Professional Documents

Culture Documents

Stablised Mud Blocks: Applications

Uploaded by

shahulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stablised Mud Blocks: Applications

Uploaded by

shahulCopyright:

Available Formats

ALTERNATIVE BUILDING TECHNIQUES

Stabilized mud blocks (SMBs) are manufactured by compacting a wetted mixture of soil, sand, and stabilizer in a machine into

a high-density block. Such blocks are used for the construction of load-bearing masonry. Cement soil mortar is commonly

used for SMB masonry.

THE BASIC MATERIALS REQUIRED -

BLOCKS ARE SOIL, WATER AND

STABILIZER. TO ACHIEVE

MAXIMUM STRENGTH SMB’s ARE

NEED A PERIOD OF DAMP CURING,

IF THE BLOCKS ARE LEFT

EXPOSED TO HOT DRY WEATHER

CONDITIONS, THE SURFACE

MATERIAL WILL LOSE ITS

Stabilized mud blocks (SMBS)

MOISTURE

are manufactured by compacting a wetted

mixture of soil, sand and stabilizer in a

machine into a high-density block.

Such blocks are used for the

construction of load bearing masonry.

Stabilized mud block (SMB) or pressed

earth block is a building material made

primarily from damp soil compressed at high

pressure to form blocks. He

➢ SMB MASONRY STRENGTH IS SENSITIVE TO BLOCK compression strength of properly made SMB

STRENGTH AND INCREASES WITH INCREASE IN can meet or exceed that of typical cement or

BLOCK STRENGTH. ➢ SMB MASONRY WITH CEMENT-

SOIL MORTARS SHOWS HIGHER STRENGTH THAN THE

adobe brick

MASONRY USING CLAY FRACTION.

Applications

➢ CONSTRUCTION OF RETAINING WALLS

➢ ALSO USED IN THE CONSTRUCTION OF CHIMNEYS’

➢ USED IN THE SIDES OF PATHWAYS IN GARDENS

➢ CONSTRUCTION OF FOUNDATIONS

➢ CONSTRUCTION OF WALLS, OF ANY SIZE ➢ RECYCLABLE ➢ ECHO-FRIENDLY IN NATURE ➢ NON

➢ CONSTRUCTION OF ARCHES AND CORNICES TOXIC ➢ LESS ENERGY IN MAKING PROCESS ➢ COST

EFFECTIVE ➢ AN ADAPTED MATERIAL ➢ LOW

MAINTENANCE

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

STABLISED MUD BLOCKS 1SI18AT035

SOA SIT

ALTERNATIVE BUILDING TECHNIQUES

➢ advantages disadvantages

➢ A local material Proper soil identification is required or lack of soil.

➢ A bio-degradable material Unawareness of the need to manage resources.

➢ An adapted material Ignorance of the basics for production & use.

➢ Energy efficiency and eco friendliness Wide spans, high & long building are difficult to do.

➢ Cost efficient Low technical performances compared to concrete.

➢ Transferable energy Untrained teams producing bad quality products.

Over-stabilization through fear or ignorance, implying outrageous costs.

Case study-1 brick house

➢ Type of building- residential

Case study-2 brick cave

➢ Location- Mysuru, Karnataka ➢ Type of building- residential

➢ Year of compilation- 2016 ➢ Location- Hanoi

➢ Architect- paradigm ➢ Year of compilation- 2017

➢ Plot size- 325sqm ➢ Architect- h and p architects

➢ Plot size- 190sqm

Brick Cave reminds

its users of

INTEGRATED SITE emotional pieces of

PLANNING FOR both strangeness

EFFECTIVE and familiarity by

MANAGEMENT OF offering them images

SURFACE. USE OF of corners of a

APPROPRIATE BUILDING yard, expanses of

MATERIALS AND the sky, strips of a

TECHNOLOGY LIKE ; garden, and parts of

STABILIZED EARTH an alley… which is

The house is designed to

BLOCKS, FERRO tentative to uses of

bring in a sense of intimacy

CEMENT, RAMMED space at different

and connection through

EARTH, LIGHT ROOFING, times in a typical

subtle changes in the scales

NATURAL STONE tropical monsoon

of the various spaces. We

FLOORS, MINIMUM climate of the North

looked at the material of

WOOD USE. of Vietnam.

modernity, reinforced

concrete forming the

armature along with the

traditional brick forming

walls, floors , screens and

vaults defining the spaces

bringing in a sense of

warmth.

