Professional Documents

Culture Documents

Safety System For Gas Pipeline: Asst. Prof. Mr. Aniket Kale

Uploaded by

Saurabh BhiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety System For Gas Pipeline: Asst. Prof. Mr. Aniket Kale

Uploaded by

Saurabh BhiseCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 04, April-2015

Safety System for Gas Pipeline

Asst. Prof. Mr. Aniket kale

Assistant Professor,

Department of Electronics and telecommunication Engineering;

Dr. Dulatrao Aher college of Engineering, K

arad, Dist-SATARA; Maharashtra, India.

Miss. Jadhav Shital.U1, Miss.Patil Priyanka P 2 .and Mr. Kavathekar Shital A3.

B.E. student,

Department of Electronics and telecommunication Engineering;

Dr. Dulatrao Aher college of Engineering, Karad, Dist-SATARA;

Maharashtra, India

Abstract –To detect a presence of a dangerous LPG leak in Electromagnetic valve will turn off gas supply. Alert sms

your car or in a service station, storage tank environment will be send to concert person.[3]

used MQ-6 Gas sensor. This unit can be easily in incorporated

to sound an alarm or give a visual indication of the LPG

concentration. The sensor has excellent sensitivity, with a

quick and excellent response time. Also there is one pressure

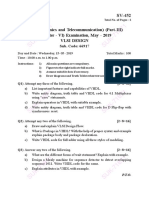

sensor to detect pressure in gas pipeline. If the LPG sensor II.BLOCK DIAGRAM

senses any gas leakage form storage it will give signal to

microcontroller. Also if the pressure of gas increases above SIM 300/900

given threshold it also give signal to microcontroller. This GSM Module

signal is monitored by the micro controller and it will identify

the gas leakage. Now micro controller is turn on LED and

buzzer whenever gas is detected by sensor. After few

milliseconds delay it also turn off electromagnetic valve and LCD 16X2 Display MAX 232

send massages to mobile number. Also if pressure increases

Buzzer

then it will turn off the electromagnetic valve.

Index Term – ATmega8A AVR microcontroller, Gas sensor Power

MQ6, Pressure sensor, GSM Module, Electromagnetic valve. Supply AVR Microcontroller

(Rectifier Keypad

Filter

Regulator)

(ATmega8L)

I.INTRODUCTION

Liquidised Petroleum Gas (LPG) is one of the Relay Driver

inflammable gas which is used in excess in homes and

industries as the name indicates liquidised, that means the

gas is filled under pressure. If the gas leaks it may cause

destruction to the lives and as well as the property. So Electromagnetic

Valve MQ-6 Sensor

keeping this concept in mind our group has decide to built Pressure (LPG)

detector system which detects the leak LPG gas and protect Sensor

the plant by taking corrective action. Some people have

GAS Pipeline

low sense of smell, may not respond on low concentration

of gas leakage. Become an essential and help to protect

Figure.1 Block Diagram of safety system for gas pipeline

from gas leakage accidents. Embedded system for

Hazardous gas detection and Alerting has been proposed in The system consist of, Sensor module consists of sensor for

literature. Whenever the alarm is activating immediately, each parameter and its respective power circuitry. The micro

the gas concentration exceeds normal level. controller is interfaced with sensor modules communication

In our project we have provided the provision back, if the module. The required computations for the analog signals

gas leakage is detected then following action is taken- [1] received from sensors data transmission are done within

There one LPG sensor to detect the LPG gas leakage. Also microcontroller unit.

there is one pressure sensor to detect pressure in gas The GSM is highly flexible plug and play quad band GSM

pipeline.[3] If there is gas leakage detected, also if pressure modem for direct and easy integration to MAX232 supports

features like SMS, GPRS and integrated TCP/IP stack.

in pipeline increases above given threshold then buzzer

(siren) turns on. Buzzer (siren) is indication of leakage.

