Professional Documents

Culture Documents

Bulletin2005 05prd02

Uploaded by

essameldin0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

bulletin2005_05prd02

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesBulletin2005 05prd02

Uploaded by

essameldinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Bulletin of GTSJ 2005 New Models and Products

Woodward Gas Fuel Control System for DLE Turbines

MAEDA Shinobu

Woodward Governor Japan,Ltd.

1. General Information development of the SonicFlo™ fuel system to offer a

Woodward Governor Company has developed a new more advanced method of control that is targeted for

control system architecture for large industrial gas use on large industrial gas turbines.

turbines. The core product for the control system is The SonicFlo™ valve improves fuel flow accuracy and

the SonicFlo™ gas fuel control valve (GFCV) that responsiveness by creating a choked flow condition

generates higher accuracy performance than conven- that reduces the flow rate to a function of inlet pres-

tional valve systems. sure and inlet temperature.

This control system is designed for use on DLE

(dry low-emissions) technology turbines and is based 3. System outline

on the company's extensive experience with fuel con- Woodward is able to supply fuel control systems that

trol systems for aeroderivative gas turbine control and control DLE burners, from single stage up to five

DLE control theory. The components within the sys- stages. The figure shown below is the four-outlet,

tem have a high reputation with both domestic and parallel fuel delivery system with higher metering

overseas gas turbine manufacturers, who have ap- accuracy.

plied this system due to its high performance, com-

pact design and low cost. As a supplier of fuel con- The main components for the system consist of four

trol valves, electronic controls and combustion key products. These components can be supplied indi-

systems, Woodward is able to optimize these systems vidually, depending on customer requirements and

and interactions to increase accuracy and reliable specifications.

while at the same time lowering the total system cost.

2. Background Vent

Highly accurate fuel control is required to control a

DLE gas turbine (aeroderivative or large industrial 2~N

Premix Nozzle

Gas Turbine

Combustor

gas turbine) with a multi-stage burner. However, it Stop Ratio Valve SonicFlo Valve

is difficult to get the fuel flow accuracy and respon-

SonicFlo Valve

siveness demanded by these turbines using conven- RTOS

Digital

Control Unit

tional fuel flow meter feedback systems. In support

SonicFlo Valve

of this market need, over a decade ago Woodward de-

System Drawing of

veloped aeroderivative fuel systems and control FuelControl SonicFlo Valve

methods that sense fuel temperature and fuel pres-

sure of the metering valves in real-time. The control

calculates real gas flow in a digital control unit incor- Fig. 1

porating high-speed processors and sends control sig-

nals to the fuel valves to maintain accurate control of * MicroNet digital control (gas turbine

mass flow. More recently, Woodward has leveraged controller)

this system experience along with the * SRV stop-ratio valve (combined pressure

control and shut-off valve)

* SonicFlo™ GFCV valves (metering valve)

251-1 Nakazawa, Tomisato-Shi, Chiba 286-0291, JAPAN

Phone: +81-476-93-4662 Fax: +81-476-93-7939 * Lean pre-mixing nozzle

http://www.woodward.com/ic/

Copyright © 2005 by GTSJ

Gas Turbine Technology in Japan

maintain choked flow on a conventional globe valve.

4. Specifications of each component The SonicFlo™ valve guarantees the choked flow op-

* MicroNet digital control eration at outlet/inlet pressure ratios up to 0.8 by ap-

Woodward's MicroNet control is a digital control plying a pressure recovery sleeve to the outlet of

incorporating a Real-Time Operation System (RTOS). 90-degree angle valve. The practical outlet/inlet

The MicroNet performs general turbine control - in- pressure ratio of this valve exceeds 0.8, and with

cluding inlet guide vane control, variable stator con- high-recovery versions of this valve the pressure ratio

trol, air bleed valve control, accessory control and se- can reach up to 0.9.

quence control - as well as gas turbine fuel control. There are two standard valve flow curves; "linear"

To provide accurate, high-speed control, the MicroNet and "modified equal percentage". Modified equal

digital control uses a deterministic operational rate percentage curve is made of combining two flow char-

control strategy, which defines the required opera- acteristics, one is equal percentage characteristics for

tional speed of each task into rate group categories higher resolution at the low flow region for reliable

(some as fast as five milliseconds), corresponding to and accurate starting and the second is linear char-

task urgency level. This flexible control is designed acteristic for simpler control at the medium and high

for use on gas turbines and can be applied on many flow regions of the valve.

different system configurations with proven software

functionality that is designed for the latest gas tur-

bines.

