Professional Documents

Culture Documents

SOP For Pasteurizer

Uploaded by

Umesh Poudel0 ratings0% found this document useful (0 votes)

182 views1 page1) Clean with water for 15-20 minutes until water runs clear.

2) Circulate 1.5% caustic soda at 80°C for 20-30 minutes.

3) Clean with hot water at 70-80°C for 15-20 minutes.

4) Circulate 0.5-1% nitric acid solution at 70°C for 30 minutes, except for coolers and pre-heaters which are cleaned the same way but without acid treatment.

Original Description:

Original Title

SOP For pasteurizer

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Clean with water for 15-20 minutes until water runs clear.

2) Circulate 1.5% caustic soda at 80°C for 20-30 minutes.

3) Clean with hot water at 70-80°C for 15-20 minutes.

4) Circulate 0.5-1% nitric acid solution at 70°C for 30 minutes, except for coolers and pre-heaters which are cleaned the same way but without acid treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

182 views1 pageSOP For Pasteurizer

Uploaded by

Umesh Poudel1) Clean with water for 15-20 minutes until water runs clear.

2) Circulate 1.5% caustic soda at 80°C for 20-30 minutes.

3) Clean with hot water at 70-80°C for 15-20 minutes.

4) Circulate 0.5-1% nitric acid solution at 70°C for 30 minutes, except for coolers and pre-heaters which are cleaned the same way but without acid treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

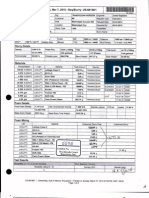

Standard Operating Procedure for CIP of Pasteurizer Plant

KnfG6 ;/;kmfO{ ug]{ lalw

Clean with normal water for 15 to 20 minutes till water is clear.

;fw/0f kfgLn] !% b]lv @) ldg]6 ;Dd ;kmfug]{ -;]tf] kfgL /lxt kfgL gcfpbf

;Dd_ .

Circulated 1.5 % caustic at 80°C for 20 to 30 minutes in pasteurizer.

पास्चाराइजर df !=% k|lt;t sfl:6s sf] *) l8u|Lsf] tftf] emf]nn] @) b]lv #) ldg]6 ;Dd

;kmfug]{ .

Clean with hot water at 70 to 80°C for 15 to 20 minutes

&) l8u|L;]G6Lu|8sf] tftf] kfgLn] !% b]lv @) ldg]6 ;Dd ;kmf ug]{ .

This is followed by the circulation of 0.5 % to 1% Nitric acid solution at 70°C

for 30 minutes.

To; k5L, ! k|lt;t gfO6«Ls Pl;8sf] 3f]nn] &) l8u|Ldf #) ldg]6 3'dfpg] .

Then the pasteurizer is flushed with water for about 5 to 10 minutes.

KffZr'/fOh/nfO{ %) l8u|Lsf] tftf] kfgLn] ˆnl;ª ug]{ .

Again 1% caustic soda is used to neutralize the acidity if present in the plate.

k'g M ! k|lt;t sfl:6s ;f]8fsf] 3f]n rnfO{ clDno kfgLnfO{ t7:y agfpg] .

Then the final rising is carried out for 10 minutes.

clGtd ˆnl;ª !) ldg]6 ;Dd ug]{ .

Note: Cooler and Pre-heaters which heat milk up to 50°C are cleaned by the same methods as

detailed above for pasteurizers, except that acid treatment is not done.

Gff]6M Kn]6 lrn/, Kn]6 lk|–lx6/x?nfO{ kf:r/fO{h/nfO{ h:t} u/L l;=cfO{=kL= ug]

{ t/ cDnsf] k|of]u gug]{ .

Prepared By Approved By

Narayan Sharma

Umesh Poudyal

You might also like

- SOP For PasteurizerDocument1 pageSOP For PasteurizerUmesh PoudelNo ratings yet

- Homebiogas - Leaflet - SampleDocument4 pagesHomebiogas - Leaflet - SampleBashu GautamNo ratings yet

- En 15662Document12 pagesEn 15662Ina Bulat RotariNo ratings yet

- Extra Note of Building ServicesDocument10 pagesExtra Note of Building ServicesAakash PandeyNo ratings yet

- Trizol RNeasy Plus MiniKitDocument1 pageTrizol RNeasy Plus MiniKitjojojazzprogNo ratings yet

- Jibachha Veterinary Laboartory DiagnosisDocument20 pagesJibachha Veterinary Laboartory DiagnosisJibachha ShahNo ratings yet