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

STABLISED MUD BLOCKS 1SI18AT035

SOA SIT

ALTERNATIVE BUILDING TECHNIQUES

Rammed earth, building material made by compacting certain soils,

used by many civilizations. The most durable of the earth-building

forms, rammed earth may be used for making building blocks or

for constructing whole walls in place, layer by layer.

THERE ARE FIVE BASIC RAW MATERIALS(GRAVEL, SAND, SILT, CLAY,

modern rammed earth

AND ORGANIC, AND THE DIRT IN A GIVEN LOCATION IS GENERALLY

walls are composed

SOME COMBINATION OF ALL OR MOST OF THESE TYPES. THE SOIL

of stone, sand, clay,

FROM A BUILDING SITE IS TESTED TO DETERMINE ITS SUITABILITY.

silt, color pigment,

ORGANIC MATERIAL MUST BE REMOVED FROM THE SOIL AND, IF

and cement that is

NECESSARY, A DIFFERENT TYPE OF SOIL

blended with water to

make a damp mixture 1.PREPARING THE SITE

that is packed inside AN INCH OR TWO (2.5-5 CM) OF TOPSOIL IS REMOVED FROM THE

wooden formwork in BUILDING SITE ANDSTORED SO IT CAN BE REPLACED AROUND THE

layers. The walls are COMPLETED SIRUCTURE. ORGANIC MATTER SUCH AS WEEDS AND

stone-like after 24 ROOTS ARE REMOVED AND MAY BE COMPOSTED FOR USE INPOST-

hours of curing.” CONSTRUCTION LANDSCAPING.

2.LAYING THE FOUNDATION

THE FOUNDATION, WHICH IS MADE OF REINFORCED CONCRETE, CONSISTS OF AFOOTING THAT

Standard rammed earth construction involves MAY BE AS NARROW AS THE THICKNESS OF THE WALL OR UP TO THREETIMES THAT

erecting wood forms and compacting the prepared THICKNESS, DEPENDING ON THE STRENGTH OF THE UNDERLYING SOIL

soil into these molds, which are removed after 3.FRAMING THE WALLS

the walls are completed. The rammed-earth tire AFTER THE MOLD WAS FILLED WITH FULLY COMPACTED SOLL, IT WOULD BE REMOVEDAND

method is a commonly used alternative. RESET TO FORM THE NEXT SECTION OF WALL. MORE EFFICIENT METHODS NOW ALLOWFORMS

TO BE CONSTRUCTED FOR THE ENTIRE HEIGHT OF THE WALL (EVEN MORE THAN ONESTORY).

4.TAMPING THE SOIL

TRADITIONAL TAMPERS ARE MADE OF AD HEAVY WOODEN BLOCK WITH A HANDLE EXTENDING

UPWARDTHROUGH ITS CENTER. A MORE COMPACT VERSION CAN BE MADE FROM A 4 IN (10

CM) SQUARE STEELPLATE WELDED TO A SECTION OF IN (2.5 CM) PIPE

5.FINISHING THE WALLS

INTERIOR FACES OF WALLS ARE OFTEN FINISHED WITH PLASTER. IF SUCH A COATING IS NOT

APPLIED,THE WALL SHOULD BE TREATED WITH A CLEAR, PENETRATING SEALANT TO PREVENT

DUST FROMSLOUGHING OFF. BECAUSE STONE IS SOMEWHATPOROUS

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

RAMMED EARTH 1SI18AT035

SOA SIT

ALTERNATIVE BUILDING TECHNIQUES

ADVANTAGES disadvantages

➢ VIRTUALLY FIRE PROOF-THE PROPERTIES OF EARTH RAMMED ➢ NOT A GOOD INSULATOR-NOT A GOOD INSULATOR AS RAMMEDEARTH

WALLS DO NOT CONDUCT FIREEASILY. OFTEN REQUIRES INSULATION IN COLDER CLIMATES.

