Professional Documents

Culture Documents

Spc-Concrete Bridges & Erection Procedures

Uploaded by

bentley adamsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spc-Concrete Bridges & Erection Procedures

Uploaded by

bentley adamsCopyright:

Available Formats

Section VII.

Works Requirements

SECTION 5.09 CONCRETE BRIDGES & ERECTION PROCEDURES

5.09.1 SCOPE

This work shall consist of erecting bridge structures and decks in the conformity with the

lines, grades and dimensions shown on the Drawings and in accordance with the

Specification.

5.09.2 MATERIALS

The materials shall conform to the requirements of the following sections of the

Specification:

Concrete - Sections 5.01 and 5.02

Forms and Falsework - Section 5.04 "Forms, Formwork and Falswork"

Reinforcement - Section 5.03 "Steel Reinforcement and Fixing"

Prestressing - Section 5.07 "Prestressed Concrete Construction"

5.09.3 CONSTRUCTION

A. Precast Beam and Slab Construction

A.1Manufacture of Prestressed Beams

A.1.1 The details of method of manufacture shall be approved by the Engineer before work

is started. No changes shall subsequently be made without the consent of the Engineer.

A.1.2 The Contractor shall inform the Engineer in advance of the date of commencement of

manufacture and the dates when tensioning of tendons, casting of members and transfer of

stress will be undertaken for the first time for each type of beam.

CONCRETE BRIDGES & ERECTION PROCEDURES 5.09 - Page 1 of 3

N17036-0100D-TD-SPC-BR-07 REV 0

Section VII. Works Requirements

A.1.3 The Contractor shall submit to the Engineer, not more than 7 days after the transfer of

stress, a certificate showing the force and strain in the tendons immediately after they were

anchored, the strength and age of the test cylinders cast in accordance with this Specification,

and the minimum age in hours of the concrete at the time stress was applied to the members.

Copies of all 28-day cylinder test results relating to the work shall be kept so that the identity

of those who stressed the tendons, cast the concrete and transferred the stress, on any member

or line of members, can be traced.

A.1.4 Where the Engineer requires tests to be carried out on beams, the beams to which

these tests relate, shall not be dispatched to Site until the tests have been satisfactorily

completed.

A.2 Storage and Handling of Prestressed Members

Members shall be firmly supported at such bearing positions as will ensure that the stresses

induced in them are always less than the permissible design stresses. Members shall be lifted

or supported only at the points specified and shall be handled and placed without impact.

A.3Tolerance in Pre-Cast Members

Dimensional Variations shall not exceed the tolerances given below:

- Length +12 mm

- Width and depth +6 mm

- Bow in the vertical plane +15 mm or -0 mm

- Bow in the horizontal plane +12 mm

- Difference between longest and

shortest dimensions (check for

squareness of beam) in any plane 6mm

- Twist (measured by the deviation

of any corner from the plane

containing the other 3 corners) 6 mm

- Flatness (the maximum deviation

from a 1.5 meter straightedge

placed in any position on

nominally plane surface) 6 mm

- Cover to reinforcement +5 or -0 mm

- Prestressing tendons 3 mm in any direction

- Dowel holes 3 mm in any direction

A.4Composite Slab Construction

CONCRETE BRIDGES & ERECTION PROCEDURES 5.09 - Page 2 of 3

N17036-0100D-TD-SPC-BR-07 REV 0

Section VII. Works Requirements

A.4.1 Where in-situ concrete deck is cast to act compositely with pre-cast beams, the beams

shall be installed to correct line and level, starting from the outer most beam and working

inwards progressively. When the beams are laid side by side just before erection the

difference in soffit level between adjacent beams shall nowhere exceed 6 mm. Where

permanent soffit shutters are used, they shall be to the approval of the Engineer and they shall

be fixed securely so that there is no movement or grout loss during deck concreting.

A.4.2 The in-situ concrete deck over any one span shall be poured in one continuous

operation and shall be placed in such a sequence that the advancing edge of the freshly

deposited concrete over the full width of deck or between longitudinal construction joints is

approximately parallel to the deck supports. Lateral displacement of beams shall be

prevented during the placing of in-situ concrete.

