Professional Documents

Culture Documents

Iso-Corrosion Diagrams Continued: Sulfuric Acid

Uploaded by

suiafwgehjdfOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso-Corrosion Diagrams Continued: Sulfuric Acid

Uploaded by

suiafwgehjdfCopyright:

Available Formats

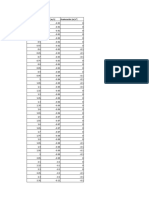

Iso-Corrosion Diagrams Continued

Sulfuric Acid

Concentration 75°F 100°F 125°F 150°F 175°F 200°F 225°F 250°F 275°F 300°F 350°F Boiling

Wt. % 24°C 38°C 52°C 66°C 79°C 93°C 107°C 121°C 135°C 149°C 177°C

1 - - - - - - - - - - - -

2 - - - - - - - - - - - -

3 - - - - - - - - - - - -

4 - - - - - - - - - - - -

5 - - - - <0.01 0.06 - - - - - 0.4

10 - - - - 0.01 0.24 - - - - - 1.05

20 - - - - 0.02 0.58 - - - - - 2.84

30 - - - 0.01 0.03 0.68 - - - - - -

40 - - <0.01 0.02 0.58 - - - - - - -

50 - - - 0.01 0.89 - - - - - - -

60 - - <0.01 0.48 0.92 - - - - - - -

70 - <0.01 0.23 0.63 - - - - - - - -

80 - 0.05 0.31 0.91 2.54 - - - - - - -

90 <0.01 0.17 1.26 - 6.97 - - - - - - -

96 - - - - - - - - - - - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year,

divide by 0.0254.

Data are from Corrosion Laboratory Jobs 57-97 and 4-98.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to

industrial use.

Comparative 0.1 mm/y Line Plots

To compare the performance of HAYNES® 625 alloy with that of other materials, it is useful

to plot the 0.1 mm/y lines. In the following graphs, the lines for 625 alloy are compared with

those of G-35® alloy, 254SMO alloy, and 316L stainless steel, in hydrochloric and sulfuric

acids. The hydrochloric acid concentration limit of 20% is the azeotrope, above which cor-

rosion tests are less reliable.

Haynes International - HAYNES® 625 alloy

Selected Corrosion Data

Hydrobromic Acid

Conc. 50°F 75°F 100°F 125°F 150°F 175°F 200°F 225°F

Wt.% 10°C 24°C 38°C 52°C 66°C 79°C 93°C 107°C Boiling

2.5 - - - - <0.01 - <0.01 - <0.01

5 - - - - <0.01 0.13 0.6 - -

7.5 - - - - <0.01 <0.01 0.93 - -

10 - - - - 0.15 0.82 - - -

15 - - <0.01 0.3 0.64 - - - -

20 - 0.01 0.16 0.33 0.65 - - - -

25 - - - - - - - - -

30 - - 0.11 0.21 0.34 0.72 - - -

40 - - 0.08 0.15 0.25 0.42 0.79 - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year, divide by 0.0254.

Data are from Corrosion Laboratory Job 17-04.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to industrial use.

Haynes International - HAYNES® 625 alloy

Selected Corrosion Data Continued

Hydrochloric Acid

Conc. 50°F 75°F 100°F 125°F 150°F 175°F 200°F 225°F

Wt.% 10°C 24°C 38°C 52°C 66°C 79°C 93°C 107°C Boiling

1 - - - - - <0.01 <0.01 - 0.23

1.5 - - - - - - - - -

2 - - - - - - - - -

2.5 - - - - - - - - -

3 - - <0.01 <0.01 <0.01 2.07 - - -

3.5 - - - - - - - - -

4 - - - - - - - - -

4.5 - - - - - - - - -

5 - - <0.01 <0.01 - 4.65 - - -

7.5 - - 0.07 0.49 - - - - -

10 <0.01 0.15 0.3 1.16 - - - -

15 0.06 0.19 0.4 1.06 - - - -

20 0.06 0.16 0.36 0.82 - - - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year, divide by 0.0254.

