Professional Documents

Culture Documents

Jamie Atkinson ET3-030E Practical Assessment Burning Health and Safety

Uploaded by

Polarcheif 01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jamie Atkinson ET3-030E Practical Assessment Burning Health and Safety

Uploaded by

Polarcheif 01Copyright:

Available Formats

Jamie Atkinson

ET3-030E Practical Assessment

Burning

Health and safety:

Make sure that all the tools and equipment are checked to see if they are safe to use

before using them.

You must have the correct PPE for the job.

Make sure you have done a risk assessment before you commence the job and that all

the risks have been identified.

Potential Hazards

Slips and trips: Make sure your workplace is clean and tidy so that there is a low chance

of slips and trips.

Fire: Make sure to always point the oxy/gas cutter away from you especially when

lighting it.

Sharp objects: Make sure to be safe when picking up the material.

Arc eye: Wear the correct googles and do not look at the cutting without them.

Personal Protective Equipment (PPE):

Goggles/full face screen

Flame retardant overalls

Steel toe cap boots

Gauntlet gloves

Tools and Equipment Used For The Task:

Oxy/propane gas cutter

Nozzle size of 1 over 32

Propane tank at 5 PSI

Oxygen tank at 12 PSI

Flash backs

Non return valves

Straight line guide bar

Trammel peg

6-inche file

1. Collect the equipment like the oxy/propane gas cutter.

2. Check if the equipment is safe (make sure flash backs and non return valves are in place.

3. Turn on the oxy/propane gas and listen for any leaks, if you suspect a leak use the soapy water

method to check.

4. If the equipment is safe to use, check that the oxy/propane gas cutter has a 1 over 32 nozzle

fitted.

5. After this collect your work material which should be a length of 180mm by 180mm

6. Mark out from the drawing the through lines which are 90mm from each end, the straight lines

which are 60mm from each end and go down 60mm, the bevel at 30˚ from each through line,

the circle a diameter of 50 from the point the through lines connect and the radii one with a

radius of 60 and one with a radius of 90.

7. When you are ready you can turn on the gas and light the flame with a flint and steal lighter,

when the flame is lit adjust the amount of oxygen and propane with the valves until you get a

solid blue flame.

8. When you are ready cut out the straight lines using a straight-line guide bar at 60mm each until

they connect to each other.

9. Then cut both of the radii using a Trammel peg from the center of where the two through line

connect adjusting it to cut both the radius of 60 and the radius of 90.

10. Cut the circle using the Trammel peg at the center of the through lines to get a circle with the

diameter of 50.

11. Next cut the 30˚ bevel using a straight line guide bar and angling the oxy/propane gas cutter at

30˚.

12. Take the work piece to a work bench and clean up and rough parts with a 6-inch file.

13. After this I cleared up the work area and put all of the tools back into there places and double

checked that the oxygen and propane valves where shut.

You might also like

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Jamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyDocument2 pagesJamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyPolarcheif 01No ratings yet

- Jamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyDocument2 pagesJamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyPolarcheif 01No ratings yet

- Jamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyDocument2 pagesJamie Atkinson ET3-030E Practical Assessment Burning Health and SafetyPolarcheif 01No ratings yet

- SWP 013 Oxy Acetylene WeldingDocument4 pagesSWP 013 Oxy Acetylene WeldingBajaj NitinNo ratings yet

- Method Statement For Copper Pipe CuttingDocument3 pagesMethod Statement For Copper Pipe Cuttingamg007100% (1)

- Gas Cutting by GnanasekaranDocument44 pagesGas Cutting by GnanasekaranKavipriyan KaviNo ratings yet

- Despiece y Numero de Parte MRD-60Document6 pagesDespiece y Numero de Parte MRD-60jordan navarroNo ratings yet

- Lava Heat Italia - Lava Lite KD Patio Heater - Owners ManualDocument23 pagesLava Heat Italia - Lava Lite KD Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- Lava Heat Italia - Alto Patio Heater - Owners ManualDocument21 pagesLava Heat Italia - Alto Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- Haz Repair&MaintDocument29 pagesHaz Repair&MaintSANJAY PANDYANo ratings yet

- Oxygen/ Fuel Cutting and Welding: by Ryan SaucierDocument36 pagesOxygen/ Fuel Cutting and Welding: by Ryan Saucierprasannaanjaneya sarmaNo ratings yet

- Burners and Torches: National Handtorch Type 3A BlowpipeDocument14 pagesBurners and Torches: National Handtorch Type 3A Blowpipefrenzy personNo ratings yet

- Plumbing Theory Notes CPB 019j 2Document90 pagesPlumbing Theory Notes CPB 019j 2aloycekisingu910No ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- Welding ChecklistDocument1 pageWelding Checklistsafety86No ratings yet

- To Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentDocument17 pagesTo Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentRaja GuruNo ratings yet

