escalator fitted with on-demand starting.

• Skirt lighting - Skirt lights are spot light type with LED lights. The spot lights are installed starting

from the curve and inclined sections at an interval of 600 mm.

• Handrail lighting - Fiber optics handrail lighting is available as an option. The handrail lights comes

in several colors: white, blue, yellow, red, green, pink and purple. The lights can be switched to

display a gradual change in colors, skip a color change, or fix on one color. The intensity of the

lights is 25 Lux/100 mm and it is meant to be decorative instead of lighting the surrounding area.

There is no change in handrail profile (still the slimline type, EJV-S) as the fiber optics are fixed to

the side between the handrail and glass panel with a clip profile and 3M water resistant glue tape.

• Under step lighting (step demarcation lights) with green fluorescent tubes are installed at the

landings under the comb segments to aid passengers when boarding or disembarking

• Comb lights - Comb lights are LED lights to aid passengers when boarding or disembarking from

the moving step band by highlighting the comb segment line.

• Traffic lights - Traffic lights are bicolor LED lights that show the direction of travel of the escalator. It

will have a green scrolling arrow showing the direction of travel and a red bar indicating no entry on

the opposite direction. Traffic lights are equipped as a standard when the optional automatic start is

selected (for standby speed, traffic lights are optional).

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 6 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.1.4 Step color

As standard, China will have natural aluminium with silver or black painted steps as options. For the

rest of the countries, you can select silver or black. This is a similar color to the die-cast aluminium, so

the step maintains a good visual appearance, even as the paint wears or if it is scratched.

For black powder coated steps, the groove is black while the surface is ground back to the die-cast

aluminium to help the steps maintain a good visual appearance for a longer period.

2.1.5 Access cover

The standard access covers are made of 1.2 mm thick stainless steel with punched pattern welded to

the steel structure which provides sufficient strength and rigidity to withstand passenger loads.

The grooves are finished in etched black.

The access covers sits within a frame, which is normally manufactured from carbon steel. Only the

visible edge is stainless steel.

Floor numbering is available as an option. The access cover will have a cutout for the etched numbers

to be welded on. The dimension of the floor numbering is available on drawing 520151D10.

2.1.6 Comb segments and combplate

The standard comb segments are made of yellow plastic, with black as an option. The easily

replaceable yellow plastic comb segments interlock effectively with the treads of the steps to assist in

the transfer from a moving step to the combplate. The movable bar underneath the combplate will

activate a safety switch to stop the escalator if any foreign object is carried into the combplate. This

minimizes damage to equipment and risk to the public in accordance to EN115.

Yellow colored comb segments provide a clear demarcation between the moving step band and the

combplates. Studies have shown that passengers tend to step over yellow comb segments and

consequently the instances of stoppage due to tripping the comb switches are significantly reduced.

The standard combplate is made of carbon steel and covered by stainless sheet steel (similar to the

access cover).

2.1.7 Skirt, decks, frontplate, and skirt brush

Skirt panel is constructed of 3 mm sheet steel with black anti-friction coating. Stainless steel skirts in

clear anti-friction coating are available as an option.

Deck material is constructed of 1.5 mm thick stainless steel and is the standard supply. Silver powder

coated decks (EH004J) is available as an option. The deck material is constructed of 1.5 mm thick

carbon steel.

Frontplate is supplied in black plastic as standard, with light gray and blue as frontplate options.

There is no side cladding in the standard supply, only a soffit made of 4 mm thick steel plate in prime

finish. The cladding is available as follows:

– 1.5 mm hairline-brushed stainless steel - available for two sides and soffit

•cladding without sprinkler - shallow type - recess between soffit and cladding is 21.5 mm

•cladding with sprinkler - recess of 105 mm between the soffit and the cladding

– 1.5 mm sheet steel with powder coating in grey available for two sides and soffit

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 7 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

•cladding without sprinkler - shallow type - recess between soffit and cladding is 21.5 mm

•cladding with sprinkler - recess of 105 mm between the soffit and the cladding

– 1.5 mm sheet steel in prime finish (similar color as truss) available for two sides (there will be no

additional panel under the escalator 4 mm soffit).

The maximum allowable weight for cladding is 15kg/m2

Single row skirt brush deflector with aluminium holder is available as an option.

2.2 Electrification and control options

2.2.1 Electrification platform

The standard wiring is plastic cables, but halogen free cables are available as an option. Standard

starting is by star-delta with the following available as an option:

Stand-by speed

• Initially the escalator runs in stand-by mode (approximately half travel speed). If an escalator user

walks through the light barrier in the area of at the bottom or top escalator entries, the step band

speed is increased to full travel speed.

• Upon expiration of the normal run-time (travel time plus after-run-time) the step band is switched

automatically back to stand-by mode (for energy saving reasons). Truss extension is not required.

Automatic start/stop (on-demand starting)

Telco sensors are mounted on the handrail inlet panel on both sides at upper and lower landings.

The escalator will start when the sensors detect people 1.3 m from the comb segment intersection line.

The escalator is pre-set to run only in one direction (either up or down). If a passenger tries to enter

from the opposite direction of travel, the escalator will start running in the pre-set direction as a safety

measure to prevent the passenger from using the escalator as a stairway.

After a pre-determined time of 10 second (time is adjustable) when there is no passenger, the

escalator will come to a complete. stop. Traffic lights are standard with this feature.

Truss or access cover extension is not required for this feature.

Please note that autostart by means of contact mat is no longer available.

