Professional Documents

Culture Documents

Wem Aw 011: Method Statement

Uploaded by

PrinterHaapcolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wem Aw 011: Method Statement

Uploaded by

PrinterHaapcolCopyright:

Available Formats

Method Statement

WEM HS.MS.15WEM AW 011

Site Address / Branch Office Cooper Yard, Old Cider Works, Abbotskerswell, Newton Abbot, TQ12 5NF

Specific Location Details Not Known

Job / Task Details: Inspection, Clean & Disinfection – Cold Water Storage Tanks

Precise Location Not Known

Planned Dates Not Known

BRIEF DESCRIPTION OF THE WORKS, TASK OR PROCESS:

Carrying out Water Hygiene Monitoring activities on customer sites

Water Hygiene Monitoring

-Arrive on site on date and time as agreed with the customer contact

-Report to site contact and discuss works to be undertaken, access required and any disruption to water services

-Carry out health and safety risk assessment or sign risk assessment continuation sheet (if work activity and risks are the same as a previous site visit) prior

to commencing works

-Post warning notices/signs where applicable

-Complete water hygiene monitoring activities as detailed in worksheet

-Ensure the work area is left in the same condition as it was found

-Discuss findings and implications with responsible person on site

-Detail all results, actions and recommendations etc. on worksheet

-Detail all results, action, recommendations in site logbook where available

-Ensure customer signature on worksheet

-Issue Customer Feedback Survey sheet to customer if required

-Leave site

-Complete all ancillary paperwork concerning dip slide reports, samples etc.

-Return all paperwork for works carried out to the supervisor/administrator as soon as possible (but no longer than one week) after completion of the

work

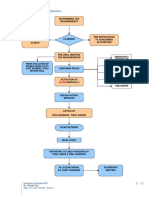

SEQUENCE OF OPERATIONS:

Water Storage Tank - Visual General Inspection

Using a calibrated thermometer, measure and report the following:

-Ambient (external temperature).

-Tank room temperature.

-Stored water temperature (Temperature of the tanked water shall be monitored via the drain point if practicable).

-Supply temperature.

-Visually inspect tank room for bird and/or rodent infestation and state amount.

-If insulation allows for inspection of the external condition of the tank walls, inspect for corrosion pitting and leaks.

-Visually inspect internal walls of tank for signs of scale deposition, corrosion and slime deposits.

-Visually inspect tank and associated valves/pipework for leaks.

-Visually inspect bottom of tank for sludge deposition and state amount.

-Visually inspect internal walls of tank for corrosion and state amount.

-Visually inspect for signs of stagnation such as water surface dirt, oil films, insects, smell, low input.

-Visually inspect water surface for; dirt, oil films, insects and state amount.

-Visually inspect for slimy deposits on the internal walls of tank and state the colour of substance and state amount.

-Visually inspect for algae growth indicated by either green or red plant like growth on water surface.

-Visually inspect the insulation for signs of wear and tear and areas where the insulation has been removed.

-Visually inspect that the lid is correctly fitted and that any bolts are securely tightened.

-Visually inspect that all insect/rodent screens fitted are clear from debris so that water can flow easily.

-Visually inspect that the ball valve opens and closes correctly.

-Visually inspect all pipework for signs of corrosion and leaks, and check the condition of insulation fitted.

-Visually inspect all valves for correct operation, signs of corrosion and leaks.

-Visually inspect all booster pumps fitted for correct operation.

-Indicate the date that the tank was last cleaned and disinfected and indicate whether it was disinfected as routine or due to adverse conditions.

Water Storage Tank - Cleaning and Disinfection

Tank Cleaning

WEMCO Ltd. Health and Safety Department

Full details regarding Access Authorisation can be found in the WEMCO Ltd. Health and Safety Rulebook

HS.MS.15 - WEM AW 011 - Cold Water Storage - Version 01 - 19.01.2015

Method Statement

WEM HS.MS.15WEM AW 011

The pH of the water shall be measured and must be between 5.5 and 9.0 before chlorinating solution is introduced. If pH is found to be below 5.5 the

system shall be drained, flushed and refilled with fresh water.