IJERTV4IS040313 www.ijert.org 162

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 04, April-2015

1. SENSOR 3. GSM MODEM

1.1gas sensor This module can be easily connected with low cost

MQ6 is a semiconductor type gas sensor which detects the MCUs like AVR/PIC/8051. The communication is over

Gas leakage. The sensitive material used in MQ-6 is tin dioxide asynchronous serial line.

(SnO2). In clean air it has very low conductivity. This Gas sensor Specification:

not only has sensitivity to propane and butane, it also sensitive to

other natural gases like cigarette smoke and alcohol. a. Low Supply Current 8 mA.

This sensor can be used for detection of other combustible gas b. It has two drivers and two receivers.

such as methane. The concentration range of MQ-6 gas sensor is

300-1000ppm. This sensor is available in 6 pins package, out of c. Required +12V power supply.

which 4pins are used for fetching the signals and other 2 pins are

used for providing heating current. 4. ELECTROMAGNETIC VALVE

1.2 pressure sensor

Figure.3 Electromagnetic valve

Electromagnetic valve has been used, A 12V external

DC supply has been given to the Electromagnetic valve.

Figure.2 pressure sensor The main purpose of the electromagnetic valve to turn off the

Pressure sensor is used to sense the pressure of gas in pipeline. main Gas supply. Electromagnetic valve is attached to a main gas

When pressure of gas in pipeline is increase above threshold level pipeline in such a way that electromagnetic valve rotates 180o.

then pressure sensor sends signal to microcontroller. It turns of When gas leakage or high pressure occurs, immediately the knob

main gas supply through relay driver. is closed. Electromagnetic valve is fast and safe switching, high

Pressure is an expression of the force required to stop a fluid reliability, long life services, good medium. Compatibility of the

from expanding. Pressure is stated in terms of force per unit area. materials used low control power and compact design. It works in

A pressure sensor is generates a signal as a function of the 5-10ms.

pressure imposed.

III.SOFTWARE REQUIREMENT

2. MICROCONTROLLER The software for the GAS leakage was coded in embedded C.

It is a low power high performance AVR 8 bit microcomputer Because of compiler availability, our familiarity with the

with 8K bytes of flash programmable & erasable read only language, and the greater control of the system offered as

memory (PEROM). compared to other high level languages. AVR Microcontroller

The ATmega8uc is a low -power , high performance AVR 8-bit supports ASM language, it was avoided because it’s a difficult to

microcomputer with 8K bytes of flash programmable and erasable maintain, and varies largely from processor to processor. C allows

read only memory (PEROM).The process of erasure of the entire us to easily break apart the components of software design so that

contains takes less than a second ,or one might say in a flash different members of the team could code the system due to its

,hence the name ,flash memory. EEPROM and flash memory is properties of easy understanding and not variant from system to

the fact that when flash memory’s contains are erase the entire system.

devise erased, in contrast to EEPROM, where one can erase a

desired section or byte. Although there are some flash memories

are available in which the contains are divided into blocks and the

erasure con be done block by block, unlike EEPROM, no byte

erasure option is available .Due to the fact that flash memory con

be programmed while it is in socket on the system board, it is

becoming widely used as a way upgrade the BIOS ROM of the

PC.

IJERTV4IS040313 www.ijert.org 163

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 04, April-2015

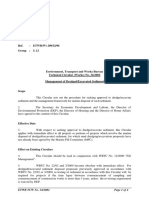

IV.EXPERIMENTAL RESULT VI. FLOWCHART

START

Initiate All Port

Turn On ADC

Close Valve &

Send SMS?

Figure 4. Top view of hardware of safety system for gas pipeline.

Is LPG

Sensor

Detect?

Y

N

Detect

N The

Pressure?

Figure 5. LCD displays

Is Pressure

Cross Threshold

Level?

Y

Beep The

N

Buzzer, make

valve OFF &

Send SMS to Display Current

User. System

N

Figure 6. Output of Proposed System

V. EXPERIMENTAL RESULTS

TABLE I

Figure 7. Flowchart of project system

Time GAS Leakage Gas Pressure

VII.CONCLUSION

Duration

5 Min No gas leakage 103.42 kPa While going through this project we concluded that this

design is very useful for detection of LPG gas. It is very

10 Min No gas leakage 103.42 kPa useful in domestic as well as industrial applications, gas

15 Min Gas leakage detected 0.0 kPa

powered vehicles. Using this project we can avoid

accidents associated with gas leakage.