A.4.3 The width of the in-situ deck shall be within +25 mm of that specified. On curved

bridge deck, the in-situ deck may be in a series of straights such that the width is within +25

mm of that specified.

B. In-situ Construction

Where bridge decks are constructed in-situ, the details of all forms and falsework shall first

be approved by the Engineer. Dimensional variations shall not exceed the following

tolerances:

- Length +12 mm

- Width +10 mm

- Thickness +6 mm

- Levels +10 mm or -0 mm

- Void Location 6 mm in any direction

- Cover to reinforcement +5 mm or -0 mm

- Prestressing tendons 5 mm in any direction

CONCRETE BRIDGES & ERECTION PROCEDURES 5.09 - Page 3 of 3

N17036-0100D-TD-SPC-BR-07 REV 0

You might also like

- Technical Specifications of Boundary WallDocument5 pagesTechnical Specifications of Boundary WallAndy100% (1)

- Specification For Jack in PileDocument4 pagesSpecification For Jack in Pilekhuanoz100% (1)

- Division 3 Specs WrittingDocument16 pagesDivision 3 Specs WrittingJaymar Palomares OrilloNo ratings yet

- Structural Specs 2Document10 pagesStructural Specs 2hadjie ansayNo ratings yet

- Piling ProcedureDocument7 pagesPiling ProcedureimranNo ratings yet

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDocument15 pagesMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhNo ratings yet

- I Girder Prestressing Methodology DRNDocument11 pagesI Girder Prestressing Methodology DRNAkarsh KorishettarNo ratings yet

- BearingsDocument24 pagesBearingsAnonymous g1LSaANo ratings yet

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- 2700 Wearings Coat and AppurtenancesDocument5 pages2700 Wearings Coat and Appurtenancesdhamu_i4uNo ratings yet

- Method Statement Installation of Sheet PileDocument9 pagesMethod Statement Installation of Sheet PileRonnie Jungco SarmientoNo ratings yet

- BearingsDocument24 pagesBearingskvijayasokNo ratings yet

- Method Statement - DEMOLITION BUILDING - FENCINGDocument7 pagesMethod Statement - DEMOLITION BUILDING - FENCINGprisma integratedNo ratings yet

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Jack in Pile PDFDocument4 pagesJack in Pile PDFlattmdyNo ratings yet

- Jack in PileDocument4 pagesJack in PileNyu123456No ratings yet

- No Mesh/Net: RequirementsDocument3 pagesNo Mesh/Net: RequirementsSABEASNNo ratings yet

- Specification For Jack-In-Piles: 1.0 GeneralDocument4 pagesSpecification For Jack-In-Piles: 1.0 Generalmhamed1No ratings yet

- General specifications-GILODocument7 pagesGeneral specifications-GILOHannah Cesaree Mae TadeoNo ratings yet

- Mos For Pilling Foundation - SucDocument9 pagesMos For Pilling Foundation - SucEngr Muhammad Azam ThaheemNo ratings yet

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocument31 pagesSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNo ratings yet

- Work Procedure For STB Steel ErectionDocument108 pagesWork Procedure For STB Steel ErectionLeo PascualNo ratings yet

- Description & InstalationDocument3 pagesDescription & InstalationEhtesham AliNo ratings yet

- Method Statement: ApprovalDocument21 pagesMethod Statement: ApprovalzhanghuiNo ratings yet

- QES PEVC-EnG245-Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesQES PEVC-EnG245-Checklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 pagesWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- Method Statement FOR Steel Reinforcement: ProjectDocument5 pagesMethod Statement FOR Steel Reinforcement: ProjectKelvin Lau100% (1)

- Alform System Formwork Procedures October 2016Document40 pagesAlform System Formwork Procedures October 2016Syerifaizal Hj. MustaphaNo ratings yet

- 01 Method Statement For Pile Cap Foundations (Findal)Document8 pages01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Methodology For Track LinkingDocument11 pagesMethodology For Track LinkingAnkala Saibaba100% (2)

- Part 8 Kerbs, FootwaysDocument11 pagesPart 8 Kerbs, FootwaysElvis GrayNo ratings yet

- M S For RaftDocument10 pagesM S For RaftvidhyaNo ratings yet

- Reinforced Concrete Slab Design Using The Empirical MethodDocument9 pagesReinforced Concrete Slab Design Using The Empirical MethodRezky MuliaNo ratings yet

