Professional Documents

Culture Documents

Study Material For Textile Testing II

Uploaded by

Sushma BalgarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study Material For Textile Testing II

Uploaded by

Sushma BalgarCopyright:

Available Formats

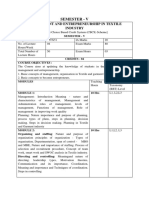

Department of Collegiate and Technical Education

TEXTILE TESTING LABORATORY – II

Course Objectives:

The objective of this course is to make students understand the importance of textile

testing and quality control in textile industry. Students are trained to understand various

methods and instruments used for testing of yarns, fabrics, garments and other

accessories. Students are trained to test the yarns, fabrics, garments, and other accessories

for various properties, and calculate, analyse, compare and draw suitable conclusions.

Experiment – 1

Determination of fabric geometrical properties.

Aim of the experiment: Determination of geomertic parameters of woven

textile fabrics.

Scope:

It prescribes the methods of testing of fabric for determination of various

geometrical parameters namely, EPI, PPI, Cover factor, Crimp etc.

The performance of fabric is ultimately related to the end use conditions of a

material.

Although all agents affect textile performance at the fiber, yarns &fabric level,

emphasis is generally given to fabrics since they represent the largest class of

textiles structures in variety of applications.

Terminology: For the purpose of the test method, the following definitions shall be

used.

Fabric thread density: It is a measure of the coarseness or fineness of fabric. It is

measured by counting the number of threads contained in one square inch of fabric or one

square centimeter,including both warp and weft threads.

Textile testing Laboratory – II (17TXL76)

a)Ends per inch / Ends per centimeter (EPI /EPC): The number of warp thread per

inch is called ends per inch.

b)Picks per inch / Picks per centimeter (PPI / PPC): The number of weft thread per

inch is called picks per inch.

Yarn count: It is a numerical value which expresses the coarseness or fineness

(diameter) of the yarn and also indicates the relationship between length and weight

(mass per unit length or the length per unit mass) of that yarn.

a)Warp yarn count in Ne and Tex

b)Weft yarn count in Ne and Tex

Yarn crimp %: The difference between the straightened length of yarn and the length

of yarn while in the cloth, expressed as percentage of the latter.

a)Warp yarn crimp

b)Weft yarn crimp

Yarn take- up %: Take-up is the deviation from straightness of the yarns as they lie

in the cloth, expressed as percentage of the original length of the yarn before weaving.

a)Warp yarn take-up

b)Weft yarn take-up

Cover factor (kc) : Cover factor is a number that indicates the extent to which the area

of a fabric is covered by one set of threads. For any woven fabric, there are two cover

factors: a warp cover factor and a weft cover factor. Under the cotton system, the cover

factor is the ratio of the number of threads per inch to the square root of the cotton yarn

count.

a)Warp cover factor

b)Weft cover factor

Fractional cover factor : It is the ratio of area covered by the yarns to the total area

of the fabric. If warp yarn diameter is ‘d 1’ inch and spacing between two consecutive ends

is ‘p1’ inch then fractional cover for warp (k1) is d1/p1.

a)Warp fractional cover factor

b)Weft fractional cover factor

Fabric bulk density (dF) : It is the ratio of fabric mass per unit area to the fabric

thickness in cm.

Fabric packing factor (pF) : It repersents the extent of closeness of yarns within

the fabric structure.

Textile testing Laboratory – II (17TXL76)

Fabric thickness : The distance between top and bottom surface of the fabric under

standard pressure is called fabric thickness. It is normaly measured in millimeters.

Fabric Porosity % (P) : Porosity is determined by measuring the total volume of a

fabric and calculating the total volume of fiber in the sample.The difference between

these two values is air space and,when calculated as per cent of the total voulme, gives

the porosity.

Fabric mass per unit length : The weight of a fabric depends on the thickness of

the threads its made of the density of the weave.Depending of the system (mertic or

imperial), the wieght will be measured in grams per square meter (g/m 2 or gsm) or in

ounce per square yard (oz/y2).

