Professional Documents

Culture Documents

Etame Platform Linepipes Data Sheets

Uploaded by

William O OkolotuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Etame Platform Linepipes Data Sheets

Uploaded by

William O OkolotuCopyright:

Available Formats

ETAME PLATFORM DEVELOPMENT PROJECT

DOCUMENT NAME DOCUMENT NUMBER

Linepipes and Bends Material Data Sheets 09630-ET-305-02

PROJECT NO. PAGE REVISION

09630 2 of 6 0

CHANGE RECORD

REVISION ITEM

DESCRIPTION OF CHANGE

NUMBER NUMBER

0 1 Approved for Procurement

09630-ET-305-02-R0_Linepipes and Bends Material Data Sheets.docx MCDERMOTT ENGINEERING, LLC

ETAME PLATFORM DEVELOPMENT PROJECT

DOCUMENT NAME DOCUMENT NUMBER

Linepipes and Bends Material Data Sheets 09630-ET-305-02

PROJECT NO. PAGE REVISION

09630 3 of 6 0

09630-ET-305-02

Etame Development Project

Linepipes and Bends Material Data Sheets 08JAN13

Page 1 of 1

General Rev.

Log:

Risers for ET-5H & ET-6H, Etame2 and future. PLEM

1a Application

Pipe Spool for skid.

Outside Diameter 6.625 in

Inside Diameter 4.897 in

Wall Thickness 0.864 in B

Application Riser and Flowline for Etame3 D

Outside Diameter 4.500 in

1b

Inside Diameter 3.826 in

Wall Thickness 0.337 in (note 4) B

Manufacturing

2 Seamless (notes 1, 2, & 3)

Process

Material

3 Specification API 5L PSL 2

X-52 for 6.625" OD Linepipe B

4 Grade

X-52 for 4.500" OD Linepipe B

Service

5 Temperature Maximum: 220°F Minimum: 55 °F

Charpy V-Notch Test

6 Ref. to API 5L 44th edition

Temp

3,350 psig for 6.625" OD Linepipe B

7 Design Pressure

2,200 psig for 4.500" OD Linepipe B

8 Conditions Standard, Yes Critical, No Sweet Service

Well Stream for ET-

9a 5H, ET-6H & Two Gas/Oil/Water Three Phases

Nos. of Future Risers

Product Stream Export Product for

9b Gas/Oil Two Phases

Etame2

Fuel Supply/Gas Lift

9c Gas/Oil/Water Three Phases

for Etame3

Fluid Composition

10a Export Product for Etame2, ET-5H & ET-6H & Future Risers, Skid Spools - see Table 1

Fuel Supply/Gas Lift/Gas Production for Etame3 riser and Flowline and Spools - See

10b

Table 1

09630-ET-305-02-R0_Linepipes and Bends Material Data Sheets.docx MCDERMOTT ENGINEERING, LLC

ETAME PLATFORM DEVELOPMENT PROJECT

DOCUMENT NAME DOCUMENT NUMBER

Linepipes and Bends Material Data Sheets 09630-ET-305-02

PROJECT NO. PAGE REVISION

09630 4 of 6 0

Notes:

1. Manufacturing, Tolerances and testing of linepipe shall be in accordance with API 5L 44th

edition. Table 2 or Table 3 shall supersede those given in API 5L for linepipes installed using

S-Lay or reel lay vessel, respectively.

2. Marking on the pipe shall include the API Monogram, heat number, pipe number, and

dimensions in accordance with API 5L 44th edition.