IJERTV4IS040313 www.ijert.org 164

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 04, April-2015

VI.ACKNOWLEDGMEN

We are using this opportunity to express our gratitude to

everyone who supported us for writing this review paper. We

are thankful for their guidance and invaluably advice during this

work. We are sincerely grateful to them for sharing their truthful

and illuminating views on a number of issues.

We are expressing our warm thanks to our guide Prof. Mr.

Aniket Kale. For her support and guidance at Department of

Electronics and telecommunication Engineering; Dr. Dulatrao

Aher college of Engineering, Karad, 415001;

Maharashtra, India

VII.REFERENCES

1. Ashish Strivastava, Ratnesh Prabhakar, GSM Based

Gas Leakage Detection System”IEEE transactions on

industrial electronics, vol. 53, no. 5, .pp.1398-

1409, October 2006.

2. L. Shaw, S. Bagha,A. G. Mahapatra and N. Nayak,

“Kernel” Approach on Detection of Ethanol connetion

using Zno Gas Sensor, “International Journal of

Machine Learning and computing, vol. 2, no. 1, Feb.

2012.

3. V. Ramya and B. Palaniappan, “Embedded system for

Hazardous gas detection and Alerting,” in Proc. Of

International Journal of Distribted and parallel system

(IJDPS), vol. 3, no. 3, May 2012.

4. T.Murugan,A.Periasamyand S.Muruganand,

“Embedded Based Industrial temperature monitoring

system using GSM,”International Journal of computer

application, vol. 58, no. 19, Nov. 2012.

5. Y.J.Jung Y.K.Lee, D.G Lee k. H. Ryu,and S. Nittel,

“Air Pollution monitoring system based on geo sensor

network” in proc. IEEE Int. Geoscience Remote Sensing

Symp., 2008, vol, 3, pp.1370-1373.

6. Johansson, A.; Birk, W.; Medvedev, A.,” Model-based

gas leakage detection and isolation in a pressurized

system via Laguerre spectrum analysis”, Proc. of IEEE

International Conference on Control Applications, pp.

212-216, 1998.

IJERTV4IS040313 www.ijert.org 165

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Joby Aviation - Analyst Day PresentationDocument100 pagesJoby Aviation - Analyst Day PresentationIan TanNo ratings yet

- The Duke and I PDFDocument2 pagesThe Duke and I PDFNuhaNo ratings yet

- Detection of The Gas Leak Based On IotDocument13 pagesDetection of The Gas Leak Based On Iotvivekanand_bonalNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Dharmakirti39s Commentary On ChakrasamvaraDocument15 pagesDharmakirti39s Commentary On ChakrasamvaraThiago AlbuquerqueNo ratings yet

- Edi LPG-1Document4 pagesEdi LPG-1sumitraina4uNo ratings yet

- Projectphase1 03finlDocument20 pagesProjectphase1 03finlPoojaNo ratings yet

- A Microcontroller Based LPG Cylinder Booking and Leakage Detection Using GSMDocument3 pagesA Microcontroller Based LPG Cylinder Booking and Leakage Detection Using GSMEditor IJTSRDNo ratings yet

- Gas Leakage Detection System Using 8051 Microcontroller: Harshit Sharma, Varun Bharathi J, Gowtham V, Debashish DashDocument6 pagesGas Leakage Detection System Using 8051 Microcontroller: Harshit Sharma, Varun Bharathi J, Gowtham V, Debashish DashSyeda NazneenNo ratings yet

- GSM Based Gas and Fire Accident Avoiding System With Smart ManagementDocument10 pagesGSM Based Gas and Fire Accident Avoiding System With Smart ManagementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gas Booking LeakinageDocument35 pagesGas Booking LeakinageDHINESH ITNo ratings yet

