Professional Documents

Culture Documents

Dupont Teflon Ptfe 3859

Dupont Teflon Ptfe 3859

Uploaded by

hermioneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dupont Teflon Ptfe 3859

Dupont Teflon Ptfe 3859

Uploaded by

hermioneCopyright:

Available Formats

DuPont™ Teflon PTFE ®

TE-3859

Aqueous Fluoropolymers

made with

Echelon™ Dispersion Technology

Product Information

Aqueous Dispersion

Brand

When properly processed, the PTFE resin in Teflon® PTFE

Teflon® is a registered trademark of DuPont for its brand of TE-3859 exhibits the superior properties typical of the

fluoropolymer resins, which can only be licensed by DuPont fluoropolymer resins: retention of properties after service at

for use in approved applications. Customers who wish to use 260°C (500°F), useful properties at –240°C (–400°F), chemi-

the Teflon® trademark in connection with DuPont products cal inertness to nearly all industrial chemicals and solvents,

under license from DuPont should contact (800) 262-2745. and low friction and antistick surfaces. Dielectric properties

Without a license, customers may not identify their product are outstanding and stable with frequency and temperature.

as containing Teflon®, but may refer to the resin as PTFE Refer to Table 1 for typical property data.

fluoropolymer dispersion TE-3859.

Typical End Products

Description

Teflon® PTFE TE-3859 is used for coated glass fabric for

DuPont™ Teflon® PTFE TE-3859 fluoropolymer resin is high-performance industrial or food conveyor belting and non-

a negatively charged, hydrophobic colloid, containing adhesive separator sheets for laminating or press blankets

approximately 60% (by total weight) of 0.05 to 0.5 µm requiring high-quality surface finish; electrical insulation for

polytetrafluoroethylene (PTFE) resin particles suspended in wire, printed circuit boards, and rotating equipment; cast film

water. Seen as a milky white liquid, it also contains approxi- for capacitors or chemical barriers; to impregnate packing

mately 6% (by weight of PTFE) of a nonionic wetting agent made from braided fibers for severe chemical and thermal

and stabilizer. Viscosity at room temperature is approximately service; nonadhesive separator sheets for laminating, and

20 cP. Nominal pH is 10. press blankets and gaskets, and surface coatings for other

substrates.

Compared with other grades of PTFE dispersions, Teflon®

PTFE TE-3859 is especially formulated to provide void-free

coatings with enhanced surface smoothness and gloss. It

imparts many of the unique properties of PTFE resin to

porous structures.

FDA Compliance Safety Precautions

Properly processed products (sintered at high temperatures WARNING!

common to the industry) made from Teflon® PTFE TE-3859 VAPORS CAN BE LIBERATED THAT MAY BE HAZARD-

resin can qualify for use in contact with food in compliance OUS IF INHALED.

with FDA Regulation 21 CFR 177.1550. Products made from

unsintered dispersion do not comply. Before using Teflon® PTFE TE-3859, read the Material Safety

Data Sheet and the detailed information in the “Guide to the

Safe Handling of Fluoropolymer Resins,” latest edition, pub-

Processing lished by the Fluoropolymers Division of The Society of the

PTFE resin does not respond to solvent or melt processes. A Plastics Industry—available from DuPont.

dispersion of PTFE particles provides an alternate method for

making coated or impregnated products. Open and use containers only in well-ventilated areas using

local exhaust ventilation (LEV). Vapors and fumes liberated

Conventional dip or flow techniques can be used for coating during hot processing, or from smoking tobacco or cigarettes

or impregnating other products with Teflon® PTFE TE-3859. contaminated with Teflon® PTFE TE-3859 fluoropolymer

The resin particles can be consolidated by heat into a coher- resin, may cause flu-like symptoms (chills, fever, sore throat)

ent matrix or coating or left as particles to influence the that may not occur until several hours after exposure and

properties of a finished product. pass within about 24 hours. Vapors and fumes liberated dur-

ing hot processing should be exhausted completely from the

A continuous PTFE resin coating on woven fabrics can be

work area; contamination of tobacco with polymers should be

made by dip coating. Successive passes must be used to

avoided.