- TowersDocument72 pagesTowersboltgingerkoppyNo ratings yet

- The Method Statement For Concrete WorksDocument7 pagesThe Method Statement For Concrete WorksJeffrey WeyNo ratings yet

- Morth 2700 Wearing Coat and AppurtenancesDocument7 pagesMorth 2700 Wearing Coat and AppurtenancesRamesh100% (1)

- Wsdot 6-03.3Document3 pagesWsdot 6-03.3Dave MulvihillNo ratings yet

- Prestressing Works SpecsDocument30 pagesPrestressing Works SpecsVladimir Simeunovic100% (1)

- Work Method Statement FOR Reinforced Concrete WorksDocument5 pagesWork Method Statement FOR Reinforced Concrete WorksLynn Mail100% (1)

- Singapore Cruise Terminal Project Pile Spec.Document22 pagesSingapore Cruise Terminal Project Pile Spec.kim y hNo ratings yet

- Pre-Stressed ConcreteDocument23 pagesPre-Stressed ConcreteShabbar Abbas MalikNo ratings yet

- IQ1048-U-CLC070-600030 - R00 FORMWORK DRAWING معدلةDocument14 pagesIQ1048-U-CLC070-600030 - R00 FORMWORK DRAWING معدلةmaga2292No ratings yet

- Dubai Metro ProjectDocument67 pagesDubai Metro ProjectMustafa Uzyardoğan100% (4)

- General Specifications MoryDocument7 pagesGeneral Specifications MoryHannah Cesaree Mae TadeoNo ratings yet

- Bridge Presentation 02 PDFDocument44 pagesBridge Presentation 02 PDFkondaNo ratings yet

- Construction Technology Assignment FirstDocument26 pagesConstruction Technology Assignment FirstPaduma WijenayakeNo ratings yet

- Post Tension SlabDocument15 pagesPost Tension SlabkrishNo ratings yet

- Method Statement For PumpDocument7 pagesMethod Statement For PumpkbldamNo ratings yet

- Structural Steel ErectionDocument8 pagesStructural Steel Erectionbratishkaity100% (1)

- Part S17 Continuous Flight Auger Piles (2017)Document4 pagesPart S17 Continuous Flight Auger Piles (2017)CK TangNo ratings yet

- Optional Precast Reinforced Concrete (2-14-04) Box Culvert at StationDocument5 pagesOptional Precast Reinforced Concrete (2-14-04) Box Culvert at StationSayed Moussa El-KellawyNo ratings yet

- Wearing CoatDocument5 pagesWearing Coatnandi_scrNo ratings yet

- Section 671 - Concrete and Combined Concrete and Steel Bridge BarriersDocument2 pagesSection 671 - Concrete and Combined Concrete and Steel Bridge BarriersFAROOQ UL HAQUE FAROOQ UL HAQUENo ratings yet

- Xover Booklet July2015Document12 pagesXover Booklet July2015NiallBegleyNo ratings yet

- Method Statement For Construction of PilesDocument27 pagesMethod Statement For Construction of PilesShakti SharmaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- How Express Entry Works-1Document5 pagesHow Express Entry Works-1bentley adamsNo ratings yet

- Reminder July 2021Document1 pageReminder July 2021bentley adamsNo ratings yet

- Delegates Information2 (Repaired)Document14 pagesDelegates Information2 (Repaired)bentley adamsNo ratings yet

- Generator and Solar (Cover Page)Document1 pageGenerator and Solar (Cover Page)bentley adamsNo ratings yet

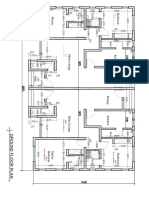

- 2 Bedroom Terrace-2Document1 page2 Bedroom Terrace-2bentley adamsNo ratings yet

- Development of Access Road For Ostia Island, Eti-Osa L.G.A. LagosDocument1 pageDevelopment of Access Road For Ostia Island, Eti-Osa L.G.A. Lagosbentley adamsNo ratings yet

- Group Registration FormDocument1 pageGroup Registration Formbentley adamsNo ratings yet