The tank(s) shall be filled with fresh water and chlorinating agent to give a minimum free chlorine concentration of 50ppm (50mg/l), and when full, allowed

to stand for 1 hour.

After 1 hour, measure free chlorine level, if free chlorine level is below 30ppm, repeat above step.

The tank(s) shall be drained and then thoroughly flushed out with clean mains water until tests indicate that the residual chlorine concentration is no

greater than 0.5ppm (0.5mg/l), or that present in the mains water supply.

Where the volume exceeds 2000 litres, the disinfected water must be neutralised, using sodium thiosulphate, before disposal. The neutralised waste MUST

NOT be drained through the system.

Fix ball valve in close position.

Isolate Tank from system, outlets must be sealed from inside tank.

Empty the Tank via drain-point or by using a submersible or barrel type pump, in the absence of a drain-point or if draining from drain-point is

impracticable.

Clean Tank and remove all deposits of scale, corrosion and sludge deposition using a combination of hand scraping and brushing together with application

of chemicals to dissolve or soften the scale (where necessary). Vacuum out all loose debris and deposits.

When using high-pressure jet washers to clean the internal surfaces of the Tank, suitable PPE must be used, including a positive pressure respirator. In this

circumstance, the escape of aerosols must be restricted or minimised.

Where oil and grease contaminants on the tank surface are implicated, they shall be removed using suitable de-greasants. Where necessary (and

practicable) the tank can be steam cleaned to remove grease contaminants.

Where “significant” or “highly-significant” levels of biological contamination is reported, the Tank shall be disinfected (using the disinfection method

below), before the cleaning process is commenced.

Tank Disinfection Using Sodium Hypochlorite

The pH of the water shall be measured and must be between 5.5 and 9.0 before chlorinating solution is introduced. If pH is found to be below 5.5 the

system shall be drained, flushed and refilled with fresh water.

The tank(s) shall be filled with fresh water and chlorinating agent to give a minimum free chlorine concentration of 50ppm (50mg/l), and when full, allow

to stand for 1 hour.

After 1 hour, measure free chlorine level, if free chlorine level is below 30ppm, repeat above step.

The tank(s) shall be drained and then thoroughly flushed out with clean mains water until tests indicate that the residual chlorine concentration is no

greater than 0.5ppm (0.5mg/l), or that present in the mains water supply.

Where the volume exceeds 2000 litres, the disinfected water must be neutralised, using sodium thiosulphate, before disposal. The neutralised waste MUST

NOT be drained through the system.

The tank is to be refilled with fresh water via the inlet ball valve(s).

Using a suitable sterile container, collect a water sample and submit for biological analysis. The analysis shall measure the presence of contamination by

general bacteria (Total Viable Colony Count – TVCC). Samples to be collected no earlier than 48 hours following disinfection.

Tank Disinfection Using Chlorine Dioxide (ClO2) – Soaking Method

Once the activated solution is in the system and adequately mixed, check that a reserve of at least 50mg/L as ClO2 is given. Add more activated solution if

necessary.

Draw chlorinating agent from all outlets and ensure the presence of at least 50ppm ClO2. After 1 hour, check ClO2 level, if below 30ppm, repeat above

steps. If level is >30ppm ClO2, after one hour flush system with fresh water and put to drain.

The tank(s) and system shall be thoroughly flushed out with clean mains water until tests indicate that the residual ClO2 concentration is no greater than

0.5ppm (0.5mg/l), or that present in the mains water supply.

After the one hour soak period, the system can be drained and flushed out and provided the system volume is less than 2m3 and the residual less than

20mg/L as ClO2 can be discharged to sewer without deactivation. For larger volumes/higher residuals then this shall be deactivated using Sodium

Thiosulphate solution.