3. Steel bevel protector shall be provided to both ends of the pipe. B

4. Minimum wall thickness after bending shall be no thinner than 0.3154" for 4.500" OD linepipe.

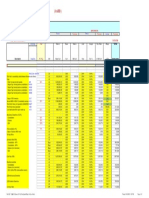

Table 1 - Product Stream Composition

Etame1 &

Etame2 , ET- Etame3 Etame3

5H & ET-6H, Fuel Gas

Future Risers, Supply Lift

PLEM Spools

Component Mixture Liquid (Mole %) Gas (Mole %)

N2 2.876 0.2382 5.512

CO2 0.219 0.0840 0.400

C1 41.491 7.2561 77.948

C2 5.195 2.7464 8.865

C3 2.431 2.3915 3.321

iC4 0.976 1.2956 0.991

nC4 1.223 1.7380 1.043

iC5 0.754 1.2347 0.374

nC5 0.993 1.6669 0.408

C6 1.608 2.8864 0.275

C7 1.959 3.6090 0.154

C8 2.389 4.4457 0.092

C9 1.906 3.5596 0.031

C10 1.762 3.2958 0.011

C11+ 33.873 63.4168 --

H2O 0.343 0.1353 0.575

Total 100.000 100.000 100.000

09630-ET-305-02-R0_Linepipes and Bends Material Data Sheets.docx MCDERMOTT ENGINEERING, LLC

ETAME PLATFORM DEVELOPMENT PROJECT

DOCUMENT NAME DOCUMENT NUMBER

Linepipes and Bends Material Data Sheets 09630-ET-305-02

PROJECT NO. PAGE REVISION

09630 5 of 6 0

Table 2 - Linepipe Tolerances for S-Lay

09630-ET-305-02-R0_Linepipes and Bends Material Data Sheets.docx MCDERMOTT ENGINEERING, LLC

ETAME PLATFORM DEVELOPMENT PROJECT

DOCUMENT NAME DOCUMENT NUMBER

Linepipes and Bends Material Data Sheets 09630-ET-305-02

PROJECT NO. PAGE REVISION

09630 6 of 6 0

Table 3 - Additional Requirements for the Reeling of Linepipes

(Carbon Steel - Seamless)

Additional pipe requirements for reeling are stated in this addendum. This addendum shall be used in conjunction with the

base line pipe specification, AWS specification and API 5L

General Requirements

b. Applicable for pipes subjected to single event normal strain > 1% or accumulated strain > 2% during installation or operation

e. In case of conflict between governing standards, the more stringent requirement shall apply.

Manufacturing Process

1 Steel making process shall be either 'Normailized' or 'Quenched and Tempered'

Mechanical Properties Before Strain Aging

Test shall be performed at the following frequency for the same cold expansion ratio

2

Once in not more than 100 pipes for D < 18"

3 Yield strength spread (Measured max Y.S – Measured min Y.S) ≤ 14.5ksi

4 Maximum yield strength shall be ≤ SMYS+17.4 ksi

Measured yield to tensile ratio

5 Transverse specimen ≤ 0.85

Longitudinal specimen ≤ 0.87

Minimum elongation

6 Proportional tests ≥ 20% and

Non-proportional tests (if applicable) converted to ISO 2566/1 ≥ 25%

Mechanical Properties After Strain Aging

Finished pipe shall be tested after subjecting it to longitdinal, uniaxial strain of 3% (or greater if stated in purchase

order) and aging it at 250°C (482°F) for 1 hr. Test specimen shall be extracted from the regions of the pipe that

experience the maximum cumulative strain. Following test requirements shall be met after strain aging.

7 Measured yield to tensile ratio (after strain aging) ≤ 0.97

8 Minimum elongation (after strain aging) ≥ 15%

9 Requirements for V-notch impact toughness test are same as that of the base metal before strain aging

10 Requirements for hardness test are same as that of the base metal before strain aging

Dimensional Tolerances

Item Characteristic to be tested Extent of Test Tolerance

11 Wall thickness, t ≤ 0.787" 100% -5.0% t, +15% t

-5.0% t, but max. 0.059"

12 Wall thickness, t > 0.787" 100%

+15% t, but max. 0.177"

13 Pipe body OD ≤ 12" 20% ± 0.5% D but max. ± 0.05"

14 Pipe body OD 12" < D ≤ 18" 20% ± 0.75% D but max. ± 0.118"

15 Pipe end ID for OD ≤ 12" 100% (Note 4) Greater of ± 0.02" or ± 0.3% D

16 Pipe end ID for 12" < D ≤ 18" 100% (Note 4) ± 0.063"

≤ 15% or max. combined

17 ID to OD Eccentricity 20% difference in wall thickness ≤

0.075", whichever is lesser.