- Section A-A: Development of Access Road For Ostia Island, Eti-Osa L.G.A. LagosDocument1 pageSection A-A: Development of Access Road For Ostia Island, Eti-Osa L.G.A. Lagosbentley adamsNo ratings yet

- Oyo Ogun Oyo: Ogun River Network Ogun River Basin State BoundaryDocument1 pageOyo Ogun Oyo: Ogun River Network Ogun River Basin State Boundarybentley adamsNo ratings yet

- Map Showing Ogun River and BasinDocument1 pageMap Showing Ogun River and Basinbentley adamsNo ratings yet

- Ground Floor Plan CBT Centre: 100 Seater 50 Seater 50 SeaterDocument3 pagesGround Floor Plan CBT Centre: 100 Seater 50 Seater 50 Seaterbentley adamsNo ratings yet

- School Design 5Document3 pagesSchool Design 5bentley adamsNo ratings yet

- Class Room Class Room Class Room: Office OfficeDocument2 pagesClass Room Class Room Class Room: Office Officebentley adamsNo ratings yet

- Ground Floor Plan CBT Centre: 100 Seater 50 Seater 50 Seater OfficeDocument3 pagesGround Floor Plan CBT Centre: 100 Seater 50 Seater 50 Seater Officebentley adams100% (3)

- Class Room Class Room: OfficeDocument3 pagesClass Room Class Room: Officebentley adamsNo ratings yet

- Bentley Adams: Consultant: 01 Sht. No. D Project Title Client: Consulting EngineersDocument1 pageBentley Adams: Consultant: 01 Sht. No. D Project Title Client: Consulting Engineersbentley adamsNo ratings yet

- 20mmø Upvc CWP: Adeoye K.B Adeoye K.B Engr. OgunniyanDocument1 page20mmø Upvc CWP: Adeoye K.B Adeoye K.B Engr. Ogunniyanbentley adamsNo ratings yet

- B.Q BedroomDocument1 pageB.Q Bedroombentley adamsNo ratings yet

- Map Showing Ogun River and BasinDocument1 pageMap Showing Ogun River and Basinbentley adamsNo ratings yet

- Spares: - Project Management .Mechanical and Electrical Design .Solar &inverterinstallationsDocument1 pageSpares: - Project Management .Mechanical and Electrical Design .Solar &inverterinstallationsbentley adamsNo ratings yet

- Store: Adeoye K.B Adeoye K.B Engr. OgunniyanDocument1 pageStore: Adeoye K.B Adeoye K.B Engr. Ogunniyanbentley adamsNo ratings yet

- B.Q BedroomDocument1 pageB.Q Bedroombentley adamsNo ratings yet

- Nasirudeen Olayinka: ProfileDocument2 pagesNasirudeen Olayinka: Profilebentley adamsNo ratings yet

- Bentley Adams: Consultant: 03 Sht. No. D Project Title Client: Consulting EngineersDocument1 pageBentley Adams: Consultant: 03 Sht. No. D Project Title Client: Consulting Engineersbentley adamsNo ratings yet

- Bentley Adams: Consultant: 02 Sht. No. D Project Title Client: Consulting EngineersDocument1 pageBentley Adams: Consultant: 02 Sht. No. D Project Title Client: Consulting Engineersbentley adamsNo ratings yet

- Section B - B Section A - A: 5T16-01@250 B1 5T16-01@250 B1Document1 pageSection B - B Section A - A: 5T16-01@250 B1 5T16-01@250 B1bentley adamsNo ratings yet

- Form Work From 3 - SPC-L1 (73891)Document11 pagesForm Work From 3 - SPC-L1 (73891)bentley adamsNo ratings yet

- Formwork Cop 2016Document54 pagesFormwork Cop 2016bentley adamsNo ratings yet

- Temporary Works ManagementDocument15 pagesTemporary Works ManagementHasitha Athukorala50% (2)

- Failure in Pescadero BridgeDocument17 pagesFailure in Pescadero BridgeAlejandra De La TorreNo ratings yet

- Shape Memory Alloys: A Seminar Report ONDocument16 pagesShape Memory Alloys: A Seminar Report ONSantosh KumarNo ratings yet