The area of the storage vessel above the water line (overflow, lid, ball valve etc.) shall be manually cleaned and then disinfected by spraying with 500 ppm

ClO2 solution using garden type pressure sprayer ensuring surfaces remain wet for 10 minutes

WEMCO Ltd. Health and Safety Department

Full details regarding Access Authorisation can be found in the WEMCO Ltd. Health and Safety Rulebook

HS.MS.15 - WEM AW 011 - Cold Water Storage - Version 01 - 19.01.2015

Method Statement

WEM HS.MS.15WEM AW 011

If the water volume is less than 2m3 and the residual ClO2 content is less than 20 mg/L as ClO2 then it is acceptable to discharge the water to sewer

without further deactivation.

The tank is to be refilled with fresh water via the inlet ball valve(s).

Using a suitable sterile container, collect a water sample and submit for biological analysis. The analysis shall measure the presence of contamination by

general bacteria (Total Viable Colony Count – TVCC). Samples to be collected no earlier than 48 hours following disinfection.

Tank Disinfection Using Chlorine Dioxide – Spray Method

Spray all surfaces of the tank using a knapsack or garden pressure sprayer or fogger, with ready prepared 500ppm ClO2 solution, ensuring that all surfaces

remain wet with disinfectant for at least 10 minutes. Note the requirements for personal protective equipment when spraying of fogging chlorine dioxide

solutions.

When the spray disinfection is complete and the solution has been in contact with all surfaces for at least 10 minutes, thoroughly rinse all sprayed surfaces

with clean water and remove any residues with pump/wet vac or flush through to drain.

Refill with fresh water and put back into service. Check residual of chlorine dioxide is below 1ppm.

Using a suitable sterile container, collect a water sample and submit for biological analysis. The analysis shall measure the presence of contamination by

general bacteria (Total Viable Colony Count – TVCC). Samples to be collected no earlier than 48 hours following disinfection.

EQUIPMENT AND PROCEDURES:

Plant/Tools needed Hand tools

PPE required Safety footwear

Delete and/or add as Eye protection

appropriate: Positive Respirator, as required see Method Statement

Materials to be used N/A

Operatives required Plumber / Water Hygiene Technician

Specific Training needed – give Trade Specific

details

Permits to Work needed N/A

Delete and/or add as

appropriate:

Machinery Shutdown and Lock- N/A

Off Procedures

Is Electricity needed N/A

Mobile Phone use – any No

Restricted Areas

WEMCO Ltd. Health and Safety Department

Full details regarding Access Authorisation can be found in the WEMCO Ltd. Health and Safety Rulebook

HS.MS.15 - WEM AW 011 - Cold Water Storage - Version 01 - 19.01.2015

Method Statement

WEM HS.MS.15WEM AW 011

Means of protection to other N/A

people

Delete and/or add as

appropriate:

Site Access and Egress Site specific information not known

Access to Works Area Site specific information not known

Means of Access to Height Site specific information not known

Delete and/or add as

appropriate:

Fall Prevention Measures Site specific information not known

COSHH Assessment Carried Out See MSDS in operatives file

Suitable Welfare Arrangements N/A

– give details

Traffic Management in Place N/A

First Aid Cover – give details Sign into client site register

Accident Procedures – give Sign into client site register. All accidents to be reported with client and WEMCO office

details

Overhead Power Cables – are N/A

goalposts in place

Noise Issues N/A

Dust Control N/A

Vibration Control N/A

Fire Plan in Place See RA 800 – Fire Risk Assessment at workplaces other than our own.

