Professional Documents

Culture Documents

10-4 Activity Wise Inspection Check List R804

Uploaded by

Kingston RivingtonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10-4 Activity Wise Inspection Check List R804

Uploaded by

Kingston RivingtonCopyright:

Available Formats

Page : 1 of 5 .

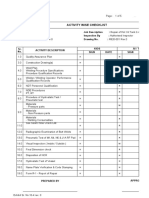

ACTIVITY WISE CHECKLIST

Job No. : KIOS/R820 Job Description : Repair of Hot Oil Tank 2-411-VA-01

Customer : KPO B.V Inspection By : Authorised Inspector

QAP No. : KIOS / R820 Rev.0 Drawing No. : R820-001 Rev.0

Sr. KIOS AI / TPI

ACTIVITY DESCRIPTION

No. SIGN DATE SIGN

1.0 Quality Assurance Plan H H

3.0 Construction Drawing(s) H R

Weld Plan

4.0 Welding Procedure Specifications H R

Procedure Qualification Records

Welder / Welding Operator Performance

5.0 H R

Qualification Records

6.0 NDT Personnel Qualification H R

NDE Procedures

7.0 H R

PT, RT

Procedure of Hydrostatic Test /

8.0 H R

Pneumatic test

Materials H W

- Pressure parts

Materials

9.0 H R

- Non-Pressure parts

Materials H R

- Welding

Fit-up Consumables

Inspection

See Seam Wise Check List

11.0 H R

12.0 Radiographic Examination of Butt Welds H R

13.0 Pneumatic Test of M1,N4, N6 & J1A RF Pad H R

14.0 Visual Inspection ( Inside / Outside ) H W

15.0 Final Dimension check H R

16.0 Disposition of NCR H H

17.0 Hydrostatic Test of Vessel H H

18.0 Name Plate Verification & Code Stamping H H

19.0 Form R-1 - Report of Repair H H

PREPARED BY APPROVED BY

Exhibit Sr. No 10-4 rev. 0

Page : 2 of 5 .

ACTIVITY WISE CHECKLIST

Job No. : KIOS/R820 Job Description : Repair of Hot Oil Tank 2-411-VA-01

Customer : KPO B.V Inspection By : Authorised Inspector

QAP No. : KIOS / R820 Rev.0 Drawing No. : R820-001 Rev.0

Sr. KIOS AI / TPI

ACTIVITY DESCRIPTION

No. SIGN DATE SIGN

QC INSPECTOR QUALITY MANAGE

Exhibit Sr. No 10-4 rev. 0

Page : 3 of 5 .

CTIVITY WISE CHECKLIST

Job Description : Repair of Hot Oil Tank 2-411-VA-01

AI / TPI

DATE

APPROVED BY

Exhibit Sr. No 10-4 rev. 0

Page : 4 of 5 .

CTIVITY WISE CHECKLIST

Job Description : Repair of Hot Oil Tank 2-411-VA-01

AI / TPI

DATE

QUALITY MANAGER

Exhibit Sr. No 10-4 rev. 0

Page : 5 of 5 .

ACTIVITY WISE CHECKLIST

Job No. : KIOS/U103 Job Description : Sub-assmbly for Hot Oil Tank 2-411-VA-01

Customer : KPO B.V Inspection By : Authorised Inspector

QAP No. : KIOS / U103 Rev.1 Drawing No. : U103-001 TO 004 Rev.0

Sr. KIOS AI / TPI

ACTIVITY DESCRIPTION

No. SIGN DATE SIGN DATE

1.0 Quality Assurance Plan H H

2.0 Construction Drawing(s) H R

Weld Plan

3.0 Welding Procedure Specifications H R

Procedure Qualification Records

Welder / Welding Operator

4.0 H R

Performance Qualification Records

5.0 NDT Personnel Qualification H R

NDE Procedures

6.0 H R

PT, RT

Materials H W

- Pressure parts

Materials

7.0 H R

- Non-Pressure parts

Materials

Fit-up Inspection

- Welding Consumables

H R

See Seam Wise Check List

8.0 H R

Radiographic Examination of Butt

9.0 H R

Welds

10.0 Visual Inspection ( Inside / Outside ) H W

11.0 Final Dimension check H R

12.0 Disposition of NCR H H

Name Plate Verification & Code

13.0 H H

Stamping

Form U-2A - Mfgr's Partial Data

14.0 H H

Report

PREPARED BY APPROVED BY

QC INSPECTOR QUALITY MANAGER

Exhibit Sr. No 10-4 rev. 0

You might also like

- Ut Level Spec QB 7Document12 pagesUt Level Spec QB 7Kingston RivingtonNo ratings yet