build up thickness slowly and without cracks. Teflon® PTFE

TE-3859 fluoropolymer provides good rewetting on each Mixtures with some finely divided metals, such as magne-

pass and void-free buildup suitable for more demanding elec- sium or aluminum, can be flammable or explosive under

trical and chemical service applications. Each coating layer some conditions.

is usually dried to remove water (typically at 120°C [250°F]),

baked to remove the wetting agent (typically at 290°C Teflon® PTFE TE-3859 contains additives in the aqueous

[554°F]), sometimes calendered, and finally heated above the phase that are irritants. In case of skin contact, flush with

crystalline melting point of the resin particles (approximately water immediately. In case of eye contact, flush with water

337°C [639°F]). Glass, PTFE, Nomex ® aramid fiber, Kevlar ® immediately and get medical help.

aramid fiber, or other high-temperature resistant fibers must

be used.

Storage and Handling

Products utilizing entrained PTFE resin particles only for their The dispersion particles in Teflon® PTFE TE-3859 will settle

lubricating or hydrophobic properties are dried and baked, but on prolonged standing or on heating above 66°C (150°F).

not heated above the crystalline melting point of the particles. They usually can be redispersed by mild agitation. Drums

For example, rope-like products, such as shaft packings, can may be rolled or the product stirred gently just prior to use.

be made from braided fabrics in a variety of cross sections. The dispersion must be protected from freezing, which will

The dispersion wets internal surfaces and promotes penetra- cause irreversible settling.

tion of the extremely small particles. The unmelted particles

Ammonium hydroxide is used by DuPont to set pH to 10

are sheared and retained as an impregnant, even when

at the time of shipment. High ambient temperatures can

compressed in service and exposed to steam or chemicals.

deplete the ammonia level and reduce the pH. Declining pH

Unmelted particles also can improve flexibility and flex life.

eventually favors bacterial growth, which causes odor and

High-temperature resistant fibers are not necessarily required

scum. The pH should be measured and maintained between

in these applications.

9.5 and 10.

Other solid or liquid ingredients can be added to Teflon® PTFE

TE-3859 to provide specific processing or finished product

behavior.

Both very high and very low temperatures may be detrimen- Packaging

tal. Dispersions must not be allowed to freeze. The opti- Teflon® PTFE TE-3859 is packaged in 19- and 114-L

mum storage temperature range is 7–24°C (45–75°F), with (5- and 30-gal) nonreturnable drums and 1037-L (275-gal)

temperatures low in the range preferred. Storage at 7–32°C recyclable containers.

(45–90°F) is acceptable within nominal shelf life for standard

dispersions. If dispersions are to be stored for extended

periods beyond their nominal shelf life, low-temperature stor- Freight Classification

age is especially desirable because the particles are harder Teflon® PTFE TE-3859, when shipped by rail or express,

at lower temperatures and, therefore, are less likely to stick is classified “Plastics, Synthetic, Liquid, NOIBN.” Resin

together as they settle. shipped by truck is classified “Plastics, Materials, Liquid,

NOI.”

High-speed stirring, pumping, or any other violent agitation

must be avoided to minimize sheared particles or coagulation

and to minimize foaming. Ideally, the dispersion should be

conveyed by gravity from storage to processing stations.

Storage and handling areas should be clean. Keep disper-

sion drums closed and clean to avoid both contamination and

coagulation by drying at the liquid surface. High processing

temperatures will cause even very small foreign particles to

become visible or to make defects in finished products. Good

housekeeping and careful handling are essential.

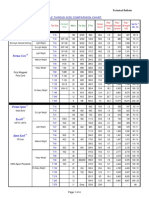

Table 1

Typical Property Data for DuPont™ Teflon® PTFE Fluoropolymer Resin Dispersion Grade TE-3859

ASTM Nominal

Property Standard Unit Value

Percent PTFE Resin Solids D4441 % 60

Weight of PTFE Resin Solids D4441 kg/m3 900

(lb/gal) (7.5)

Specific Gravity of Dispersion D4441 — 1.5

Average Dispersion Particle Size — µm 0.22

pH (min.) of Dispersion E70 — 9.5

Viscosity of Dispersion (at 25°C [77°F]) D2196 cP 20

(Pa sec)

•

(0.02)

Melting, Peak Temperature

Initial D1457 °C (°F) 337 (639)

Second D1457 °C (°F) 327 (621)

Notes: Teflon® PTFE TE-3859 is ASTM D4441-98, II 6B.