* SonicFlo™ GFCV Cutaway view

The SonicFlo™ valve is a compact, high accuracy GFCV-SonicFloTM

gas fuel control valve that is a key component in the

Fig. 2

total control system architecture. The SonicFlo™

valve includes the valve, hydraulic actuator, servo * SRV stop ratio valve

valve, filter, trip valve and LVDT (linear variable dif- The SRV stop ratio valve is normally installed up-

ferential transformer). This integrated package re- stream of the SonicFlo™ GFCV valves, and acts as

duces error and variability by eliminating linkages both a pressure control valve and as an ANSI class 6

and connections between the actuator and valve. shut-off valve, reducing the number of components.

Reliability and accuracy of the system are increased

by using a triple coil servo-valve and dual LVDT for * Lean pre-mixing nozzle

position sensing. The most significant feature of Lean pre-mixing nozzle injects fuel metered by a fuel

SonicFlo™ valve is that the valve can maintain control valve into the burner.

choked flow at outlet/inlet pressure ratios of up to 0.8.

Choked flow is characterized by flow speeds of Mach 5. Conclusion

number 1 at the control region of the valve. This The design of the Woodward gas turbine control sys-

feature makes fuel flow control possible without ef- tem achieves significantly higher accuracy and per-

fects from changes in the control valve outlet pres- formance for fuel metering and control at a low sys-

sure. tem cost than conventional systems. The SonicFlo™

This means fuel flow is determined only by the fuel valve design integrates the valve and actuator into a

control valve inlet pressure and inlet temperature compact assembly which improves accuracy and re-

which increases the overall accuracy of the system by peatability. This close integration allows for lower cost,

reducing measurement error between multiple pres- smaller envelope and better re

sure sensors. This also simplifies the system design peatability. As turbines continue to require better

which results in lower cost. performance from the fuel and control system, Wood-

It has been commonly accepted that the outlet/inlet ward is working to offer solutions which integrate

pressure ratio should be limited to less than 0.53 to proven components and robust designs.

You might also like

- Bulletin2005 05prd02 PDFDocument2 pagesBulletin2005 05prd02 PDFHeryanto SyamNo ratings yet

- Boiler Control Systems Engineering, Second EditionFrom EverandBoiler Control Systems Engineering, Second EditionRating: 4.5 out of 5 stars4.5/5 (15)

- Common Rail Fuel System and Exhaust Valve ControlDocument12 pagesCommon Rail Fuel System and Exhaust Valve ControlAlagarsamyvenkat ShanmugarajaNo ratings yet

- Optimized for SEN00303-03 Engine Shop Manual SpecsDocument25 pagesOptimized for SEN00303-03 Engine Shop Manual SpecsЕгорNo ratings yet

- CRS 2-25 Diesel Common-Rail System With Solenoid Valve Injectors and 2,500 BarDocument3 pagesCRS 2-25 Diesel Common-Rail System With Solenoid Valve Injectors and 2,500 BarRooffNo ratings yet

- GT Various Systems (G)Document62 pagesGT Various Systems (G)shtiwari2002100% (2)

- PB4202Document2 pagesPB4202parrastevens930No ratings yet

- ALFA LAVAL - Fuel Conditioning ModuleDocument4 pagesALFA LAVAL - Fuel Conditioning ModuleJoan Maria Carulla100% (1)

- Fuel Conditioning Module Product BrochureDocument4 pagesFuel Conditioning Module Product BrochureRyan EncomiendaNo ratings yet

- OH 1 Control System: For Heavy Duty, Lean Burn, Natural Gas EnginesDocument4 pagesOH 1 Control System: For Heavy Duty, Lean Burn, Natural Gas EnginesAhmed Sherif CupoNo ratings yet