➢ ENERGY EFFICIENT, RAMMED EARTH HOUSES TO BE ENERGY ➢ SOIL SELECTION IS CRITICAL. NOT ANY SOIL CAN BE USED.

EFFICIENT SAVING YOU MONEY ON YOURUTILITY BILLS. ➢ OVERHANGING ROOF NEEDED-CAN BE USED IN WETTERCLIMATES

➢ LONG LASTING STRENGTH AND DURABILITY. BUT MUST BE PROTECTED FROM HEAVY RAINBY AN OVERHANGING

➢ RAMMED EARTH HAS EXCELLENT THERMAL QUALITIES. ROOF.

Case study-1 Ajijic The materials of the cubes are considered as

➢ Type of building- residential a contrast of transparent and opaque,

Case study-2 debris house

➢ Location- Mexico reflective (the inner space and the ➢ Type of building- residential

➢ Year of compilation- 2010 surrounding) and shining through. The ➢ Location- Kerala

➢ Architect- Tatiana Bilbao openings orchestrate with the surroundings ➢ Year of compilation- 2017

➢ Plot size- 3870sqm exposing permeability towards the views and ➢ Architect- h and p architects

protecting against cold northern winds. All ➢ Plot size- 190sqm

of that shall give the complex of the Recycled materials, also salvaged

building an appearance of simplicity and in from the immediate area, were used

the same way a very high complexity inside to form a spiraled wall — dubbed

and in its relation to the ambient. the Debris Wall — that serves as a

focal point defining the central

courtyard, which allows cooling

cross-winds into the home.

Constructing with the surrounding

material rediscovers an ancient system

which we often forget trough

technological advance. Colors and

textures in the walls and the landscape

merge to bring house and environment

together. To protect against

THE RAMMED EARTH AT

unwanted solar gain,

WINDHOVER WAS

the windows are

DESIGNED AS A

protected with meter

BACKDROP TO THE

boxes sourced from a

PAINTINGS. THE SOIL

local scrapyard. The

UNDER THE BUILDING

concrete roof and slab

PRODUCED A RICH BROWN,

were mixed with coconut

THE PREDOMINATE COLOR

shells, thus reducing

OF ALL THE SANDSTONE

the amount of cement

BUILDINGS OF THE

used.

ORIGINAL CAMPUS.

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

RAMMED EARTH 1SI18AT035

SOA SIT

ALTERNATIVE BUILDING TECHNIQUES

As construction materials, bamboo has a very strong fiber. The compressive PROPERTIES OF BAMBOO Process OF BAMBOO

strength of bamboo is two times higher than concrete, while the tensile strength • TENSILE STRENGTH

is close to steel. Bamboo fiber has a shear stress that is higher • SHRINKING

than wood. Bamboo has wider span than wood. • FIRE RESISTANCE

• STRENGTH COMPRESSIVE

• ELASTICAL MODULUS

• FLEXURAL (BENDING) STRENGTH

• SHEARING STRENGTH

• SLIP RESISTANCE splitting

USES OF BAMBOO IN CONSTRUCTION

1.BAMBOO FOOTINGS • BAMBOO CAN BE WORKED WITH THE

2. BAMBOO WALLS SIMPLEST TOOLS WHICH MUST BE

3. BAMBOO SCAFFOLDING ESPECIALLY SHARP BECAUSE OF THE

4. BAMBOO ROOFING HIGHLY SILICIFIED OUTER ZONE. TOOL shaping

5. BAMBOO FLOORS WEAR IS CONSIDERABLY HIGH.

METHODS OF TREATMENT

• SURFACE APPLICATION: THIS IS DONE BY BRUSHING, SPRAYING OR DIPPING OF

TIMBER IN PRESERVATIVE SOLUTION FOR THE REQUIRED PERIOD

• SOAKING PROCESS: THE DEBARKED TIMBER IS SUBMERGED IN THE PRESERVATIVE

SOLUTION FOR SUFFICIENT PERIOD TIL L THE DESIRED ABSORPTION IS OBTAINED

BAMBOO WALLS bending

• The most extensive use of bamboo in

construction is for walls and partitions. BAMBOO FOOTINGS

• The major elements of a bamboo wall • BAMBOO POSTS CAN BE

(posts and beams) generally constitute DRIVEN DIRECTLY INTO THE

part of the structural framework. GROUND.