Typical properties are not suitable for specification purposes.

For more information call (302) 479-7731

www.teflon.com

DuPont Fluoroproducts

P.O. Box 80713

Wilmington, DE 19880-0713

Europe Asia Pacific South America

DuPont de Nemours Int’l SA DuPont China, Limited DuPont do Brasil S/A

DuPont Fluoroproducts 26/F., Tower 6, The Gateway Fluoropolymers

2, chemin du Pavillon 9 Canton Road, Tsimshatsui Alameda Itapecuru, 506

P.O. Box 50 Kowloon, Hong Kong 06454-080 - Alphaville

CH-1218 Le Grand-Saconnex (852) 27341948 P.O. Box 263

Geneva, Switzerland Tim-S.T.Leung@hkg.dupont.com Barueri, Sao Paulo, Brazil

+44 22 717 5111 0800-171715

Fax: +41 22 717 5411 Canada Produtos.Brazil@bra.dupont.com

DuPont Canada, Inc.

Japan DuPont Fluoroproducts

DuPont Mitsui Fluorochemicals P.O. Box 2200, Streetsville

Co., Ltd. 7070 Mississauga Road

Chiyoda Honsha Building Mississauga, Ontario, Canada

5–18, Sarugaku-cho 1-chome L5M 2H3

Chiyoda-ku, Tokyo 101 Japan (800) 207-0756

81-3-5281-5872

Copyright © 2006 DuPont or its affiliates. All rights reserved. The DuPont Oval Logo, DuPont™, The miracles of science™,

Nomex®, Kevlar®, and Teflon®, are registered trademarks or trademarks of E. I. du Pont de Nemours and Company or its affiliates.

NO PART OF THIS MATERIAL MAY BE REPRODUCED, STORED IN A RETRIEVAL SYSTEM OR TRANSMITTED IN ANY FORM OR

BY ANY MEANS ELECTRONIC, MECHANICAL, PHOTOCOPYING, RECORDING OR OTHERWISE WITHOUT THE PRIOR WRITTEN

PERMISSION OF DUPONT.

The information set forth herein is furnished free of charge and is based on technical data that DuPont believes to be reliable. It is

intended for use by persons having technical skill, at their own discretion and risk. The handling precaution information contained

herein is given with the understanding that those using it will satisfy themselves that their particular conditions of use present no

health or safety hazards. Because conditions of product use are outside our control, we make no warranties, express or implied,

and assume no liability in connection with any use of this information. As with any material, evaluation of any compound under

end-use conditions prior to specification is essential. Nothing herein is to be taken as a license to operate under or a recommen-

dation to infringe any patents.

CAUTION: Do not use in medical applications involving permanent implantation in the human body or contact with internal body

fluids or tissues. For other medical applications, see “DuPont Medical Caution Statement,” H-50102.

(6/06) RWJ333 Printed in U.S.A.

Reorder No.: K-10918

You might also like

- Assignment - Proposal Writting Assignment July 20Document2 pagesAssignment - Proposal Writting Assignment July 20Digital Era0% (1)

- Hse Plan Asl PDFDocument87 pagesHse Plan Asl PDFBudi Prasetyo100% (1)

- RHOPLEX™ MC-1834P: Cement Mortar ModifierDocument6 pagesRHOPLEX™ MC-1834P: Cement Mortar Modifierhemantrulz100% (1)

- Vehicular AccidentDocument9 pagesVehicular AccidentCharm TanyaNo ratings yet

- Dupont Teflon: Teflon S Coatings 958-203 and 958-207Document4 pagesDupont Teflon: Teflon S Coatings 958-203 and 958-207Abdul RafiiNo ratings yet

- Xylan 80-510-G3196 Pfa BeDocument2 pagesXylan 80-510-G3196 Pfa BeSYED MAZHARNo ratings yet

- 1058-E2787a Black2Document2 pages1058-E2787a Black2christianNo ratings yet

- TDS - TROYKYD D209W (Micro Foam Highgloss Silicone)Document3 pagesTDS - TROYKYD D209W (Micro Foam Highgloss Silicone)Yến HoàngNo ratings yet