- 10 Vol 98 No 15Document11 pages10 Vol 98 No 15myo htetNo ratings yet

- Overview: 1.1 ABSTRACT (Problem Statement)Document46 pagesOverview: 1.1 ABSTRACT (Problem Statement)Mayank PatilNo ratings yet

- Intelligent Helmet Safety System For Mine WorkersDocument5 pagesIntelligent Helmet Safety System For Mine WorkersIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- House Safety SystemDocument2 pagesHouse Safety Systemsumitraina4uNo ratings yet

- Gas Leakage SystemDocument3 pagesGas Leakage SystemSuplex CityNo ratings yet

- B PDFDocument4 pagesB PDFChandu ThorNo ratings yet

- Edi LPG-3Document5 pagesEdi LPG-3sumitraina4uNo ratings yet

- Prototype of Gas Leak Detector System Us d8791654Document7 pagesPrototype of Gas Leak Detector System Us d8791654oumaima Al bakaliNo ratings yet

- Gas Leakage Detection and Prevention SystemDocument3 pagesGas Leakage Detection and Prevention SystemInternational Journal of Trendy Research in Engineering and TechnologyNo ratings yet

- Smart Gas Leakage Detecting System A ReviewDocument3 pagesSmart Gas Leakage Detecting System A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Wireless Gas Leakage & Level Detection With Auto Renewal SystemDocument6 pagesA Wireless Gas Leakage & Level Detection With Auto Renewal SystemShahid KhanNo ratings yet

- Fin Irjmets1650097715Document7 pagesFin Irjmets1650097715jddatu15No ratings yet

- IOT Based Smart Gas Monitoring System: Anandhakrishnan S, Deepesh Nair, Rakesh K, Sampath K, Gayathri S NairDocument6 pagesIOT Based Smart Gas Monitoring System: Anandhakrishnan S, Deepesh Nair, Rakesh K, Sampath K, Gayathri S NairMunya ChiksNo ratings yet

- JMESTN42353239Document4 pagesJMESTN42353239Zia UllahNo ratings yet

- Automatic Gas StoveDocument3 pagesAutomatic Gas StoveVishal TalwatkarNo ratings yet

- Project ReportDocument28 pagesProject ReportGururaj RevankarNo ratings yet

- LPG Gas Detector Using ArduinoDocument19 pagesLPG Gas Detector Using Arduinoharshith dsNo ratings yet

- MINI ProjectDocument25 pagesMINI ProjectmunaNo ratings yet

- Smart Transformer Using Advanced Metering Infrastructure (AMI) and Advance Sensor Infrastructure (ASI)Document4 pagesSmart Transformer Using Advanced Metering Infrastructure (AMI) and Advance Sensor Infrastructure (ASI)AvaniPujaraNo ratings yet

- Microcontroller Based LPG Gas Leakage Detector Using GSM Module-1561Document6 pagesMicrocontroller Based LPG Gas Leakage Detector Using GSM Module-1561Dr-Harish Chandra Mohanta100% (1)

- 11 VI June 2023Document6 pages11 VI June 2023panchalharshit0077No ratings yet

- Design and Construction of A GSM Based GDocument6 pagesDesign and Construction of A GSM Based GE L Sai BalajiNo ratings yet

- Ijetr April 2014 Stet 36Document5 pagesIjetr April 2014 Stet 36akashNo ratings yet

- Gas Robot SensorDocument25 pagesGas Robot SensorlekhaNo ratings yet

- Advanced Anti-Theft & Home Safety System Using GSM: International Research Journal of Engineering and Technology (IRJET)Document3 pagesAdvanced Anti-Theft & Home Safety System Using GSM: International Research Journal of Engineering and Technology (IRJET)Shivam ChaurasiyaNo ratings yet

- 786 1488211888 PDFDocument10 pages786 1488211888 PDFsso bernaNo ratings yet

- LPG Gas Leakage Monitoring and Alert System Using Arduino: Ayesha Siddika, Imam HossainDocument4 pagesLPG Gas Leakage Monitoring and Alert System Using Arduino: Ayesha Siddika, Imam HossainMahabub AlamNo ratings yet