• An infill between framing members is • BAMBOO WITH LARGE

required to complete the wall. BAMBOO FLOORS Layers of woven mats or strips, DIAMETER AND SHORT INTER

• The infill should also be designed to laid at right angles, are bonded together into NODAL DISTANCE ARE CHOSEN

allow for light and ventilation boards using resins and pressure and thermal • WHEN LARGER BAMBOO POSTS

processes .These are then nailed to the joists ARE NOT AVAILABLE SMALLER

ONES MAY BE BOUND TOGETHER

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

bamboo 1SI18AT035

SOA SIT

ALTERNATIVE BUILDING TECHNIQUES

ADVANTAGES OF BAMBOO disadvantages OF BAMBOO

➢ FAST GROWING ➢ LIGHT, STRONG AND VERSATILE ➢ REQUIRES PRESERVATION.

➢ HIGHLY PRODUCTIVE ➢ ENVIRONMENT FRIENDLY ➢ SHAPED BY NATURE.

➢ EARTHQUAKE RESISTANCE ➢ ACCESSIBLE TO THE POOR ➢ DURABILITY IS LESS LESS BECAUSE ATTACK BY FUNGI, INSECTS.

➢ COST EFFECTIVE ➢ SELF RENEWING RESOURCE ➢ LACK OF DESIGN GUIDANCE AND CODES.

➢ JOINTING-ALTHOUGH MANY JOINTING TECHNIQUES EXIST, THEIR

➢ STRUCTURAL EFFICIENCY IS LOW.

➢ PRONE TO CATCH FIRE VERY FRICTION AMONG THE CULMS DURING WIND.

Case study-1 bamboo house

Case study-1 bamboo house

➢ Type of building- residential ➢ Type of building- residential

➢ Location- brazil ➢ Location- Vadodara

➢ Year of compilation- 2020 ➢ Year of compilation- 2019

➢ Architect- bl studio ➢ Architect-Ms design studio

➢ Plot size- 800sqm ➢ Plot size- 5097sqm

THE BUILDING IS 100% NATURALLY LIT The house follows a subtle Indian

THROUGHOUT THE DAY. DAYLIGHT PIPES and earthy aesthetic as per the

MADE FROM 6″PVC PLUMBING PIPES client’s taste, and has been

HAVE BEEN INTRODUCED IN THE SLAB. designed keeping in mind the climatic

conditions of the place. The

To ensure both comfort and material palette of the project

the timelessness of the consists of earthy materials such

project, we used natural as the Kota Stone, terrazzo tiles

materials that we are with a plenty of wood and a dash of

absolutely passionate about; cane. The kota has been used in

wood, wood stone and Hijau different colors and finishes such

stone for the wet spaces. The as mirror finish and river finish to

almost 100% green vegetation define the different areas.

provides tropical air. The

bamboo is been widely used in

the construction of building

the large glass panels have been covered

by wooden muxarabi panels, which allow a

discreet glance of the interior,

heightening the curiosity of those

looking in from the outside

SHAHUL HAMEED

S I DDAGANGA SCHOOL OF ARCHITECTURE

bamboo 1SI18AT035

SOA SIT

You might also like

- Masonry Wall ConstructionDocument29 pagesMasonry Wall ConstructionAbdullah Mostafa100% (1)

- MEXBORO Cast StoneDocument28 pagesMEXBORO Cast StoneMalisa StefanovicNo ratings yet

- Group8 ConcreteDocument12 pagesGroup8 ConcreteShubhrata SahareNo ratings yet

- 01 Concrete and Concrete ProductsDocument36 pages01 Concrete and Concrete ProductsAngel Mine AlcantaraNo ratings yet