- Guide To Whitford Industrial Products: 9th Edition - 2010Document42 pagesGuide To Whitford Industrial Products: 9th Edition - 2010cristianoluzNo ratings yet

- Cement, Concrete & Mortar: Product Characteristics Brand NameDocument2 pagesCement, Concrete & Mortar: Product Characteristics Brand NameAliaksandr PrybauNo ratings yet

- Product Information Sheet CE-1618, Methyl Palmitate/ OleateDocument2 pagesProduct Information Sheet CE-1618, Methyl Palmitate/ OleateYassine LemsyehNo ratings yet

- TDS - KemFoamX 2550 - ENDocument2 pagesTDS - KemFoamX 2550 - ENSteven CoultonNo ratings yet

- Adhesives Folder RuetgersDocument16 pagesAdhesives Folder RuetgersPROYECTOS SQNo ratings yet

- Guar Gum PricesDocument5 pagesGuar Gum PricesGuar Gum PricesNo ratings yet

- Data SheetDocument8 pagesData SheettomychalilNo ratings yet

- VN110 Cross-Linked PVA GLUEDocument2 pagesVN110 Cross-Linked PVA GLUEDgek LondonNo ratings yet

- Pidilite Industries Limited: Technical Data Sheet Fevicol HeatxDocument2 pagesPidilite Industries Limited: Technical Data Sheet Fevicol HeatxParas AgrawalNo ratings yet

- Rheofibre - BasfDocument2 pagesRheofibre - BasftheshadowknightNo ratings yet

- CoatOSil 1220 SILICADocument4 pagesCoatOSil 1220 SILICAzulemaNo ratings yet

- Inakyd 3234 B-X-70Document1 pageInakyd 3234 B-X-70roybombomNo ratings yet

- Falamine Plus Pages LQDocument1 pageFalamine Plus Pages LQSatish ChipkarNo ratings yet

- Shell SolDocument2 pagesShell Solpetrofacumar100% (1)

- Byk-066 N enDocument2 pagesByk-066 N enΒασίληςΜουρατίδηςNo ratings yet

- Brochure LatamDocument2 pagesBrochure LatamShelby_CobraxNo ratings yet

- Oil and Gas Brochure - US - InddDocument8 pagesOil and Gas Brochure - US - InddRomán M Martín del CNo ratings yet

- S2300 PaintDocument40 pagesS2300 PaintArun KastwarNo ratings yet

- Raghucarbolinepresentations22122011 PDFDocument101 pagesRaghucarbolinepresentations22122011 PDFTanmay GorNo ratings yet

- Brochure Resins Polyols and Aspartics Polyols For Reaction With Polyisocyanates 14-06-2011 EDocument28 pagesBrochure Resins Polyols and Aspartics Polyols For Reaction With Polyisocyanates 14-06-2011 EΣταύρος Βουγιουκλίδης100% (2)

- Datasheet MONARCH 430Document2 pagesDatasheet MONARCH 430Nicoleta HomescuNo ratings yet

- DECORATIVE CEMENT COLOR WASHINGpptDocument10 pagesDECORATIVE CEMENT COLOR WASHINGpptKhalida ParveenNo ratings yet

- TI Acronal S 400 PDFDocument1 pageTI Acronal S 400 PDFAPEX SONNo ratings yet

- Technical Info Librel RMX 26Document4 pagesTechnical Info Librel RMX 26Rijalul AuthonNo ratings yet

- Organo ClayDocument4 pagesOrgano ClayRaoni Batista Dos AnjosNo ratings yet

- Hostage LCLDocument2 pagesHostage LCLSampathNo ratings yet

- Performance Chemicals For Enhanced Oil RecoveryDocument6 pagesPerformance Chemicals For Enhanced Oil RecoveryMiguel MartinezNo ratings yet

- Weberfix PU - DatasheetDocument7 pagesWeberfix PU - DatasheetAnonymous PkvM83sNo ratings yet

- Lubrizol Engineered Polymers Injection Molding GuideDocument12 pagesLubrizol Engineered Polymers Injection Molding GuideOmer SenNo ratings yet