- Ijetae Ncetet 2018 04Document2 pagesIjetae Ncetet 2018 04Ajaysinh SolankiNo ratings yet

- Pre-Crash Sensing and Warning System in Hilly Region: R.Meena, R.Lavanya and K.Suresh KumarDocument3 pagesPre-Crash Sensing and Warning System in Hilly Region: R.Meena, R.Lavanya and K.Suresh KumaryasirNo ratings yet

- Gas Leakage Alarm Mini ProjectDocument6 pagesGas Leakage Alarm Mini Projectarunajoseph92_868114100% (1)

- Microcontroller Based LPG Gas Leakage Detector Using GSM ModuleDocument6 pagesMicrocontroller Based LPG Gas Leakage Detector Using GSM ModuleMadhan KumarNo ratings yet

- 09-13 PDFDocument5 pages09-13 PDFMohit Kumar chaubeyNo ratings yet

- 5.2 Multi Purpose Security System in Automobile IndustryDocument5 pages5.2 Multi Purpose Security System in Automobile Industrysathish kumarNo ratings yet

- Iot Based Gas Leakage Detection: Pranay Y, Arpit K, Satya Kumar C Vellore Institute of Technology, VelloreDocument10 pagesIot Based Gas Leakage Detection: Pranay Y, Arpit K, Satya Kumar C Vellore Institute of Technology, Vellorepranay yanamalaNo ratings yet

- LPG Detection AlarmDocument26 pagesLPG Detection AlarmsravanNo ratings yet

- IoT Based Gas Leakage DetectionDocument24 pagesIoT Based Gas Leakage Detectionakashlogic100% (1)

- CNG/LPG Leakage Detection and Accidential Prevention System Using GSMDocument38 pagesCNG/LPG Leakage Detection and Accidential Prevention System Using GSMAnanthu J V33% (3)

- Load Cell Based Gas Monitoring System: December 2021Document6 pagesLoad Cell Based Gas Monitoring System: December 2021BinojNo ratings yet

- Design and Construction of LPG Detection and Control System With SMS AlertDocument23 pagesDesign and Construction of LPG Detection and Control System With SMS AlertInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- LPG Gas Monitoring and Cylinder Booking Alert System: Divyansh Srivastava, Varshini ADocument6 pagesLPG Gas Monitoring and Cylinder Booking Alert System: Divyansh Srivastava, Varshini Ashital shermaleNo ratings yet

- HM-3300/3600 Dust Sensor Data Sheet: Version Number V2.1 Prepared by Audit Release Date July 20, 2018Document17 pagesHM-3300/3600 Dust Sensor Data Sheet: Version Number V2.1 Prepared by Audit Release Date July 20, 2018bomman69No ratings yet

- Wireless Sensor Node To Detect Dangerous Gas Pipeline Abstract NewDocument6 pagesWireless Sensor Node To Detect Dangerous Gas Pipeline Abstract NewsravanthiNo ratings yet

- V6i4 0130Document8 pagesV6i4 0130Willy WankaNo ratings yet

- MQ8 Hydrogen Gas Sensor Datasheet - Working & Its ApplicationsDocument10 pagesMQ8 Hydrogen Gas Sensor Datasheet - Working & Its Applicationssangilipandi2003No ratings yet

- GAS & Smoke Leakage Detection and Automatic Valve Control SystemDocument3 pagesGAS & Smoke Leakage Detection and Automatic Valve Control SystemManivannanNo ratings yet

- Fin Irjmets1653279593Document7 pagesFin Irjmets1653279593akttripathiNo ratings yet

- HGN Iot PDFDocument18 pagesHGN Iot PDFGagan SinghviNo ratings yet

- Smart Crop Protection System From Animals and Fire Using ArduinoDocument5 pagesSmart Crop Protection System From Animals and Fire Using Arduinonamekole123No ratings yet

- Sensor-Based Gas Leakage Detector System: ProceedingsDocument6 pagesSensor-Based Gas Leakage Detector System: ProceedingsEnamulKhanNo ratings yet