- CX Aggregates Brochure FINAL LowRes PDFDocument4 pagesCX Aggregates Brochure FINAL LowRes PDFRafael Obusan100% (1)

- Ringtrac: Reliable Ground Improvement For Weak SoilsDocument9 pagesRingtrac: Reliable Ground Improvement For Weak SoilsGustavo Andres Mayorga RehbeinNo ratings yet

- Stabilised Mud BlocksDocument8 pagesStabilised Mud BlocksAravind BobbiliNo ratings yet

- Stabilised Mud BlocksDocument8 pagesStabilised Mud BlocksAravind BobbiliNo ratings yet

- What Is Permeable Concrete?: Design of The SampleDocument1 pageWhat Is Permeable Concrete?: Design of The SampleRanu GamesNo ratings yet

- Insulation For Geotechnical ApplicationsDocument16 pagesInsulation For Geotechnical ApplicationsfostbarrNo ratings yet

- Cement Treated Base Pca LogoDocument2 pagesCement Treated Base Pca LogoErick ChendratamaNo ratings yet

- Dynamic Compaction and Dynamic Replacement1Document4 pagesDynamic Compaction and Dynamic Replacement1Nicoleta Maria IliesNo ratings yet

- 2017 Maxi Spec-SheetDocument1 page2017 Maxi Spec-SheetNick BesterNo ratings yet

- Cement and Fly-Ash StabilizationDocument30 pagesCement and Fly-Ash StabilizationJohn Dalton ValenciaNo ratings yet

- Mainmark - Permeation PDFDocument4 pagesMainmark - Permeation PDFAndrea David RodriguesNo ratings yet

- Types of Mud Wall ConstructionDocument23 pagesTypes of Mud Wall ConstructionJency Kuruvilla71% (14)

- Types of Dams Design Criteria Criteria of Materials To Be UsedDocument3 pagesTypes of Dams Design Criteria Criteria of Materials To Be UsedDivine LlorenteNo ratings yet

- CBRIDocument15 pagesCBRIsonakshiNo ratings yet

- Construction Material and Testing ReviewerDocument6 pagesConstruction Material and Testing ReviewerLea gggNo ratings yet

- Construction Folio: Shikhar Singhal B.Arch 4 Year (8 Semester) Ansal School of Architecture, LucknowDocument24 pagesConstruction Folio: Shikhar Singhal B.Arch 4 Year (8 Semester) Ansal School of Architecture, LucknowShikhar SinghalNo ratings yet

- CN-DT-007 - ENG - Stone Pitching vs. Mattresses - Rev. 0 PDFDocument2 pagesCN-DT-007 - ENG - Stone Pitching vs. Mattresses - Rev. 0 PDFszemianNo ratings yet

- MASONRYDocument31 pagesMASONRYNiña AizelNo ratings yet

- Foundation Packages - COMBISLAB - AshfordDocument2 pagesFoundation Packages - COMBISLAB - AshfordFaraz HussainNo ratings yet

- Safe Fast Efficient: SteelDocument2 pagesSafe Fast Efficient: SteelJesus Villaflor Jr.No ratings yet

- BSD FinalsDocument21 pagesBSD FinalsAndrea Leigh BoreresNo ratings yet

- Weberwall Premium PlasterDocument5 pagesWeberwall Premium PlasterRahulNo ratings yet

- What Is Mud Arachitecture: Straw, Plant Juices, Gum Arabic, Sugar or Molasses, Cow Dung, Animal Urine Tannic Acid, OilDocument1 pageWhat Is Mud Arachitecture: Straw, Plant Juices, Gum Arabic, Sugar or Molasses, Cow Dung, Animal Urine Tannic Acid, OilDhanashri MirajkarNo ratings yet

- Sikagrout FMDocument2 pagesSikagrout FMKasyie AbrahamNo ratings yet

- BTECHDocument6 pagesBTECHJustine Rose AngolluanNo ratings yet

- GEOBAMTILE Presentation 25 Oct 2019 PDFDocument64 pagesGEOBAMTILE Presentation 25 Oct 2019 PDFsal harun100% (1)