- Ut Level Spec QB 7Document12 pagesUt Level Spec QB 7Kingston RivingtonNo ratings yet

- Davis Butler API StandardsDocument27 pagesDavis Butler API StandardsAnkit GandhiNo ratings yet

- Ultrasonic Testing Ferritic Steel Butt WeldsDocument14 pagesUltrasonic Testing Ferritic Steel Butt WeldsKingston RivingtonNo ratings yet

- Ultrasonic SolutionDocument46 pagesUltrasonic Solutionsoumyadev86% (14)

- Eddy Current Testing of Inconel Tubes SpecificationDocument7 pagesEddy Current Testing of Inconel Tubes SpecificationkingstonNo ratings yet

- DEMO Vessel Calc R2Document48 pagesDEMO Vessel Calc R2Kingston RivingtonNo ratings yet

- 10-4 Activity Wise Inspection Check List R804Document5 pages10-4 Activity Wise Inspection Check List R804Kingston RivingtonNo ratings yet

- Iso15848 2Document8 pagesIso15848 2manuneedhiNo ratings yet

- Rev.02 Drawings 10-10-07Document1 pageRev.02 Drawings 10-10-07Kingston RivingtonNo ratings yet

- Order Acceptance: "Important Notes/Enclosures"Document1 pageOrder Acceptance: "Important Notes/Enclosures"Kingston RivingtonNo ratings yet

- Sample ASME QC Manual For U, U2, S&PPDocument53 pagesSample ASME QC Manual For U, U2, S&PPKingston RivingtonNo ratings yet

- Inspection Report: Karachaganak Petroleum Oper. B.V ProjectDocument5 pagesInspection Report: Karachaganak Petroleum Oper. B.V ProjectKingston RivingtonNo ratings yet

- Quality Assurance Plan (Qap)Document3 pagesQuality Assurance Plan (Qap)Kingston RivingtonNo ratings yet

- DCR 1Document1 pageDCR 1Kingston RivingtonNo ratings yet

- DCR 1Document1 pageDCR 1Kingston RivingtonNo ratings yet

- Rev.02 Drawings 10-10-07Document1 pageRev.02 Drawings 10-10-07Kingston RivingtonNo ratings yet

- Inspection Report: D A DonovanDocument5 pagesInspection Report: D A DonovanKingston RivingtonNo ratings yet

- 8-1 Din R0Document2 pages8-1 Din R0Kingston RivingtonNo ratings yet

- Inspection Report Highlights Key TestDocument4 pagesInspection Report Highlights Key TestKingston RivingtonNo ratings yet

- Carbon steel technical specificationsDocument8 pagesCarbon steel technical specificationsKingston RivingtonNo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- Purchase Request (PR) : Procurement SupervisorDocument2 pagesPurchase Request (PR) : Procurement SupervisorKingston RivingtonNo ratings yet

- MOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseDocument25 pagesMOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseKingston RivingtonNo ratings yet

- MOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsDocument20 pagesMOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsKingston RivingtonNo ratings yet

- Thermal InsulationDocument17 pagesThermal InsulationKamal SkNo ratings yet

- MOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsDocument45 pagesMOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsKingston RivingtonNo ratings yet

- MOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsDocument45 pagesMOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsKingston RivingtonNo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MRP FormatDocument39 pagesMRP Formatgyan ganga higher secondary school rampur baghelanNo ratings yet

- Module 2: Assignment: PROBLEM 9 - Treasury SharesDocument8 pagesModule 2: Assignment: PROBLEM 9 - Treasury SharesYvonne DuyaoNo ratings yet