- Byk 4510Document2 pagesByk 4510Juan Angel DechimaNo ratings yet

- Aradur 140: Advanced MaterialsDocument2 pagesAradur 140: Advanced MaterialsBinod SharmaNo ratings yet

- M-P-A 1078-X: Anti-Settling Additive For Solvent-Borne SystemsDocument2 pagesM-P-A 1078-X: Anti-Settling Additive For Solvent-Borne SystemsさいとはちこNo ratings yet

- TDS - Masterseal 525Document2 pagesTDS - Masterseal 525Venkata RaoNo ratings yet

- Omyacarb 1TDocument1 pageOmyacarb 1TArifin HNNo ratings yet

- Tds Uk 905tx (Urethane Thinner A) v1Document1 pageTds Uk 905tx (Urethane Thinner A) v1HAFIDZ100% (1)

- Technical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Document1 pageTechnical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Fadi Magdy0% (1)

- Hydroxyl Value of Acrylic Resins: Sr. No. Legacy No. Description Material NoDocument2 pagesHydroxyl Value of Acrylic Resins: Sr. No. Legacy No. Description Material NoKrishna Yeole100% (1)

- DYNAPOL BADGE Free AlternativsDocument2 pagesDYNAPOL BADGE Free AlternativsAlptekinNo ratings yet

- Cryol 912 60 - TDSDocument2 pagesCryol 912 60 - TDSShafiq LatifNo ratings yet

- BRB Silanes Presentation PDFDocument48 pagesBRB Silanes Presentation PDFgokhanyaparNo ratings yet

- Foamstar ST 2412: Formulation AdditivesDocument2 pagesFoamstar ST 2412: Formulation AdditivesAPEX SONNo ratings yet

- Adhersives & BondingDocument19 pagesAdhersives & BondingSavindra SilvaNo ratings yet

- Bentone 38 - TDS - eDocument2 pagesBentone 38 - TDS - eDũng ĐỗNo ratings yet

- Chap12 PDFDocument44 pagesChap12 PDFYassine OuakkiNo ratings yet

- Calculos de Poliuretano RigidoDocument46 pagesCalculos de Poliuretano Rigidosescobar86100% (1)

- Desmocoll 540 5Document2 pagesDesmocoll 540 5lobocernaNo ratings yet

- Polyurethanes May11 ImpDocument3 pagesPolyurethanes May11 ImpittobaneNo ratings yet

- Ceramic Coating Application On Car Paintings and RimsDocument5 pagesCeramic Coating Application On Car Paintings and RimsRaybert ParedesNo ratings yet

- Marketing Plan AkimDocument10 pagesMarketing Plan AkimqpwoeirituyNo ratings yet

- Mold Release Composition - European Patent Office - EP 0094574 A2Document32 pagesMold Release Composition - European Patent Office - EP 0094574 A2Hida Al-FithriNo ratings yet

- Luwax LG Flakes EVD1128 eDocument8 pagesLuwax LG Flakes EVD1128 ePawan K ChowdharyNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentFrom EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Anecot® Organic: A&E's 100% Organic Cotton Sewing ThreadDocument2 pagesAnecot® Organic: A&E's 100% Organic Cotton Sewing ThreadhermioneNo ratings yet

- Anecot®: A&E's 100% Short Staple Spun Cotton ThreadDocument2 pagesAnecot®: A&E's 100% Short Staple Spun Cotton ThreadhermioneNo ratings yet

- Techx Performance Threads: Service & TechnologyDocument8 pagesTechx Performance Threads: Service & TechnologyhermioneNo ratings yet

- B Schuhe Lederwaren ENDocument12 pagesB Schuhe Lederwaren ENhermioneNo ratings yet

- B Polstermoebel ENDocument8 pagesB Polstermoebel ENhermioneNo ratings yet

- Loose Button Causes: Service & TechnologyDocument2 pagesLoose Button Causes: Service & TechnologyhermioneNo ratings yet

- AMANN Garment Dyeing ENDocument7 pagesAMANN Garment Dyeing ENhermioneNo ratings yet

- Sewing Equipment For Special ApplicationsDocument2 pagesSewing Equipment For Special ApplicationshermioneNo ratings yet