- DS ProductDataSheet CRS3-27 ENDocument3 pagesDS ProductDataSheet CRS3-27 ENberbagidatakantor123No ratings yet

- AGV 10 - Gas Turbine Fuel ValveDocument4 pagesAGV 10 - Gas Turbine Fuel ValvewalidNo ratings yet

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocument4 pagesGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Single-Stage VPM (VFD+PM) Screw Air Compressor - UCSDocument9 pagesSingle-Stage VPM (VFD+PM) Screw Air Compressor - UCSRUN GONo ratings yet

- 0802 B GeneratorsDocument77 pages0802 B GeneratorsAI Sari DewiNo ratings yet

- FuelSafe-brochure VIEWDocument8 pagesFuelSafe-brochure VIEWSimon manoenNo ratings yet

- Hydrovane Brochure 2012Document16 pagesHydrovane Brochure 2012Luis ParraNo ratings yet

- WAVE 8.0 Release NotesDocument31 pagesWAVE 8.0 Release NotesDarren CamilleriNo ratings yet

- Prospekt RS75-250 GBDocument8 pagesProspekt RS75-250 GBClaudio Andres Lagos GuerreroNo ratings yet

- Car Park Ventilation Control SystemDocument8 pagesCar Park Ventilation Control Systemroshan jaiswalNo ratings yet

- H2 Fuelled Internal Combustion EngineDocument8 pagesH2 Fuelled Internal Combustion EnginePRASAD326No ratings yet

- Commissioning Commercial KitchensDocument3 pagesCommissioning Commercial KitchensMoh'd KhadNo ratings yet

- Uniflo Fog Reduction ModuleDocument8 pagesUniflo Fog Reduction Modulecristi_molinsNo ratings yet

- Tecjet™ 85: DescriptionDocument4 pagesTecjet™ 85: DescriptionKaiser IqbalNo ratings yet

- 210 MW Seal Oil SystemDocument6 pages210 MW Seal Oil Systemmag_ktps20021520No ratings yet

- Pws 002712Document4 pagesPws 002712Ronnie Hilda Edward SeliNo ratings yet

- SP Renner RSFDocument12 pagesSP Renner RSFNaDeem NmsNo ratings yet

- Manual Powerflame C PDFDocument56 pagesManual Powerflame C PDFRoberto MnedezNo ratings yet

- Sulzer Common Rail Fuel Injection SystemsDocument5 pagesSulzer Common Rail Fuel Injection SystemsRachitNo ratings yet

- WP06GNA_APPLICATION_MANUALDocument27 pagesWP06GNA_APPLICATION_MANUALsulistyoagus81No ratings yet

- Trane Rtwa 217Document10 pagesTrane Rtwa 217Dalila AmmarNo ratings yet

- Advanced Process Control Systems Improve Ammonia Plant SafetyDocument8 pagesAdvanced Process Control Systems Improve Ammonia Plant Safetyvaratharajan g rNo ratings yet

- 0416 VHP Afr2 UpgradeDocument1 page0416 VHP Afr2 Upgradenicol_sgNo ratings yet

- Instrumentation and Control: 10.1 ObjectivesDocument8 pagesInstrumentation and Control: 10.1 ObjectivesMuhammadNo ratings yet

- CJK5 - Equipment Specification (En 2011)Document12 pagesCJK5 - Equipment Specification (En 2011)Christian ThompsonNo ratings yet

- D 941 SeriesvalvesDocument24 pagesD 941 SeriesvalvesLucas ScioscioliNo ratings yet

- 2071 GB 10 08Document16 pages2071 GB 10 08otto2212No ratings yet

- BMU Cutsheets - 44-51Document8 pagesBMU Cutsheets - 44-51angelNo ratings yet

- Valvulas FC WoodwortDocument2 pagesValvulas FC WoodwortMigue MedZa100% (1)

- GE 10-1 Gas TurbineDocument29 pagesGE 10-1 Gas TurbineAtanda Babatunde Mutiu33% (3)

- Altronic EPC100E Brochure PDFDocument4 pagesAltronic EPC100E Brochure PDFpspsuparingNo ratings yet