Data are from Corrosion Laboratory Jobs 56-97 and 3-98.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to industrial use.

Haynes International - HAYNES® 625 alloy

Selected Corrosion Data Continued

Sulfuric Acid

Conc. 75°F 100°F 125°F 150°F 175°F 200°F 225°F 250°F 275°F 300°F 350°F

Wt.% 24°C 38°C 52°C 66°C 79°C 93°C 107°C 121°C 135°C 149°C 177°C Boiling

1 - - - - - - - - - - - -

2 - - - - - - - - - - - -

3 - - - - - - - - - - - -

4 - - - - - - - - - - - -

5 - - - - <0.01 0.06 - - - - - 0.4

10 - - - - 0.01 0.24 - - - - - 1.05

20 - - - - 0.02 0.58 - - - - - 2.84

30 - - - 0.01 0.03 0.68 - - - - - -

40 - - <0.01 0.02 0.58 - - - - - - -

50 - - - 0.01 0.89 - - - - - - -

60 - - <0.01 0.48 0.92 - - - - - - -

70 - <0.01 0.23 0.63 - - - - - - - -

80 - 0.05 0.31 0.91 2.54 - - - - - - -

90 <0.01 0.17 1.26 - 6.97 - - - - - - -

96 - - - - - - - - - - - -

All corrosion rates are in millimeters per year (mm/y); to convert to mils (thousandths of an inch) per year, divide by 0.0254.

Data are from Corrosion Laboratory Jobs 57-97 and 4-98.

All tests were performed in reagent grade acids under laboratory conditions; field tests are encouraged prior to industrial use.

Haynes International - HAYNES® 625 alloy

You might also like

- Awesome Info Lock PickingDocument19 pagesAwesome Info Lock PickingApparatchiki310100% (7)

- Your Money MattersDocument150 pagesYour Money MattersJasmine NgNo ratings yet

- Hastelloy C-276 Alloy: Principal FeaturesDocument17 pagesHastelloy C-276 Alloy: Principal FeaturesLNo ratings yet

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarNo ratings yet

- MulcoaDocument2 pagesMulcoaRolando Cordova100% (1)

- Classification of Conductors According To IEC 60228Document3 pagesClassification of Conductors According To IEC 60228Jacob de Wilde100% (1)

- Book 1Document11 pagesBook 1TahirJabbarNo ratings yet

- English For Business: Level 1Document24 pagesEnglish For Business: Level 1anonymous9196806No ratings yet

- Mis11e ch03Document42 pagesMis11e ch03Vasudha RaoNo ratings yet

- Lipped ChannelDocument2 pagesLipped ChannelNabilla ZaheraNo ratings yet

- Hastelloy G-30 Alloy: Principal FeaturesDocument12 pagesHastelloy G-30 Alloy: Principal FeaturesLizbeth CamachoNo ratings yet

- Hastelloy G-30 Alloy: Principal FeaturesDocument12 pagesHastelloy G-30 Alloy: Principal FeaturesggulsuNo ratings yet

- CAMPIMETRIA EXCEL Formulado Nov 2019 60 - 24Document53 pagesCAMPIMETRIA EXCEL Formulado Nov 2019 60 - 24ACMANo ratings yet

- 2305 Refm 2Document18 pages2305 Refm 2m yudhi pramanaNo ratings yet

- Pipe B2.4.5Document1 pagePipe B2.4.5the alchemistNo ratings yet

- Nutrient content of various foodsDocument8 pagesNutrient content of various foodsPiero PrayogaNo ratings yet

- Book 1Document2 pagesBook 1David RočekNo ratings yet

- Chemical Composition of Nickel AlloysDocument1 pageChemical Composition of Nickel AlloyscandraNo ratings yet

- Fiber Laser Cutting SheetDocument2 pagesFiber Laser Cutting SheetRodrigo CruzNo ratings yet

