Professional Documents

Culture Documents

EDC-M9102 Detector Manual F3.780.1099ASY Issue1.01

Uploaded by

EDWINOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EDC-M9102 Detector Manual F3.780.1099ASY Issue1.01

Uploaded by

EDWINCopyright:

Available Formats

EDC-M9102

Conventional Photoelectric

Smoke Detector

Features

Reed switch testing

Drift sensitivity, suit to environment extensively.

Removable innovative sensing chamber, easy for maintenance.

The fire LED allows 360°viewing.

Providing alarm output terminal connecting with remote

indicator.

Complying with UL 268

Description

EDC-M9102 Conventional Photoelectric Smoke Detector (the

detector) is a new-generation product by building in a

microprocessor, embedding a solid fire analyzing program, and

performing effectively and efficiently.

Recommended Wiring

Checking a fire alarm signal, the detector will send it to a fire alarm 1.0mm2 or above fire cable for all terminals laid through metal conduit

control panel (FACP) or addressable zone monitor unit by means of or flame proof conduit, subject to local codes.

current changes. The detector indicates its fire condition by turning

Note: Different color cables are used to avoid wiring mistake.

on fire LED and keeping the LED on until it is reset.

Up to 25 conventional devices can be connected to a

Using infrared scattering technology, with an innovative chamber,

module/FACP. See next page, compatibility section, for

the detector receives very weak infrared light under normal

detector capacity per circuit

smokeless condition. If smoke particles enter the chamber, the

received light signal will increase by scattering. When smoke

density reaches certain density, the detector will output fire signal. In

order to reduce interference and power consumption, the emitting Installation

circuit works in pulse mode to prolong the life of IR LED.

Refer to D Series Detector Application Bulletin for additional installation

Connection and cabling instructions.

Fix the base with two taping screws. Then align A (Fig.1) on the

Mounting Cable Entry bottom of the detector to B (Fig.2) of the base, and rotate the

Hole

detector clockwise to mark C.

Mounting of the detector is shown in Fig.4.

5

Electrical Box

Conduit

45

75

Fig. 1 Fig. 2

Orientation Base

Please install the base according to the following steps:

1) Locate the mounting holes on the rubber seal of the base 54.5mm

Detector

according to the holes on the electrical junction box, and

punch the holes with a screwdriver.

2) Count the number of cables needed and punch correct

number of holes with a screwdriver on the rubber seal at the

cable entry position. Thread the cables through the cable Fig. 4

entry holes. Warning: The alarm current depends on the current limit of the

3) Install the base onto the junction box with screws. control panel. 24VDC cannot power the detector directly.

Warning: Do not punch mounting holes and cable entry holes Otherwise the detector will be blown up for lack of current limit

bigger than needed. Do not punch more holes than needed. resistor.

There are four terminals with numbers on the base.

1: Detection zone positive IN Testing

2: Detection zone positive OUT Before testing, please ensure that the detector has been

3: Detection zone negative IN and OUT installed correctly and powered up. After 10 seconds, testing

2: Positive terminal of alarm output can begin.

4: Negative terminal of alarm output Before testing, notify the proper authorities that the system is

Refer to respective Module/FACP Installation sheets for the

undergoing maintenance and will temporarily be out of service.

wiring connections

Disable the zone or system undergoing maintenance to avoid

unwanted alarms.

O+

All detectors must be tested after installation and periodically

EOL Resistor

thereafter. Testing methods must satisfy the Authority Having

Jurisdiction (AHJ). Detectors offer maximum performance when

tested and maintained in compliance with NFPA 72. The detector

O- can be tested in the following way:

Conventional Detector Conventional Detector

Fig. 3

30311161 Issue 1.01

Test zone

safety hazards, arson or children playing with fire.

6. The alarm of a smoke detector used in high velocity

environment will be delayed due to dilution of smoke by frequent

and fast airflow.

7. Smoke detectors have their own service life. In order to keep

the detector working in good condition, please maintain them

according to recommendations from manufacturers and relative

state standards.

8. The detectors must be tested regularly, at least once a year.

9. Smoke detectors are not to be used with detector guards

Fig. 5 Fig. 6 unless the combination has been evaluated and found suitable for

1) Reed Switch Testing that purpose.