Note: 1. D = Outside pipe diameter.

2. t = Specified wall thickness.

3. Eccentricity = Difference between maximum and minimum wall thickness divided by nominal wall thickness

4. Dimensions to be taken within 4in. of pipe ends

09630-ET-305-02-R0_Linepipes and Bends Material Data Sheets.docx MCDERMOTT ENGINEERING, LLC

You might also like

- Dictionary of Physical GeographyDocument626 pagesDictionary of Physical GeographyDiana Olarasu100% (3)

- Basics of Paint FormulationDocument21 pagesBasics of Paint FormulationTORA75% (4)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pipeline Quality Control ProcedureDocument20 pagesPipeline Quality Control Procedurebelhaska100% (2)

- Ts LSAW SpecificationDocument40 pagesTs LSAW Specificationkbpatel123No ratings yet

- Flanged Joints, Gaskets, and Bolting: ScopeDocument20 pagesFlanged Joints, Gaskets, and Bolting: Scopebenedicto soto mestanzaNo ratings yet

- Design Philosophy - StaticDocument61 pagesDesign Philosophy - StaticDarshan PanchalNo ratings yet

- Structural SectionsDocument45 pagesStructural SectionsIgnatius SamrajNo ratings yet

- Powerpoint DoseDocument16 pagesPowerpoint DoselcsmfoxNo ratings yet

- Hydrotest Blind PDFDocument9 pagesHydrotest Blind PDFManu Jojo100% (1)

- API 5CT Casing MaterialDocument6 pagesAPI 5CT Casing Materialkaveh-bahiraee100% (2)

- SE Sumatra Gas Project Feed Shop Pipe Bend SpecDocument12 pagesSE Sumatra Gas Project Feed Shop Pipe Bend SpecRokan PipelineNo ratings yet

- HLV & Express Mobilization for Offshore Gabon ProjectDocument97 pagesHLV & Express Mobilization for Offshore Gabon ProjectWilliam O OkolotuNo ratings yet

- Standard Spec for SAWL Line PipeDocument35 pagesStandard Spec for SAWL Line PipeNima Sharifi100% (1)

- Metocean Design Criteria ReportDocument129 pagesMetocean Design Criteria ReportWilliam O OkolotuNo ratings yet

- Pump House Piping ProcedureDocument9 pagesPump House Piping ProcedureSaurabh Kumar VermaNo ratings yet

- A Fast Integration Method For Translating-Pulsating Green's Function in Bessho's FormDocument12 pagesA Fast Integration Method For Translating-Pulsating Green's Function in Bessho's FormYuriy KrayniyNo ratings yet

- GP-06!01!01 TEMA Type Shell-And-Tube HeatDocument23 pagesGP-06!01!01 TEMA Type Shell-And-Tube HeatFrancesco AvogadroNo ratings yet

- Phase Array Ultrasonic Testing ProcedurDocument43 pagesPhase Array Ultrasonic Testing ProcedurTĩnh Hồ Trung100% (5)

- Total Field Development: Integrated ServicesDocument16 pagesTotal Field Development: Integrated ServicesWilliam O Okolotu100% (1)

- MEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorDocument10 pagesMEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorimyourscinNo ratings yet

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- 2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Document217 pages2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Thiago Schmitt De Araujo de MattosNo ratings yet

- Uu00 B LDSG 000 0001 - Oldpipingdesign - Useful PDFDocument51 pagesUu00 B LDSG 000 0001 - Oldpipingdesign - Useful PDFBharuk MechNo ratings yet

- DR Engp 1.1 R 6Document740 pagesDR Engp 1.1 R 6Beatriz BerçotNo ratings yet

- Thermal Comfort in ArchitectureDocument11 pagesThermal Comfort in ArchitecturearchaikhNo ratings yet