- K/Liff Of) HGF Fdfgo 1Fg !) ) $) J:T'Utm Ax'J) Slnks K - ZG !) ) K - ZG × ! Cí Ö !) ) Cí ! 306F #) LDG) 6Document5 pagesK/Liff Of) HGF Fdfgo 1Fg !) ) $) J:T'Utm Ax'J) Slnks K - ZG !) ) K - ZG × ! Cí Ö !) ) Cí ! 306F #) LDG) 6Sugam limbu100% (1)

- Prepare Plan, Design and Estimate of Slaughterhouse For 20 Large Animal and 100 Small Animals.Document35 pagesPrepare Plan, Design and Estimate of Slaughterhouse For 20 Large Animal and 100 Small Animals.अविनाश भाल्टरNo ratings yet

- 0 OPEN - Engg TechnicianHelperDocument3 pages0 OPEN - Engg TechnicianHelpermadhu chaudharyNo ratings yet

- Death CaseDocument14 pagesDeath CaseRaphael Eddy AngNo ratings yet

- Percentage For STD 9-13Document2 pagesPercentage For STD 9-13Shankar NepalNo ratings yet

- Formulations ToiletriesDocument13 pagesFormulations ToiletriesErrol FernandesNo ratings yet

- R (Hpa BTG G Ed Dpuhf FP: 3 Ypl LH: /ehs . 3 Liters / DayDocument10 pagesR (Hpa BTG G Ed Dpuhf FP: 3 Ypl LH: /ehs . 3 Liters / DayerkiruthirajNo ratings yet

- 0-OPEN - Engg-TechnicianHelper - 2080-8-4Document4 pages0-OPEN - Engg-TechnicianHelper - 2080-8-4Prashant ShahNo ratings yet

- Ncle) PSF Ejwnfmq) RC RCPF) B) N I) Lbsle) L Q) K KGLM Esjk) B) L: Ejtrjwvx Lzytvpjuvx Gnujssj Rjwxs1ZwsjDocument9 pagesNcle) PSF Ejwnfmq) RC RCPF) B) N I) Lbsle) L Q) K KGLM Esjk) B) L: Ejtrjwvx Lzytvpjuvx Gnujssj Rjwxs1ZwsjSeth ThomasNo ratings yet

- RS5577 - Hydroponic Technology and Potato Seed ProductionDocument9 pagesRS5577 - Hydroponic Technology and Potato Seed Productionkaladhar timilsinaNo ratings yet

- Sanitary Status of BanepaDocument17 pagesSanitary Status of BanepaBee CashNo ratings yet

- Consumer Protection in NepalDocument40 pagesConsumer Protection in NepalYakindra TimNo ratings yet

- P PN L K/Liff @) &@ Clgjfo (Lj1Fg PTT/ S'L HSF: S (Kof PTT/K'L:TSF K/Lif0F Odfgbf/Ltfsf Fy Ul/Lbg'Xf) NFDocument7 pagesP PN L K/Liff @) &@ Clgjfo (Lj1Fg PTT/ S'L HSF: S (Kof PTT/K'L:TSF K/Lif0F Odfgbf/Ltfsf Fy Ul/Lbg'Xf) NFDo Something GoodNo ratings yet

- U - Fg8: NFD CLG Lypdsf) KGF: CF (GN LHN) LjholDocument1 pageU - Fg8: NFD CLG Lypdsf) KGF: CF (GN LHN) Ljholram singhNo ratings yet

- Introduction of Pet: Solid State Polymerization (SSP)Document3 pagesIntroduction of Pet: Solid State Polymerization (SSP)Furqan SaeedNo ratings yet

- 4.3 Climate Change and Carbon Bizness (2079-09-12) OffDocument18 pages4.3 Climate Change and Carbon Bizness (2079-09-12) OffSonika DhakalNo ratings yet

- RQM K - FB 9'+ufgf S/ Clws (T, G) KFN /SFDocument20 pagesRQM K - FB 9'+ufgf S/ Clws (T, G) KFN /SFdiwash khatriNo ratings yet

- N) Vs LJ - Ml:6G:6F) G Lrqfígstf (Blks Uf) TD Dkfbs ZFGTBF DFGGWDocument28 pagesN) Vs LJ - Ml:6G:6F) G Lrqfígstf (Blks Uf) TD Dkfbs ZFGTBF DFGGWsatyaNo ratings yet

- CTAB DNA ExtractionDocument2 pagesCTAB DNA ExtractionHumam-bmNo ratings yet

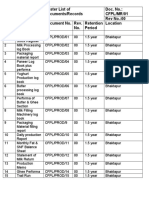

- QC AnusuchiDocument4 pagesQC AnusuchiSamir KaranjitNo ratings yet

- AachamDocument121 pagesAachamdeven gcNo ratings yet

- Silt Density Index Test (SDI) : Ondeo Nalco Applied Services Part # 420-C0412.88 Awr # X0Sdi-NcoDocument3 pagesSilt Density Index Test (SDI) : Ondeo Nalco Applied Services Part # 420-C0412.88 Awr # X0Sdi-Ncoalaluci11No ratings yet

