Professional Documents

Culture Documents

Wp06 Training Material

Uploaded by

Kurd SkorvskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wp06 Training Material

Uploaded by

Kurd SkorvskiCopyright:

Available Formats

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.

com

WP6 Gas Engine

Key point of maintenance and assembly

Aug 2018

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

1

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

CONTENTS

1. Maintenance

2. Key point of assembly

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

2

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Specification of fuel, lubricating oil and coolant

• Natural Gas: at least 70% methane by volume or have a heating

value of 950-1100 BTUs per standard cubic foot

Fuel • LPG: minimum of 90% propane, maximum of 5% propylene, and

maximum 5% of other gases

• Wellhead gas(emergency only, WP06 naturally aspirated only):

have a heating value of 700-2362 BTUs per standard cubic foot

• Recommends using a straight weight or multi-weight low ash

Oil content oil specifically formulated for Natural Gas Engines

• Specific weight depends on operating temperatures: (10W-30 : -

25 to 30℃), (15W-40 : -20 to 40℃), (20W-50 : -15 to 45℃)

• recommends using a 50/50 mixture of fully formulated Ethylene

Coolant Glycol or fully formulated Propylene Glycol coolant and distilled

water

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

3

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Maintenance schedule

Non-emergency

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

4

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Maintenance schedule

Emergency

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

5

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Daily check

1.Check engine oil level 3. Check operation conditions

❖Check hoses, clamps, pipes for loose

connection or leak.

❖Check connectors for loose connection.

❖Check harness for cut, short, corrosion

or abrasions.

❖Check belt for loose or fraying.

❖Assure battery voltage is ≥12v each.

2.Check coolant level

4. Check oil pressure

Oil Pressure

Idle PSI KPI

Min 19 120

Rated Speed

Min 55 300

Max 84 600

Caution : Never remove radiator

or top tank cap when coolant is

hot!

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

6

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Replace lubricating oil and oil filter element

Engine model Oil refill volume Material details

WP06 25L (6.6 Gal) Recheck dipstick 1 filter element and 1 O-ring

Replace oil filter element:

1.Drain oil completely.

2.Remove oil filter cover.

3.Remove oil filter and O-ring.

4.Install new filter and O-ring (apply a thin coat of

motor oil to o- ring before installing)

5.Install filter cover and tighten to 40N.m.

6.Fill new oil and run engine for 5 minutes, check

for leaks.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

7

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

1.Maintenance—Adjust valve lash

TDC mark

Valve lash (cold)

intake 0.2mm

Exhaust(WP6GTA) 0.4mm

1.The first piston is on the “TDC” of compression stroke

Fan #1@TDC INT EXH INT EXH INT EXH Flywheel

side (COMPRESSION STROKE) 1 1 2 3 4 5 side

2.The number six piston is on the “TDC” of compression stroke

Fan EXH INT EXH INT INT EXH #6@TDC Flywheel

side 2 3 4 5 6 6 (COMPRESSION STROKE) side

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

8

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

CONTENTS

1. Maintenance

2. Key point of assembly

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

9

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Gear timing

Rotate the crankshaft until 0 tick on timing gear is closest to camshaft, install

camshaft timing gear, make sure 0 tick of timing gear is engaged with 0 tick of

crankshaft gear.

0 tick of camshaft

timing gear should

be engaged with 0

tick of crankshaft

gear.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

10

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Signal generator

1. Rotate the crankshaft to “OT” mark, make sure the first piston is on the top

dead center of compression stroke.

2. Install the signal generator and adjust angle of the fluted disc until its TDC mark

points at the center of the phase sensor and the predetermined ignition angle is

reached.

3. Tighten the locknut (80~100N·m) on the signal generator fluted disc.

Note: the correct value of the gap between the fluted disc and sensor is 0.8~1.5mm

1th piston@ TDC of Fluted disc TDC mark points at the

compression stroke center of phase sensor.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

11

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Connecting rod and piston

Key points:

1.The connecting rod oblique split and piston cooling oil gallery inlet should be in

the same direction.

2.The connecting rod oblique split and oil cooler should be in the same direction.

3.The torque of connecting rod bolt is :30N·m + (60±4°), (Reach 85 to

135N·m at the same time)

NOTE: 1.The connecting rod bolts can’t be re-used.