- JetVent Guide PDFDocument44 pagesJetVent Guide PDFPhanhai KakaNo ratings yet

- Prospekt Steuerung ENG 01Document8 pagesProspekt Steuerung ENG 01titiNo ratings yet

- Vilter VSSG VSG Brochure en Us 5411280 PDFDocument8 pagesVilter VSSG VSG Brochure en Us 5411280 PDFCarlos Roberto TamarizNo ratings yet

- VSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsCarlos Roberto TamarizNo ratings yet

- Closing The Performance Loop-GE CLOCDocument13 pagesClosing The Performance Loop-GE CLOCMochamad SolehNo ratings yet

- Steam Turbine Governing Systems and Electronic Governor Retrofit by Josephs. Lamberson and Jack ReedDocument8 pagesSteam Turbine Governing Systems and Electronic Governor Retrofit by Josephs. Lamberson and Jack ReedEr Mahendra KeshriNo ratings yet

- Industrial Combustion System Riello PDFDocument8 pagesIndustrial Combustion System Riello PDFAnonymous QY7Iu8fBNo ratings yet

- RENNER RS (F) 11,0 - 75,0 - Brochure - ENDocument12 pagesRENNER RS (F) 11,0 - 75,0 - Brochure - ENAriantoNo ratings yet

- Vane Gaz Honeywell PDFDocument16 pagesVane Gaz Honeywell PDFCezaryCezasNo ratings yet

- CB AutoflameDocument10 pagesCB AutoflameWylbert ConsueloNo ratings yet

- ATA103 NoticeDocument1 pageATA103 NoticeIrvan SaherNo ratings yet

- Gas Metering System-Woodward - SwiftDocument4 pagesGas Metering System-Woodward - Swiftkats2404No ratings yet

- G3520C Spec - 1972 KweDocument4 pagesG3520C Spec - 1972 KweAnonymous 5m1EMDc6idNo ratings yet

- Nebol Ungere Aer-Ulei EnglezaDocument30 pagesNebol Ungere Aer-Ulei Englezaangela_draguNo ratings yet

- Reyrolle LMT Long Term CareDocument15 pagesReyrolle LMT Long Term Carecgoober100% (3)

- Main Steam Turbine Controls Retrofit ISA FinalDocument13 pagesMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- G3516e 2000Document6 pagesG3516e 2000Zaineb ElhamdiNo ratings yet

- Wet Gas Compressor Capacity Control Systems: A Petrotech, Inc. White PaperDocument8 pagesWet Gas Compressor Capacity Control Systems: A Petrotech, Inc. White PaperGhazaleh GhazanfariNo ratings yet

- TIA14 SP1 SitePack TorrentDocument2 pagesTIA14 SP1 SitePack TorrentessameldinNo ratings yet

- Datasheet 3Document7 pagesDatasheet 3essameldinNo ratings yet

- PC 922 SharpDocument7 pagesPC 922 Sharpjulianca94No ratings yet

- Uesd3.3dt5g, Uesd5.0dt5g, Uesd6.0dt5g OnDocument5 pagesUesd3.3dt5g, Uesd5.0dt5g, Uesd6.0dt5g OnessameldinNo ratings yet

- Data Sheet 6ES7215-1AG40-0XB0: General InformationDocument7 pagesData Sheet 6ES7215-1AG40-0XB0: General InformationOliver Ochoa GarciaNo ratings yet

- Design of Industrial Automated Systems Via Relay LDocument15 pagesDesign of Industrial Automated Systems Via Relay LessameldinNo ratings yet

- SS12 THRU S100: Surface Mount Schottky Barrier Rectifier VOLTAGE - 20 To 100 Volts CURRENT - 1.0 AmpereDocument2 pagesSS12 THRU S100: Surface Mount Schottky Barrier Rectifier VOLTAGE - 20 To 100 Volts CURRENT - 1.0 AmpereJOHN BRICCO A. MATACSILNo ratings yet

- SIMATIC PCS 7 Automation Systems, S7-400 SeriesDocument22 pagesSIMATIC PCS 7 Automation Systems, S7-400 SeriesOmar Sánchez2No ratings yet