Operation panel

• The operation panel has a key start switch and a stop button. The operation panel is available at

both upper and lower landings. Customer key switch is not pre-designed

Available supply voltages are:

• 3 x 380V, 50Hz, 220V lighting supply

• 3 x 400V, 50Hz, 230V lighting supply

• 3 x 415V, 50Hz, 240V lighting supply

• 3 x 380V, 60Hz, 220V lighting supply

• 3 x 220V, 60Hz, 110v lighting supply

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 8 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.2.2 Control cabinet

The escalator control cabinet controls the general operation of the escalator and monitors all safety

devices. This incorporates the latest advances in microprocessor technology and, as a result, has a

much simplified single circuit board construction.

LCD diagnostic display located on the upper left inner deck is available as an option. The controller

cabinet has IP54 and cable has IP65 protection as standard.

Monitoring contacts are available as options. The signals are:

• Escalator stop due to emergency

• Escalator stop due to fault

• Up direction

• Down direction

• Escalator stationary

The controller has the capability for remote monitoring (KoneXion), but the feature itself has to be

ordered separately from KONE Spares unit in Netherlands.

2.2.3 Remote stop

Remote stop is available as an option. It is for connection to customer's building management system

(BMS) or fire alarm system so that the escalator can be stopped in the event of fire (preventing the risk

of transporting passenger to the vicinity of a fire).

2.2.4 Safety devices

All equipment is in accordance with construction code EN115:

• Combplate impact device (step inlet switches)

• Handrail inlet switches

• Step sag switches

• Broken step-chain (chain tension control switches)

• Motor speed monitor (over speed, under speed, reversal direction)

• Motor thermal protection

• Mains supply isolator

• Emergency stop buttons at both ends of escalator

• Stop switches within upper and lower maintenance pits

• Handrail speed and break monitor (optional)

• Skirt switches (optional)

• Broken drive chain device (optional)

• Step upthrust switch (optional)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 9 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.3 Mechanical and structural options

2.3.1 Drive

The motor operates with 3 phase, 6 pole induction, F insulation with IP21 protection (IP55 is available

as an option for Jiali motor only). The transmission from gear to main shaft is by chain. Gear type is

worm gear from Flender (current supplier), while SEW motor and helical-worm gearbox is an option.

The steps chains are driven via the main shaft and handrail via handrail drive shaft from the duplex

drive chain.

Power supply: 415V-50HZ 1 piece 1 line

Jiali Motor

Motor power (KW) 7.5 8.0 11.0 15.0

Nominal current of motor (A) 16.0 16.0 21.5 28.5

Starting current wye/star (A) 33.0 33.0 44.5 58.0

Starting current inverter (A) * 23.2 23.2 30.9 40.7

Power supply: 400V-50HZ 1 piece 1 line

Jiali Motor

Motor power (KW) 7.5 8.0 11.0 15.0

Nominal current of motor (A) 16.5 16.8 22.5 30.0

Starting current wye/star (A) 32.0 35.0 45.0 62.0

Starting current inverter (A) * 23.9 24.3 32.3 42.8

Power supply: 380V-50HZ 1 piece 1 line

Jiali Motor SEW Motor (helical gear)

Motor power (KW) 7.5 8.0 11.0 15.0 7.5 9.2 11.0

Nominal current of motor (A) 17.0 17.5 23.5 31.0 16.5 20.0 24.0

Starting current wye/star (A) 36.0 38.0 47.0 64.0 30.3 46.0 47.0

Starting current inverter (A) * 24.6 25.3 33.7 44.2 23.9 28.8 34.4

Power supply: 380V-60HZ 1piece 1 line

Jiali Motor

Motor power (KW) 7.5 8.0 11.0 15.0

Nominal current of motor (A) 17.0 17.5 23.5 32.0

Starting current wye/star (A) 36.0 38.0 47.0 65.0

Starting current delta (A) 24.6 25.3 33.7 44.2

* - when used with inverter for standby speed feature

Max. rises (m)

30 degree 35 degree

Motor power [kW]

Step nominal width (mm)

1000 800 1000 800

7.5 (Jiali Motor + Flender Gearbox) 4.5 5.0 4.5 5.0

8.0 (Jiali Motor + Flender Gearbox) 5 5.5 5.0 5.5

11.0 (Jiali Motor + Flender Gearbox) 7 7.8 6.0 6.0

15.0 (Jiali Motor + Flender Gearbox) 9.5 9.5 - -

7.5 (SEW Motor + SEW Gearbox) 4.8 5.3 4.8 5.3

9.2 (SEW Motor + SEW Gearbox) 6 6.7 6.0 6.0

11.0 (SEW Motor + SEW Gearbox K97) 8 9.5 - -

11.0 (SEW Motor + SEW Gearbox K107) 9.5 - - -

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 10 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.3.2 Truss

The truss is constructed of L-angles. Material of the truss is according KONE spec. 5200750D30,

5200751D30 and 5200752D30, similar to Q235B. The treatment of the truss is painted with primer for

corrosion protection. The maximum deflection is less than 1/750 of the distance between two supports.

The soffit is made of 4 mm thick steel panel welded to the truss structure.

2.3.3 Intermediate support

Rise 2 to 6.0 m

No intermediate support required for the following:

– 1) truss package - 35-2/2 R1.0/1.0 with truss extension 0 to 700 mm at top or bottom

– 2) truss package - 35-3/3 R1.0/1.0 with truss extension 0 to 700 mm at top or bottom

– 3) truss package - 30-2/2 R1.0/1.0 with truss extension 0 to 700 mm at top or bottom

Rise 2 to 9.5 m

– truss package - 30-3/3 R1.5/1.0, one intermediate support starting from L > 16370 mm

The support is of removable type and is located at standard location. Customer's specific location is

available as an option. When intermediate support is not allowed, reinforced truss is available as an

option for rise up to 9.5 m.