- Gas Leak Detector Using Arduino UNO: MicrocontrollerDocument5 pagesGas Leak Detector Using Arduino UNO: MicrocontrollerSENBAGA PRIYA.H cse2015No ratings yet

- Shivani Project Report-1Document7 pagesShivani Project Report-1mr.arjunb27No ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Lecture4-Introduction To 8085 Instruction SetDocument47 pagesLecture4-Introduction To 8085 Instruction SetSaurabh BhiseNo ratings yet

- Lecture14-8085 Memory InterfacingDocument18 pagesLecture14-8085 Memory InterfacingSaurabh BhiseNo ratings yet

- B.E. Draft P Oct 2022Document9 pagesB.E. Draft P Oct 2022Saurabh BhiseNo ratings yet

- Text Blocks Come To JavaDocument7 pagesText Blocks Come To JavaSaurabh BhiseNo ratings yet

- Capr-I 6005Document40 pagesCapr-I 6005Saurabh BhiseNo ratings yet

- Lecture13 8085 Architecture DemultiplexingDocument10 pagesLecture13 8085 Architecture DemultiplexingSaurabh BhiseNo ratings yet

- Im May 16Document4 pagesIm May 16Saurabh BhiseNo ratings yet

- TK2633-Lecture3-Introduction To 8085 Assembly Language ProgrammingDocument43 pagesTK2633-Lecture3-Introduction To 8085 Assembly Language ProgrammingSunny SinghNo ratings yet

- Lecture1-Microprocessors, Microcontroller Assembly LanguageDocument59 pagesLecture1-Microprocessors, Microcontroller Assembly LanguageSaurabh BhiseNo ratings yet

- HTML TutorialDocument280 pagesHTML TutorialSaurabh BhiseNo ratings yet

- Awp May 17Document4 pagesAwp May 17Saurabh BhiseNo ratings yet

- Lect2programming ModelDocument37 pagesLect2programming ModelSandeep BansalNo ratings yet

- DSP Nov 18Document2 pagesDSP Nov 18Saurabh BhiseNo ratings yet

- Awp Dec 18Document3 pagesAwp Dec 18Saurabh BhiseNo ratings yet

- VLSI Design NOV 18Document2 pagesVLSI Design NOV 18Saurabh BhiseNo ratings yet

- Im May 18Document3 pagesIm May 18Saurabh BhiseNo ratings yet

- T.E, (Part V) Examination, Antenna and Wave Propagation: (Revised) Sub. CodeDocument3 pagesT.E, (Part V) Examination, Antenna and Wave Propagation: (Revised) Sub. CodeSaurabh BhiseNo ratings yet

- VLSI Design MAY 19Document2 pagesVLSI Design MAY 19Saurabh BhiseNo ratings yet

- VLSI Design NOV 17Document2 pagesVLSI Design NOV 17Saurabh BhiseNo ratings yet

- Awp Dec 16Document3 pagesAwp Dec 16Saurabh BhiseNo ratings yet

- Awp Dec 15Document3 pagesAwp Dec 15Saurabh BhiseNo ratings yet

- Java byDocument94 pagesJava bySaurabh BhiseNo ratings yet

- VLSI Design NOV 19Document2 pagesVLSI Design NOV 19Saurabh BhiseNo ratings yet

- Awp Dec 17Document3 pagesAwp Dec 17Saurabh BhiseNo ratings yet

- CombinepdfDocument40 pagesCombinepdfSaurabh BhiseNo ratings yet

- Introduction To The C LanguageDocument41 pagesIntroduction To The C LanguageReycelyn CorsinoNo ratings yet

- F.Y. B.Tech. (Part - I) (Semester - I) (Revised) Examination, May - 2019Document2 pagesF.Y. B.Tech. (Part - I) (Semester - I) (Revised) Examination, May - 2019Saurabh BhiseNo ratings yet

- 8-T.Y. B.Tech Syallabus EandTC 23.8.2020Document61 pages8-T.Y. B.Tech Syallabus EandTC 23.8.2020Saurabh BhiseNo ratings yet