2. The opening of piston rings should not overlap.

Adjust the angle of piston

Oil inlet and the rings to make sure the Face to oil cooler

oblique split should be opening not overlap.

in same direction

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

12

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Main bearing bolt

Main bearing bolts:

70N·m + (90±4°), required sequence of tightening as below

Note: the oil groove on the thrust plate should face to crankshaft.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

13

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Cylinder head bolts

Cylinder head bolts:

30N·m +2x (120±4°), required sequence of tightening as below, (Reach

230 to 300N.m at the same time)

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

14

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

2. Key point of assembly—Flywheel housing

Flywheel housing bolts:

M10: 80~85N·m, follow the sequence of arrow to tighten

M12: 140~145N·m, required sequence of tightening as below (1-2-3-4-

5-6)

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

15

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

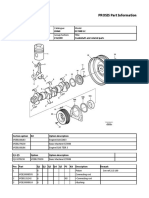

2. Key point of assembly—

Engine Fastener Torque Specifications

Tightening torque (N·m) + further turned Permissible times

Fastener’s Name Bolt Specification

angle (°) of repeat used

70N·m + (90±4°), required sequence of

Main bearing M14-10.9 2

tightening

Connecting rod 30N·m + (60±4°), (Reach 85 to 135N·m at

M12x1.5-12.9 0

(machine cut) the same time)

Connecting rod 30N·m + (120±5°), (Reach 67 to 107N·m at

M10 0

(fracture split) the same time)

30N·m +2x (120±4°), required sequence of

Cylinder head M14-12.9 tightening (Reach 230 to 300N.m at the same 3

time)

Flywheel M16x1.5 290±5N·m 2

Camshaft gear M8-12.9 55N.m+5N·m 2

Exhaust manifold M10 65~80N·m 2

Intake manifold M10 23N.m -

Crankshaft pulley M16-12.9 300~310N·m -

Damper M10-10.9 65~70N·m -

Rocker seat M10-8.8 40~45N·m -

Spark-plug M14x1.25 (25 to 28) N·m -

UEGO sensor M18x1.5 40N.m±5 N·m -

Water temperature

M14x1.5 25N.m±5 N·m -

sensor

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

16

Document Courtesy of Fly Parts Guy Co. - www.FlyPartsGuy.com

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

17

You might also like

- Motor Mitsubishi 2.6Document55 pagesMotor Mitsubishi 2.6maqvere100% (1)

- Especificaciones de Servicios Kia G6da g6db PDFDocument180 pagesEspecificaciones de Servicios Kia G6da g6db PDFOliver Eduardo100% (1)

- Me370sti 6tc 1989 OsaluetteloDocument78 pagesMe370sti 6tc 1989 OsaluetteloMake100% (1)

- Maintenance Schedule TCG2020KDocument8 pagesMaintenance Schedule TCG2020KHendri Bowo100% (2)

- Manual Chipeadora 18XP (059-119)Document61 pagesManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Ecom Driver Installation ManualDocument11 pagesEcom Driver Installation ManualKurd SkorvskiNo ratings yet

- JP Sauer Manual WP65LDocument114 pagesJP Sauer Manual WP65LMohamed MusaNo ratings yet

- Zupco Critical Spares ListDocument12 pagesZupco Critical Spares ListMakhosini Mpofu100% (1)

- 13ta - TrainingDocument17 pages13ta - TrainingKurd SkorvskiNo ratings yet

- 10na - Training - Flypartsguy - 8.2018Document18 pages10na - Training - Flypartsguy - 8.2018Kurd SkorvskiNo ratings yet

- Wp06Gna Installation and Application ManualDocument29 pagesWp06Gna Installation and Application ManualKurd SkorvskiNo ratings yet

- Wp13Gta Installation and Application ManualDocument25 pagesWp13Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- Wp06Gta Installation and Application ManualDocument25 pagesWp06Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- Wp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGDocument26 pagesWp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGKurd SkorvskiNo ratings yet

- Wp10Gta Installation and Application ManualDocument27 pagesWp10Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- Boat ManualDocument15 pagesBoat ManualBrandon PriceNo ratings yet

- Guia 695Document16 pagesGuia 695Elikaty Servicios AereosNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP13Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP13Kurd SkorvskiNo ratings yet

- Pilot Operational Procedures: Stratford On Avon Gliding ClubDocument16 pagesPilot Operational Procedures: Stratford On Avon Gliding ClubVlad TomescuNo ratings yet

