Professional Documents

Culture Documents

Edi LPG-1

Uploaded by

sumitraina4uOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edi LPG-1

Uploaded by

sumitraina4uCopyright:

Available Formats

View metadata, citation and similar papers at core.ac.

uk brought to you by CORE

provided by International Journal of Innovative Technology and Research (IJITR)

Arun Raj* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.3, Issue No.2, February – March 2015, 1957 – 1960.

LPG Gas Monitoring System

ARUN RAJ ATHIRA VISWANATHAN

Final year B.Tech student Final year B.Tech student

Dept of Applied Electronics and Instrumentation Dept of Applied Electronics and Instrumentation

Adi Shankara Institute of Engineering and Adi Shankara Institute of Engineering and

Technology Technology

ATHUL T S

Final year B.Tech student

Dept of Applied Electronics and Instrumentation

Adi Shankara Institute of Engineering and Technology

Abstract— The design of LPG leakage monitoring system is proposed for home safety. The accidents due to

the explosion of LPG is increasing now days which became a threaten to human life. In this system, the

gas sensor detects the leakage of the LPG and alert the owner about the leak by sending SMS to his

personal mobile and activate the alarm. In additional to this, the system continuously monitors the level of

the LPG in the cylinder using load sensor and if the level is below the threshold limit the system inform

them by SMS and also by the LCD display. So that the user have an idea about the max time the LPG

lasts. An automatically booking of the cylinder using a GSM module is also used in this proposed system.

The device ensures safety and prevents suffocation and explosion due to gas leakage.

Keywords— LPG- Liquid Petroleum Gas LCD-Liquid Crystal Display

GSM- Global System for Mobile Communications

ETSI- European Telecommunications Standards Institute

1G- First Generation 2G- Second Generation 3G- third Generation 4G- Fourth Generation

GPRS- General Packet Radio Services

EDGE- Enhanced Data rates for GSM Evolution LCD- Liquid Crystal Display

INTRODUCTION L6D), GSM module (SIMCOM 300), and display(s).

These days the usage of the liquid petroleum MICROCONTROLLER

gas(LPG) is widely used in many fields, especially in

To monitor the LPG, an efficient and fast working

household purposes. As the usage of the LPG

microcontroller is required. The microcontroller also

increases, the accidents occur by these LPG

controls the working of the gas sensor and load

explosion is also increases. The leakage of the LPG

sensor output. The microcontroller used in this is PIC

may lead to high explosion. So it's necessary to have

16F877A. If the sensor sense a leakage then the

a system which continuously monitor the LPG and

microcontroller must make a fast response. The

alarming. The aim of this proposed system is to

microcontroller is the central part of the system. It

monitor the LPG in house hold applications and

has an operating frequency of 20 MHz. it also have 3

leakage detection. The system shows remaining time

timers and 5 input output ports.

of LPG cylinder can be used in full flame. The

gas sensor used to detect the amount of LPG in GAS SENSOR

atmosphere and alerts the consumer about the gas

This is a simple-to-use LPG sensor, suitable for

leakage if any by sending SMS to a particular

sensing LPG (composed of mostly propane and

mobile number. Now a days the booking of the

butane) concentrations in the air. The MQ-6 can

LPG cylinders is by sending SMS to the booking

agent. In this system the GSM module which detect gas concentrations anywhere from 200 to

automatically books the cylinder by SMS to the 10000ppm.

agent booking number. This will help the owner to This sensor has a high sensitivity and fast response

get the new cylinders in time without any fail. time. The sensor’s output is an analog resistance. The

1drive circuit is very simple; all you need to do is

SYSTEM OVERVIEW

power the heater coil with 5V, add a load resistance,

The system block diagram comprises of parts as and connect the output to an ADC.

shown in figure 1. It consists of microcontroller (PIC

16F877A), gas sensor, weight sensor (Load Cell-

2320 –5547 @ 2013 http://www.ijitr.com All rights Reserved. Page | 1957

Arun Raj* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.3, Issue No.2, February – March 2015, 1957 – 1960.