- F.Y. B.Tech. (Semester - I) (Revised) Examination, December - 2018 Fundamentals of Electronics and Computers (All Branches)Document2 pagesF.Y. B.Tech. (Semester - I) (Revised) Examination, December - 2018 Fundamentals of Electronics and Computers (All Branches)Saurabh BhiseNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- EXAMPLE 8.6 Veneer Grades and RepairsDocument2 pagesEXAMPLE 8.6 Veneer Grades and RepairsnickNo ratings yet

- 1F-Korean-Nami Mun - Miles From NowhereDocument4 pages1F-Korean-Nami Mun - Miles From NowhereNeil PatelNo ratings yet

- Birla MEEP Op ManualDocument43 pagesBirla MEEP Op ManualAshok ChettiyarNo ratings yet

- SAT Practice Test 10 - College BoardDocument34 pagesSAT Practice Test 10 - College BoardAdissaya BEAM S.No ratings yet

- Esterification Oil of WintergreenDocument8 pagesEsterification Oil of WintergreenMaria MahusayNo ratings yet

- Optik: Original Research ArticleDocument6 pagesOptik: Original Research ArticlesimarpreetNo ratings yet

- Notes Transfer of Thermal EnergyDocument12 pagesNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- GSD Puppy Training Essentials PDFDocument2 pagesGSD Puppy Training Essentials PDFseja saulNo ratings yet

- 8-General Rules For Erection ProcedureDocument4 pages8-General Rules For Erection ProcedurePrijin UnnunnyNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Chillers VoltasDocument4 pagesChillers Voltasanil shuklaNo ratings yet

- Worksheet - 143760187HS-II, TUTORIAL ON CH-5Document14 pagesWorksheet - 143760187HS-II, TUTORIAL ON CH-5A MusaverNo ratings yet

- Ecall Vs NG EcallDocument6 pagesEcall Vs NG EcallTrần Văn DũngNo ratings yet

- Coffee Quality Manual by Abra Rand Nig Use IDocument25 pagesCoffee Quality Manual by Abra Rand Nig Use IIpungNo ratings yet

- MC MATH 01 Syllabus SJCCDocument11 pagesMC MATH 01 Syllabus SJCCAcire NonacNo ratings yet

- The Manufacture and Uses of Expanded Clay Aggregate: Thursday 15 November 2012 SCI HQ, LondonDocument36 pagesThe Manufacture and Uses of Expanded Clay Aggregate: Thursday 15 November 2012 SCI HQ, LondonVibhuti JainNo ratings yet

- Hypothesis Testing - IDocument36 pagesHypothesis Testing - Isai revanthNo ratings yet

- Physics Unit 11 NotesDocument26 pagesPhysics Unit 11 Notesp.salise352No ratings yet

- Bchem 455 - Module 3Document42 pagesBchem 455 - Module 3WilliamNo ratings yet

- CS402 Mcqs MidTerm by Vu Topper RMDocument50 pagesCS402 Mcqs MidTerm by Vu Topper RMM. KhizarNo ratings yet

- Chapter 7 - Stress - TransformationsDocument21 pagesChapter 7 - Stress - TransformationsroselleNo ratings yet

- Indoor Air Quality Standard Procedures - 2014 RevDocument12 pagesIndoor Air Quality Standard Procedures - 2014 RevFioriAmeliaHathawayNo ratings yet

- Crma Unit 1 Crma RolesDocument34 pagesCrma Unit 1 Crma Rolesumop3plsdn0% (1)

- Human Wildlife Conflict Resolution PDFDocument9 pagesHuman Wildlife Conflict Resolution PDFdemiNo ratings yet

- Climbing FormworkDocument4 pagesClimbing FormworkAshwin B S RaoNo ratings yet

- Management of DredgedExcavated SedimentDocument17 pagesManagement of DredgedExcavated SedimentMan Ho LamNo ratings yet

- The Working of KarmaDocument74 pagesThe Working of KarmaSuhas KulhalliNo ratings yet