- Job HAzard Analysis Welding Operations MiftahDocument3 pagesJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- Pdqxdo: Extractor Hood 3BT730.P, 3BT736. Campana Extractora 3BT730.P, 3BT736. Exaustor 3BT730.P, 3BT736Document24 pagesPdqxdo: Extractor Hood 3BT730.P, 3BT736. Campana Extractora 3BT730.P, 3BT736. Exaustor 3BT730.P, 3BT736pessaryNo ratings yet

- Oxyacetylene Ppe and Safety PlanDocument3 pagesOxyacetylene Ppe and Safety PlanMems CamaraNo ratings yet

- Advanced Welding Electrofusion Best Practice 2018Document16 pagesAdvanced Welding Electrofusion Best Practice 2018Igor IvanovskiNo ratings yet

- Hot Work Safety GuideDocument7 pagesHot Work Safety Guideafifmahfud09No ratings yet

- Go5 PPPresentationDocument15 pagesGo5 PPPresentationLo Shun FatNo ratings yet

- Welding Workshop ManualDocument16 pagesWelding Workshop ManualMuhammad FarooqNo ratings yet

- TIG Welding SOPDocument2 pagesTIG Welding SOPGnanasekaran M (TECHNICAL TRAINING/TVSTS)100% (1)

- AAS Manual PG-990Document87 pagesAAS Manual PG-990Eyad Al-KhraisatNo ratings yet

- SV198B2-SPI30 SV198B2-SPI36 SV198Z2-SPI36 ManualDocument32 pagesSV198B2-SPI30 SV198B2-SPI36 SV198Z2-SPI36 ManualEuro-Kitchen, Inc.100% (2)

- Environment, Health and Safety Orientation TrainingDocument76 pagesEnvironment, Health and Safety Orientation TrainingIsmail ZamaaNo ratings yet

- Plumbing Theory NotesDocument133 pagesPlumbing Theory NotesAustine OtienoNo ratings yet

- 50x70-Poster SafetyChecklist LowresDocument1 page50x70-Poster SafetyChecklist LowresMuhd Khir RazaniNo ratings yet

- HSE - Safety Gas Welding & CuttingDocument16 pagesHSE - Safety Gas Welding & CuttingAnonymous dvrhf5No ratings yet

- Welding GAS ReportDocument11 pagesWelding GAS Report15 thn50% (2)

- Aa990 1Document88 pagesAa990 1manuel_andrade_35No ratings yet

- Plasma YH-400 English ManualDocument29 pagesPlasma YH-400 English ManualOLVERACNCMAQUINAS EMPRESANo ratings yet

- APC4028 ManualDocument32 pagesAPC4028 Manualvaibhavgitevaibhav_9No ratings yet

- Welding Safety HazardDocument32 pagesWelding Safety HazardjeonronbacurinNo ratings yet

- 810 5301 CDocument16 pages810 5301 Cwayout2dayNo ratings yet

- Cutting Torch SafetyDocument1 pageCutting Torch SafetyDocholosoNo ratings yet

- Lava Heat Italia - Illume Outdoor Light Post - Owners ManualDocument13 pagesLava Heat Italia - Illume Outdoor Light Post - Owners ManuallavaheatitaliaNo ratings yet

- Oxy Fuel Cutting Text Cover PageDocument14 pagesOxy Fuel Cutting Text Cover Pagekevin mundaNo ratings yet

- Cutting Torch SafetyDocument1 pageCutting Torch Safetyyasser awadallhNo ratings yet

- Standard UnitsDocument10 pagesStandard UnitsysilangitNo ratings yet

- Ocean Electronic Tabletop Heater Users Manual 496074Document14 pagesOcean Electronic Tabletop Heater Users Manual 496074LUIS FERNANDO PINONo ratings yet

- User's Manual: Item# 891340 Electric Pipe Cutting ThreaderDocument13 pagesUser's Manual: Item# 891340 Electric Pipe Cutting ThreaderRanj Japs0% (1)

- Department: P/W Mechanic Shop Area Shop Subject: Atlas Lathe Atlas Lathe WarningDocument2 pagesDepartment: P/W Mechanic Shop Area Shop Subject: Atlas Lathe Atlas Lathe WarningNStone79No ratings yet

- Mek TopicDocument5 pagesMek TopicdevmarineacademyNo ratings yet

- Tips On SafetyDocument14 pagesTips On SafetyMani GNo ratings yet

- Caswell, Inc - Plating Manual - Powder Coating Gun InstructionsDocument8 pagesCaswell, Inc - Plating Manual - Powder Coating Gun InstructionsClaudio SiqueiraNo ratings yet

- SafetyDocument7 pagesSafetykelvin mundiaNo ratings yet

- Manual Operacion Aas 100 SeriesDocument104 pagesManual Operacion Aas 100 Seriesdéborah_rosalesNo ratings yet

- Sure Bonder 9610 A StaplerDocument4 pagesSure Bonder 9610 A StaplergpedensNo ratings yet