2.3.4 Chain lubrication

The step chain is manually lubricated. KONE technicians lubricate the step chain manually during a

regular service visit. The technicians ensure that only the optimum amount of lubricating oil is used to

achieve the service life of the chains; a lightly used escalator requires less lubrication than a heavily

used escalator. This minimizes the accumulation of excess oil within the escalator truss and the

resultant environmental and fire hazards. Automatic step chain lubrication is also available if deemed

necessary for commercial reasons or by the customer.

As an option, lubrication-free step chains are also available. As these do not require regular oil

lubrication, maintenance time is reduced and, as there is no accumulation of oil within the truss,

internal truss cleaning requirements are minimal. Due to their higher initial cost, however, lubrication-

free step chains are normally only considered essential in the following circumstances:

• A long-term maintenance contract is included in the new escalator order. The savings in

maintenance times due to the reduced internal truss cleaning requirements will improve the

profitability of the maintenance contract.

• The escalator is installed in a semi-outdoor or outdoor environment in a coastal or desert location.

With standard chains, sand can stick to the lubricating oil and this effectively makes a grinding

paste. This causes excessive wear in the chains and sprockets, thereby drastically reducing their

service life.

NOTE! The drive chain from motor to main shaft and main shaft to handrail drive are not lubrication-

free. The drive chain is always automatically lubricated by an oiler.

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 11 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.3.5 Hand winding

In some countries there is a requirement to be able to manually move the step band while the power

supply is isolated, either for maintenance purposes or to free a trapped passenger. This is commonly

known as hand winding.

The flywheel of the motor serves as a hand winding device which is available as a standard.

2.3.6 Auxiliary brake

The EN115 requires an auxiliary brake to be fitted for extra safety if the escalator rise is > 6.0 m. The

auxiliary brake is available for rises < 6.0 m as an option. The auxiliary brake is fitted to the right side of

the main shaft.

NOTE! Broken drive chain device (mechanical) will not be available when auxiliary brake is fitted.

2.4 Semi-outdoor options

• Truss with zinc painting

The truss is painted with two layers of zinc dust anti-corrosion paint and one finishing prime coat.

• Water drainage at lower truss

The water drainage is located at the lower truss covered with a mesh to prevent debris from going

into the drainage. The pit has to be designed with a drainage for water to be directed out of the

building.

• Oil water separator

Oil water separator is available as an option. The structural pit will need to have an additional depth

of 300 mm.

• IP protection

The motor is protected against ingress of water with IP55.

• Step and drive chain covers

Step and drive chain covers are available as an option. The cover is made of 1.0 mm thick zinc

coated sheet steel.

• Heater - truss heaters

Heaters are installed on the truss (one 500W heater in each maintenance pit and one 1000W

heater every 2400 mm along the incline length).

• Heater - combplate heaters

Heaters are installed underneath each combplate (two 250W heaters).

• Heater - controller heaters

Heaters are installed inside the controller (one 20W heater).

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 12 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

2.5 Others

2.5.1 Sprinkler

Sprinkler is available as a C option. The sprinkler is only available outside the truss. It is available with

or without cladding. For without cladding, the sprinkler will be visible underneath the soffit.

As the position and spacing of the sprinkler head outlets varies depending on local building

regulations/country codes, Front-lines must specify these when placing the order.

2.5.2 Seismic support

Option is available for seismic requirement, the lower end will have slip-end support and the upper end

with fix-end support.

7-000725 (2007-01)

Escalator Mounting Detail Escalator Mounting Detail

(Seismic slip-end support-lower) (Seismic fix-end support-upper)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 13 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

3 SHIPPING

The escalator will be delivered in one of the following shipping configurations.

• one piece

• two to four sections with balustrade disassembled for 2-in-1, 3-in-2 and 4-in-2 container(s)

shipment

• more than two sections specified by customer due to building constraints

An Owners Manual is provided as standard. For further documentation, please contact ESB Customer

Service.

Escalator Type Vertical Rise mm Sections Container Truss extension Sprinkler

arrangement range, E1=truss system

extension at lower space

head; E2=truss below

extension at upper truss

head

2000≤H≤3450 1 40GP

E1=0, E2=0

3451≤H≤6000 2 40HC

2000≤H≤2800 1 40HC With

2801≤H≤5110 2 40HC+20GP 0<E1≤700, 0<E2≤700

5111≤H≤6000 3 40GP+40GP

EJV1.2-30-2-2 2000≤H≤3450 1 40GP

E1=0, E2=0

3451≤H≤6000 2 40HC

2000≤H≤2800 1 40HC

Without

2801≤H≤5110 2 40HC+20GP 0<E1≤700, 0<E2≤700

5111≤H≤6000 3 40GP+40GP

2801≤H≤6000 2 40HC 0<E1=500, 0<E2=300

2000≤H≤4000 1 40HC

E1=0, E2=0

4001≤H≤6000 2 40HC+20GP

2000≤H≤3200 1 40HC With

3201≤H≤4800 2 40HC+20GP 0<E1≤700, 0<E2≤700

4801≤H≤6000 3 40GP+40GP

EJV1.2-35-2-2

2000≤H≤4000 1 40HC

E1=0, E2=0

4001≤H≤6000 2 40HC

2000≤H≤3200 1 40HC Without

0<E1≤700, 0<E2≤700

3201≤H≤6000 2 40HC+20GP

3201≤H≤6000 2 40HC 0<E1≤100, E2=0

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 14 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

