Professional Documents

Culture Documents

Hastelloy G-30 Alloy: Principal Features

Uploaded by

Lizbeth CamachoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hastelloy G-30 Alloy: Principal Features

Uploaded by

Lizbeth CamachoCopyright:

Available Formats

HASTELLOY® G-30® alloy

Principal Features

30 years of proven performance in “wet process” phosphoric acid

HASTELLOY® G-30® alloy (UNS # N06030) is a nickel-chromium-iron material highly re-

sistant to “wet process” phosphoric acid (P2O5). P2O5 is one of the most important indus-

trial chemicals, being the primary source of phosphorus for agrichemical fertilizers. G-30®

alloy is also moderately resistant to chloride-induced localized attack, which can be a prob-

lem beneath deposits in the evaporators used to concentrate P2O5. Furthermore, G-30®

alloy is less susceptible to chloride-induced stress corrosion cracking than the stainless

steels.

As a result of its high chromium content, G-30® alloy is also very resistant to other oxidizing

acids, such as nitric, and mixtures containing nitric acid. It possesses moderate resistance

to reducing acids, such as hydrochloric and sulfuric, as a result of its appreciable molybde-

num and copper contents.

HASTELLOY® G-30® alloy is available in the form of plates, sheets, strips, billets, bars,

wires, pipes, tubes, and covered electrodes. Applications include P2O5 evaporator tubes

and nitric acid-based, metal pickling hardware.

Nominal Composition

Weight %

Nickel: 43 Balance

Chromium: 30

Iron: 15

Molybdenum: 5.5

Tungsten: 2.5

Copper: 2

Niobium: 0.8

Cobalt: 5 max.

Manganese: 1.5 max.

Silicon: 0.8 max.

Carbon: 0.03 max.

H-2028F © 2020 Haynes International

Resistance to "Wet Process"

Phosphoric Acid

“Wet process” phosphoric acid (P2O5) is made by reacting phosphate rock with sulfuric

acid. As produced, it contains many impurities, and has a P2O5 concentration of only about

30%, because of the large amount of rinse water needed to separate it from the other main

reaction product, calcium sulfate. Typical impurities include unreacted sulfuric acid, various

metallic ions, fluoride ions, and chloride ions. The fluoride ions tend to form complexes with

the metallic ions, and are therefore less of a problem than the chloride ions, which strongly

influence electrochemical reactions between “wet process” phosphoric acid and metallic

materials. Particulate matter (for example, silica particles) can also be present in “wet pro-

cess” acid.

The main use of metallic materials is in the concentration process, where the “wet process”

acid is taken through a series of evaporation steps, involving metallic tubing. Typically, the

P2O5 concentration is raised to 54% during this process. The concentration effect upon the

corrosivity of the acid is somewhat offset by the fact that the impurity levels drop as the

concentration increases.

The following chart, comparing G-30® alloy with competitive stainless steels, is based on

tests in three concentrations (36, 48, and 54%) of “wet process” phosphoric acid (supplied

by a producer in Florida, USA) at 121°C (250°F).

Haynes International - HASTELLOY® G-30® alloy

Iso-Corrosion Diagrams

Each of these iso-corrosion diagrams was constructed using numerous corrosion rate

values, generated at different acid concentrations and temperatures. The blue line repre-

sents those combinations of acid concentration and temperature at which a corrosion rate

of 0.1 mm/y (4 mils per year) is expected, based on laboratory tests in reagent grade ac-

ids. Below the line, rates under 0.1 mm/y are expected. Similarly, the red line indicates the

combinations of acid concentration and temperature at which a corrosion rate of 0.5 mm/y

(20 mils per year) is expected. Above the line, rates over 0.5 mm/y are expected. Between

the blue and red lines, corrosion rates are expected to fall between 0.1 and 0.5 mm/y.

Comparative 0.1 mm/y Line Plots

To compare the performance of HASTELLOY® G-30® alloy with that of other materials, it

is useful to plot the 0.1 mm/y lines. In the following graphs, the lines for G-30® alloy are

compared with those of 625 alloy, 254SMO alloy, and 316L stainless steel, in hydrochloric

and sulfuric acids. Note that the line for G-30® alloy is slightly higher than that for 625 alloy

in sulfuric acid. The hydrochloric acid concentration limit of 20% is the azeotrope, above

which corrosion tests are less reliable.