WEIGHT SENSOR MODULE originally described a digital, circuit- switched

network optimized for full duplex voice telephony.

The weight sensor we used is the load cell module. A

This was expanded over time to include data

load cell is described as a “weight measurement

communications, first by circuit-switched transport,

device necessary for electronic scales that display

then packet data transport via GPRS and EDGE.

weights in digits.” However, load cell is not restricted

Subsequently, the 3GPP developed 3G UMTS

to weight measurement in electronic scales.

standards followed by 4G Advanced standards,

Load cell is a passive transducer or sensor which which are not part of the ETSI GSM standard.

converts applied force into electrical signals. They

ii. Displays

are also referred to as “Load transducers”. Load cells

use different operating principles, viz. Here we use an LCD screen is an electronic display

module and find a wide range of applications. A

Load Cells based on fluid pressure 16x2 LCD display is very basic module and is very

Load Cells based on elasticity commonly used in various devices and circuits.

These modules are preferred over seven segments

Load Cells based on magnetostriction and other multi segment LEDs. The reasons being:

effect or piezoelectric effect LCDs are economical; easily programmable; have no

However, the only load cells which are prevalent are limitation of displaying special & even custom

the load cells based on strain gages. Hence, the term characters (unlike in seven segments), animations and

‘load cell’ means ‘strain gage-based load cells’. The so on.

reason behind the wide adoption of strain gage- based A 16x2 LCD means it can display 16 characters

load cells is their characteristics per line and there are 2 such lines. In this LCD

1) Highly precise and linear measurements each character is displayed in 5x7 pixel matrix. This

LCD has two registers, namely, Command and Data.

2) Little influence due to temperature changes. The command register stores the command

3) Small size compared with other types of load instructions given to the LCD. A command is an

cells. instruction given to LCD to do a predefined task

like initializing it, clearing its screen, setting the

4) Long operating life due to lack of moving cursor position, controlling display etc. The data

parts or any parts that generate friction. register stores the data to be displayed on the LCD.

5) Ease in production due to small number of The data is the ASCII value of the character to be

components. displayed on the LCD. Click to learn more about

internal structure of a LCD.

6) Excellent fatigue characteristics

SYSTEM OPERATION

An efficient and fast working controller is needed

to continuously sense the LPG gas and its level

(weight) sensor’s output. Also a fast reply is desired

when leakage is found. Along with this a system

must possess capacity to store some information

which can be used for further processing. Above

operations require a very fast, single cycle execution

rate microcontroller like PIC 16F877A as shown in

above figure 1, the microcontroller is at the centre of

the system. It is having features like 16Kb internal

Fig.1. Basic block diagram of the proposed RAM making easy storage of entire code in

model of the system microcontroller itself, also the 1 MIPS per MHz

instruction cycle execution rate enhanced overall

i. GSM Module system performance. The LCD module connected to

GSM is a standard developed by the ETSI to describe port B of PIC 16F877A in 4-bit mode is used to

protocols for 2G digital cellular networks used by display the required messages. GSM module using

mobile phones. It is the default global standard for AT commands connected to Rx and Tx pins of port

mobile communications with over 90% market D of PIC 16F877A are used to receive and transmit

share, and is available in over 219 countries and messages to desired family members and distributor.

territories. The GSM standard was developed as a The weight sensor module output taken from relay

replacement for 1G analog cellular networks, and circuit is connected to pins of port A which is used

2320 –5547 @ 2013 http://www.ijitr.com All rights Reserved. Page | 1958

Arun Raj* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.3, Issue No.2, February – March 2015, 1957 – 1960.

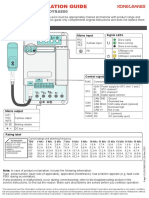

to monitor gas level continuously. given to the port pins PA0 and PA1 of PIC

16F877A as per the truth table.