Magnet test zone is shown in Fig.5. Put the magnet of commission

tool close to the zone of the detector and hold on for a few seconds

until the detector generates alarm.

1) Smoke test Specification

The Trutest model 300 Aerosol Smoke Detector Tester can be used

for smoke entry testing. Set the generator to represent 4%/ft to 5%/ft Operating Voltage 16VDC~28VDC

obscuration as described in the Trutest manual. Using the bowl Standby Current ≤60μA

shaped applicator, apply aerosol until the panel alarms. Alarm Current ≤55mA

Additionally, canned aerosol simulated smoke (canned smoke agent) Red, periodically flash once in polling,

may be used for smoke entry testing of the smoke detector. Fire LED Periodically flash twice in fault or sensing

Recommended aerosol smoke products are: chamber dirty; illuminate in alarming.

Manufacturer Model Polarized output. Cycle 0.25S, duty ratio 1/2,

Trutest AERO400 Alarm Output Voltage range 13V~24V(built in 10k resistor in

When used properly, the canned smoke agent will cause the smoke series, maximum output current is 2.0mA);

detector to go into alarm. Refer to the manufacturer’s published

Max. ripple

instructions for proper use of the canned smoke agent. 2V(peak to peak value)

voltage

2) After testing, cut off the power above 10 seconds and reset the

detector and then notify the proper authorities that the system is Alarm reset Instant power down (10s Min, 1.0VDC Max

back in operation. Wiring Two-wire, polarity sensitive.

Warning: Canned aerosol simulated smoke (canned smoke agent) Sensitivity Range 1.23%~3.20% per ft

formulas will vary by manufacturer. Misuse or overuse of these Environment

products may have long term adverse effects on the smoke detector. 32℉(0℃)~100℉(+37.8℃)

Temperature

Consult the canned smoke agent manufacturer’s published Relative Humidity ≤95%, non condensing

instructions for any further warnings or caution statements.

Material and color ABS, white (RAL 9016)

When testing is complete, restore the system to normal operation

and notify the proper authorities that the system is back in operation. Ingress Protection

IP2X

Rating

Maintenance Dimension

Diameter:100mm Height: 44.5mm (without

base)

1. The detector must be cleaned once a year to ensure normal

Mounting Hole

operation of the system. 45mm-75mm

Spacing

2. Before cleaning, notify the proper authorities that the system is

undergoing maintenance and will temporarily be out of service. Weight About 110g

Disable the zone or system undergoing maintenance to avoid Compatibility EST3/3x IDC (detector capacity:19)

unwanted alarms.

SIGA-UM/MAB(detector capacity:10)

Chamber Clearing Steps:

a) Open the top cover of detector, and draw out the sensing RZI16-2 (detector capacity:25)

chamber by slightly lifting its two sides using a straight Fireshield Plus(detector capacity:25)

screwdriver, as shown in Fig. 6.

b) Use a vacuum cleaner or cleaned, compressed air to Listing UL268

remove dust and debris from the insect guard and the sensing

chamber. The sensing chamber can also be cleaned by clear Accessories and Tools

water and brush. Put the sensing chamber in clean water to Model Name Remark

brush the dust inside and take out to dry it.

EDB-M01 Base Supplied separately

c) Install the sensing chamber and the top cover back.

T-MT Commission tool Supplied separately

Cautions

1. Dust covers can’t be removed until the project is put into use

formally. Take well care of dust covers for future use.

2. Dust covers effectively but not absolutely prevent dust particles

from going into detectors. So, we recommend that detectors

should be removed prior to construction, decoration, or other

activities producing dust. The proper authority should be informed

of detectors removing.

3. Be careful not to damage the detector in maintenance.

The smoke detector may not sense fire that where smoke cannot

reach it, such as in chimneys, in walls, on roofs, or on the other

side of closed doors.