Haynes International - HASTELLOY® G-30® alloy

Selected Corrosion Data

Hydrochloric Acid

Conc. 50°F 75°F 100°F 125°F 150°F 175°F 200°F 225°F

Wt.% 10°C 24°C 38°C 52°C 66°C 79°C 93°C 107°C Boiling

1 - - - - <0.01 <0.01 <0.01 - 0.01

1.5 - - - - - - - - -

2 - - - <0.01 <0.01 - - - 9.47

2.5 - - - <0.01 1.04 2.06 4.23 - 12.67

3 - - <0.01 <0.01 - - - - -

3.5 - - - - - - - - -

4 - - - - - - - - -

4.5 - - - - - - - - -

5 - <0.01 0.33 0.71 1.33 2.65 9.06 - -

7.5 <0.01 0.05 - - - - - - -

10 0.08 0.19 0.44 0.64 1.48 3.96 15.21 - -

15 0.13 0.31 0.66 1.87 1.47 - 11.98 - -

20 - 0.13 0.3 0.55 1.24 - 10.9 - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year, divide by 0.0254.

Data are from Corrosion Laboratory Jobs 446-82, 168-89, and 66-96.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to industrial use.

Haynes International - HASTELLOY® G-30® alloy

Selected Corrosion Data Continued

Sulfuric Acid

Conc. 75°F 100°F 125°F 150°F 175°F 200°F 225°F 250°F 275°F 300°F 350°F

Wt.% 24°C 38°C 52°C 66°C 79°C 93°C 107°C 121°C 135°C 149°C 177°C Boiling

1 - - - - - - - - - - - -

2 - - - - - - - - - - - -

3 - - - - - - - - - - - -

4 - - - - - - - - - - - -

5 - - - - <0.01 <0.01 - - - - - 0.47

10 - - - - <0.01 <0.01 - - - - - 0.78

20 - - - - <0.01 0.36 - - - - - 1.35

30 - - - - 0.01 0.55 - - - - - 1.53

40 - - - 0.02 0.05 0.54 - - - - - 1.95

50 - <0.01 <0.01 0.01 0.26 0.56 0.93 - - - - 3.68

60 - - <0.01 0.09 0.27 0.73 1.07 - - - - 8.46

70 - <0.01 0.01 0.11 0.36 0.98 1.38 - - - - -

80 - - 0.31 1.13 2.62 4.52 4.7 - - - - -

90 - <0.01 0.67 2.01 3.25 6.55 6.25 - - - - -

96 - - 0.45 1.86 2.04 1.86 1.52 - - - - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year, divide by 0.0254.

Data are from Corrosion Laboratory Job 449-82.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to industrial use.

Haynes International - HASTELLOY® G-30® alloy

Selected Corrosion Data (Reagent Grade Solutions, mm/y)

Concentration 100°F 125°F 150°F 175°F 200°F

Chemical wt.% 38°C 52°C 66°C 79°C 93°C Boiling

Acetic Acid 99 - - - - - 0.03

5 - - 0.02 - - 0.4

Chromic Acid

10 - - 0.14 - - 1.23

Formic Acid 88 - - - - - 0.05

1 - - <0.01 <0.01 <0.01 0.01

2 - <0.01 <0.01 - - 9.47

2.5 - <0.01 1.04 2.06 4.23 -

Hydrochloric 3 <0.01 <0.01 - - - -

Acid 5 0.33 0.71 1.33 2.65 - -

10 0.44 0.64 1.48 3.96 - -

15 0.66 1.87 1.47 - - -

20 0.3 0.55 1.24 - - -

50 - - - - - 0.08

Nitric Acid 60 - - - - - 0.14

65 - - - - - 0.16

50 - - - - <0.01 0.01

60 - - - - - 0.14

Phosphoric Acid

70 - - - - 0.01 0.35

(Reagent Grade)