The LPG gas consists of isobutene, propane,

methane, etc. A sensitive, efficient gas sensor is PA0 PA1 Conditions

required that senses only LPG gas contents and is

less sensitive to other gases like cooking fumes,

cigarettes, etc. Sensitive material of MQ- 6 gas 0 0 Full Cylinder

sensor is SnO2, which has lower conductivity in

clean air and its sensitivity increases with the 1 0 Booking Cylinder(≤10

concentration of gas, also it avoids gases like Kg)

cooking fumes. It requires a voltage of 0-5 volts

which is low and safe as per as the gaseous 1 1 Empty Cylinder(≤0.5

environment is considered .This sensor continuously Kg)

senses the gas, and if concentration level goes above

danger level then it turns relay ON which gives

interrupt to microcontroller and alternately switches fig 2. level of LPG is measured using load cell

on buzzer and exhaust fan. approximation

Gas sensor detects the presence of gas, weight sensor The Rx and Tx pins of GSM are connected to the

gives the gas level in cylinder, and microcontroller Tx and Rx pins of PIC 16F877A respectively. The

will take corrective or necessary actions. The status output is shown by the LCD display which is

of all these happening has to be conveyed to the operated in 4 bit mode. The higher data pins D4-D7

owner of system or housemates .The technology are connected to the PB0-PB3 pins and control pins

making it very easy to send and receive messages R/s, R/W and Enable pins of LCD are connected

using GSM module works on simple AT commands to PIC 16F877A.

which can be implemented by interfacing it to the The output of the MQ6 drives the relay circuitry

microcontroller Rx and Tx pins. The GSM module which eventually switches on the alarm and exhaust

used is SIMCOM 300 which uses SIM memory to fan as soon as the gas is detected and both are

store the number of system owner or housemates reset by a manual reset switch.

and distributor or to whoever the messages have to

be forwarded. It requires very less memory to send RESULT

and receive text messages and operates on simple The system prototype is constructed and when a

12 Volt adapter. small amount of LPG is leaked near the system, the

As the system performs controlling and monitoring system sensor detects the leakage and sends the

operations, it is primary requirement to put a display SMS to housemates and activates the alarm. Also

in the system which shows various message such as system prototype continuously monitors the LPG

gas leakage detection, booking number of cylinder level of the cylinder and books the cylinder

in case of refill of cylinder and also will display automatically.

actions taken by microcontroller. CONCLUSION

Liquid Crystal Display (LCD) of 16X2 characters A cost-effective gas leakage detection system was

operating on +5Volt supply and operated in 4-bit proposed, designed and successfully implemented

mode is implemented for the task of displaying in this paper. Along with gas leakage detection, this

required messages. Interfacing with PIC16F877A and system gives a fully automated approach towards

short code of programming makes it very useful to the gas booking. Real time weight measurement of

make system more user friendly. the gas and its display on LCD makes it an

EXPERIMENTAL SETUP efficient home security system and also can be

used in industries and other places to detect gas

PIC 16F877A is the base of the system. The inputs leaks. The cost involved in developing the system

given to the PIC 16F877A are the output of gas is significantly low and is much less than the cost of

sensor MQ-6 and load cellL6D .The output of PIC gas detectors commercially available in the market.

16F877A are given to the SIMCOM 300 and LCD

16×2 display. ACKNOWLEDGMENT

The gas output of MQ6 is given to the INT0 pin The authors would like to thank Sreedeep Krishnan,

of PIC 16F877A as far as the highest priority is Dileep K for their valuable comments and their

given to the leakage detection. The output of L6D is constructive criticism which helped to improve the

amplified and digitized by A/D converter and is quality of the paper.

2320 –5547 @ 2013 http://www.ijitr.com All rights Reserved. Page | 1959

Arun Raj* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.3, Issue No.2, February – March 2015, 1957 – 1960.

REFERENCES

[1]. Sunithaa.J, Sushmitha.D, “Embedded control

system for LPG leakage detection and

prevention”

[2]. V.Ramya, B.Palaniappan,“Embedded system

for hazardous gas detection and alerting”

[3]. Mr.SagarShinde, Dr.A.J.Patil, “Development

of movable gas tanker leakage detection using

wireless sensor network based on embedded

system”,

[4]. M. B. Fish, R.T. Wainer, “Standoff Gas

Leakage detectors based on tunable diodes

laser absorption spectroscopy”

[5]. A. Mahalingam, R. T. Naayagi, N. E.