- Matshya Prajanan Prabidhi Sangalo - Srinkhala 26 - 1596783779Document5 pagesMatshya Prajanan Prabidhi Sangalo - Srinkhala 26 - 1596783779kishan khatiNo ratings yet

- Presentation For WFD NEPAL NewDocument22 pagesPresentation For WFD NEPAL NewKhimlal DevkotaNo ratings yet

- fli6 O K/Liff Af) 8 (Jflif (S K/Liff RFNG DagwlDocument2 pagesfli6 O K/Liff Af) 8 (Jflif (S K/Liff RFNG DagwlrahulNo ratings yet

- 0F - P Afaf FC (A Vf/A (0Sz Vm5G I) LGJL "8L Êf/T 5Zl1Ff O (A ) VFZLDocument13 pages0F - P Afaf FC (A Vf/A (0Sz Vm5G I) LGJL "8L Êf/T 5Zl1Ff O (A ) VFZLNilesh PatelNo ratings yet

- District Profile 01Document107 pagesDistrict Profile 01merogaunNo ratings yet

- IPM in NepaliDocument33 pagesIPM in Nepaliextension educationNo ratings yet

- अनुसन्धानको परिचय र विधि र तथ्याङ्कशास्त्र प्रस्ताव तथा कार्यमूलक अनुसन्धानDocument44 pagesअनुसन्धानको परिचय र विधि र तथ्याङ्कशास्त्र प्रस्ताव तथा कार्यमूलक अनुसन्धानShyamNo ratings yet

- Open Vacancy Notice 2070-1-17 AIRPORTDocument3 pagesOpen Vacancy Notice 2070-1-17 AIRPORTAbhishekNo ratings yet

- ETP ReportDocument13 pagesETP ReportMUHAMMED SHAMEEMNo ratings yet

- S (Lif Tyf Kz'Kgifl Ladf O SF Lawl Tyf K - Lsofx?Document35 pagesS (Lif Tyf Kz'Kgifl Ladf O SF Lawl Tyf K - Lsofx?Sashi ThapaNo ratings yet

- Protein Precipitation Protocols PDFDocument6 pagesProtein Precipitation Protocols PDFJeTiKNo ratings yet

- 2010 05 19 - DrsfaDocument1 page2010 05 19 - DrsfaZach EdwardsNo ratings yet

- Mdac and Ndac Meeting FormateDocument6 pagesMdac and Ndac Meeting FormateDo Something GoodNo ratings yet

- Popular Panchase Monthly Mansir 2067Document12 pagesPopular Panchase Monthly Mansir 2067Dharma Raj PaudelNo ratings yet

- अन्नबाली खेती प्रविधि पुस्तिकाDocument116 pagesअन्नबाली खेती प्रविधि पुस्तिकाNabin SubediNo ratings yet

- "Lrs (T SDKGLX?SF) Jul (S/0F K - ) Z Lj1Ktl: DJGWL G) Kfn:6S Ps R) GH Lnld6) 8N) HF/L U/) SF)Document5 pages"Lrs (T SDKGLX?SF) Jul (S/0F K - ) Z Lj1Ktl: DJGWL G) Kfn:6S Ps R) GH Lnld6) 8N) HF/L U/) SF)Ram NyaupaneNo ratings yet

- Ililil Iluilil) Ilil Ililt Ilililililil1 Ilil Il$: Cennent Lab Weigh - Up Sheet, Mar7,2010. Req/Slurry: US-68156/1Document8 pagesIlilil Iluilil) Ilil Ililt Ilililililil1 Ilil Il$: Cennent Lab Weigh - Up Sheet, Mar7,2010. Req/Slurry: US-68156/1OSDocs2012No ratings yet

- C 1 NW CZDKR S200809094707Document28 pagesC 1 NW CZDKR S200809094707Light King ChaudharyNo ratings yet

- ADDCN - Energy and Environment Bulletin-11-6Document3 pagesADDCN - Energy and Environment Bulletin-11-6Shambhu BaralNo ratings yet

- Apple CoverDocument146 pagesApple CoverMamta AdhikariNo ratings yet

- Dhodi SaagDocument4 pagesDhodi SaagNabin GhimireNo ratings yet

- SNF) L/G) G / 8f) LH / (Chlorination and Dosing) : /D) Z 'J) BLDocument29 pagesSNF) L/G) G / 8f) LH / (Chlorination and Dosing) : /D) Z 'J) BLBipin GyawaliNo ratings yet