- Product Data Sheet: USB PC Connecting Cable, For Smart Relay Zelio Logic, 3 MDocument2 pagesProduct Data Sheet: USB PC Connecting Cable, For Smart Relay Zelio Logic, 3 MessameldinNo ratings yet

- Easy enDocument23 pagesEasy enVirgil DamianNo ratings yet

- Repair Parts For 100-C / 100L-C / 100Q-C / 100S-C / 104-C / 104S-C ContactorsDocument3 pagesRepair Parts For 100-C / 100L-C / 100Q-C / 100S-C / 104-C / 104S-C ContactorsessameldinNo ratings yet

- Siemens Simatic s7 1200Document2 pagesSiemens Simatic s7 1200essameldinNo ratings yet

- Replace contactor coils and repair partsDocument3 pagesReplace contactor coils and repair partsessameldinNo ratings yet

- 224 Datasheet PDFDocument5 pages224 Datasheet PDFTom MarkNo ratings yet

- SIMATIC PCS 7 Automation Systems, S7-400 SeriesDocument22 pagesSIMATIC PCS 7 Automation Systems, S7-400 SeriesOmar Sánchez2No ratings yet

- Connecting S7-200 PLCsDocument4 pagesConnecting S7-200 PLCsessameldinNo ratings yet

- Product Data Sheet 6ES7214-1BD23-0XB0Document6 pagesProduct Data Sheet 6ES7214-1BD23-0XB0essameldinNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- SIMATIC PCS 7 Automation Systems, S7-400 SeriesDocument22 pagesSIMATIC PCS 7 Automation Systems, S7-400 SeriesOmar Sánchez2No ratings yet

- URLLinkDocument1 pageURLLinkessameldinNo ratings yet

- Design: Mar 2008 Siemens ITSDocument24 pagesDesign: Mar 2008 Siemens ITSessameldinNo ratings yet

- SS12 THRU SS110: 1.0 AMP. Surface Mount Schottky Barrier RectifiersDocument3 pagesSS12 THRU SS110: 1.0 AMP. Surface Mount Schottky Barrier RectifiersessameldinNo ratings yet

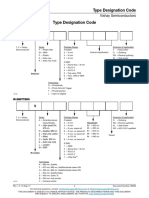

- Type Designation Code: Vishay SemiconductorsDocument1 pageType Designation Code: Vishay SemiconductorsessameldinNo ratings yet

- S1A, S1B, S1D, S1G, S1J, S1K, S1M: Vishay General SemiconductorDocument4 pagesS1A, S1B, S1D, S1G, S1J, S1K, S1M: Vishay General SemiconductoressameldinNo ratings yet

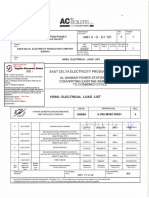

- 41-HRSG Electrical Load ListDocument7 pages41-HRSG Electrical Load Listessameldin0% (1)

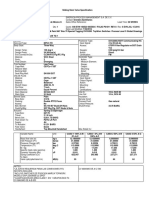

- Saronix: Technical DataDocument2 pagesSaronix: Technical DataessameldinNo ratings yet

- Siemens Simatic s7 1200Document2 pagesSiemens Simatic s7 1200essameldinNo ratings yet

- 42-HRSG IO ListDocument18 pages42-HRSG IO ListessameldinNo ratings yet

- Equipment Definition: Operation and Maintenance ManualDocument8 pagesEquipment Definition: Operation and Maintenance ManualessameldinNo ratings yet

- Modicon Premium Automation Platform: DescriptionDocument4 pagesModicon Premium Automation Platform: DescriptionessameldinNo ratings yet

- In Land LNG Receiving and Regas TerminalDocument20 pagesIn Land LNG Receiving and Regas TerminaltcandelarioNo ratings yet

- Capstone Report-FinalDocument91 pagesCapstone Report-FinalBurak GülenNo ratings yet

- Vactor Jet Rodder: Single Piston Water PumpDocument1 pageVactor Jet Rodder: Single Piston Water PumpRocko CallejasNo ratings yet

- SR No. Vendors Scope of Supply Address Proprietary Vendor'S ListDocument10 pagesSR No. Vendors Scope of Supply Address Proprietary Vendor'S ListCOLONEL ZIKRIANo ratings yet