- Refrigeration ToolsDocument6 pagesRefrigeration ToolsHenry DatangelNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- Em 2600 U ManualDocument76 pagesEm 2600 U ManualBogdan PleteaNo ratings yet

- SK4891PRODocument16 pagesSK4891PROjibooryNo ratings yet

- Welding and Oxy - Acetylene CuttingDocument10 pagesWelding and Oxy - Acetylene CuttingRaj MohapatraNo ratings yet

- PD05P XXX XXX B enDocument8 pagesPD05P XXX XXX B enkarthik_mohankumarNo ratings yet

- Manual Dremel VersatipDocument89 pagesManual Dremel Versatipkamikadze4747No ratings yet

- Woodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)From EverandWoodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)No ratings yet

- Automatic Oil Bath Air FilterDocument22 pagesAutomatic Oil Bath Air FilterLLNo ratings yet

- Lab Heat Experment 2Document5 pagesLab Heat Experment 2حسين عمريNo ratings yet

- 1234 Sasdfasdf 12341234Document20 pages1234 Sasdfasdf 12341234NysekNo ratings yet

- REV615 - CapacitorDocument56 pagesREV615 - CapacitorthiagodorockkNo ratings yet

- Everyday2 M8 S2 Student GrammarDocument2 pagesEveryday2 M8 S2 Student GrammarIvan MQNo ratings yet

- Bending Machine Centurion ModelDocument4 pagesBending Machine Centurion ModelbharathaninNo ratings yet

- Technovate Refrigeración y Aire AcondicionadoDocument34 pagesTechnovate Refrigeración y Aire Acondicionadojpg60No ratings yet

- Coop Conference Proceeding (21-22aug 2022)Document585 pagesCoop Conference Proceeding (21-22aug 2022)oliviahuda75No ratings yet

- ZILLENIALSDocument1 pageZILLENIALSakhilNo ratings yet

- Dream DeferredDocument10 pagesDream DeferredJayesh JainNo ratings yet

- Mindfulness in Primary School Children ADocument15 pagesMindfulness in Primary School Children AMuhammad Irfan AneesNo ratings yet

- Fm-npd-16 (Temp. Change Request Note)Document1 pageFm-npd-16 (Temp. Change Request Note)akash.vd.1603No ratings yet

- Margaret Sharon Worsham v. A.H. Robins Company, 734 F.2d 676, 11th Cir. (1984)Document21 pagesMargaret Sharon Worsham v. A.H. Robins Company, 734 F.2d 676, 11th Cir. (1984)Scribd Government DocsNo ratings yet

- Array in Java (F)Document4 pagesArray in Java (F)Brajesh RajawatNo ratings yet

- Akram M Zepeda S J 2015-2 PDFDocument17 pagesAkram M Zepeda S J 2015-2 PDFsheyla_liwanagNo ratings yet

- M MMMMMMMMMMDocument3 pagesM MMMMMMMMMMDavid R Paucara0% (1)

- Auditing Routine Checking and Test Checking: (PART-11) (UNIT-II) (PART-4)Document9 pagesAuditing Routine Checking and Test Checking: (PART-11) (UNIT-II) (PART-4)ŠhříÑůNo ratings yet

- Hartnell Governor Isochronous Speed Equations - Engineers EdgeDocument1 pageHartnell Governor Isochronous Speed Equations - Engineers Edgestallone21No ratings yet

- Analisis GC MS Fusel OilDocument23 pagesAnalisis GC MS Fusel OilKarenLissNo ratings yet

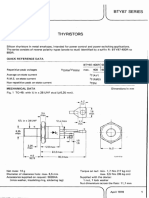

- BTY87 PhilipsDocument8 pagesBTY87 PhilipsmatheuzalexsanderNo ratings yet

- 03 - Leviticus PDFDocument162 pages03 - Leviticus PDFGuZsolNo ratings yet

- Market Analysis and Sales Development of AmulDocument19 pagesMarket Analysis and Sales Development of AmulPrabhakar ManoharanNo ratings yet

- TW - Datasheet Piercing RPGDocument2 pagesTW - Datasheet Piercing RPGarthur9mozoNo ratings yet

- ReadMe WinDocument4 pagesReadMe WinpundaiNo ratings yet

- Aide MemoireDocument3 pagesAide MemoireValerie Mae AbuyenNo ratings yet

- Heating Cable Selection GuideDocument4 pagesHeating Cable Selection Guidehassan3012No ratings yet

- Astron BrochureDocument9 pagesAstron BrochureNaga JothiNo ratings yet

- User Mannual For Student Training Services For RTTC - CTTC - DTTCDocument8 pagesUser Mannual For Student Training Services For RTTC - CTTC - DTTCVijay KumarNo ratings yet

- Latest GPS Tracker Quotation From PST Mary (2012!07!23)Document2 pagesLatest GPS Tracker Quotation From PST Mary (2012!07!23)Hitendra Nath BarmmaNo ratings yet

- Week 5 TaskDocument3 pagesWeek 5 TaskSonia Martinez RamosNo ratings yet