Escalator Type Vertical Rise mm Sections Container Truss extension Sprinkler

arrangement range, E1=truss system

extension at lower space

head; E2=truss below

extension at upper truss

head

2000≤H≤3000 1 40HC

3001≤H≤5230 2 40HC+20GP

E1=0, E2=0

5231≤H≤7600 2 40HC+40HC

7601≤H≤9500 3 40HC+40HC

2000≤H≤2200 1 40HC With

2201≤H≤3200 2 40HC+20GP

3201≤H≤4250 3 40GP+20GP 0<E1≤700, 0<E2≤700

4251≤H≤7350 3 40GP+40GP

EJV1.2-30-3-3 7351≤H≤9500 4 40HC+40GP

2000≤H≤3000 1 40HC

3001≤H≤8200 2 40HC+40HC E1=0, E2=0

8201≤H≤9500 3 40HC+40HC

2000≤H≤2330 1 40HC

Without

2331≤H≤3600 2 40HC+20GP

3601≤H≤4250 3 40GP+20GP 0<E1≤700, 0<E2≤700

4251≤H≤7350 3 40GP+40GP

7351≤H≤9500 4 40HC+40GP

2000≤H≤3540 1 40HC With and

E1=0, E2=0

3541≤H≤6000 2 40HC+20GP Without

2000≤H≤2750 1 40HC

2751≤H≤4000 2 40HC+20GP

0<E1≤700, 0<E2≤700 With

4001≤H≤4875 3 40GP+20GP

EJV1.2-35-3-3

4876≤H≤6000 3 40GP+40GP

2000≤H≤2750 1 40HC

2751≤H≤4600 2 40HC+20GP

0<E1≤700, 0<E2≤700 Without

4601≤H≤4875 3 40GP+20GP

4876≤H≤6000 3 40GP+40GP

Reinforced 5400≤H≤7410 3 40GP+40GP With and

0<E1≤700, 0<E2≤700

Truss for 30-3 7411≤H≤9500 4 40GP+40GP+20GP Without

Notes

1. The shipping container length limit is 11900 mm, and the shipping container height limit is 2560 mm

(for HC) /2260 mm (for GP). The container arrangement is decided by these limits.

2. For non-split (1 section) shipment, the balustrade is partially disassembled. For one or three splits

(2 or 4 sections) shipment, the balustrade is completely disassembled.

3. If there is an intermediate support, the removable intermediate support is temporarily removed for

shipment.

4. If there are more than one escalators in one project, it is possible to optimize the container arrange-

ment. However, the arrangement should be calculated case by case.

For more detailed information, please refer to the Engineering Instruction 5201037D10.

7-000726 (2007-01)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 15 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

4 INSTALLATION DESCRIPTION

Hoisting holes, 50kN load per hole (By customer)

2-Ø100

100 145 W3 (145)

Hoisting holes, 50kN load per hole (By customer)

AA CC BB W5

Safety fense

(By customer) EE W2

Safety fense

W1

_1100

Floor

2-Ø100 v

600

HH

100

GG

600

R1

min. 2300

90

5

H

900

Rm For the intermediate support requirement,

DD please refer the clause 2.3.3 in this DL.

Floor a

1000

1200

Min.FF W4

M N

R2 W6

Span between support beams L=AA+BB+CC +15

0

Min.360

min.1100 200

200 Min.FF

W6

Min.360

Escalator Mounting Detail Passenger Circulation Area Requirements Minimum Clearances Required

To Comply With EN115:1995 &

Handrail centre line 2 x Handrail centre line GB16899

Permanent elastic

Hexagon socket

joint by others

set screw A C B

min.2000

200 Final floor

min.2500

min.2300

min.2100

Landing 120 (By customer)

plate

2 x Handrail centre line

By

140

2 x Handrail centre line

KONE

65

Rubber A = 80mm minimum clearance between the edge of a

min.2000

Steel plate Circulation areas can be shared handrail & wall or other obstacles.

between adjacent escalators B = If this dimension is less than 500mm a headguard is required.

Support 50 200 C = For adjacent escalators the distance between

angle

L200x200x20 adjacent handrails shall not be less than 120mm.

5012709(2007-01)

Figure 1. Installation description

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 16 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

4.1 Installation notes

• The floor opening dimensions shown are clear plumb line dimensions between supports.

• All dimensions are in millimeters.

• The figures shown for the support loads include the dead weight of the escalator and the live

passenger load (500kg/m2).

• Load per lifting hole or lifting eye depending on length of sections = 30~40KN.

• An access opening 2.50 m wide and 3.0 m high into and through the building is required for

installation.

• The escalator complies to CEN-guidelines.

4.2 Loading information

Type W3: Step Reaction Force (KN)

width

1000 mm R1=5.5L+11 R2=5.5L+2.6

EJV1.2-30-2-2

800 mm R1=4.8L+10.4 R2=4.8L+2.5

1000 mm R1=5.5L+11 R2=5.5L+2.6

EJV1.2-35-2-2

800 mm R1=4.8L+10.4 R2=4.8L+2.5

1000 mm R1=5.5L+11.9 R2=5.5L+3.3

EJV1.2-35-3-3

800 mm R1=4.8L+11.3 R2=4.8L+3.1

EJV1.2-30-3-3 1000 mm R1=5.5L+11.9 R2=5.5L+3.3

L<=16370 mm 800 R1=4.8L+11.3 R2=4.8L+3.1

EJV1.2-30-3-3 1000 mm R1=5.5*N R2=5.5*M Rm=5.5*L+38

L>16370 mm

(intermediate 800 mm R1=4.8*N R2=4.8*M Rm=4.8*L+38

support required

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 17 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