- 446 Evn 160523 0035934 1Document3 pages446 Evn 160523 0035934 1Ernesto VazquezNo ratings yet

- Lennox 12acb IomDocument8 pagesLennox 12acb Iomapi-311201132No ratings yet

- C06-018 Rev B-C02 Design Manual IndustrialDocument138 pagesC06-018 Rev B-C02 Design Manual IndustrialLuis Enrique Bernal GarciaNo ratings yet

- Mce412 - Boundary Layer Concept in The Study of Fluid FlowDocument37 pagesMce412 - Boundary Layer Concept in The Study of Fluid FlowClifford100% (1)

- 08-Sundyne Presentation - Fs Installation1Document15 pages08-Sundyne Presentation - Fs Installation1joseellargo100% (1)

- PumpsDocument26 pagesPumpsFakher AlrashidNo ratings yet

- Exercises: Che 418-Computer Applications in Chemical EngineeringDocument12 pagesExercises: Che 418-Computer Applications in Chemical EngineeringeverletteNo ratings yet

- OMV Kadanwari Plant Gas ProcessingDocument62 pagesOMV Kadanwari Plant Gas ProcessingSyed Haider Abbas Bukhari100% (1)

- 2015DynamicCatalog Pump F20Document1 page2015DynamicCatalog Pump F20Sagra HuelitlNo ratings yet

- PIC MG-Aguaytia PP GT11 C5 2014 Insp. Final Report Rev00Document39 pagesPIC MG-Aguaytia PP GT11 C5 2014 Insp. Final Report Rev00Jeyson ReynosoNo ratings yet

- P2021 Erection Tracking Sheet Rev.6Document6 pagesP2021 Erection Tracking Sheet Rev.6Er PatelNo ratings yet

- Nitrogen Services For Pipeline and Process ApplicationsDocument2 pagesNitrogen Services For Pipeline and Process ApplicationsgobiNo ratings yet

- Vertical Spray Tower (No Packings) : Ka G LDocument6 pagesVertical Spray Tower (No Packings) : Ka G Lsafar bahariNo ratings yet

- BBS SLT PLL RP 0002 0 RevA - Pipeline HydraulicDocument33 pagesBBS SLT PLL RP 0002 0 RevA - Pipeline HydraulicAnonymous E3sSdt851X0% (1)

- Experiment 1Document10 pagesExperiment 1Shweta YadavNo ratings yet

- RHEOLOGYDocument18 pagesRHEOLOGYArchie CabacheteNo ratings yet

- Homework solutions fluid mechanics problemsDocument25 pagesHomework solutions fluid mechanics problemsHirman De NovaNo ratings yet

- Transportation and Metering of FluidsDocument34 pagesTransportation and Metering of FluidsPRAJWAL RASTOGINo ratings yet

- Automatic Fire Sprinkler CalcualtionDocument2 pagesAutomatic Fire Sprinkler CalcualtionKyaw HtayNo ratings yet

- Medical Gas Alarm PointsDocument4 pagesMedical Gas Alarm PointsMesiah MaphakelaNo ratings yet

- Vapor Pressure of Ammonium Nitrate Je60013a020Document2 pagesVapor Pressure of Ammonium Nitrate Je60013a020jerryNo ratings yet

- Performance of Strongly Bowed Stators in A 4-Stage High Speed CompressorDocument7 pagesPerformance of Strongly Bowed Stators in A 4-Stage High Speed CompressorSamrrt zNo ratings yet

- HLCP 05 BrochureDocument11 pagesHLCP 05 BrochureResul UygunNo ratings yet

- Tank Blanketing ApplicationsDocument5 pagesTank Blanketing ApplicationsMurali MuthuNo ratings yet

- Saacke Dictionary PDFDocument68 pagesSaacke Dictionary PDFSanjin MehinovićNo ratings yet

- Liquid Fuel Requirements For Ge Aeroderivative Gas TurbinesDocument5 pagesLiquid Fuel Requirements For Ge Aeroderivative Gas TurbinesMohammed ElarbedNo ratings yet