Site Contact Details including Sign into client register

Emergency Numbers Etc

Office telephone 01626 363668

WEMCO Ltd. Health and Safety Department

Full details regarding Access Authorisation can be found in the WEMCO Ltd. Health and Safety Rulebook

HS.MS.15 - WEM AW 011 - Cold Water Storage - Version 01 - 19.01.2015

Method Statement

WEM HS.MS.15WEM AW 011

ISSUED TO:

Name Signature Date

WEMCO Ltd. Health and Safety Department

Full details regarding Access Authorisation can be found in the WEMCO Ltd. Health and Safety Rulebook

HS.MS.15 - WEM AW 011 - Cold Water Storage - Version 01 - 19.01.2015

You might also like

- Check ListDocument88 pagesCheck ListRaafat SaadNo ratings yet

- Self Esteem and The Real Body ImageDocument12 pagesSelf Esteem and The Real Body ImageChy Alcarde50% (2)

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Document14 pagesInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040No ratings yet

- HSE Plan TemplateDocument8 pagesHSE Plan Templatederson50% (2)

- Rolling Stock Design CriteriaDocument17 pagesRolling Stock Design CriteriahamzaNo ratings yet

- Daily Montly Checklist 04JUN2007Document9 pagesDaily Montly Checklist 04JUN2007tomiNo ratings yet

- IRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistDocument3 pagesIRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistAsif HameedNo ratings yet

- Package Unit Test Commission RptDocument3 pagesPackage Unit Test Commission RptameerNo ratings yet

- Thermal Destruction of Microorganisms in 38 CharactersDocument6 pagesThermal Destruction of Microorganisms in 38 CharactersRobin TanNo ratings yet

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocument18 pagesCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- Bacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional SystemsDocument8 pagesBacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional Systemsamjadjaved033148100% (1)

- Emergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTDocument3 pagesEmergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTSyifa Ula HamidyaNo ratings yet

- 25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedDocument7 pages25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedAnonymous RVO3O6zm0No ratings yet

- Tools & Equipment's 5,000-20,000 PSI Hydrojetting CatalogDocument7 pagesTools & Equipment's 5,000-20,000 PSI Hydrojetting CatalogTools & EquipmentsNo ratings yet

- Water System Test ReportDocument2 pagesWater System Test ReportNorman MuñizNo ratings yet

- Cleaning Steam Injection SystemDocument9 pagesCleaning Steam Injection SystemSiva KulanjiNo ratings yet

- HANDING OVER PROJECT NOTEDocument1 pageHANDING OVER PROJECT NOTEBoyak KunNo ratings yet

- Water DisinfectionDocument24 pagesWater DisinfectionJaycen RussellNo ratings yet

- Daily Factory Cleaning Sheet ChecklistDocument5 pagesDaily Factory Cleaning Sheet ChecklistSaroj KatwalNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- Hetp For Sideboom From Eg56 Fl-Mqura To Jm28 Fl-ds05Document35 pagesHetp For Sideboom From Eg56 Fl-Mqura To Jm28 Fl-ds05Isma'el El-AyyashNo ratings yet

- Calcium Hypochlorite MSDSDocument5 pagesCalcium Hypochlorite MSDStradeasiagroupNo ratings yet

- Method Statement for Water ChlorinationDocument7 pagesMethod Statement for Water Chlorinationarshad iqbal100% (1)

- MSDS - Hydrex 5914 (Cleaning Chemical) - CO2 PlantDocument4 pagesMSDS - Hydrex 5914 (Cleaning Chemical) - CO2 PlantFAREEDNo ratings yet

- RISK ASSESSMENT FOR Ac Cleaning ServicesDocument5 pagesRISK ASSESSMENT FOR Ac Cleaning ServicesEGSC HSENo ratings yet

- 33 16 13 - Ground Storage TanksDocument5 pages33 16 13 - Ground Storage TanksHizbar ArsjadNo ratings yet

- F-030-Diesel Generator Inspection ChecklistDocument1 pageF-030-Diesel Generator Inspection ChecklistAbdus SamadNo ratings yet

- Method For Cleaning Concrete TankDocument3 pagesMethod For Cleaning Concrete TankSpecial MahooNo ratings yet

- Maintenance / Custodial Work Request: For Office Use OnlyDocument1 pageMaintenance / Custodial Work Request: For Office Use OnlyRoha AdamNo ratings yet

- D27/D36 Marine Diesel Engines Technical SpecificationsDocument4 pagesD27/D36 Marine Diesel Engines Technical SpecificationsMermaid TanajibNo ratings yet