Span (mm) M (mm

16371-19330 9053+X

19331-21410 10092+X

21411-23490 11131+X

Notes: X =truss extension at lower end

4.3 Structure dimensions

Dimension unit mm

Step type S1000 S800

W1: Width of step 1000 800

W2: Handrail center distance 1262 1064

W3: Hoisting holes distance 1360 1160

W4: Width of truss 1510 1310

W5: Width of escalator 1547 1347

W6: Width of pit 1650 1450

Type AA BB CC DD EE FF GG HH

EJV R1.2-30-2-2 30 deg. 2215 2500 1.7321H 667 667 4285 780 1000

EJV R1.2-35-2-2 35 deg. 2250 2560 1.4281H 667 667 4080 737 1000

EJV R1.2-30-3-3 30 deg. 2615 3034 1.7321H 667 667 4685 780 1300

EJV R1.2-35-3-3 35 deg. 2650 2960 1.428H 667 667 4480 737 1000

7-000727 (2007-01)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 18 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

5 COMPETITOR COMPARISON

5.1 Specification

Brand KONE Schindler Otis Thyssen Mitsubishi

Type EJV 9300 AE 506 NCE FT 823 JS-SB

Rise - min. 2.0 m 2.5 m 2.8 m 3.0 m 3.0 m

- max. 9.5 m 6.5 m 7.5 m 7.5 m 6.5 m

Step width n.a. 600 mm 600 mm 600 mm 600 mm

800 mm 800 mm 800 mm 800 mm 800 mm

1000 mm 1000 mm 1000 mm 1000 mm 1000 mm

Inclination 30 deg 30 deg 30 deg 30 deg 30 deg

35 deg 35 deg 35 deg 35 deg 35 deg

Speed 0.5m/s 0.5m/s 0.5m/s 0.5m/s 0.5m/s

Balustrade 10 mm glass 10 mm glass 10 mm glass 10 mm glass 10 mm glass

Balustrade height 900 mm 900 mm 930 mm 1000 mm 950 mm

- option 1000/1100 mm 1000 mm 1000 mm 1100 mm n.a.

Truss L-angle L-angle hollow section L-angle L-angle

Truss deflection 1/750 1/750 1/750 1/750 1/750

Transition radii 1.0/1.0 1.0/1.0 1.0/1.0 1.0/1.0 1.0/1.0

Step painted painted painted painted painted

Decks 1.5 mm stain. st 1.5 mm stain. st 1.5 mm stain. st 1.5 mm stain. st 1.5 mm stain. st

Skirt 3 mm sheet st 3 mm sheet st 2 mm sheet st 2 mm stain. st 2 mm stain. st

- option 3 mm stain. st 3 mm stain. st 2 mm stain. st n.a. n.a.

Landing plate

stain. st stain. st stain. st stain. st stain. st

(combplate)

Comb yellow plastic yellow plastic aluminum aluminum black plastic

Handrail inlet panel black black black black black

- option blue / grey blue / grey n.a. n.a. n.a.

AC squirrel AC squirrel AC squirrel AC squirrel AC squirrel

Motor

cage, 6 pole cage, 6 pole cage, 4 pole cage, 4 pole cage, 4 pole

outside step outside step outside step outside step outside step

Location

band band band band band

Motor protection IP21 IP21 IP21 IP21 IP21

- option IP55 IP55 IP55 IP55 IP55

Gear type worm worm worm worm helical

helical helical helical helical n.a.

key switch at key switch at key switch at key switch at key switch at

Operation panel

both ends both ends both ends both ends both ends

Yellow plastic insert available available available available available

Colored handrail available available available available available

Handrail lights available available available available available

Traffic light available available available available available

Comb light available available available available available

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 19 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

Brand KONE Schindler Otis Thyssen Mitsubishi

Type EJV 9300 AE 506 NCE FT 823 JS-SB

Understep light

(step demarcation available available available available available

light)

Skirt lights available available available available available

Standby speed available available available available available

Auto start/stop available available available available available

Skirt brushes available available available available available

5.2 Dimension

Base specification Step width 1000 mm

Inclination 30 degree

Rise 4500 mm

Lower Upper Total beam

head head Incline to beam Compared Balustrade Pit

AA BB CC (L) to EJV height FF

TravelMasterTM EJV1.1 2215 2500 7794 12509 - 900 4285

ECO3000 2194 2469 7794 12457 - 52 1000 4150

Schindler 9300AE 2239 2492 7794 12525 +16 900 4450

Otis 506NCE 2213 2449 7794 12456 - 53 930 4300

Thyssen Velino FT823 2210 2490 7794 12494 -15 1000 4300

Mitsubishi JS-SB 2290 2560 7794 12644 +135 950 4290

Base specification Step width 1000 mm

Inclination 35 degree

Rise 4500 mm

Lower Upper Total beam

head head Incline to beam Compared Balustrade Pit

AA BB CC (L) to EJV height FF

TravelMasterTM EJV1.1 2250 2560 6426 11236 - 900 4080

ECO3000 2136 2439 6426 11001 -235 1000 3850

Schindler 9300AE 2273 2552 6426 11251 +15 900 4250

Otis 506NCE 2280 2487 6426 11193 -43 930 4300

Thyssen Velino FT823 2210 2490 6426 11126 -110 1000 4000

Mitsubishi JS-SB 2350 2600 6426 11376 +140 950 4150

All dimension in mm

7-000728 (2006-06)

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 20 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

6 APPROVALS AND VERSION HISTORY

Compiled by: Training & Product Information / Moline

Product management / Lee Khong Lock

Checked by: R&D / Martin Kley

Approved by: LCM / Fei Guo Jing

Issue Date Description of change Ref CR Approved by

- 2006-06-30 First Issue Fei Guo Jing

A 2006-07-17 Minor revisions per LCM. Fei Guo Jing

B 2006-09-18 Revisions per LCM to sections 1.0, 2.0, 3.0 and 4.0 Fei Guo Jing

C 2007-01-29 Revision for R1.2 Fei Guo Jing

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 21 (22) (C) 2007-01-29

KONE TravelMaster™ (EJV1.2) Escalator

Technical Information for Sales

© 2006 KONE Corporation DL1-02.56.210

All rights reserved. 22 (22) (C) 2007-01-29

You might also like

- Orion - Gulliver Vertical Platform Lift: User ManualDocument24 pagesOrion - Gulliver Vertical Platform Lift: User ManualSuraj Yadav100% (1)