4. The detector cannot monitor the place beyond protection area.

5. The detector may not warn you about fires caused by

insufficient safety measures, violent explosions, leaking gas,

improper storage of flammable materials like diluents and other

30311161 Issue 1.01

You might also like

- Autocall Programmer 6.01 Software ReleaseDocument2 pagesAutocall Programmer 6.01 Software ReleaseEstaNo ratings yet

- BCC8002 BC8002 Advanced Mainboard: Building TechnologiesDocument4 pagesBCC8002 BC8002 Advanced Mainboard: Building TechnologiestorillazNo ratings yet

- Hood System Inspection Check LDocument2 pagesHood System Inspection Check LWaheeb SaidNo ratings yet

- To Install Consys Master" Get Files FromDocument21 pagesTo Install Consys Master" Get Files FromjohnNo ratings yet

- Perbaikan Fire AlarmDocument23 pagesPerbaikan Fire AlarmAbdul KurniadiNo ratings yet

- LIM800 Line Isolator Module - Installation Instruction: Technical SpecificationsDocument8 pagesLIM800 Line Isolator Module - Installation Instruction: Technical SpecificationsICEMANNo ratings yet

- S4100 0056 PDFDocument12 pagesS4100 0056 PDFNarciso TorresNo ratings yet

- iF410/420 Service Manual GuideDocument41 pagesiF410/420 Service Manual Guideluis enrique saiz ortizNo ratings yet

- Scaffold TowerDocument20 pagesScaffold TowerAndhika HerdiawanNo ratings yet

- DF1191, 92, Ex DF1151-Ex Technical Description, Planning, Installation, Commissioning (E1673d)Document36 pagesDF1191, 92, Ex DF1151-Ex Technical Description, Planning, Installation, Commissioning (E1673d)Majid MohammadianNo ratings yet

- 4010 Service ManualDocument72 pages4010 Service ManualMorella Rojas LinaresNo ratings yet

- Functional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualDocument24 pagesFunctional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualPaul Ramos CarcaustoNo ratings yet

- 579 197 PDFDocument93 pages579 197 PDFfmanriquezarceNo ratings yet

- AMTRONIC Profibus DP R1300 User InstructionsDocument32 pagesAMTRONIC Profibus DP R1300 User InstructionsHandriono OnoNo ratings yet

- PROFILE Panels: From Firmware Version 25 GUI Version 2.0.3Document20 pagesPROFILE Panels: From Firmware Version 25 GUI Version 2.0.3johnNo ratings yet

- VESDA Troubleshooting Guide - Rev05Document26 pagesVESDA Troubleshooting Guide - Rev05Eduardo Diaz PichardoNo ratings yet

- GS690 Installation Manual Rev ADocument63 pagesGS690 Installation Manual Rev Acasmadi casmadi100% (1)

- Bản vẽ Cummins C2250D5 PDFDocument10 pagesBản vẽ Cummins C2250D5 PDFbacNo ratings yet

- Simplex 4100ES-S1 Fire Indicator PaneLDocument120 pagesSimplex 4100ES-S1 Fire Indicator PaneLHamid KhanNo ratings yet

- MCFA 4100ES (250 Devices)Document10 pagesMCFA 4100ES (250 Devices)Dani AhmadNo ratings yet

- GAITRONICS - SPEAKER SKU-GTC-Manual-42004-353EDocument3 pagesGAITRONICS - SPEAKER SKU-GTC-Manual-42004-353Eelectrician 15100% (1)

- S400 Point Gas Detector Operating ManualDocument17 pagesS400 Point Gas Detector Operating ManualelliotmoralesNo ratings yet

- Maxpro VMS R300 SP1Document164 pagesMaxpro VMS R300 SP1rana98722No ratings yet

- ATV6000 Handbook Manual EN QGH83255 02.1Document226 pagesATV6000 Handbook Manual EN QGH83255 02.1nto_ntoNo ratings yet

- Using SIGA-CC2A With Supervised SpeakersDocument3 pagesUsing SIGA-CC2A With Supervised SpeakersRaviNo ratings yet

- Argo Nite ManualDocument90 pagesArgo Nite ManualApostol AlexandruNo ratings yet

- In Amenas Compression Project Fire Equipment FAT ProcedureDocument8 pagesIn Amenas Compression Project Fire Equipment FAT ProcedureDaoued HaouesNo ratings yet

- Nfs2-8 Instal Manual WebDocument0 pagesNfs2-8 Instal Manual WebDota NgNo ratings yet

- ULLD For Nohmi - Brand - (TN51483e - Rev.0)Document33 pagesULLD For Nohmi - Brand - (TN51483e - Rev.0)vu thien100% (1)