80 - - - - - 0.61

85 - - - - - 0.84

10 - - - <0.01 <0.01 0.78

20 - - - <0.01 0.36 1.35

30 - - - 0.01 0.55 1.53

40 - - 0.02 0.05 0.54 1.95

50 <0.01 <0.01 0.01 0.26 0.56 -

Sulfuric Acid

60 - <0.01 0.09 0.27 0.73 -

70 <0.01 0.01 0.11 0.36 0.98 -

80 - 0.31 1.13 2.62 4.52 -

90 <0.01 0.67 2.01 3.25 6.55 -

96 - 0.45 1.86 2.04 1.86 -

Haynes International - HASTELLOY® G-30® alloy

Resistance to Pitting and Crevice Corrosion

Various chloride-bearing environments, notably Green Death (11.5% H2SO4 + 1.2% HCl

+ 1% FeCl3 + 1% CuCl2) and Yellow Death (4% NaCl + 0.1% Fe2(SO4)3 + 0.021M HCl),

have been used to compare the resistance of nickel alloys to pitting and crevice attack

(using tests of 24 hours duration). In Green Death, the lowest temperature at which pitting

has been observed in G-30 alloy is 55°C, and the lowest temperature at which crevice cor-

rosion has been observed is 45°C. In Yellow Death, the corresponding temperatures are

55°C and 25°C.

Resistance to Stress Corrosion Cracking

One of the chief attributes of the nickel alloys is their resistance to chloride-induced stress

corrosion cracking. A common solution for assessing the resistance of materials to this

extremely destructive form of attack is boiling 45% magnesium chloride (ASTM Standard G

36), typically with stressed U-bend samples. As is evident from the following results, G-30®

alloy is much more resistant to this form of attack than the comparative, austenitic stainless

steels.

Alloy Time to Cracking

316L 2h

254SMO 24 h

28 36 h

31 36 h

G-30® 168 h

Corrosion Resistance of Welds

To assess the resistance of welds to corrosion, Haynes International has chosen to test all-

weld-metal samples, taken from the quadrants of cruciform assemblies, created using mul-

tiple gas metal arc (MIG) weld passes. Notably, the resistance of all-weld-metal samples

of G-30 alloy to key, inorganic acids is close to that of the wrought, base metal in several

cases.