- LN 4 Foundation PDFDocument9 pagesLN 4 Foundation PDFHazwani RadziNo ratings yet

- CLC International Brochure - EnglishDocument4 pagesCLC International Brochure - EnglishAishwarya KumarNo ratings yet

- 4 - Vibro Replacement & Stone ColumnsDocument2 pages4 - Vibro Replacement & Stone ColumnsAmw Mohamed AmwNo ratings yet

- Earthquake Mitigation Measures Retrofitting & Repairing DamagesDocument45 pagesEarthquake Mitigation Measures Retrofitting & Repairing DamagesPushpak GaikarNo ratings yet

- Refuerzo de Pavimentos - PavementDocument12 pagesRefuerzo de Pavimentos - PavementJohan SiciliaNo ratings yet

- Ncma Tek: Surface Bonded Concrete Masonry Construction TEK 3-5ADocument4 pagesNcma Tek: Surface Bonded Concrete Masonry Construction TEK 3-5AjerryNo ratings yet

- CementDocument21 pagesCementTHE BEST GAMERNo ratings yet

- Eccovoid TDSDocument2 pagesEccovoid TDSAnonymous YW5mvpNo ratings yet

- Methods of Concrete CompactionDocument1 pageMethods of Concrete CompactionPrabhakar SvNo ratings yet

- Sika - Sikagrout 215Document9 pagesSika - Sikagrout 215afnan hamimiNo ratings yet

- Chapter 6 (p1)Document25 pagesChapter 6 (p1)Jullie Anne SantoyoNo ratings yet

- Masonry Information: Masonry Cement: Product Data SheetDocument4 pagesMasonry Information: Masonry Cement: Product Data SheetarylananylaNo ratings yet

- Online Civil Engineering - Accelerated Curing TestDocument2 pagesOnline Civil Engineering - Accelerated Curing TestPritha DasNo ratings yet

- Table 1-1 Tank Foundation Design GuideDocument1 pageTable 1-1 Tank Foundation Design GuiderabzihNo ratings yet

- Product DevelopmentDocument1 pageProduct Developmentshubham gandhiNo ratings yet

- Sikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDocument2 pagesSikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDani LerviNo ratings yet

- Casting - Processes - and - Defects 1Document1 pageCasting - Processes - and - Defects 1Nunya ByznisNo ratings yet

- Module 6.1 - Masonry and AsphaltPart 2 2Document47 pagesModule 6.1 - Masonry and AsphaltPart 2 2EUREKA JANAH MENDOZANo ratings yet

- Principles of Reinforced Concrete DesignDocument24 pagesPrinciples of Reinforced Concrete Designibarrientosirene1011No ratings yet

- Maintenance of Building ElementsDocument10 pagesMaintenance of Building ElementsaremyulNo ratings yet

- Chapter Eight Check DamDocument30 pagesChapter Eight Check DamSurendra Maharjan100% (1)

- Groundimprovementtechniques 150910194018 Lva1 App6891Document15 pagesGroundimprovementtechniques 150910194018 Lva1 App6891Carol TumanengNo ratings yet

- 1 - Geotube Project Oil-Terminal PEMEX (Lerma, Campeche, Mexico)Document23 pages1 - Geotube Project Oil-Terminal PEMEX (Lerma, Campeche, Mexico)pjgomezdNo ratings yet

- Protect Your Building With A Low Perm RWMSK FacingDocument2 pagesProtect Your Building With A Low Perm RWMSK FacingHuy Phạm Ngô HoàngNo ratings yet

- Plaster Data SheetDocument2 pagesPlaster Data SheetHempire Building MaterialsNo ratings yet

- Interlocking Stabilised Soil Blocks ISSB UETN 20Document4 pagesInterlocking Stabilised Soil Blocks ISSB UETN 20DhavamNo ratings yet

- MSE Wall Systems Brochure 2016 11 EDocument8 pagesMSE Wall Systems Brochure 2016 11 EAbdul Aziz RamadhanNo ratings yet