- GST C-9404 (Ex) SounderDocument2 pagesGST C-9404 (Ex) SounderReinaldo SouzaNo ratings yet

- NFPA 12 Technical Suppression BulletinDocument14 pagesNFPA 12 Technical Suppression Bulletinkofijoe_No ratings yet

- Beam Smoke DetectorDocument2 pagesBeam Smoke Detectornastyn-1No ratings yet

- 06.-Medidor Cloro CL4000enDocument18 pages06.-Medidor Cloro CL4000enLeonel RubioNo ratings yet

- 579 825Document4 pages579 825Robel MTNo ratings yet

- R4.0 FireWorks Software Installation GuideDocument18 pagesR4.0 FireWorks Software Installation Guideamjadjaved033148No ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- MK 201 ADocument4 pagesMK 201 AAli AhmadNo ratings yet

- Operating Manual Including Operations Logbook Manual For Installation, Commissioning, and MaintenanceDocument62 pagesOperating Manual Including Operations Logbook Manual For Installation, Commissioning, and MaintenanceBob MillerNo ratings yet

- XYLEM - Type XA ModulesDocument62 pagesXYLEM - Type XA Modulessindalisindi100% (2)

- ULMA Studio User GuideDocument10 pagesULMA Studio User GuideJorge ChavezNo ratings yet

- Plasma YH-400 English ManualDocument29 pagesPlasma YH-400 English ManualOLVERACNCMAQUINAS EMPRESANo ratings yet

- AW-FP200 Addressable Fire Alarm Control Panel User Manual 20230809Document33 pagesAW-FP200 Addressable Fire Alarm Control Panel User Manual 20230809Sefa AkdemirNo ratings yet

- Preventing Falls and Injuries in Long-Term Care (LTC) : Bridges To Care Resource ManualDocument157 pagesPreventing Falls and Injuries in Long-Term Care (LTC) : Bridges To Care Resource ManualHeather MoralesNo ratings yet

- Instructions for Using FpThick Coating Thickness SoftwareDocument47 pagesInstructions for Using FpThick Coating Thickness Softwarehuynh thi y viNo ratings yet

- Dvc-Rpu: Remote Paging Unit For The DVC System ManualDocument28 pagesDvc-Rpu: Remote Paging Unit For The DVC System ManualRicardo StimpelNo ratings yet

- Fire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanDocument21 pagesFire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanmarvinNo ratings yet

- A100K10602 Alphacom XE User GuideDocument119 pagesA100K10602 Alphacom XE User GuideAlberto R PerezNo ratings yet

- Furse - Flat Tape SystemDocument12 pagesFurse - Flat Tape SystemnknfiveNo ratings yet

- Fisher Specification Manager User ManualDocument28 pagesFisher Specification Manager User Manualtareq.sefatNo ratings yet

- DRT-301C Series User ManualDocument12 pagesDRT-301C Series User ManualRigonatoAlencarNo ratings yet

- Ba Test Com Panel TMDocument7 pagesBa Test Com Panel TMAhmad Gofur100% (1)

- Grundfos JPD - PT-22-24 PDFDocument3 pagesGrundfos JPD - PT-22-24 PDFmandahandriNo ratings yet

- Q8-USB - Quick Start GuideDocument4 pagesQ8-USB - Quick Start GuidedhruvNo ratings yet

- ATS-1192 - Manual de ProgramareDocument33 pagesATS-1192 - Manual de Programaresilviu_djNo ratings yet

- Loop Explorer Users Guide 09212012 V1 00Document75 pagesLoop Explorer Users Guide 09212012 V1 00Trung Thành Võ100% (1)

- Manual-C-9102 (UL) Conventional Photoelectric Smoke Detecto20Issue1.04Document10 pagesManual-C-9102 (UL) Conventional Photoelectric Smoke Detecto20Issue1.04ThullyNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- KECA 80 C104 KECA 80 C165 Current Sensors: Instructions For Installation, Use and MaintenanceDocument5 pagesKECA 80 C104 KECA 80 C165 Current Sensors: Instructions For Installation, Use and MaintenanceLaurentiu CatalinNo ratings yet