- Amann Product RangeDocument15 pagesAmann Product RangehermioneNo ratings yet

- PAS 223 TerjemahanDocument19 pagesPAS 223 TerjemahanhermioneNo ratings yet

- 5 Thread Size Comparison Chart 2-4-10Document4 pages5 Thread Size Comparison Chart 2-4-10hermioneNo ratings yet

- Ranjit Kumar Research Methodology A Step by Step G 29 30Document2 pagesRanjit Kumar Research Methodology A Step by Step G 29 30Trendy NewsNo ratings yet

- HACCP-Manual ExampleDocument26 pagesHACCP-Manual ExampleRONo ratings yet

- Letter Writing Dce MceDocument2 pagesLetter Writing Dce Mceaishasunkwa83No ratings yet

- Samma-Likha Vs Samma CorporationDocument5 pagesSamma-Likha Vs Samma CorporationAllen OlayvarNo ratings yet

- When AN IEP Meeting Is ConvenedDocument9 pagesWhen AN IEP Meeting Is ConvenedTwinkle CambangNo ratings yet

- Heat Transfer Rate - Decay Heat Exchanger: John Abish (14BME0085) Narenther M S (14BME0092) Gowutham (14BME0579)Document1 pageHeat Transfer Rate - Decay Heat Exchanger: John Abish (14BME0085) Narenther M S (14BME0092) Gowutham (14BME0579)narenNo ratings yet

- Oneplus TwoDocument18 pagesOneplus TwoKishor ChaudharyNo ratings yet

- NHIF 38 Choice of Outpatient Medical Facility FormDocument2 pagesNHIF 38 Choice of Outpatient Medical Facility FormMuji GillNo ratings yet

- Poison InformationDocument27 pagesPoison InformationJanvi PatelNo ratings yet

- Beautiful BeginningsDocument16 pagesBeautiful BeginningsNew Jersey Jewish StandardNo ratings yet

- NA OG: Cable Reheading Made Simple (After GOI)Document4 pagesNA OG: Cable Reheading Made Simple (After GOI)RoyNo ratings yet

- Original Schmidt Live CueCards OnlyDocument24 pagesOriginal Schmidt Live CueCards OnlyPanji OctawirawanNo ratings yet

- Home Economics 2Document64 pagesHome Economics 2Kaia FerdivilaNo ratings yet

- Group Cohesiveness Case StudyDocument9 pagesGroup Cohesiveness Case Studynsparth0% (1)

- Dosage Chapter 1 PDFDocument4 pagesDosage Chapter 1 PDFLena EmataNo ratings yet

- American College of Gastroenterology Guidelines .14Document19 pagesAmerican College of Gastroenterology Guidelines .14fernando sebastian godina arzolaNo ratings yet

- Shining A Light On High Volume Photocurable MaterialsDocument16 pagesShining A Light On High Volume Photocurable MaterialsDan MPNo ratings yet

- BatteryChargers U211Document32 pagesBatteryChargers U211sabar5No ratings yet

- Basic Guide To Explosives.Document8 pagesBasic Guide To Explosives.Seng BoucherNo ratings yet

- Hilti X-U NailsDocument10 pagesHilti X-U NailsLightninWolf32No ratings yet

- ARM - Grid Tie Inverter 1.5kW - 5kW SpecsDocument1 pageARM - Grid Tie Inverter 1.5kW - 5kW SpecsPhạm QuyếnNo ratings yet

- Httner 2008Document8 pagesHttner 2008gabriel avilaNo ratings yet

- APC Silcon 60-80kW 208/480V UPS Installation GuideDocument94 pagesAPC Silcon 60-80kW 208/480V UPS Installation GuideHector GuizzardNo ratings yet

- 2018-08-01 PowerDocument148 pages2018-08-01 Powerbar catalinNo ratings yet

- 127 Metal Spinner Maintenance ManualDocument348 pages127 Metal Spinner Maintenance ManualHadi NurtaqwaNo ratings yet

- 03 Handout 1Document9 pages03 Handout 1genesis nadonggaNo ratings yet

- About Flow CytometryDocument28 pagesAbout Flow CytometrySH Y A MNo ratings yet