- Both LetterDocument37 pagesBoth LetterRajib MaharjanNo ratings yet

- 08 OPEN+INT Engg ChemicalDocument5 pages08 OPEN+INT Engg ChemicalsachinNo ratings yet

- 8 FG:S - L%8 Omd"Df/ CLVL SSF SZJF Df8 (GL VZHLGM GD) GMDocument2 pages8 FG:S - L%8 Omd"Df/ CLVL SSF SZJF Df8 (GL VZHLGM GD) GMRock PatelNo ratings yet

- Press Release Rhino 500DDocument1 pagePress Release Rhino 500DVinod JoshiNo ratings yet

- V JTA Level 4Document9 pagesV JTA Level 4Picture 2023No ratings yet

- (Examination Scheme) (Written Examination) ×: (Multiple Choice)Document7 pages(Examination Scheme) (Written Examination) ×: (Multiple Choice)nishantaNo ratings yet

- Vegetables PoP तरकारी बालीको प्याकेज अफ प्राक्टिस PDFDocument208 pagesVegetables PoP तरकारी बालीको प्याकेज अफ प्राक्टिस PDFSandesh PoudelNo ratings yet

- KirantiLangsCover Content TextDocument330 pagesKirantiLangsCover Content TextDr Lal-Shyãkarelu RapachaNo ratings yet

- Institute of Science and Technology Central Department of Food TechnologyDocument20 pagesInstitute of Science and Technology Central Department of Food TechnologyUmesh PoudelNo ratings yet

- UntitledDocument30 pagesUntitledUmesh PoudelNo ratings yet

- Chemical Physical Properties of MilkDocument55 pagesChemical Physical Properties of MilkUmesh PoudelNo ratings yet

- Ijie V2i3p103Document5 pagesIjie V2i3p103Umesh PoudelNo ratings yet

- Sensory Evaluation of CreamDocument10 pagesSensory Evaluation of CreamUmesh PoudelNo ratings yet

- M.Tech. First Sem. Numerical Methods.: Ax X, X e B I 1 A 0Document119 pagesM.Tech. First Sem. Numerical Methods.: Ax X, X e B I 1 A 0Umesh PoudelNo ratings yet

- Date: 2076/2/26 Experiment No-1: Typical CompositionDocument3 pagesDate: 2076/2/26 Experiment No-1: Typical CompositionUmesh PoudelNo ratings yet

- FA - Yoghurt.1 ENDocument3 pagesFA - Yoghurt.1 ENUmesh PoudelNo ratings yet

- Shrawan Milk ReportDocument10 pagesShrawan Milk ReportUmesh PoudelNo ratings yet

- Original Research Article: Effects of Various Stabilizers On Sensorial Quality of YoghurtDocument6 pagesOriginal Research Article: Effects of Various Stabilizers On Sensorial Quality of YoghurtUmesh PoudelNo ratings yet

- Improvement of The Texture of Yogurt by Use of ExoDocument7 pagesImprovement of The Texture of Yogurt by Use of ExoUmesh PoudelNo ratings yet

- A.1 Process Flow Diagram of Standardized Milk: StepsDocument8 pagesA.1 Process Flow Diagram of Standardized Milk: StepsUmesh PoudelNo ratings yet

- Red Cabbage and Turmeric Extracts As Potential Natural Colors and Antioxidants Additives in Stirred YogurtDocument10 pagesRed Cabbage and Turmeric Extracts As Potential Natural Colors and Antioxidants Additives in Stirred YogurtUmesh PoudelNo ratings yet

- Hetauda Dairy Industries Pvt. LTDDocument9 pagesHetauda Dairy Industries Pvt. LTDUmesh PoudelNo ratings yet

- Bhadrakali Krishi Co-Operative Ltd. Dairy Division: Daily Production Record Sheet. DateDocument9 pagesBhadrakali Krishi Co-Operative Ltd. Dairy Division: Daily Production Record Sheet. DateUmesh PoudelNo ratings yet

- K/Liff Of) HGF Tyf Kf7/Oqmd: B'Uw LJSF +:yfgDocument8 pagesK/Liff Of) HGF Tyf Kf7/Oqmd: B'Uw LJSF +:yfgUmesh PoudelNo ratings yet

- Microbiological Quality of Set Yoghurt Supplemented With Turmeric Powder (Curcuma Longa) During StorageDocument7 pagesMicrobiological Quality of Set Yoghurt Supplemented With Turmeric Powder (Curcuma Longa) During StorageUmesh PoudelNo ratings yet