- Installation Wiring Diagram: DetectorDocument2 pagesInstallation Wiring Diagram: Detectorparallax1957No ratings yet

- Mil-B-8976 (Asg) : I 6 February 1969Document12 pagesMil-B-8976 (Asg) : I 6 February 1969kkpatel87No ratings yet

- Finishing MaterialsDocument4 pagesFinishing MaterialsdrapascuaNo ratings yet

- Chapter 24 - Intro To Turbulence Modeling in CFDDocument23 pagesChapter 24 - Intro To Turbulence Modeling in CFDprashanthreddyhNo ratings yet

- RV WU1348 Eldoret Mtungi Road - DesignDocument6 pagesRV WU1348 Eldoret Mtungi Road - DesignIKO NETWORKNo ratings yet

- C-758 Power Cable Schdule R-0Document2 pagesC-758 Power Cable Schdule R-0HARSHAL KIRITBHAI PATELNo ratings yet

- Untitled 2Document31 pagesUntitled 2Kootaroo TVNo ratings yet

- Electricity - Ready ReckonerDocument2 pagesElectricity - Ready Reckonersam_4any1No ratings yet

- Heat Treatment of Pressure VesselsDocument31 pagesHeat Treatment of Pressure VesselsAkeel Aijaz Malik100% (1)

- Engineering Materials: ReinforcementDocument32 pagesEngineering Materials: ReinforcementPromee Nafiza AnjumNo ratings yet

- HONG KONG INTERNATIONAL AIRPORT DRAWINGSDocument6 pagesHONG KONG INTERNATIONAL AIRPORT DRAWINGSChung Him Joe ChanNo ratings yet

- Plastic-Glass Skylight PDFDocument5 pagesPlastic-Glass Skylight PDFJonathan SchauderNo ratings yet

- A New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesDocument6 pagesA New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesIoana KruckeNo ratings yet

- AR Porta CabinDocument2 pagesAR Porta CabinVp SreejithNo ratings yet

- Analysis and Design of Foundation SystemsDocument31 pagesAnalysis and Design of Foundation SystemsJAY PATELNo ratings yet

- Cau 2014Document25 pagesCau 2014vinay1999No ratings yet

- Roof TrussesDocument20 pagesRoof Trussesalexmihai00100% (1)

- Shore D Hardness Test (Durometer Scale) - Hardness of Plastic MaterialsDocument3 pagesShore D Hardness Test (Durometer Scale) - Hardness of Plastic MaterialsValentin0% (1)

- GR-P207TJA Service ManualDocument146 pagesGR-P207TJA Service Manualboxopen0% (1)

- Excel Tube Corporation: Sub: QuotationDocument1 pageExcel Tube Corporation: Sub: QuotationHarish RanaNo ratings yet

- Introduction to Electrical Installation Cable SizingDocument7 pagesIntroduction to Electrical Installation Cable SizingLinus AbokiNo ratings yet

- SN003a-EN-EU - NCCI - Elastic Critical Moment For Lateral Torsional BucklingDocument13 pagesSN003a-EN-EU - NCCI - Elastic Critical Moment For Lateral Torsional BucklingJ ZhangNo ratings yet

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 pagesSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRNo ratings yet

- EPC PDS BarChipMQ58Document2 pagesEPC PDS BarChipMQ58pankaj_paul6451No ratings yet

- MRT Industrial Training ReportDocument48 pagesMRT Industrial Training ReportFadzrul FaizNo ratings yet

- McGill Complete Tech Catalogue FY2021Document67 pagesMcGill Complete Tech Catalogue FY2021apollo castroNo ratings yet

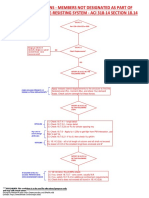

- Concrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14Document2 pagesConcrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14stephanie madridNo ratings yet

- Grund ForceDocument150 pagesGrund ForceFabrizio MansuetoNo ratings yet

- RFI Log - July-2021Document24 pagesRFI Log - July-2021navneet1986No ratings yet

- Isi Lesson 07 MaterialsDocument8 pagesIsi Lesson 07 MaterialsRizwan NazirNo ratings yet

- Astm D3039D3039MDocument13 pagesAstm D3039D3039MJhon Michael Antony Florez RoaNo ratings yet