- Rumus Asal 3Document5 pagesRumus Asal 3Piero PrayogaNo ratings yet

- Tabel Fungsi Bessel: Nama: Jihan Shafira Adini Kelas / Nim: TT 2A / 1803332020Document2 pagesTabel Fungsi Bessel: Nama: Jihan Shafira Adini Kelas / Nim: TT 2A / 1803332020jihan shafiraNo ratings yet

- Dainita TitpDocument4 pagesDainita TitpExko RosdiantoNo ratings yet

- Digikore StudiosDocument10 pagesDigikore Studioswebinfo.vedantNo ratings yet

- Design Constrain LithologiDocument4 pagesDesign Constrain LithologiYaqin YusufNo ratings yet

- Tugas Perencanaan Tambang: Software SurfacDocument5 pagesTugas Perencanaan Tambang: Software SurfacReski FausiNo ratings yet

- Edenor Oleo Basic Catalogue 20230508Document20 pagesEdenor Oleo Basic Catalogue 20230508AlexanderNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- astm-b348-asme-sb348 не полныйDocument7 pagesastm-b348-asme-sb348 не полныйtit3dpowderNo ratings yet

- Rúbrica Email 2020 PDFDocument1 pageRúbrica Email 2020 PDFcristinamapaNo ratings yet

- Hasil Pemeriksaan Uji Kualitas Air Desa Suatang Baru (Keresik Bara) Bulan Maret 2018Document16 pagesHasil Pemeriksaan Uji Kualitas Air Desa Suatang Baru (Keresik Bara) Bulan Maret 2018RainhardNo ratings yet

- Hasil Pemeriksaan Uji Kualitas Air Desa Suatang Baru (Keresik Bara) Bulan Maret 2018Document20 pagesHasil Pemeriksaan Uji Kualitas Air Desa Suatang Baru (Keresik Bara) Bulan Maret 2018RainhardNo ratings yet

- Tiempo (S) Velocidad (M/S) Aceleración (M/s )Document4 pagesTiempo (S) Velocidad (M/S) Aceleración (M/s )BriianVannegazNo ratings yet

- C36000 (Free-Cutting Brass)Document2 pagesC36000 (Free-Cutting Brass)Eminent RishNo ratings yet

- Clasificación NEMA-IEC-ControlDocument1 pageClasificación NEMA-IEC-ControlAlejandro TrejoNo ratings yet

- Pipe Thickness Sizes PDFDocument1 pagePipe Thickness Sizes PDFSualp EsenliNo ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- TOP-NOTCH TECHNOLOGY FOR ANALYZING OILS AND FATSDocument18 pagesTOP-NOTCH TECHNOLOGY FOR ANALYZING OILS AND FATSChoice OrganoNo ratings yet

- X016 Conductor Resistance PDFDocument1 pageX016 Conductor Resistance PDFŽeljko BokanovićNo ratings yet

- Tolerances For Cold-Finished BarsDocument9 pagesTolerances For Cold-Finished BarsugurNo ratings yet

- Process Capability Index - CPK: Potato Chip Salter % Salt 1.00 0.98 1.02 1.01 0.005Document33 pagesProcess Capability Index - CPK: Potato Chip Salter % Salt 1.00 0.98 1.02 1.01 0.005Abdulaziz AlzahraniNo ratings yet

- Reinf For VariationDocument6 pagesReinf For Variationepe civil1No ratings yet

- BZX55B Zener DiodeDocument5 pagesBZX55B Zener DiodecsclzNo ratings yet

- Financial Performance and Ratios of Saral Mining LtdDocument18 pagesFinancial Performance and Ratios of Saral Mining LtdvishalNo ratings yet

- 1° Identificamos Los GDL, Las Direcciones, Las Juntas y Los ElementosDocument2 pages1° Identificamos Los GDL, Las Direcciones, Las Juntas y Los ElementosCarlos Brayan Curi QuilcaNo ratings yet