Concentration Temperature Corrosion Rate

Weld Metal Wrought Base Metal

Chemical wt.% °F °C mpy mm/y mpy mm/y

H2SO4 30 150 66 <0.4 <0.01 <0.4 <0.01

H2SO4 50 150 66 0.4 0.01 0.4 0.01

H2SO4 70 150 66 5.5 0.14 4.3 0.11

H2SO4 90 150 66 102.4 2.6 102.8 2.61

HCl 5 100 38 <0.4 <0.01 13 0.33

HCl 10 100 38 27.6 0.7 17.3 0.44

HCl 15 100 38 25.2 0.64 26 0.66

HCl 20 100 38 20.5 0.52 11.8 0.3

HNO3 70 Boiling 5.5 0.14 5.5 0.14

Haynes International - HASTELLOY® G-30® alloy

Physical Properties

Physical Property British Units Metric Units

Density RT 0.297 lb/in3 RT 8.22 g/cm3

RT 45.7 μohm.in RT 1.16 μohm.m

200°F 46.0 μohm.in 100°C 1.17 μohm.m

400°F 46.9 μohm.in 200°C 1.19 μohm.m

Electrical

600°F 47.8 μohm.in 300°C 1.21 μohm.m

Resistivity

800°F 48.5 μohm.in 400°C 1.23 μohm.m

1000°F 49.0 μohm.in 500°C 1.24 μohm.m

- - 600°C 1.25 μohm.m

RT 69 btu.in/h.ft2.°F RT 10 W/m.°C

200°F 81 btu.in/h.ft2.°F 100°C 12 W/m.°C

400°F 98 btu.in/h.ft2.°F 200°C 14 W/m.°C

Thermal

600°F 120 btu.in/h.ft2.°F 300°C 17 W/m.°C

Conductivity

800°F 134 btu.in/h.ft2.°F 400°C 19 W/m.°C

1000°F 141 btu.in/h.ft2.°F 500°C 20 W/m.°C

- - 600°C 21 W/m.°C

86-200°F 7.1 μin/in.°F 30-100°C 12.8 μm/m.°C

86-400°F 7.7 μin/in.°F 30-200°C 13.8 μm/m.°C

Mean Coefficient of 86-600°F 8.0 μin/in.°F 30-300°C 14.3 μm/m.°C

Thermal Expansion 86-800°F 8.3 μin/in.°F 30-400°C 14.8 μm/m.°C

86-1000°F 8.6 μin/in.°F 30-500°C 15.3 μm/m.°C

86-1200°F 8.9 μin/in.°F 30-600°C 15.8 μm/m.°C

RT 29.3 x 106 psi RT 202 GPa

400°F 28.4 x 106 psi 200°C 196 GPa

Dynamic Modulus

600°F 28.2 x 106 psi 300°C 195 GPa

of Elasticity

800°F 27.8 x 106 psi 400°C 192 GPa

1000°F 26.7 x 106 psi 500°C 187 GPa

RT= Room Temperature

Haynes International - HASTELLOY® G-30® alloy

Impact Strength

Plate Thickness Test Temperature Impact Strength*

in mm °F °C ft.lbf J

0.5 12.7 RT RT 260 353

0.5 12.7 -320 -196 262 355

*Transverse Charpy V-Notch Samples

RT=Room Temperature

Tensile Strength and Elongation

Thickness/ Test 0.2% Offset Ultimate Tensile

Bar Diameter Temperature Yield Strength Strength Elongation

Form in mm °F °C ksi MPa ksi MPa %

Sheet 0.028 0.71 RT RT 47 324 100 689 56

Sheet 0.125 3.2 RT RT 51 352 100 689 56

Plate 0.25 6.4 RT RT 46 317 98 676 55

Plate 0.375 9.5 RT RT 45 310 100 689 65

Plate 0.5 12.7 RT RT 46 317 100 689 64

Plate 0.75 19.1 RT RT 47 324 98 676 65

Plate 1.25 31.8 RT RT 45 310 99 683 60

Bar 1 25.4 RT RT 46 317 100 689 60

Plate & Bar* Various 200 93 42 290 95 655 54

Plate & Bar* Various 400 204 36 248 88 607 59

Plate & Bar* Various 600 316 33 228 83 572 59

Plate & Bar* Various 800 427 31 214 80 552 60

Plate & Bar* Various 1000 538 29 200 76 524 62

*Average results from tests of 11 plate and bar products of thickness/diameter 6.4 to 31.8 mm

RT= Room Temperature

Haynes International - HASTELLOY® G-30® alloy

Hardness

Form Hardness, HRBW Typical ASTM Grain Size

Sheet 81 1.5 - 4

Plate 80 0-3

Bar 78 0-2

All samples tested in solution-annealed condition.

HRBW = Hardness Rockwell “B”, Tungsten Indentor.

Welding and Fabrication

HASTELLOY® G-30® alloy is very amenable to the Gas Metal Arc (GMA/MIG), Gas

Tungsten Arc (GTA/TIG), and Shielded Metal Arc (SMA/Stick) welding processes. Matching

filler metals (i.e. solid wires and coated electrodes) are available for these processes, and

welding guidelines are given in our “Welding and Fabrication” brochure.

Wrought products of HASTELLOY® G-30® alloy are supplied in the Mill Annealed (MA)

condition, unless otherwise specified. This solution annealing procedure has been

designed to optimize the alloy’s corrosion resistance and ductility. Following all hot forming

operations, the material should be re-annealed, to restore optimum properties. The alloy

should also be re-annealed after any cold forming operations that result in an outer fiber

elongation of 7% or more. The annealing temperature for HASTELLOY® G-30® alloy

is 1177°C (2150°F), and water quenching is advised (rapid air cooling is feasible with

structures thinner than 10 mm (0.375 in). A hold time at the annealing temperature of

10 to 30 minutes is recommended, depending on the thickness of the structure (thicker

structures need the full 30 minutes). More details concerning the heat treatment of

HASTELLOY® G-30® alloy are given in our “Welding and Fabrication” brocure.