- New Scientist - 13 February 2016 PDFDocument60 pagesNew Scientist - 13 February 2016 PDFEugenio Manuel Fernández AguilarNo ratings yet

- Banchmark Olga Vs LedaDocument79 pagesBanchmark Olga Vs Ledasri9987100% (1)

- Screw Thread ReportDocument17 pagesScrew Thread Reportkittikhun_simlee100% (1)

- Physics Investigatory ProjectDocument14 pagesPhysics Investigatory ProjectAbhishek Raja88% (16)

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- ALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials SupplementDocument327 pagesALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials Supplementahmed.njahNo ratings yet

- Post Weld Head Treament Piping-ProcedureDocument12 pagesPost Weld Head Treament Piping-ProcedureAnh Võ100% (1)

- Piping Standard and Material For Oil Production and Process FacilitiesDocument1,277 pagesPiping Standard and Material For Oil Production and Process FacilitiesCarlosIkedaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Gen-Spc-Pip-5050 - Rev. BDocument40 pagesGen-Spc-Pip-5050 - Rev. BAHMED AMIRANo ratings yet

- SNO P GS 001 Rev0 EPC General RequirementDocument160 pagesSNO P GS 001 Rev0 EPC General Requirementaike_5No ratings yet

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocument15 pages(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiNo ratings yet

- Easily control your TV with one remoteDocument4 pagesEasily control your TV with one remoteJeradin_01No ratings yet

- Coating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04Document16 pagesCoating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04lemuel bacsaNo ratings yet

- Vaalco Etame Pipeline NDE SOW - Rev ADocument8 pagesVaalco Etame Pipeline NDE SOW - Rev AWilliam O OkolotuNo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Provision of EPCC Services for Sufyan EPF Project Globe Valve Data SheetDocument4 pagesProvision of EPCC Services for Sufyan EPF Project Globe Valve Data SheetSandeepNBabuNo ratings yet

- 04 Datasheet Control ValveDocument8 pages04 Datasheet Control ValveFadlila MuhammadNo ratings yet

- GAIL Gas City Project Piping SpecificationDocument199 pagesGAIL Gas City Project Piping SpecificationankeshkatochNo ratings yet

- Air Filter Regulator CA Gas 94539Document2 pagesAir Filter Regulator CA Gas 94539mishtinilNo ratings yet

- Flexible HoseDocument1 pageFlexible HoseKhánh TrầnNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- UE-BHEL-054-MPP-04 Rev.03Document6 pagesUE-BHEL-054-MPP-04 Rev.03udayakarnaNo ratings yet

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocument7 pagesDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967No ratings yet

- 04 JP - WeldingDocument8 pages04 JP - WeldingShubhamShuklaNo ratings yet

- UE-BHEL-054-MPP-03 Rev.01Document6 pagesUE-BHEL-054-MPP-03 Rev.01udayakarnaNo ratings yet

- Isulation GasketDocument1 pageIsulation GasketKhánh TrầnNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Daewoong Environment Technology Company ProfileDocument46 pagesDaewoong Environment Technology Company ProfileAndy ChristyonoNo ratings yet

- 1280a4-8230-Sp-0001 Rev F3Document18 pages1280a4-8230-Sp-0001 Rev F3Stephen LowNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Gen-Spc-Pip-5100 - Rev. BDocument8 pagesGen-Spc-Pip-5100 - Rev. BAHMED AMIRANo ratings yet

- New 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveDocument4 pagesNew 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveSandeepNBabuNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- Required Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesDocument23 pagesRequired Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesmladenprNo ratings yet

- 5 PDFDocument28 pages5 PDFJunaidNo ratings yet

- Piper SB 952 One Piece Exhaust Pipe InstallationDocument6 pagesPiper SB 952 One Piece Exhaust Pipe InstallationGeorgios AsimakopoulosNo ratings yet