- Rumus Asal 2Document5 pagesRumus Asal 2Piero PrayogaNo ratings yet

- Open RMF Report SpreadsheetsDocument3 pagesOpen RMF Report SpreadsheetswillyNo ratings yet

- Material OptimDocument4 pagesMaterial OptimAurica FlorentinaNo ratings yet

- IB InfotechDocument10 pagesIB Infotechshivapalle1708No ratings yet

- Lampiran 3. Tabel Pengamatan MingguanDocument1 pageLampiran 3. Tabel Pengamatan MingguanIvan AlfiansyahNo ratings yet

- Data Tables - V2Document1 pageData Tables - V2Person GainableNo ratings yet

- Simple VISData ComparisonDocument1 pageSimple VISData ComparisonEdwinAcuñaNo ratings yet

- Foodlog Date 2 12 24 - Daily IntakeDocument2 pagesFoodlog Date 2 12 24 - Daily Intakeapi-732118476No ratings yet

- ECT Probe Selection Guide for Tube MaterialsDocument5 pagesECT Probe Selection Guide for Tube MaterialsVikram VibrantNDTServicesNo ratings yet

- Data Hujan Harian: Nama Pos: 03. PASEH No. 180 Tahun: 2014Document2 pagesData Hujan Harian: Nama Pos: 03. PASEH No. 180 Tahun: 2014umarNo ratings yet

- Formosa MS LL55C Series Zener diode data sheetDocument5 pagesFormosa MS LL55C Series Zener diode data sheetmoakNo ratings yet

- Formosa MS LL55C Series Zener diode data sheetDocument5 pagesFormosa MS LL55C Series Zener diode data sheetmoakNo ratings yet

- Farha ProjectDocument18 pagesFarha ProjectBhavya PabbisettyNo ratings yet

- DIODADocument2 pagesDIODAMuhammad RodanNo ratings yet

- (MM) (Inches) MM MM MM MM MM MM (Inchi) (Inchi) (Inchi) (Inchi) (Inchi) MM kg/6000 MM kg/6000 MM kg/6000 MM kg/6000 MM kg/6000 MM (In)Document3 pages(MM) (Inches) MM MM MM MM MM MM (Inchi) (Inchi) (Inchi) (Inchi) (Inchi) MM kg/6000 MM kg/6000 MM kg/6000 MM kg/6000 MM kg/6000 MM (In)teguhNo ratings yet

- LL55C Series Zener Diode Features and ApplicationsDocument5 pagesLL55C Series Zener Diode Features and Applicationstommy99No ratings yet

- OR - 3Document6 pagesOR - 3Ishan Gauravkumar AgrawalNo ratings yet

- Concerned Person For BRDocument8 pagesConcerned Person For BRMichael JohnsonNo ratings yet

- Tugas BesarDocument70 pagesTugas Besarkxjne 16No ratings yet

- ReportingDocument3 pagesReportingRyan Joseph LunaNo ratings yet

- Physical Properties: Physical Property British Units Metric Units Density Melting RangeDocument4 pagesPhysical Properties: Physical Property British Units Metric Units Density Melting RangesuiafwgehjdfNo ratings yet

- Resistance To Pitting and Crevice CorrosionDocument6 pagesResistance To Pitting and Crevice CorrosionsuiafwgehjdfNo ratings yet

- Creep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HoursDocument4 pagesCreep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HourssuiafwgehjdfNo ratings yet

- Haynes 625 Alloy: Principal FeaturesDocument4 pagesHaynes 625 Alloy: Principal FeaturessuiafwgehjdfNo ratings yet

- How Children Learn LanguageDocument8 pagesHow Children Learn LanguageFakhruRozyNo ratings yet