- E ChoupalDocument8 pagesE ChoupalRakesh NandanNo ratings yet

- Supply Chain Analysis of Ambuja CementDocument42 pagesSupply Chain Analysis of Ambuja Cementpallavc100% (1)

- ELSS Investment ReceiptDocument6 pagesELSS Investment ReceiptKaran MitrooNo ratings yet

- Empowering Others Through DelegationDocument8 pagesEmpowering Others Through DelegationMonique LasolaNo ratings yet

- Company Profile: Inside Look at Leading Jacket ManufacturerDocument41 pagesCompany Profile: Inside Look at Leading Jacket ManufacturerVanika SharmaNo ratings yet

- L&T Elastomeric Bearing ApprovalDocument2 pagesL&T Elastomeric Bearing ApprovalSubarnarekha HL BridgeNo ratings yet

- Attendees discuss SEO strategies and tactics in online meetingDocument8 pagesAttendees discuss SEO strategies and tactics in online meetingCUSTOMER CARE ALIF PNLNo ratings yet

- Dinda Putri Novanti - Summary Budgeting and Financial Performance TargetDocument5 pagesDinda Putri Novanti - Summary Budgeting and Financial Performance TargetDinda Putri NovantiNo ratings yet

- Tosun Lang 2017 - Policy IntegrationDocument19 pagesTosun Lang 2017 - Policy IntegrationEdward T MaiaNo ratings yet

- Swifts Cable TrayDocument148 pagesSwifts Cable TrayMichael Bou KarimNo ratings yet

- Maharashtra Pharmacy Seat Allotment for CAP Round IIIDocument2 pagesMaharashtra Pharmacy Seat Allotment for CAP Round IIIPharmacy Admission ExpertNo ratings yet

- MAS BackgroundDocument2 pagesMAS BackgroundJie FifieNo ratings yet

- FX Factsheet Leveraged Forward enDocument2 pagesFX Factsheet Leveraged Forward enPiyushKumarNo ratings yet

- Super Savings Account: Common Service ChargesDocument2 pagesSuper Savings Account: Common Service ChargesSantosh ThakurNo ratings yet

- Internationalization CanvasDocument1 pageInternationalization CanvasRomulo Alexandre Soares - RASNo ratings yet

- Chapter-5 A Comparative AnalysisDocument5 pagesChapter-5 A Comparative Analysisshoyeb1204No ratings yet

- BS en 10250-3Document16 pagesBS en 10250-3butterflyhuahuaNo ratings yet

- Amigo Manufacturing V. Cluett Peabody CoDocument3 pagesAmigo Manufacturing V. Cluett Peabody CoShiela Arboleda MagnoNo ratings yet

- B.E - Spring Sem - 2019Document9 pagesB.E - Spring Sem - 2019Aritra MahatoNo ratings yet

- Conceptual Framework and Accounting Standards OverviewDocument170 pagesConceptual Framework and Accounting Standards OverviewJ LagardeNo ratings yet

- Strength: Cultural Dimension of IndiaDocument3 pagesStrength: Cultural Dimension of IndiaRashmi PahariNo ratings yet

- On September 1 2011 The Account Balances of Rand Equipment PDFDocument1 pageOn September 1 2011 The Account Balances of Rand Equipment PDFM Bilal SaleemNo ratings yet

- Adani Ports Financial RatiosDocument2 pagesAdani Ports Financial RatiosTaksh DhamiNo ratings yet

- 5.a Study On Utilization and Convenient of Credit CardDocument11 pages5.a Study On Utilization and Convenient of Credit CardbsshankarraviNo ratings yet

- Marketing CommunicationsDocument19 pagesMarketing CommunicationsGracezel Evangelista GarciaNo ratings yet

- Pteroleum Economy Exercise - DepreciationDocument31 pagesPteroleum Economy Exercise - Depreciationshaziera omarNo ratings yet

- Online Tutorial 8 Audit of Human Resources and Payment CycleDocument3 pagesOnline Tutorial 8 Audit of Human Resources and Payment CycleleiannetumamaoNo ratings yet

- Saving Canada's Tallest TreeDocument7 pagesSaving Canada's Tallest TreeNarcisa Anabel Valeriano Veliz.No ratings yet