HASTELLOY® G-30® alloy can be hot forged, hot rolled, hot upset, hot extruded, and

hot formed. However, it is more sensitive to strain and strain rates than the austenitic

stainless steels, and the hot working temperature range is quite narrow. For example, the

recommended start temperature for hot forging is 1149°C (2100°F) and the recommended

finish temperature is 927°C (1700°F). Moderate reductions and frequent re-heating provide

the best results, as described in our “Welding and Fabrication” brochure. This reference

also provides guidelines for cold forming, spinning, drop hammering, punching, and

shearing of the HASTELLOY® alloys. G-30® alloy is stiffer than most austenitic stainless

steels, and more energy is required during cold forming. Also, G-30® alloy work hardens

more readily than most austenitic stainless steels, and may require several stages of cold

work, with intermediate anneals.

While cold work does not usually affect the resistance of HASTELLOY® G-30® alloy

to general corrosion, and to chloride-induced pitting and crevice attack, it can affect

resistance to stress corrosion cracking. For optimum corrosion performance, therefore,

the re-annealing of cold worked parts (following an outer fiber elongation of 7% or more) is

important.

Haynes International - HASTELLOY® G-30® alloy

Specifications & Codes

Specifications

HASTELLOY® G-30® alloy

(N06030, W86030)

SB 582/B 582

Sheet, Plate & Strip

P= 45

SB 581/B 581

Billet, Rod & Bar B 472

P= 45

SFA 5.11/ A 5.11 (ENiCrMo-11)

Coated Electrodes

F= 45

SFA 5.14/ A 5.14 (ERNiCrMo-11)

Bare Welding Rods & Wire

F= 45

SB 622/B 622

Seamless Pipe & Tube

P= 45

SB 619/B 619

Welded Pipe & Tube SB 626/B 626

P= 45

SB 366/B 366

Fittings SB 462/B 462

P= 45

SB 462/B 462

Forgings

P= 45

DIN No. 2.4603 NiCr30FeMo

TÜV -

NACE MR0175

Others

ISO 15156

Haynes International - HASTELLOY® G-30® alloy

Codes

HASTELLOY® G-30® alloy

UNS N06030 (W86030)

Section l -

Class 1 -

Section lll Class 2 800°F (427°C)1

Class 3 800°F (427°C)1

Div. 1 800°F (427°C)2

Section Vlll

ASME Div. 2 800°F (427°C)3

Section Xll 650°F (343°C)4

B16.5 800°F (427°C)5

B16.34 800°F (427°C)6

B31.1 -

B31.3 -

VdTÜV (doc #) -

1

Approved material forms: Plate, Sheet, Bar, Forgings, fittings, welded pipe/tube, seamless pipe/tube

2

Approved material forms: Plate, Sheet, Bar, Forgings, fittings, welded pipe/tube, seamless pipe/tube, Bolting

3

Approved material forms: Bolting

4

Approved material forms: Plate, Sheet, Bar, fittings, welded pipe/tube, seamless pipe/tube, Bolting

5

Approved material forms: Plate, Forgings, fittings

6

Approved material forms: Plate, Bar, Forgins, seamless pipe/tube

Disclaimer:

Haynes International makes all reasonable efforts to ensure the accuracy and correctness of the data in this document

but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general

information only and not for providing design advice. Alloy properties disclosed here are based on work conducted

principally by Haynes International, Inc. and occasionally supplemented by information from the open literature and,

as such, are indicative only of the results of such tests and should not be considered guaranteed maximums or

minimums. It is the responsibility of the user to test specific alloys under actual service conditions to determine their

suitability for a particular purpose.

For specific concentrations of elements present in a particular product and a discussion of the potential health affects

thereof, refer to the Safety Data Sheets supplied by Haynes International, Inc. All trademarks are owned by Haynes

International, Inc., unless otherwise indicated.