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Garmin 2.1 Liter High Performance Pump Kit Owners ManualDocument8 pagesGarmin 2.1 Liter High Performance Pump Kit Owners ManualDannerNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Parts Manual: Gas Engine Models: WP10GTA, Bi-FuelDocument112 pagesParts Manual: Gas Engine Models: WP10GTA, Bi-FuelKurd Skorvski100% (1)

- Engine Testing and Rating: Standardized Gasoline TestsDocument32 pagesEngine Testing and Rating: Standardized Gasoline TestsJahmia CoralieNo ratings yet

- 03-01 Boltec S - Daily ChecksDocument30 pages03-01 Boltec S - Daily ChecksALVARO ANTONIO SILVA DELGADONo ratings yet

- Daily Maintenance Checklist for EPT20-15/18EHJ Lift TruckDocument2 pagesDaily Maintenance Checklist for EPT20-15/18EHJ Lift TruckFabricio ArteagaNo ratings yet

- SIPOM Threshing Station OptimizationDocument9 pagesSIPOM Threshing Station Optimizationcalvin tsenNo ratings yet

- X Motion 125Document219 pagesX Motion 125Vicente Torres LopezNo ratings yet

- Kia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aDocument48 pagesKia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aAmelia Sofía Sanhueza GrandónNo ratings yet

- 3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Document3 pages3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Lacatusu MirceaNo ratings yet

- Tmib0320en UsDocument1 pageTmib0320en UsBart JohnNo ratings yet

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- 503 UlDocument39 pages503 UlSURZURNo ratings yet

- Daily Report 09feb2024Document44 pagesDaily Report 09feb2024sandeep palNo ratings yet

- Parts List Operating and Service Manual: LegendDocument65 pagesParts List Operating and Service Manual: LegendAntonio CastroNo ratings yet

- Parts List Operating and Service Manual: LegendDocument49 pagesParts List Operating and Service Manual: LegendPlaneador MantenimientoNo ratings yet

- Saint Gobain Furon HPVM Manual 2 Way QT ValveDocument2 pagesSaint Gobain Furon HPVM Manual 2 Way QT ValveXavierNo ratings yet

- Super PTI' Guidelines For Very Sensitive Cargo Container: Reefer ProceduresDocument4 pagesSuper PTI' Guidelines For Very Sensitive Cargo Container: Reefer ProceduresSamo SpontanostNo ratings yet

- XS113E操作保养培训-enDocument85 pagesXS113E操作保养培训-enalex.alatorre.gortariwonNo ratings yet

- 05 Dunlop Unique FeaturesDocument31 pages05 Dunlop Unique FeaturesFikret YenenNo ratings yet

- مارك 6Document96 pagesمارك 6Mohamed Sheba92% (13)

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Volution MicroDocument27 pagesVolution MicroWiki BandachNo ratings yet

- PolyClad Manual, 200 SeriesDocument69 pagesPolyClad Manual, 200 SeriesDave ManchesterNo ratings yet

- Rolls-Royce': Record of Temporary RevisionsDocument5 pagesRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNo ratings yet

- Balancing MachineDocument2 pagesBalancing MachineZulfiqar AliNo ratings yet

- Auto Engine Cooling System RepairDocument1 pageAuto Engine Cooling System RepairBrandon AnketellNo ratings yet

- Peugeot 607 Owners Manual 2005Document206 pagesPeugeot 607 Owners Manual 2005AndreiNo ratings yet

- Parts List Operating and Service Manual: LegendDocument57 pagesParts List Operating and Service Manual: LegendAldo AlvarezNo ratings yet

- PT6A Reference GuideDocument34 pagesPT6A Reference Guide彭树超100% (1)

- Operation and Maintenance Manual: Gas Engine Model: WP10Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP10Kurd SkorvskiNo ratings yet

- Lubrizol 760C (Atf C4) PDSDocument3 pagesLubrizol 760C (Atf C4) PDSPranit More Arabian Petroleum LimitedNo ratings yet

- Calavar Condor 446q8 Operators Maintenance and Part ManualDocument20 pagesCalavar Condor 446q8 Operators Maintenance and Part ManualMichelle100% (55)

- AFMS - GAMIjectors Rev IRDocument4 pagesAFMS - GAMIjectors Rev IRMatías SignorettaNo ratings yet