- Concrete FinalDocument25 pagesConcrete FinalShubhrata SahareNo ratings yet

- Nico Sut MollerDocument9 pagesNico Sut MollerNurali MamenNo ratings yet

- Tesfa, BoqDocument52 pagesTesfa, BoqAbel TegeneNo ratings yet

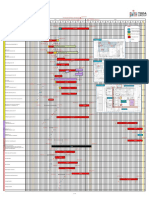

- Gantt Chart With Layout TableDocument3 pagesGantt Chart With Layout TableAbenezer Tesfaye100% (1)

- Specification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelDocument3 pagesSpecification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelSunitha KumariNo ratings yet

- Wa0014Document61 pagesWa0014Shivam KumarNo ratings yet

- Control Joints For Concrete Masonry Walls - Empirical Method: TEK 10-2CDocument8 pagesControl Joints For Concrete Masonry Walls - Empirical Method: TEK 10-2CWissam AlameddineNo ratings yet

- Jai Paras Construction & Engg. Co. Bill of Quantity For Water LineDocument3 pagesJai Paras Construction & Engg. Co. Bill of Quantity For Water LineNirajan MarwaitNo ratings yet

- Laurie Baker IntroductionDocument73 pagesLaurie Baker Introductionnonie09ashna100% (1)

- ASHRAE 62.2 Ventilation and Acceptable Indoor Air QualitDocument27 pagesASHRAE 62.2 Ventilation and Acceptable Indoor Air Qualitmanupatel12375% (4)

- Sequence of Work in Building ConstructionDocument8 pagesSequence of Work in Building ConstructionPurushottam PoojariNo ratings yet

- Global Roofing Solutions Klip-Lok 406Document6 pagesGlobal Roofing Solutions Klip-Lok 406Adhil RamsurupNo ratings yet

- ETABS Shear Wall DesignDocument2 pagesETABS Shear Wall DesignFares ShawadfyNo ratings yet

- APP002 Curtain Wall and Cladding ZoneDocument14 pagesAPP002 Curtain Wall and Cladding ZoneDave LiNo ratings yet

- Pile Cap For 4 PilesDocument4 pagesPile Cap For 4 Pileshemantkle2u100% (2)

- Besta Board: ... Building ResponsiblyDocument2 pagesBesta Board: ... Building ResponsiblyWhite RabbitNo ratings yet

- Shoring Work Sitara HeightsDocument2 pagesShoring Work Sitara HeightsaenanrocksNo ratings yet

- 19271aa028 Minimal HouseDocument19 pages19271aa028 Minimal HouseSahithi ReddyNo ratings yet

- Celotex BBA - Cavity WallsDocument12 pagesCelotex BBA - Cavity Wallsfaber1972No ratings yet

- OVNC Master Schedule - Ver 5Document19 pagesOVNC Master Schedule - Ver 5Thuỳ DungNo ratings yet

- Box CulvertDocument8 pagesBox CulvertPradeep S Gowda100% (3)

- Working DrawingsDocument7 pagesWorking DrawingsJanak NepalNo ratings yet

- Site ReportDocument19 pagesSite ReportFirzana HasmiNo ratings yet

- Approval Material Beton VUB LengkapDocument44 pagesApproval Material Beton VUB LengkapFatkhur RozakNo ratings yet

- DBR - ModelDocument10 pagesDBR - ModelLogganathan S100% (1)

- Vent and VentingDocument14 pagesVent and VentingDanbert TaopaNo ratings yet

- Nisar's Resume PDFDocument1 pageNisar's Resume PDFnisar ahamedNo ratings yet

- Cable Management CatalogueDocument32 pagesCable Management CatalogueRupertNo ratings yet

- CPP Report FormatDocument7 pagesCPP Report FormatNILESHNo ratings yet

- BOQ FlocDocument4 pagesBOQ Flocskanska07070No ratings yet

- Glass Wool Rolls: Technical Specification BenefitsDocument1 pageGlass Wool Rolls: Technical Specification BenefitsBogdan MucenicaNo ratings yet

- Estimating Guide Sheet PDFDocument2 pagesEstimating Guide Sheet PDFSwapnil S NachareNo ratings yet