- A-1101 B Primary Reformer Catalyst Change Out Work Method StatementDocument4 pagesA-1101 B Primary Reformer Catalyst Change Out Work Method StatementgururajNo ratings yet

- Which Statement On Physical Development of Infants and Toddlers Is TRUEDocument9 pagesWhich Statement On Physical Development of Infants and Toddlers Is TRUEKristylle Renz100% (1)

- Master File - MOS Water Storage Tank Cleaning and Disinfection ProceduresDocument6 pagesMaster File - MOS Water Storage Tank Cleaning and Disinfection ProceduresKaran SuleNo ratings yet

- Pre-Use Welding ChecklistDocument2 pagesPre-Use Welding ChecklistNuno LopesNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data Sheetapply19842371No ratings yet

- SOP For Passivation 1 Scope:: FM/VD/04/R0Document3 pagesSOP For Passivation 1 Scope:: FM/VD/04/R0Nishar BalkavadeNo ratings yet

- Vdocuments - MX - Weekly Air Compressor Check List PDFDocument1 pageVdocuments - MX - Weekly Air Compressor Check List PDFmahmoud ahmedNo ratings yet

- Iphone 6 Silver InvoiceDocument1 pageIphone 6 Silver InvoiceMihir KumarNo ratings yet

- MIT Spot Blasting & Coating SpecificationDocument7 pagesMIT Spot Blasting & Coating SpecificationMohd YusriNo ratings yet

- Fire Fighting Equipment Monthly Inspection ReportDocument2 pagesFire Fighting Equipment Monthly Inspection Reportnadeem mallickNo ratings yet

- Stacker Preventive Maintenance Weekly: Clean and InspectDocument1 pageStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- Professional Postgraduate Experience Form - 0Document3 pagesProfessional Postgraduate Experience Form - 0pratim deyNo ratings yet

- BlankDocument2 pagesBlankAcel Paolo MojicaNo ratings yet

- Msds 0864 Aquafill Wallfiller Fine en 1Document10 pagesMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNo ratings yet

- Hempel Paint - MSDSDocument14 pagesHempel Paint - MSDSbaseet gazaliNo ratings yet

- Month - Year - Iq Series Maintenance LogDocument2 pagesMonth - Year - Iq Series Maintenance Logrqu3lNo ratings yet

- Excavation ManuallyDocument1 pageExcavation ManuallyJack PNo ratings yet

- Flow Chart For Fire Drill Operation:: Emerrgency ControllerDocument1 pageFlow Chart For Fire Drill Operation:: Emerrgency ControllerIwan Ms100% (2)

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocument10 pagesSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNo ratings yet

- Catalogo Bomba Gabbioneta Modelo VBNDocument2 pagesCatalogo Bomba Gabbioneta Modelo VBNcristobal_tl2277No ratings yet

- Eyewashinspection Checklist 2012 - 0Document1 pageEyewashinspection Checklist 2012 - 0perezismaelNo ratings yet

- Condenser Chemical CleaningDocument12 pagesCondenser Chemical CleaningBibhu Misra100% (1)

- Concresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarDocument4 pagesConcresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarFrancois-No ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- A Sample Preventative Maintenance Schedule PDFDocument2 pagesA Sample Preventative Maintenance Schedule PDFreda100% (1)

- Welding Procedure Specification (WPS)Document30 pagesWelding Procedure Specification (WPS)ganathaNo ratings yet

- Health and Safety Induction SampleDocument5 pagesHealth and Safety Induction SampleMohamad Hafiz100% (1)

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoNo ratings yet

- SWMS 1 Loading, Unloading & ShiftingDocument8 pagesSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNo ratings yet

- Pre Flow ChecklistDocument4 pagesPre Flow ChecklistDavid Glawson0% (1)

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-No ratings yet

- Fire Safety Checklist for Saudi Aramco CampsDocument5 pagesFire Safety Checklist for Saudi Aramco CampsHaleem Ur Rashid BangashNo ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rFNo ratings yet