- Manual Series 43E - EnG Rev 07Document36 pagesManual Series 43E - EnG Rev 07asif mahmood100% (2)

- COMMISSIONING AM-11.65.066 - en - A.1 - MainDocument174 pagesCOMMISSIONING AM-11.65.066 - en - A.1 - Mainsamion741990100% (1)

- Asme B1.2 - 1983 PDFDocument190 pagesAsme B1.2 - 1983 PDFmarcelo100% (4)

- BersinandAssociates TalentMgmtModelDocument11 pagesBersinandAssociates TalentMgmtModelKumari KvnrNo ratings yet

- EN Programming ELCO Micro-ANTS LEB02 Basic Encoder V2.2 26-10-2020Document35 pagesEN Programming ELCO Micro-ANTS LEB02 Basic Encoder V2.2 26-10-2020Renny Barragan100% (1)

- Playboard V3 Iii PDFDocument90 pagesPlayboard V3 Iii PDFIván Sulbaran0% (1)

- Manual Ecw l200 Load CellDocument15 pagesManual Ecw l200 Load Cellabdul100% (1)

- Genius 20 en Ver 1.2Document307 pagesGenius 20 en Ver 1.2Kristoffer BarkmanNo ratings yet

- Orona LiftDocument4 pagesOrona LiftMarius Ionita100% (1)

- Ol35 e OsgDocument27 pagesOl35 e OsgFERNSNo ratings yet

- DOPPLER Series Cabin Assembly SerialsDocument1 pageDOPPLER Series Cabin Assembly Serialsfirasalthiyaby100% (1)

- HPV 600 PM Elevator Drive TM7323 - R4Document136 pagesHPV 600 PM Elevator Drive TM7323 - R4asif_9091No ratings yet

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocument38 pagesME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNo ratings yet

- ZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)Document24 pagesZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)BrianEstebanNo ratings yet

- EL - REPL MANUAL - 20070725 - FixedDocument231 pagesEL - REPL MANUAL - 20070725 - FixedChang Chang100% (1)

- Combined Production Order ProcessingDocument12 pagesCombined Production Order Processingsaps4hana ppNo ratings yet

- LRV 175-1 / 350-1 / 700-1 Lift Control Valve: NTA-1 Power Supply Unit and Delta Controller DELCONDocument44 pagesLRV 175-1 / 350-1 / 700-1 Lift Control Valve: NTA-1 Power Supply Unit and Delta Controller DELCONraymon janszenNo ratings yet

- KDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Document3 pagesKDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Александр ЕгоровNo ratings yet

- g400 en PDFDocument13 pagesg400 en PDFReynold SuarezNo ratings yet

- KL-UCMP Traction Examination TestsDocument3 pagesKL-UCMP Traction Examination TestsStefan Hodan100% (1)

- Hidral Maintenance HandbookDocument32 pagesHidral Maintenance HandbookBaltija MechanikasNo ratings yet

- SLYCMA Door Operator - Ariane 3 Set Up Procedure 2 PDFDocument23 pagesSLYCMA Door Operator - Ariane 3 Set Up Procedure 2 PDFMickael BourdoiseauNo ratings yet

- 10 Aaa21700xDocument17 pages10 Aaa21700xasdfNo ratings yet

- Elevator Control Module: User'SDocument9 pagesElevator Control Module: User'SjhfbtyNo ratings yet

- Variador Kone V3f20 InglésDocument30 pagesVariador Kone V3f20 InglésRDRNo ratings yet

- ASG-11.65.031 Maintenance KDL32Document12 pagesASG-11.65.031 Maintenance KDL32Mike Rushe100% (1)

- Spare Parts For KSSDocument46 pagesSpare Parts For KSSNiilo ParkkoNo ratings yet

- 1374567D01 - KCE ParametersDocument21 pages1374567D01 - KCE Parameterspaul5791100% (1)

- LiftUnit7 DocumentationDocument44 pagesLiftUnit7 Documentationangela1590No ratings yet

- KONE Motor Modernization - FinalDocument17 pagesKONE Motor Modernization - FinalEdhimj UnmeNo ratings yet

- Apostila Eco Drive HydraPlus - Manual-1Document15 pagesApostila Eco Drive HydraPlus - Manual-1Edson Alessandro Caramite100% (3)

- Di1 (Si210) Di1 (Si210) Elevator Elevator //: T Trouble Shoo Rouble Shooting TingDocument9 pagesDi1 (Si210) Di1 (Si210) Elevator Elevator //: T Trouble Shoo Rouble Shooting TingNadeem KhanNo ratings yet

- Toshiba Error CodesDocument23 pagesToshiba Error CodesHettiarachchi JayasingheNo ratings yet

- BD User Guide AP331400DAA - 2014-04-10Document167 pagesBD User Guide AP331400DAA - 2014-04-10diabNo ratings yet

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- ECO-MPU Application GuideDocument23 pagesECO-MPU Application GuideAssir El DjazairiNo ratings yet

- C607Document44 pagesC607Wander Gomes100% (4)

- Main Control Board User ManualDocument15 pagesMain Control Board User Manualmohammedalathwary100% (1)

- GSD SM Instruction Book PDFDocument15 pagesGSD SM Instruction Book PDFMitro100% (1)