Haynes International - HASTELLOY® G-30® alloy

You might also like

- CLG816C Service Manual 201404000-EN PDFDocument423 pagesCLG816C Service Manual 201404000-EN PDFJusto Paniagua100% (1)

- Hastelloy C-276 Alloy: Principal FeaturesDocument17 pagesHastelloy C-276 Alloy: Principal FeaturesLNo ratings yet

- Raw Mix Design by Rashid Jamal (16.02.2017)Document20 pagesRaw Mix Design by Rashid Jamal (16.02.2017)Muhammad Awais0% (1)

- Prosperity Game and TreatmentDocument5 pagesProsperity Game and TreatmentБојан ЈаковљевићNo ratings yet

- IMF and World Bank AssignmentDocument5 pagesIMF and World Bank AssignmentAmazing worldNo ratings yet

- Elecrama ExhDocument44 pagesElecrama ExhMayank Dixit100% (1)

- MulcoaDocument2 pagesMulcoaRolando Cordova100% (1)

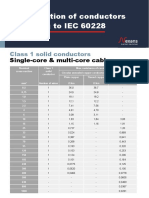

- Classification of Conductors According To IEC 60228Document3 pagesClassification of Conductors According To IEC 60228Jacob de Wilde100% (1)

- Frac SandDocument3 pagesFrac Sandcrazy boyNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Feed Water and Boiler Water of Steam GeneratorsDocument2 pagesFeed Water and Boiler Water of Steam GeneratorsIvicaT0% (2)

- Earth Magnetometer ProjectDocument17 pagesEarth Magnetometer ProjectMario Ariel VesconiNo ratings yet

- Viskositas NaOH AkhirnyaaDocument2 pagesViskositas NaOH AkhirnyaaLisa Ayu Wulandari0% (1)

- Hastelloy G-30 Alloy: Principal FeaturesDocument12 pagesHastelloy G-30 Alloy: Principal FeaturesggulsuNo ratings yet

- Iso-Corrosion Diagrams Continued: Sulfuric AcidDocument4 pagesIso-Corrosion Diagrams Continued: Sulfuric AcidsuiafwgehjdfNo ratings yet

- Chemical Compositions 1Document1 pageChemical Compositions 1Zahoor Hussain RanaNo ratings yet

- Ni-Cr-Mo Vs Ti - Part1Document4 pagesNi-Cr-Mo Vs Ti - Part1mehboobNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Physical Properties:: No Parameter Hulu Hilir Baku Mutu Aug'18 Aug'18 I II III IVDocument4 pagesPhysical Properties:: No Parameter Hulu Hilir Baku Mutu Aug'18 Aug'18 I II III IVHAFISNo ratings yet

- Zircadyne 702 705 in Formic Acid ZirconiumDocument3 pagesZircadyne 702 705 in Formic Acid ZirconiumalfinNo ratings yet

- Oil ContaminationDocument7 pagesOil ContaminationChandra AeniyahNo ratings yet

- Hervé Et Al. (2010a)Document22 pagesHervé Et Al. (2010a)Gabriel GonzálezNo ratings yet

- Kriteria Kimia Tanah-ADocument1 pageKriteria Kimia Tanah-Ayc574haNo ratings yet

- Fpi CatalogueDocument24 pagesFpi CatalogueJilce BennyNo ratings yet

- astm-b348-asme-sb348 не полныйDocument7 pagesastm-b348-asme-sb348 не полныйtit3dpowderNo ratings yet

- Improvement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingDocument38 pagesImprovement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingBinod Kumar PadhiNo ratings yet

- Direct Determination of Lime With EDTA Banerjee1976 - 2Document4 pagesDirect Determination of Lime With EDTA Banerjee1976 - 2Khalid JavedNo ratings yet

- Pipe Thickness Sizes PDFDocument1 pagePipe Thickness Sizes PDFSualp EsenliNo ratings yet

- CT Recommended Best Practices Coiled Tubing PurgingDocument2 pagesCT Recommended Best Practices Coiled Tubing PurgingAsia BelmontNo ratings yet

- Experiment 1: Zinc & CusoDocument4 pagesExperiment 1: Zinc & CusoalvintsoiwcNo ratings yet