- Split Unit InstallationDocument33 pagesSplit Unit Installationsree100% (1)

- Compressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019Document2 pagesCompressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019MOHAMMEDNo ratings yet

- Method Statement For Ultrasonic Testing: DCSM Project 2019Document5 pagesMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNo ratings yet

- PT. Citilink Indonesia N P W P: 0 2 - 8 2 7 - 5 9 7 - 2 - 0 9 3 - 0 0 0 Jl. Raya Juanda Sawotratap Gedangan SidoarjoDocument2 pagesPT. Citilink Indonesia N P W P: 0 2 - 8 2 7 - 5 9 7 - 2 - 0 9 3 - 0 0 0 Jl. Raya Juanda Sawotratap Gedangan SidoarjoZemNo ratings yet

- SupermanDocument3 pagesSupermanGlen Michael F. WongNo ratings yet

- 9-10 Manajemen Fasilitas Dan Keselamatan - PCC, HSEDocument30 pages9-10 Manajemen Fasilitas Dan Keselamatan - PCC, HSEMars Esa UnggulNo ratings yet

- Design and Development of A Three Phase Induction Motor Drive Using Ni-MyrioDocument5 pagesDesign and Development of A Three Phase Induction Motor Drive Using Ni-MyriovinaykumaarNo ratings yet

- District Potential Analysis of PilibhitDocument57 pagesDistrict Potential Analysis of PilibhitJasraj SinghNo ratings yet

- Sika Poxitar FDocument3 pagesSika Poxitar FBudhi KurniawanNo ratings yet

- Transformer Protection Techniques for Fault DetectionDocument32 pagesTransformer Protection Techniques for Fault DetectionshashankaumNo ratings yet

- ID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKDocument2 pagesID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKsaenuddinNo ratings yet

- HPLC Determination of Caffeine in Coffee BeverageDocument7 pagesHPLC Determination of Caffeine in Coffee Beveragemuhammad ihklasulNo ratings yet

- Chapter 18Document10 pagesChapter 18nehallakdawalaNo ratings yet

- ASTM D7246-06 (Reapproved 2015)Document3 pagesASTM D7246-06 (Reapproved 2015)Phạm Thu HuyềnNo ratings yet

- F 856 - 97 - Rjg1ni05nw - PDFDocument7 pagesF 856 - 97 - Rjg1ni05nw - PDFRománBarciaVazquezNo ratings yet

- Hazard Identification 2. Risk AssessmentDocument5 pagesHazard Identification 2. Risk AssessmentNoreen Syakireen Binti NormanNo ratings yet

- Subsea Cable Floats: Rising To Your Undersea ChallengesDocument1 pageSubsea Cable Floats: Rising To Your Undersea ChallengesMAURICIO DE LOS SANTOS HERNANDEZNo ratings yet

- Artificial Intelligence in Rheumatology: Applications and ChallengesDocument39 pagesArtificial Intelligence in Rheumatology: Applications and ChallengesMaryame BoutkhilNo ratings yet

- 2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFDocument16 pages2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFNaeem AnjumNo ratings yet

- Altivar 71 - ATV71H037M3Document13 pagesAltivar 71 - ATV71H037M3Mite TodorovNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak YojanaDocument19 pagesPradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak Yojanapriyajaiswal428No ratings yet

- ActinobacillosisDocument16 pagesActinobacillosisMd Shamim AhasanNo ratings yet

- How to Compost at Home: A Guide to the BasicsDocument10 pagesHow to Compost at Home: A Guide to the BasicsYeo Choon SengNo ratings yet

- Neurological Assessment CaseDocument13 pagesNeurological Assessment Casedrrajmptn0% (1)

- VAC Form 2 CityMunicipal Consolidated FormDocument1 pageVAC Form 2 CityMunicipal Consolidated Formalex almarioNo ratings yet

- RUPEX Coupling RWNDocument26 pagesRUPEX Coupling RWNWaris La Joi WakatobiNo ratings yet