- Stvf7 Troubleshooting Manuel EnglishDocument32 pagesStvf7 Troubleshooting Manuel EnglishResul ŞenayNo ratings yet

- VVMC-SCR Series M (Asme 2000) (42!02!4022 Rev A1)Document254 pagesVVMC-SCR Series M (Asme 2000) (42!02!4022 Rev A1)ElputoAmo XDNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- Microzed-A V Microzed-A V3.1 3.1: User'S ManualDocument38 pagesMicrozed-A V Microzed-A V3.1 3.1: User'S ManualWassim Baccari100% (1)

- Start Up Routine OVF10 PDFDocument12 pagesStart Up Routine OVF10 PDFEng M ElseaidyNo ratings yet

- Orona 20ARCAIICONTROLLER PDFDocument116 pagesOrona 20ARCAIICONTROLLER PDFthunderNo ratings yet

- H0409 Operating and Maintenance H0409-EngDocument37 pagesH0409 Operating and Maintenance H0409-EngRomeu100% (1)

- CX User ManuelDocument26 pagesCX User ManuelSafi100% (2)

- Control Bl2000Document9 pagesControl Bl2000AliRouyou100% (1)

- STVF5 Trouble REV0 PDFDocument42 pagesSTVF5 Trouble REV0 PDFUpien Ayah MahardikaNo ratings yet

- Brake Tool ManualDocument50 pagesBrake Tool ManualKevin SinghNo ratings yet

- Group Control System MPK 400 DescriptionDocument34 pagesGroup Control System MPK 400 DescriptionElevator & Escalator EngineeringNo ratings yet

- 201604201039062023Document205 pages201604201039062023younes100% (2)

- 1 - LCE Parameter Manual, EnG (08-2007)Document171 pages1 - LCE Parameter Manual, EnG (08-2007)Karim AhmedNo ratings yet

- LEX Serial Controller User Manual: Doc. F0269 Rel.5 04/10Document90 pagesLEX Serial Controller User Manual: Doc. F0269 Rel.5 04/10gianfranco100% (4)

- Characteristics - Igtf Landing ArrangementDocument56 pagesCharacteristics - Igtf Landing ArrangementMAYESTON100% (1)

- AS3 Manual E PDFDocument23 pagesAS3 Manual E PDFpaul5791No ratings yet

- C U H Máy Kéo Sigma OtisDocument45 pagesC U H Máy Kéo Sigma OtisQuang Pham DuyNo ratings yet

- Gcs - Gecb: List of Installation ParametersDocument58 pagesGcs - Gecb: List of Installation ParametersAlexis Mauricio100% (1)

- Thysseen Elevator Service MC2 ManualDocument47 pagesThysseen Elevator Service MC2 ManualRebecca DangNo ratings yet

- EscalatorDocument158 pagesEscalatorchristophetaglionehotmail.fr100% (1)

- Dossier 6170 (1) .FR - enDocument48 pagesDossier 6170 (1) .FR - enSatheesh Rama100% (1)

- SG Frenic Lift en 1 8 0Document42 pagesSG Frenic Lift en 1 8 0محمدحمادNo ratings yet

- (DOCS0221) GL1 - R2 v1.00 EN GSMDocument8 pages(DOCS0221) GL1 - R2 v1.00 EN GSMChang ChangNo ratings yet

- ENGINE MECHANICAL SECTIONDocument140 pagesENGINE MECHANICAL SECTIONChang ChangNo ratings yet

- Warning Chime System: SectionDocument63 pagesWarning Chime System: SectionChang ChangNo ratings yet

- Defogger: SectionDocument66 pagesDefogger: SectionChang ChangNo ratings yet

- Wiper & Washer: SectionDocument86 pagesWiper & Washer: SectionChang ChangNo ratings yet

- (DOCS0009) GL1 Manual v3.02 EN GSMDocument8 pages(DOCS0009) GL1 Manual v3.02 EN GSMChang ChangNo ratings yet

- Cibes - PORTEO - SetupDocument3 pagesCibes - PORTEO - SetupChang ChangNo ratings yet

- Road Wheels & Tires: SectionDocument65 pagesRoad Wheels & Tires: SectionChang ChangNo ratings yet

- CrashinfoDocument1 pageCrashinfoChang ChangNo ratings yet

- 8 Mbit (1Mb X 8) UV EPROM and OTP EPROM: DescriptionDocument16 pages8 Mbit (1Mb X 8) UV EPROM and OTP EPROM: DescriptionvetchboyNo ratings yet

- 204PWR Board.: Preliminary DescriptionDocument3 pages204PWR Board.: Preliminary DescriptionChang ChangNo ratings yet

- 200cory Board DescriptionDocument2 pages200cory Board DescriptionChang ChangNo ratings yet

- (DOCS0221) GL1 - R2 v1.00 EN GSMDocument8 pages(DOCS0221) GL1 - R2 v1.00 EN GSMChang ChangNo ratings yet

- (DOCS0009) GL1 Manual v3.02 EN GSMDocument8 pages(DOCS0009) GL1 Manual v3.02 EN GSMChang ChangNo ratings yet

- Approved Drawing DS1811042B - 1-1Document1 pageApproved Drawing DS1811042B - 1-1Chang ChangNo ratings yet

- Maintenance: Varidor 10 Spare PartsDocument12 pagesMaintenance: Varidor 10 Spare PartsChang ChangNo ratings yet

- 6K0007D-01 - Lista de Erros e Advertências Da MCP - InglêsDocument8 pages6K0007D-01 - Lista de Erros e Advertências Da MCP - InglêsChang ChangNo ratings yet

- Passenger Elevators: General and MRL (Machine-Room-Less) TypeDocument12 pagesPassenger Elevators: General and MRL (Machine-Room-Less) TypeChang ChangNo ratings yet