- CAMPIMETRIA EXCEL Formulado Nov 2019 60 - 24Document53 pagesCAMPIMETRIA EXCEL Formulado Nov 2019 60 - 24ACMANo ratings yet

- Pipe B2.4.5Document1 pagePipe B2.4.5the alchemistNo ratings yet

- Hydrous and Calcined Kaolin Technical DetailsDocument2 pagesHydrous and Calcined Kaolin Technical DetailsForeverNo ratings yet

- Kobrina 1977Document5 pagesKobrina 1977mic92833292No ratings yet

- Synthetic Lubricant Case Study:-Discussing Performance Benefits Compared To Conventional OilsDocument33 pagesSynthetic Lubricant Case Study:-Discussing Performance Benefits Compared To Conventional OilsasifkhanmewNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- Iarm 86C 1Document2 pagesIarm 86C 1dpk.kushwahNo ratings yet

- Análisis de Resultados PHDocument7 pagesAnálisis de Resultados PHJuanNo ratings yet

- Nominal Pipe VelocityDocument1 pageNominal Pipe VelocityzalabiNo ratings yet

- Appendix 1 Microfine Cement Grout Testing ResultsDocument20 pagesAppendix 1 Microfine Cement Grout Testing ResultsTATATAHERNo ratings yet

- SynMax UNV Oil Analysis Presentation With Oil Sample ReportsDocument20 pagesSynMax UNV Oil Analysis Presentation With Oil Sample ReportsRoozbeh PNo ratings yet

- CCompoundingFormulations&UsefulInfo Dec2010 PDFDocument35 pagesCCompoundingFormulations&UsefulInfo Dec2010 PDFloya1987No ratings yet

- Edenor Oleo Basic Catalogue 20230508Document20 pagesEdenor Oleo Basic Catalogue 20230508AlexanderNo ratings yet

- Phosphate RockDocument3 pagesPhosphate RockManoj Kumar AcharyNo ratings yet

- Valores Orientadores EPADocument87 pagesValores Orientadores EPAJailson SilvaNo ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- Aropol 7334Document4 pagesAropol 7334GautamNo ratings yet

- HTHS Low Viscosity Oils Impact On Heavy Duty Diesel EngDocument14 pagesHTHS Low Viscosity Oils Impact On Heavy Duty Diesel Engrbulnes2350No ratings yet

- Fiber Laser Cutting SheetDocument2 pagesFiber Laser Cutting SheetRodrigo CruzNo ratings yet

- Standar Mutu Biofuel: Pusat Penelitian Surfaktan Dan Bioenergi LPPM - IpbDocument37 pagesStandar Mutu Biofuel: Pusat Penelitian Surfaktan Dan Bioenergi LPPM - IpbMa'ruf NurwantaraNo ratings yet

- Planilha Projeto SUAEDDocument8 pagesPlanilha Projeto SUAEDMANOEL JOSE DE CARVALHO NETONo ratings yet

- Sulphuric Acid Simulation Part 2 - PDFDocument3 pagesSulphuric Acid Simulation Part 2 - PDFachik realNo ratings yet

- Amr 812 246Document6 pagesAmr 812 246AdindaNo ratings yet

- Printing IEC-A - BASE DetergentDocument1 pagePrinting IEC-A - BASE DetergentSigid AriewibowoNo ratings yet

- Zener Diode: Formosa MS LL55C SeriesDocument5 pagesZener Diode: Formosa MS LL55C SeriesmoakNo ratings yet

- Zener Diode: Formosa MS LL55C SeriesDocument5 pagesZener Diode: Formosa MS LL55C SeriesmoakNo ratings yet

- Foodlog Date 2 12 24 - Daily IntakeDocument2 pagesFoodlog Date 2 12 24 - Daily Intakeapi-732118476No ratings yet

- Report CRE01Document7 pagesReport CRE01munazziliitdNo ratings yet

- FOB Megaflow AW Hydraulic Oil TDSW 814637aDocument3 pagesFOB Megaflow AW Hydraulic Oil TDSW 814637aElwin arifinNo ratings yet