Mastorakis, “Design and Implementation of an

Economic Gas Leakage Detector”, Recent

Researches in Applications of Electrical and

Computer Engineering

[6]. S. Rajitha, T. Swapna,“Security alert system

using GSM for gas leakage”International

Journal of VLSI and Embedded Systems-

IJVES

[7]. Taufiq Noor Machmuda, “LPG Gas Detector

and leak prevention based microcontroller”

[8]. A. CheSoh, M.Sc.; M.K. Hassan, M.Eng.; and

A.J. Ishak, M.Sc. “ Vehicle gas leakage

detector”

[9]. National Institute of Health. (2004). “What

you need to know about natural gas

detectors”.

http://www.nidcd.nih.gov/health/smelltaste/gas

[10]. Fraiwan, L.; Lweesy, K.; Bani-Salma,

A.Mani, N, “A wireless home safety gas

leakage detection system”, Proc. of 1st

Middle East, Conference on Biomedical

Engineering, pp.11-14, 2011.

2320 –5547 @ 2013 http://www.ijitr.com All rights Reserved. Page | 1960

You might also like

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- LPG Gas Monitoring System Design Proposed for Home SafetyDocument4 pagesLPG Gas Monitoring System Design Proposed for Home SafetyChandu ThorNo ratings yet

- IEEE PaperDocument4 pagesIEEE PaperArshia TabassumNo ratings yet

- House Safety SystemDocument2 pagesHouse Safety Systemsumitraina4uNo ratings yet

- Detect Gas Leaks and Send Alerts Using ArduinoDocument4 pagesDetect Gas Leaks and Send Alerts Using ArduinoAYMAN IZZELDINNo ratings yet

- A Microcontroller Based LPG Cylinder Booking and Leakage Detection Using GSMDocument3 pagesA Microcontroller Based LPG Cylinder Booking and Leakage Detection Using GSMEditor IJTSRDNo ratings yet

- Gas Leakage Detection & MonitiringDocument23 pagesGas Leakage Detection & MonitiringParamesh.km1994gmail.com ParamNo ratings yet

- (IJCST-V11I4P6) :satyanarayana Kotha, Deepak Nedunuri, Madhava Rao CH, K Raja Gopal, Ramaiah Chowdary Parvathaneni, Vihari GulipalliDocument5 pages(IJCST-V11I4P6) :satyanarayana Kotha, Deepak Nedunuri, Madhava Rao CH, K Raja Gopal, Ramaiah Chowdary Parvathaneni, Vihari GulipalliEighthSenseGroupNo ratings yet

- Edi LPG-3Document5 pagesEdi LPG-3sumitraina4uNo ratings yet

- LPG Gas Leakage Monitoring and Alert System Using Arduino: Ayesha Siddika, Imam HossainDocument4 pagesLPG Gas Leakage Monitoring and Alert System Using Arduino: Ayesha Siddika, Imam HossainMahabub AlamNo ratings yet

- Estimation and Prediction of LPG Gas Using Data Analytics IJERTCONV10IS08051Document5 pagesEstimation and Prediction of LPG Gas Using Data Analytics IJERTCONV10IS08051amit7sinhaNo ratings yet

- IoT Based LPG Cylinder Monitoring SystemDocument31 pagesIoT Based LPG Cylinder Monitoring SystemAditya Kolhe67% (6)

- LPG Gas Monitoring and Cylinder Booking Alert System: Divyansh Srivastava, Varshini ADocument6 pagesLPG Gas Monitoring and Cylinder Booking Alert System: Divyansh Srivastava, Varshini Ashital shermaleNo ratings yet