- Stage - 3 Steam Generator Operating ProcedureDocument22 pagesStage - 3 Steam Generator Operating Procedurerishikesh chandanNo ratings yet

- Effective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Document3 pagesEffective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Naresh Kumar PrajapatNo ratings yet

- Om. TS 142Document40 pagesOm. TS 142Frank ColaciuriNo ratings yet

- Bucks Engines 2007 GM Powertrain Owners ManualDocument11 pagesBucks Engines 2007 GM Powertrain Owners ManualJuan PabloNo ratings yet

- Oil Filter Used Products Air Filter and Passenger Compartment FilterDocument1 pageOil Filter Used Products Air Filter and Passenger Compartment FilterBukky NwachukwuNo ratings yet

- 999r Instruction ManualDocument16 pages999r Instruction Manualdesmo1973 desmoNo ratings yet

- Inspection Form PM0007 Grader DailyDocument1 pageInspection Form PM0007 Grader DailyMalik RizwanNo ratings yet

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Hydro Crane Checlist PDFDocument1 pageHydro Crane Checlist PDFFandy AgitaNo ratings yet

- Weichai Murphy Control Panel Combined Operation Manual - 20200103Document65 pagesWeichai Murphy Control Panel Combined Operation Manual - 20200103Kurd SkorvskiNo ratings yet

- Wac Parts Quote FormDocument1 pageWac Parts Quote FormKurd SkorvskiNo ratings yet

- Wac Warranty Claim Form - Flypartsguy - Com - 5.2019Document1 pageWac Warranty Claim Form - Flypartsguy - Com - 5.2019Kurd SkorvskiNo ratings yet

- 6ta - Parts - Flypartsguy - Com - 3.2019Document98 pages6ta - Parts - Flypartsguy - Com - 3.2019Kurd SkorvskiNo ratings yet

- All - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Document183 pagesAll - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- Mpc-10 & Tec-10 Modbus Map 2.28.2019Document6 pagesMpc-10 & Tec-10 Modbus Map 2.28.2019Kurd SkorvskiNo ratings yet

- Murphy Configuration and Installation ManualDocument10 pagesMurphy Configuration and Installation ManualKurd SkorvskiNo ratings yet

- Wac Limited Warranty - Flypartsguy - Com - 5.2019Document15 pagesWac Limited Warranty - Flypartsguy - Com - 5.2019Kurd SkorvskiNo ratings yet

- Mpc-10 Installation Manual - 00-02-0938Document15 pagesMpc-10 Installation Manual - 00-02-0938Kurd SkorvskiNo ratings yet

- Mpc-10 & Tec-10 Setup For A Mechanical EngineDocument1 pageMpc-10 & Tec-10 Setup For A Mechanical EngineKurd SkorvskiNo ratings yet

- Tec-10 Installation Manual 20180223Document12 pagesTec-10 Installation Manual 20180223Kurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP13GTA, Bi-FuelDocument110 pagesParts Manual: Gas Engine Models: WP13GTA, Bi-FuelKurd Skorvski100% (2)

- 00-02-0181.PDF Magnetic Pick UpDocument2 pages00-02-0181.PDF Magnetic Pick UpOruteNo ratings yet

- Wp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoDocument8 pagesWp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP10GTA, Bi-FuelDocument112 pagesParts Manual: Gas Engine Models: WP10GTA, Bi-FuelKurd Skorvski100% (1)

- 10na - Wiring DiagramDocument1 page10na - Wiring DiagramKurd Skorvski100% (1)

- 13ta - Brochure - FlypWeichai America - Artsguy - Com - Mar 2019Document5 pages13ta - Brochure - FlypWeichai America - Artsguy - Com - Mar 2019Kurd SkorvskiNo ratings yet

- 13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Document84 pages13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Kurd SkorvskiNo ratings yet

- 13ta - Outline Drawing - Flypartsguy - Com - 1.2017Document2 pages13ta - Outline Drawing - Flypartsguy - Com - 1.2017Kurd SkorvskiNo ratings yet

- 10ta - Data Sheet - Flypartsguy - Com - 8.2018Document8 pages10ta - Data Sheet - Flypartsguy - Com - 8.2018Kurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP13Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP13Kurd SkorvskiNo ratings yet

- Document Courtesy of Fly Parts Guy CoDocument2 pagesDocument Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- Wp10Gta Installation and Application ManualDocument27 pagesWp10Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- 10na - Wiring DiagramDocument1 page10na - Wiring DiagramKurd Skorvski100% (1)