- Annual Report 2006: WWW - Hyundaielevator.co - KRDocument12 pagesAnnual Report 2006: WWW - Hyundaielevator.co - KRChang ChangNo ratings yet

- PresentationDocument19 pagesPresentationChang Chang100% (1)

- Profiles of Hyundai Elevator (2007) - 200787Document18 pagesProfiles of Hyundai Elevator (2007) - 200787Chang ChangNo ratings yet

- E HospitalDocument6 pagesE HospitalChang Chang100% (1)

- 128Kx8 Nonvolatile SRAM: Features General DescriptionDocument14 pages128Kx8 Nonvolatile SRAM: Features General DescriptionChang ChangNo ratings yet

- Hyundai Elevator ProfileDocument10 pagesHyundai Elevator ProfileChang ChangNo ratings yet

- CompensationRope InstallDocument7 pagesCompensationRope InstallalexdejesusNo ratings yet

- Gearless Traction Machine Application: 1. General Speed Passenger ElevatorDocument4 pagesGearless Traction Machine Application: 1. General Speed Passenger ElevatorChang ChangNo ratings yet

- Machine - Room-Less Elevator CatalogueDocument14 pagesMachine - Room-Less Elevator CatalogueChang ChangNo ratings yet

- SSF10N60A: Advanced Power MOSFETDocument7 pagesSSF10N60A: Advanced Power MOSFETChang ChangNo ratings yet

- Cambio de Hidráulico A SCMDocument1 pageCambio de Hidráulico A SCMJorge Perez GuerraNo ratings yet

- Timing Aware Dummy Metal Fill MethodologyDocument3 pagesTiming Aware Dummy Metal Fill MethodologyraveneyesdeadNo ratings yet

- A in Power Down: SWRS068 - DECEMBER 2007Document135 pagesA in Power Down: SWRS068 - DECEMBER 2007aymanNo ratings yet

- Saxxon Pro Sax7208h-S3 DataDocument3 pagesSaxxon Pro Sax7208h-S3 DataAaronNo ratings yet

- Turkish State Railways (TCDD) : Infrastructure Development & Regulations in Railway SectorDocument32 pagesTurkish State Railways (TCDD) : Infrastructure Development & Regulations in Railway Sector임동우No ratings yet

- Unit - 4Document53 pagesUnit - 4Meghna BhatnagarNo ratings yet

- Cse 2017 PDFDocument300 pagesCse 2017 PDFSREE VALSANNo ratings yet

- BIOS update instructions for Satellite P50/P55/P55t modelsDocument5 pagesBIOS update instructions for Satellite P50/P55/P55t modelsJeNo ratings yet

- B&R 2005 Modules - Cpus - Cp260: Model Number Short Description Image CpuDocument9 pagesB&R 2005 Modules - Cpus - Cp260: Model Number Short Description Image CpuahmedcoNo ratings yet

- GSMDocument119 pagesGSMAlas Mallari DonatoNo ratings yet

- DataReader in ADO.NETDocument6 pagesDataReader in ADO.NETEko SanjayaNo ratings yet

- Sun Secure Global Desktop Software Relaease NotesDocument57 pagesSun Secure Global Desktop Software Relaease Notesfplinux1No ratings yet

- CS 4700: Foundations of Artificial Intelligence - 1-Nearest Neighbor ModelsDocument9 pagesCS 4700: Foundations of Artificial Intelligence - 1-Nearest Neighbor ModelsDivira Iga FirdiantiNo ratings yet

- AnnabellaBracco Resume 2021Document1 pageAnnabellaBracco Resume 2021ANNABELLA BRACCONo ratings yet

- How To Switch From Reactive Maintenance To Preventive Maintenance - Complete Transition GuideDocument18 pagesHow To Switch From Reactive Maintenance To Preventive Maintenance - Complete Transition GuidematshonaNo ratings yet

- A Practical Guide To Using QGISDocument12 pagesA Practical Guide To Using QGISsurvmichael16No ratings yet

- TorchSA-30 June 2023 B2C EMAILDocument85 pagesTorchSA-30 June 2023 B2C EMAILChristiaanNo ratings yet

- The Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringDocument8 pagesThe Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringSalis KhanNo ratings yet

- Brocade ICX 6610 Switches: Chassis-Like Capabilities in A Stackable Form FactorDocument11 pagesBrocade ICX 6610 Switches: Chassis-Like Capabilities in A Stackable Form FactorjscerNo ratings yet

- 8000io CutsheetDocument2 pages8000io CutsheetPadmo PadmundonoNo ratings yet

- PV Is Entering The AI Era: Special Edition Developed in Partnership With HuaweiDocument44 pagesPV Is Entering The AI Era: Special Edition Developed in Partnership With Huaweimarcoant2287No ratings yet

- First American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyDocument239 pagesFirst American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyFilipeBouraNo ratings yet

- DACTS705 English PDFDocument21 pagesDACTS705 English PDFgiapy0000No ratings yet

- Recruiter Position at Noida-Based NLB ServicesDocument2 pagesRecruiter Position at Noida-Based NLB ServicesRajesh SinghNo ratings yet

- IBM Decision Optimization For IBM Cloud Pak For Data v3Document32 pagesIBM Decision Optimization For IBM Cloud Pak For Data v3Antonio BlancoNo ratings yet

- Liebert NPS-IDocument38 pagesLiebert NPS-IMahesh KumbharNo ratings yet

- How To Create APIDocument23 pagesHow To Create APIAbubakar HiyangNo ratings yet

- Essential Design Handbook SampleDocument32 pagesEssential Design Handbook SampleCarolina ZamoraNo ratings yet