- 09-13 PDFDocument5 pages09-13 PDFMohit Kumar chaubeyNo ratings yet

- Smart Gas Leakage Detecting System A ReviewDocument3 pagesSmart Gas Leakage Detecting System A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Safety System For Gas Pipeline: Asst. Prof. Mr. Aniket KaleDocument4 pagesSafety System For Gas Pipeline: Asst. Prof. Mr. Aniket KaleSaurabh BhiseNo ratings yet

- Iot Based Gas Leakage Detection: Pranay Y, Arpit K, Satya Kumar C Vellore Institute of Technology, VelloreDocument10 pagesIot Based Gas Leakage Detection: Pranay Y, Arpit K, Satya Kumar C Vellore Institute of Technology, Vellorepranay yanamalaNo ratings yet

- Microcontroller Based LPG Gas Leakage Detector Using GSM ModuleDocument6 pagesMicrocontroller Based LPG Gas Leakage Detector Using GSM ModuleMadhan KumarNo ratings yet

- Final ReviewDocument8 pagesFinal ReviewUdit SharmaNo ratings yet

- Overview: 1.1 ABSTRACT (Problem Statement)Document46 pagesOverview: 1.1 ABSTRACT (Problem Statement)Mayank PatilNo ratings yet

- GSM Based Gas and Fire Accident Avoiding System With Smart ManagementDocument10 pagesGSM Based Gas and Fire Accident Avoiding System With Smart ManagementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Gas StoveDocument3 pagesAutomatic Gas StoveVishal TalwatkarNo ratings yet

- Gas Booking LeakinageDocument35 pagesGas Booking LeakinageDHINESH ITNo ratings yet

- Microcontroller Based LPG Gas Leakage Detector Using GSM Module-1561Document6 pagesMicrocontroller Based LPG Gas Leakage Detector Using GSM Module-1561Dr-Harish Chandra Mohanta100% (1)

- Gas Leakge 4Document18 pagesGas Leakge 4Praveen ChawanNo ratings yet

- Design and Construction of Gas Detection System Using ArduinoDocument7 pagesDesign and Construction of Gas Detection System Using ArduinoSamuel Olusanya100% (1)

- Gas Leakage DT PaperDocument5 pagesGas Leakage DT PaperSrNo ratings yet

- Automated gas leak detection and shut-off system using IoTDocument20 pagesAutomated gas leak detection and shut-off system using IoTPoojaNo ratings yet

- Prototype of Gas Leak Detector System Us d8791654Document7 pagesPrototype of Gas Leak Detector System Us d8791654oumaima Al bakaliNo ratings yet

- Design and Construction of LPG Detection and Control System With SMS AlertDocument23 pagesDesign and Construction of LPG Detection and Control System With SMS AlertInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gas Leakage System FirstDocument15 pagesGas Leakage System FirstShabnamNo ratings yet

- Major - 1Document22 pagesMajor - 1sitaram choudharyNo ratings yet

- Model Development of WSN Based LPG Measure and LPG Leakage System Detection by Using GSMDocument3 pagesModel Development of WSN Based LPG Measure and LPG Leakage System Detection by Using GSMEditor IJTSRDNo ratings yet

- An SMS Based Fire Alarm & GAS LEAKAGE DETECTOR USING ARDUINO AND GSM MODULEDocument5 pagesAn SMS Based Fire Alarm & GAS LEAKAGE DETECTOR USING ARDUINO AND GSM MODULEArafad AbdallaNo ratings yet

- Air Pollution and Insurance Based Vehicle Locking SystemDocument5 pagesAir Pollution and Insurance Based Vehicle Locking SystemCrispNo ratings yet

- Gas Leakage Detection and Prevention SystemDocument3 pagesGas Leakage Detection and Prevention SystemInternational Journal of Trendy Research in Engineering and TechnologyNo ratings yet

- Automatic LPG Leakage Alert System Using IotDocument8 pagesAutomatic LPG Leakage Alert System Using IotSYED IBRAHIMNo ratings yet

- LPG Project FinalDocument17 pagesLPG Project FinaltejaswiNo ratings yet

- LPG Leakage & DetectionDocument3 pagesLPG Leakage & DetectionSravan GopuNo ratings yet