- Application of Bundled Bamboo Split As Structural Elements in Pearl Beach Lounge, Gili Trawangan " Resilient Building Design and Material For Future " 2Document15 pagesApplication of Bundled Bamboo Split As Structural Elements in Pearl Beach Lounge, Gili Trawangan " Resilient Building Design and Material For Future " 2CHANCE RNo ratings yet

- 8 - Engineering Geology and Soil Mechanics - Chapter 9 - Site Investigation and Laboratory Testings (To Student) PDFDocument45 pages8 - Engineering Geology and Soil Mechanics - Chapter 9 - Site Investigation and Laboratory Testings (To Student) PDFhessian123No ratings yet

- Alluvial SoilDocument36 pagesAlluvial Soilfrog15No ratings yet

- FoundationDocument18 pagesFoundationlawrenceNo ratings yet

- Experiment 5 OrificeDocument8 pagesExperiment 5 OrificeRazahamid904No ratings yet

- Backwater Curves & Hydraulic Jump by ChamaraDocument10 pagesBackwater Curves & Hydraulic Jump by ChamaraGimhan JayasiriNo ratings yet

- Pavement Manual: Revised October 2019Document480 pagesPavement Manual: Revised October 2019emeterioNo ratings yet

- Design and Analysis of Eot Crane Hook For Various Cross SectionsDocument6 pagesDesign and Analysis of Eot Crane Hook For Various Cross SectionsFiroz PawaskarNo ratings yet

- CEN-622 Advanced Foundation Engineering: By: Anumita MishraDocument31 pagesCEN-622 Advanced Foundation Engineering: By: Anumita Mishraabcd efghNo ratings yet

- Shell RoofsDocument131 pagesShell RoofsBGSSAP 2017100% (2)

- ActivityDocument5 pagesActivitysenior highNo ratings yet

- ProkonDocument57 pagesProkonSelvasatha0% (1)

- 'Case Studies'': Ar. EMMARA Abubakar Muhammad Arslan B-21878Document5 pages'Case Studies'': Ar. EMMARA Abubakar Muhammad Arslan B-21878Muhammad ArslanNo ratings yet

- Fields of Engineering, Physics and ChemistryDocument52 pagesFields of Engineering, Physics and ChemistryEmmanuel de LeonNo ratings yet

- Condenser Sizing Calculation Tool: InputDocument17 pagesCondenser Sizing Calculation Tool: InputAkash GedamNo ratings yet

- 05.01. Priced Bill of Quantities of Construction and Finishing WorkDocument13 pages05.01. Priced Bill of Quantities of Construction and Finishing WorkSabeoNo ratings yet

- Calculation of Bearing Capacity From Standard Penetration Test (SPT)Document28 pagesCalculation of Bearing Capacity From Standard Penetration Test (SPT)ankitNo ratings yet

- Annexure-10 Dropper SpecificationDocument1 pageAnnexure-10 Dropper SpecificationAnkit AgarwalNo ratings yet

- A94ADocument5 pagesA94AASHISH GORDENo ratings yet

- Slope DelfectionDocument89 pagesSlope DelfectiondeeokusNo ratings yet

- Specification of FormWork PDFDocument6 pagesSpecification of FormWork PDFVivek Premji100% (3)

- Slope Deflection MethodDocument34 pagesSlope Deflection MethodAshok PradhanNo ratings yet

- WW Review HandoutsDocument2 pagesWW Review HandoutsMoriel PradoNo ratings yet

- Continuous Bridges 3Document20 pagesContinuous Bridges 3Siwakorn SangwornNo ratings yet

- (UPDATED) IRRIGATION WATER RESOURSES Engineering and Hydrology Questions AnswersDocument29 pages(UPDATED) IRRIGATION WATER RESOURSES Engineering and Hydrology Questions AnswersPreetish SuvaratnaNo ratings yet

- Assembly of Antenna Tower by The Lift-Up Method: Building ConstructionDocument1 pageAssembly of Antenna Tower by The Lift-Up Method: Building ConstructionAnh Quoc VuNo ratings yet

- Modification of Mononobe-Okabe TheoryDocument3 pagesModification of Mononobe-Okabe Theorygilopez88No ratings yet

- Cantilever 1111Document36 pagesCantilever 1111Gaurav GhaiNo ratings yet