- Pressure Vessel and ExchangerDocument17 pagesPressure Vessel and ExchangerJose FedeNo ratings yet

- 4" X 3Km Onsho Terminal Produce Water Pipeline Project: Otakikpo FieldDocument6 pages4" X 3Km Onsho Terminal Produce Water Pipeline Project: Otakikpo Fieldresp-ectNo ratings yet

- Revised Weld Map (23!07!2015)Document15 pagesRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Hot Induction Bend Data SheetDocument3 pagesHot Induction Bend Data SheetRami KsidaNo ratings yet

- Junt Sub. GenDocument109 pagesJunt Sub. GenInternational companyNo ratings yet

- Ds-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Document2 pagesDs-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Panisa BanimaNo ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities Project Piping SpecificationDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities Project Piping SpecificationneivaprojetosNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- FMMG Technical Note - ETAME12-1 Advanced Final Engineering (FINAL)Document11 pagesFMMG Technical Note - ETAME12-1 Advanced Final Engineering (FINAL)William O OkolotuNo ratings yet

- LDD DiscussionDocument1 pageLDD DiscussionWilliam O OkolotuNo ratings yet

- Vaalco Manual Compliance Transmittal LetterDocument1 pageVaalco Manual Compliance Transmittal LetterWilliam O OkolotuNo ratings yet

- VaalcoDocument3 pagesVaalcoWilliam O OkolotuNo ratings yet

- Flood&VentDocument1 pageFlood&VentWilliam O OkolotuNo ratings yet

- Method Statement Drilling Operations MS002: Uncontrolled When PrintedDocument6 pagesMethod Statement Drilling Operations MS002: Uncontrolled When PrintedWilliam O OkolotuNo ratings yet

- The Mudmats Areas Shown Are Approximate. Final Areas and Details Are To Be Determined. Some Typical Details Are Shown On The Following PagesDocument4 pagesThe Mudmats Areas Shown Are Approximate. Final Areas and Details Are To Be Determined. Some Typical Details Are Shown On The Following PagesWilliam O OkolotuNo ratings yet

- Helideck (SEENT)Document1 pageHelideck (SEENT)William O OkolotuNo ratings yet

- (In Usd) : Values Values Values Values ValuesDocument1 page(In Usd) : Values Values Values Values ValuesWilliam O OkolotuNo ratings yet

- 0 4 Installation RFQ Table of ContentsDocument1 page0 4 Installation RFQ Table of ContentsWilliam O OkolotuNo ratings yet

- Sling ProtectorDocument1 pageSling ProtectorWilliam O OkolotuNo ratings yet

- 16 Children and Their Bedrooms From Across The WorldDocument51 pages16 Children and Their Bedrooms From Across The WorldWilliam O OkolotuNo ratings yet

- 1.1 General Scope of Work and Instructions To Bidders Etame-100 Offshore InstallationDocument112 pages1.1 General Scope of Work and Instructions To Bidders Etame-100 Offshore InstallationWilliam O OkolotuNo ratings yet

- LEX Vaalco Mob Summary 30 Jan 2014Document3 pagesLEX Vaalco Mob Summary 30 Jan 2014William O OkolotuNo ratings yet

- "Lewek Constellation" - Survey Equipment Costs 2010 Prices/rentalDocument3 pages"Lewek Constellation" - Survey Equipment Costs 2010 Prices/rentalWilliam O OkolotuNo ratings yet

- HW-1-SUBS6310-FA 2013spring PDFDocument1 pageHW-1-SUBS6310-FA 2013spring PDFWilliam O OkolotuNo ratings yet

- Offshore Installation ProposalDocument7 pagesOffshore Installation ProposalWilliam O OkolotuNo ratings yet

- Pipesim Ps PDFDocument2 pagesPipesim Ps PDFWilliam O OkolotuNo ratings yet

- "Lewek Constellation" Survey, Acoustic and Positioning SensorsDocument3 pages"Lewek Constellation" Survey, Acoustic and Positioning SensorsWilliam O OkolotuNo ratings yet