- 10ta - Brochure - Flypartsguy - Com - 8.2019Document5 pages10ta - Brochure - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- Assembly & Disassembly Manual: Gas Engine Model: WP10GTADocument111 pagesAssembly & Disassembly Manual: Gas Engine Model: WP10GTAKurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP10Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP10Kurd SkorvskiNo ratings yet

- Kyko Fan Stirling JDW CompletDocument3 pagesKyko Fan Stirling JDW CompletNam Hoang50% (2)

- 911 Turbo, GT2, 1975 - 1977Document349 pages911 Turbo, GT2, 1975 - 1977JZM GulfNo ratings yet

- Dokumen - Tips - New Holland t7550 Tractor Service Repair Manual 1587857454Document34 pagesDokumen - Tips - New Holland t7550 Tractor Service Repair Manual 1587857454Johnny Garcia100% (2)

- Dynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLABDocument5 pagesDynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLAByangee1201No ratings yet

- Stationary Air Compressors Compresseur D'air Stationnaire Compresores de Aire EstacionariosDocument8 pagesStationary Air Compressors Compresseur D'air Stationnaire Compresores de Aire EstacionariosA delca-No ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 104M02-0002-F1Document23 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 104M02-0002-F1Promotor FumimotorNo ratings yet

- Graco 395st 455st PumpDocument8 pagesGraco 395st 455st PumpTaylor ButlerNo ratings yet

- Abi Jdnewgen 2017 WebrdDocument36 pagesAbi Jdnewgen 2017 WebrdhuskerchampsNo ratings yet

- Kinematics of Machinery NotesDocument25 pagesKinematics of Machinery Notesnishanth87No ratings yet

- Maintenance Schedules / Maintenance PartsDocument29 pagesMaintenance Schedules / Maintenance PartsRiki Akbar100% (1)

- Mm-Io-360-N1a - 3-31-2016Document207 pagesMm-Io-360-N1a - 3-31-2016Shirley CruzNo ratings yet

- KTM Spare Parts Manual Engine 2018 enDocument28 pagesKTM Spare Parts Manual Engine 2018 enCristopher Exequiel Toro NuñezNo ratings yet

- Crankshaft and Related PartsDocument3 pagesCrankshaft and Related PartsPower MobileNo ratings yet

- Thermal Engineering IDocument50 pagesThermal Engineering IanilNo ratings yet

- Spare Parts Catalogue: Update Date 14/09/2016Document34 pagesSpare Parts Catalogue: Update Date 14/09/2016Gerencia General Services100% (1)

- Full Download Ebook PDF Managing Organizational Behavior What Great Managers Know and Do 2Nd Edition Ebook PDF Docx Kindle Full ChapterDocument23 pagesFull Download Ebook PDF Managing Organizational Behavior What Great Managers Know and Do 2Nd Edition Ebook PDF Docx Kindle Full Chapteraudrey.benbow405100% (36)

- Man Engine Shop Manual - D0836 LF - LFL 40-41-44Document394 pagesMan Engine Shop Manual - D0836 LF - LFL 40-41-44kingtiger.bkNo ratings yet

- D4B8048BC6A-4-Cylinder Injection Engine (1 4 L Direct Injection Engine Turbocharger and Supercharger)Document245 pagesD4B8048BC6A-4-Cylinder Injection Engine (1 4 L Direct Injection Engine Turbocharger and Supercharger)Carlos Garcia Godoy100% (1)

- YamahaPartsG9 AGDocument49 pagesYamahaPartsG9 AGroleskyNo ratings yet

- 1268Document20 pages1268ChiragNo ratings yet

- PC PC10014 Nov12 enDocument748 pagesPC PC10014 Nov12 enJose nildo lobato Mendes MendesNo ratings yet

- Wartsila O E W 38 TRDocument12 pagesWartsila O E W 38 TRbunguiaoNo ratings yet

- Connecting Rod Bearings, Replace (All)Document5 pagesConnecting Rod Bearings, Replace (All)Hamilton MirandaNo ratings yet

- Quincy QR-25 Series Model 340: Parts Manual Record of Change 106Document31 pagesQuincy QR-25 Series Model 340: Parts Manual Record of Change 106Ronny OrdazNo ratings yet