- Tendernotice 2Document133 pagesTendernotice 2Pratik GuptaNo ratings yet

- Komunikasi Melalui Aplikasi Whatsapp Dalam Rangka Pembelajaran Anak Sekolah Dasar Masa Pandemi Covid-19 Di Lingkungan Medan DenaiDocument8 pagesKomunikasi Melalui Aplikasi Whatsapp Dalam Rangka Pembelajaran Anak Sekolah Dasar Masa Pandemi Covid-19 Di Lingkungan Medan DenaiErwin ErlanggaNo ratings yet

- DLP Reading Comprehension 15th SeptemberDocument3 pagesDLP Reading Comprehension 15th SeptemberHanaa ElmostaeenNo ratings yet

- Consumer Satisfaction and Loyalty Towards Luxor PensDocument112 pagesConsumer Satisfaction and Loyalty Towards Luxor PensSundram KumarNo ratings yet

- Individual and Market Demand: Chapter OutlineDocument57 pagesIndividual and Market Demand: Chapter OutlineAbdullahiNo ratings yet

- Humor, Humility and National Identity in Pride and PrejudiceDocument13 pagesHumor, Humility and National Identity in Pride and PrejudiceLuz SaavedraNo ratings yet

- Roles of ManagerDocument14 pagesRoles of ManagerNurul Ain AisyaNo ratings yet

- Measuring Effectiveness of Airtel's CRM StrategyDocument82 pagesMeasuring Effectiveness of Airtel's CRM StrategyChandini SehgalNo ratings yet

- Payment Instruction Form (Pif) : Davao CentralDocument1 pagePayment Instruction Form (Pif) : Davao Centralhue sageNo ratings yet

- Rel-08 Description 20130121Document254 pagesRel-08 Description 20130121Alexandre BeckerNo ratings yet

- Aff K - Deleuze - Michigan7 2020 K LabDocument305 pagesAff K - Deleuze - Michigan7 2020 K LabEvan JackNo ratings yet

- Final Placement Report 2021 shows 70% placementsDocument14 pagesFinal Placement Report 2021 shows 70% placementsRohitNo ratings yet

- VOL. 208, MAY 7, 1992 487 Perla Compania de Seguros, Inc. vs. Court of AppealsDocument9 pagesVOL. 208, MAY 7, 1992 487 Perla Compania de Seguros, Inc. vs. Court of AppealsdanexrainierNo ratings yet

- Al Nafi Affiliate PolicyDocument12 pagesAl Nafi Affiliate PolicyIftikhar AliNo ratings yet

- Defamation of Public Officials Under American Rule of LawDocument9 pagesDefamation of Public Officials Under American Rule of LawSugar Fructose GalactoseNo ratings yet

- Nature The Gentlest MotherDocument4 pagesNature The Gentlest MotherMeeta Sharma100% (2)

- Wound Healing PhasesDocument27 pagesWound Healing PhasesAnil BasnetNo ratings yet

- Peritonitis GuiaDocument28 pagesPeritonitis GuiaAndrea ClaudieNo ratings yet

- Horno Industrial HC1 v1.1Document30 pagesHorno Industrial HC1 v1.1Cristian urielNo ratings yet

- RWJ Chapter 1Document29 pagesRWJ Chapter 1Umar ZahidNo ratings yet

- NDA Strategic PlanDocument222 pagesNDA Strategic PlanJudith AinembabaziNo ratings yet

- WEG-WEMOB-totem-10008242920-guia-de-instalacao-ptDocument2 pagesWEG-WEMOB-totem-10008242920-guia-de-instalacao-ptalexcampos172No ratings yet

- Admin Upload Food Processing Industry in India August 2013Document31 pagesAdmin Upload Food Processing Industry in India August 2013pv1977No ratings yet

- Here are the answers to the questions:1. Country or nation2. Archipelago 3. Peninsula4. Island5. Mainland6. Seven7. Asia8. ColonyDocument8 pagesHere are the answers to the questions:1. Country or nation2. Archipelago 3. Peninsula4. Island5. Mainland6. Seven7. Asia8. ColonyShiela Mae FernandezNo ratings yet