- Flow Assurance System ApproachDocument1 pageFlow Assurance System ApproachWilliam O OkolotuNo ratings yet

- HW-2-SUBS6310-FA 2013spring PDFDocument2 pagesHW-2-SUBS6310-FA 2013spring PDFWilliam O OkolotuNo ratings yet

- How A Well FlowsDocument34 pagesHow A Well FlowsfddddddNo ratings yet

- Arrangement Drawings, Reel: 3769 Vaalco Etame Project PURCHASE ORDER NO. 200002186-001 3 Off 5" Id Production FlowlinesDocument9 pagesArrangement Drawings, Reel: 3769 Vaalco Etame Project PURCHASE ORDER NO. 200002186-001 3 Off 5" Id Production FlowlinesWilliam O OkolotuNo ratings yet

- Integrated Flow Assurance Analysis From "Reservoir To Export"Document6 pagesIntegrated Flow Assurance Analysis From "Reservoir To Export"William O OkolotuNo ratings yet

- Pipe Flow Expert User GuideDocument188 pagesPipe Flow Expert User Guidejcd_9No ratings yet

- Packing, Marking & Load-Out InstructionsDocument11 pagesPacking, Marking & Load-Out InstructionsWilliam O OkolotuNo ratings yet

- Retentores - ParkerpdfDocument68 pagesRetentores - ParkerpdfdilsonramosNo ratings yet

- LT Power & Control Cables GuideDocument4 pagesLT Power & Control Cables GuideamiteshNo ratings yet

- Molecular DeviceDocument26 pagesMolecular Device7semNo ratings yet

- Understanding Lift Beyond the Skipping Stone TheoryDocument2 pagesUnderstanding Lift Beyond the Skipping Stone TheorypreetNo ratings yet

- Lecture 4 - Application To Manometry PDFDocument15 pagesLecture 4 - Application To Manometry PDFLendo PosaraNo ratings yet

- Revised 2023-24 - Sr.2Hrs Programme - Teaching & Test Schedule@17!10!2023Document67 pagesRevised 2023-24 - Sr.2Hrs Programme - Teaching & Test Schedule@17!10!2023suhasiyer02No ratings yet

- 2.2 and 2.3 TestDocument8 pages2.2 and 2.3 TestLeo DennisNo ratings yet

- Create mathematical relationships in SOLIDWORKSDocument33 pagesCreate mathematical relationships in SOLIDWORKSprasenjitsayantanNo ratings yet

- Air PermeabilityDocument3 pagesAir PermeabilityChuxuan SunNo ratings yet

- 28-Article Text-250-1-10-20210930slopeDocument7 pages28-Article Text-250-1-10-20210930slopeAhmad Nurfadil IbrohimNo ratings yet

- Bijection and Cardinality: Discrete Mathematics Slides by Andrei BulatovDocument23 pagesBijection and Cardinality: Discrete Mathematics Slides by Andrei BulatovChris HoyNo ratings yet

- Smart Hospital Fault Detection and Alert SystemDocument21 pagesSmart Hospital Fault Detection and Alert SystemPravat SatpathyNo ratings yet

- OsmosisDocument9 pagesOsmosisNadia NovitaNo ratings yet

- Crystallography 333Document613 pagesCrystallography 333Biciin MarianNo ratings yet

- Method of MomentsDocument4 pagesMethod of MomentsladyfairynaNo ratings yet

- TUCSS Annual Lecture 2023 Shirlaw SlidesDocument51 pagesTUCSS Annual Lecture 2023 Shirlaw SlidesKo Pyi SoeNo ratings yet

- Tall Buildings Paper PDFDocument5 pagesTall Buildings Paper PDFShekhar V MadhaviNo ratings yet

- Egger and Lassmann (2012) - The Language Effect in International Trade A Meta-AnalysisDocument4 pagesEgger and Lassmann (2012) - The Language Effect in International Trade A Meta-AnalysisTan Jiunn WoeiNo ratings yet