- IOT-based smart gas monitoring system detects leaks and alerts usersDocument6 pagesIOT-based smart gas monitoring system detects leaks and alerts usersMunya ChiksNo ratings yet

- Chapter No.1: GSM Based Gas Leakage Detection SystemDocument26 pagesChapter No.1: GSM Based Gas Leakage Detection SystemSiddhasen PatilNo ratings yet

- Gas Leakage Detector With Sms AlertDocument11 pagesGas Leakage Detector With Sms Alertraghu charkhaNo ratings yet

- CNG/LPG Leakage Detection and Accidential Prevention System Using GSMDocument38 pagesCNG/LPG Leakage Detection and Accidential Prevention System Using GSMAnanthu J V33% (3)

- The Design of A Wireless LPG Leakage Monitoring System Is Proposed For Home Safety GodwinDocument2 pagesThe Design of A Wireless LPG Leakage Monitoring System Is Proposed For Home Safety GodwinClement OmoiguiNo ratings yet

- Gas Detection Project FinalDocument54 pagesGas Detection Project FinalSherry Sher100% (3)

- Smart LPG Gas Cylinder Monitoring System Using Internet of ThingsDocument7 pagesSmart LPG Gas Cylinder Monitoring System Using Internet of ThingsIJRASETPublicationsNo ratings yet

- A PDFDocument4 pagesA PDFChandu ThorNo ratings yet

- 263 ArticleText 492 1 10 202105171Document7 pages263 ArticleText 492 1 10 202105171Farhan Fadal SalahNo ratings yet

- Gas Detector ReportDocument2 pagesGas Detector ReportPiyush KumarNo ratings yet

- IJERT-Smart LPG Monitoring and Automatic Booking System Using IOTDocument5 pagesIJERT-Smart LPG Monitoring and Automatic Booking System Using IOTRodrigo Savi JustiNo ratings yet

- Journals On MedicalDocument4 pagesJournals On Medicalgraphic designerNo ratings yet

- LPG Gas Detector Using ArduinoDocument19 pagesLPG Gas Detector Using Arduinoharshith dsNo ratings yet

- Gas Leak Detector Using Arduino UNO: MicrocontrollerDocument5 pagesGas Leak Detector Using Arduino UNO: MicrocontrollerSENBAGA PRIYA.H cse2015No ratings yet

- Intelligent GAS Leakage Detector: Supervised by DR Meera Viswavandya Submitted byDocument30 pagesIntelligent GAS Leakage Detector: Supervised by DR Meera Viswavandya Submitted bySwadhin Sahoo100% (1)

- IoT-Based Gas Leak Detection and Alert SystemDocument13 pagesIoT-Based Gas Leak Detection and Alert Systemvivekanand_bonalNo ratings yet

- LPG GasDocument39 pagesLPG Gasv prasanthNo ratings yet

- Ijetr April 2014 Stet 36Document5 pagesIjetr April 2014 Stet 36akashNo ratings yet

- IOT Based LPG Gas Level Detection System To Save The Expensive LPG ResourceDocument4 pagesIOT Based LPG Gas Level Detection System To Save The Expensive LPG ResourceharishNo ratings yet

- Fin Irjmets1650097715Document7 pagesFin Irjmets1650097715jddatu15No ratings yet

- 10IOT and Arduino Based Stock Empty or Full Indicator Using Weight Sensor1Document7 pages10IOT and Arduino Based Stock Empty or Full Indicator Using Weight Sensor1Samith GurusingheNo ratings yet

- Manual Changeover Switches & Automatic Transfer SwitchesDocument16 pagesManual Changeover Switches & Automatic Transfer SwitchesMitchell DanielsNo ratings yet

- 1 Toshiba 2151 TB: General InformationDocument3 pages1 Toshiba 2151 TB: General InformationGoranNo ratings yet