- Glycol BasicsDocument5 pagesGlycol Basicsangeljebas7633No ratings yet

- Ceramic Kaolins - Subject To Updating Values and Trade Marks !Document2 pagesCeramic Kaolins - Subject To Updating Values and Trade Marks !Ahmad SholehNo ratings yet

- 2305 Refm 2Document18 pages2305 Refm 2m yudhi pramanaNo ratings yet

- Officer MatrixDocument1 pageOfficer MatrixVlad PalomoNo ratings yet

- DrugscosmeticsactDocument70 pagesDrugscosmeticsacthemihemaNo ratings yet

- Satanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESDocument140 pagesSatanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESAston WalkerNo ratings yet

- Employer Engagement ScriptDocument3 pagesEmployer Engagement ScriptAzela GladyNo ratings yet

- ISGLT en IC - Inicio Temprano para Beneficios RapidosDocument10 pagesISGLT en IC - Inicio Temprano para Beneficios RapidosAnonymous envUOdVNo ratings yet

- Inventory Management SystemDocument62 pagesInventory Management SystemIshan MalhotraNo ratings yet

- John Ortolano ResumeDocument7 pagesJohn Ortolano ResumeWEAR ABC 3No ratings yet

- Groovy Tutorial PDFDocument35 pagesGroovy Tutorial PDFPratishta TambeNo ratings yet

- Cultural Innovation StationDocument5 pagesCultural Innovation StationAriana MuñozNo ratings yet

- Fruit The Art of Pastry PDFDocument1 pageFruit The Art of Pastry PDF5kyx24kzd4No ratings yet

- Resolution No. 001 S. 2023Document4 pagesResolution No. 001 S. 2023Chad Laurence Vinson CandelonNo ratings yet

- BS EN 1503-4 2002 Valves Materials For Bodies BonnetsDocument10 pagesBS EN 1503-4 2002 Valves Materials For Bodies BonnetsолегNo ratings yet

- Proposal NewDocument17 pagesProposal NewbaseNo ratings yet

- Hierarchy Control No List of Control ExampleDocument3 pagesHierarchy Control No List of Control ExampleWeyzuo TanNo ratings yet

- Indian Council of Agricultural Research Krishi Anusandhan Bhawan-Ii, Pusa, New Delhi - 110 012Document7 pagesIndian Council of Agricultural Research Krishi Anusandhan Bhawan-Ii, Pusa, New Delhi - 110 012tholasampattiNo ratings yet

- MS 221 Volunteer AllowancesDocument8 pagesMS 221 Volunteer AllowancesAccessible Journal Media: Peace Corps DocumentsNo ratings yet

- Accounting Practice Set (Journal Ledger Trial Balance)Document13 pagesAccounting Practice Set (Journal Ledger Trial Balance)Yasmien Mae ValdesconaNo ratings yet

- CSE-SS Unit 3 QBDocument43 pagesCSE-SS Unit 3 QBJKNo ratings yet

- Different Options That Can Be Used With Sapinst Command LineDocument5 pagesDifferent Options That Can Be Used With Sapinst Command Linesai_balaji_8No ratings yet

- Real Advice On How To Cheat Turnitin in 2022Document1 pageReal Advice On How To Cheat Turnitin in 2022YandiNo ratings yet

- April 14, 2017Document16 pagesApril 14, 2017Anonymous KMKk9Msn5No ratings yet

- Team-1 Module 2 Practice-ProblemsDocument10 pagesTeam-1 Module 2 Practice-ProblemsMay May MagluyanNo ratings yet

- Find Funding: Region or Country Funder (E.g. World Bank, DFID) Topic (E.g. Water & Sanitation)Document5 pagesFind Funding: Region or Country Funder (E.g. World Bank, DFID) Topic (E.g. Water & Sanitation)Bilel MarkosNo ratings yet

- MGT3102 Case StudyDocument2 pagesMGT3102 Case StudyMon LuffyNo ratings yet

- Bdm100 Ecu FlasherDocument2 pagesBdm100 Ecu FlasherJaved IqbalNo ratings yet

- Cricket RulesDocument14 pagesCricket Rulesitmefrom2007No ratings yet