- Vip 1200LDocument1 pageVip 1200LJorgeNo ratings yet

- Rosen Specs CombineDocument37 pagesRosen Specs CombineRael OrtizNo ratings yet

- Supply Erection & CommissioningDocument5 pagesSupply Erection & CommissioningChethan GowdaNo ratings yet

- DGCA CAR -66 MODULE 5 PART -4 MULTIPLEXING AND FIBRE OPTICSDocument13 pagesDGCA CAR -66 MODULE 5 PART -4 MULTIPLEXING AND FIBRE OPTICSPurna Chandra Rao ByganiNo ratings yet

- Tips For Upgrading Amps AV502Document8 pagesTips For Upgrading Amps AV502gmaldo7183100% (6)

- Msi Laptop Compatibility ListDocument16 pagesMsi Laptop Compatibility ListAbednego- Romeo Estillore AblangNo ratings yet

- Modular Analog Audio Mixer - PAPERDocument11 pagesModular Analog Audio Mixer - PAPERFabio MonteiroNo ratings yet

- Snubber Circuits ExplainedDocument9 pagesSnubber Circuits ExplainedcoolsinghrkNo ratings yet

- Manual de Partes 930e 1 - V3 - 1Document13 pagesManual de Partes 930e 1 - V3 - 1Alex L CjNo ratings yet

- Transmision Electronica (D6R)Document51 pagesTransmision Electronica (D6R)A Ramos Gaby96% (28)

- DOC665105Document2 pagesDOC665105DeivisNo ratings yet

- PSSE ReleaseDocument34 pagesPSSE ReleaseAshutosh SharmaNo ratings yet

- OsiSense XS XSAV11801EXDocument2 pagesOsiSense XS XSAV11801EXGurban MatmıradovNo ratings yet

- Post Code: 1 / Post Name: Project Associate (Freshers / Experienced Candidates)Document3 pagesPost Code: 1 / Post Name: Project Associate (Freshers / Experienced Candidates)Namani Sravan KumarNo ratings yet

- An-Introducing 32nm Technology in MicrowindDocument24 pagesAn-Introducing 32nm Technology in MicrowindAntonio LeonNo ratings yet

- Ewis Training ManualDocument36 pagesEwis Training ManualNikolaos Kechagias100% (2)

- MM ZJ6Document18 pagesMM ZJ6danlekNo ratings yet

- KSEB Power Application LT FormDocument2 pagesKSEB Power Application LT FormJoel Joy100% (1)

- AMC1306x Small, High-Precision, Reinforced Isolated Delta-Sigma Modulators With High CMTIDocument44 pagesAMC1306x Small, High-Precision, Reinforced Isolated Delta-Sigma Modulators With High CMTICristian Elieser Avila RojasNo ratings yet

- Sync To HSYNC and VSYNC ConverterDocument1 pageSync To HSYNC and VSYNC ConverterAzmi PlgNo ratings yet

- 7.performance Analysis of Wallace Tree Multiplier With Kogge Stone Adder Using 15-4 CompressorDocument38 pages7.performance Analysis of Wallace Tree Multiplier With Kogge Stone Adder Using 15-4 Compressoranil kumarNo ratings yet

- DR4500A Truline pmt-hps-44-45-03-16Document12 pagesDR4500A Truline pmt-hps-44-45-03-16鄭元豪No ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- Simple Breathalyzer Construction and Use GuideDocument3 pagesSimple Breathalyzer Construction and Use GuideFrank Cruz100% (1)

- H7 Enclosed and Gasketed Luminaire: ApplicationsDocument1 pageH7 Enclosed and Gasketed Luminaire: ApplicationsKarlos Antonio Salinas MoralesNo ratings yet

- Eeezg 512Document11 pagesEeezg 512Semil ChaliawalaNo ratings yet

- Samsung BN44-00121J, PWI1904SJ Power Ip-43130a Inverter Ip-35155a-1Document9 pagesSamsung BN44-00121J, PWI1904SJ Power Ip-43130a Inverter Ip-35155a-1Eliane100% (1)

- 1.5KE Series: 1500W Transient Voltage SuppressorDocument6 pages1.5KE Series: 1500W Transient Voltage SuppressorjefriNo ratings yet

- Computer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityFrom EverandComputer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityRating: 4.5 out of 5 stars4.5/5 (13)

- CCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationFrom EverandCCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationNo ratings yet

- AWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamFrom EverandAWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamRating: 5 out of 5 stars5/5 (1)

- Microsoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsFrom EverandMicrosoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsNo ratings yet

- The Ultimate Kali Linux Book - Second Edition: Perform advanced penetration testing using Nmap, Metasploit, Aircrack-ng, and EmpireFrom EverandThe Ultimate Kali Linux Book - Second Edition: Perform advanced penetration testing using Nmap, Metasploit, Aircrack-ng, and EmpireNo ratings yet

- Computer Networking: The Complete Beginner's Guide to Learning the Basics of Network Security, Computer Architecture, Wireless Technology and Communications Systems (Including Cisco, CCENT, and CCNA)From EverandComputer Networking: The Complete Beginner's Guide to Learning the Basics of Network Security, Computer Architecture, Wireless Technology and Communications Systems (Including Cisco, CCENT, and CCNA)Rating: 4 out of 5 stars4/5 (4)

- The Compete Ccna 200-301 Study Guide: Network Engineering EditionFrom EverandThe Compete Ccna 200-301 Study Guide: Network Engineering EditionRating: 5 out of 5 stars5/5 (4)

- Designing and Building Security Operations CenterFrom EverandDesigning and Building Security Operations CenterRating: 3 out of 5 stars3/5 (3)

- ITIL 4: Digital and IT strategy: Reference and study guideFrom EverandITIL 4: Digital and IT strategy: Reference and study guideRating: 5 out of 5 stars5/5 (1)

- The CompTIA Network+ Computing Technology Industry Association Certification N10-008 Study Guide: Hi-Tech Edition: Proven Methods to Pass the Exam with Confidence - Practice Test with AnswersFrom EverandThe CompTIA Network+ Computing Technology Industry Association Certification N10-008 Study Guide: Hi-Tech Edition: Proven Methods to Pass the Exam with Confidence - Practice Test with AnswersNo ratings yet

- Amazon Web Services (AWS) Interview Questions and AnswersFrom EverandAmazon Web Services (AWS) Interview Questions and AnswersRating: 4.5 out of 5 stars4.5/5 (3)

- Computer Networking: The Complete Guide to Understanding Wireless Technology, Network Security, Computer Architecture and Communications Systems (Including Cisco, CCNA and CCENT)From EverandComputer Networking: The Complete Guide to Understanding Wireless Technology, Network Security, Computer Architecture and Communications Systems (Including Cisco, CCNA and CCENT)No ratings yet

- AWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamFrom EverandAWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamNo ratings yet

- Evaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsFrom EverandEvaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsNo ratings yet

- ITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationFrom EverandITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationRating: 5 out of 5 stars5/5 (2)

- Introduction to Cyber-Warfare: A Multidisciplinary ApproachFrom EverandIntroduction to Cyber-Warfare: A Multidisciplinary ApproachRating: 4.5 out of 5 stars4.5/5 (3)

- ITIL® 4 Direct, Plan and Improve (DPI): Your companion to the ITIL 4 Managing Professional and Strategic Leader DPI certificationFrom EverandITIL® 4 Direct, Plan and Improve (DPI): Your companion to the ITIL 4 Managing Professional and Strategic Leader DPI certificationNo ratings yet

- AWS Certified Advanced Networking - Specialty Exam Guide: Build your knowledge and technical expertise as an AWS-certified networking specialistFrom EverandAWS Certified Advanced Networking - Specialty Exam Guide: Build your knowledge and technical expertise as an AWS-certified networking specialistNo ratings yet

- Advanced Antenna Systems for 5G Network Deployments: Bridging the Gap Between Theory and PracticeFrom EverandAdvanced Antenna Systems for 5G Network Deployments: Bridging the Gap Between Theory and PracticeRating: 5 out of 5 stars5/5 (1)