Fabric length : The distance measured from end to end, along the selvedge of a fabric.

ISI suggested the following three methods to measure the length of a fabric-

By using a measuring table

By using measuring scale

By using a measuring machine (Trumeter)

Fabric width : The distance from the outside of one selvedge to the outside of the

other, measured perpendicular to the length of the fabric.

Atmospheric conditions for conditioning and testing:

Prior to test, the fabrics shall be conditioned to moisture equilibrium in standard

atmospheric conditions of 65 + 2 percent relative humidity and 27 + 2oC temperture.

The test shall be carried out in standard atmosphere.

Procedure :

1. Determination of thread density:

Keep the test sample on a flat table and smoothen it out.

Place the counting glass on the fabrics in a direction parallel to warp if

weft density is to be determined and parallel to weft if warp density is to

be determined.

Find the number of warp and weft threads in a specified length as required.

Following the procedure prescribed in steps 1 to 4, determine the number

of warp and weft threads per inch or centimeter in at least four more

places.

Calculate the mean of all the values and report it as the number of warp

and weft threads per centimeter or inch of the fabric.

Textile testing Laboratory – II (17TXL76)

2. Determination of yarn count :

It is determined by using Beesley Balance or Electronic balance method. It

works on the principle of fixed weight and fixed length system. It is uesd when the

warp and the weft count of yarns needs to be measured for small piece of fabric.

The fabric is cut into small lengths with a template depending on the count

system required.

Yarns are then removed from the specimen.

Bessley balance consists of a light- weight beam pivoted on jewel bearings

with a hook at one end a pointer at the other end.

The beam is initially levelled to bring the pointer against a datum line.

A standard weight is suspended in a notch on the beam arm pointer side.

The total number of yarn lengths required to balance a standard weight on

the beam directly gives the count of yarn.

Same procedure is followed for weft.

3. Determination of crimp% of yarn:

Crimp is the weaveness of yarn and can be determined using hands. The yarns are

ravelled out from the sample both weft and warp way by using strength length and

fixed length of yarn.

From the given sample, warp and weft threads are ravelled.

Fixed length is measured by scale.

The yarn is gently straightened without stretching and the length is

measured.

The same procedure is repeated for both warp and weft yarns.

By using forrmula crimp% and take up% is calculated.

4. Determination fabric cover factor:

For any woven fabric, there are two cover factors: a warp cover factor and a weft

cover factor. Under the cotton system the cover factor is the ratio of the number of

threads per inch to the square root of the cotton yarn count.

5. Determination of fabric mass per unit length : The fabric weight is

expressed in GSM. The fabric is taken and weigh on a balance. It can be

determined using the formula and the sample weight is determined by cutting the

fabric into 10*10cm.

The alternate method to measure the fabric mass per unit length is Cut and weigh

method.

Textile testing Laboratory – II (17TXL76)

6. Determination of fabric thickness :

A thickness gague used for meausuring fabric thickness. It can be used to

measure thickness of various types of fabric. For example – woven and knitted

fabric.

A piece of the fabric is placed on the reference plate of the instrument

ensuring that there are no creases in the fabric.While placing the fabric it

should not be subjected to any streching. The pressure foot is gradually

brought down and after allowing it to rest on the fabric for 30 seconds, the

gauge reading is taken. The thickness is read at 10 different places on the

sample and the mean of these readings is taken as the average measured

thickness of the sample.

7. Determination of fabric length :

By measuring table & scale :

i. From full length measurement

ii. From sample length measurement

Trumeter :

Measuring roller

Pressure roller

Fabric passes through between measuring and pressure roller and the

length indicate on the counter.

8. Determination of fabric width :

The sample should be collected from at least three places from a fabric e.g

two samples from the two sides and one sample from the middle.

Measurements should take before and after conditioning. Then it should be

watched that if there is any change in width.

On a piece of the cloth, 10 width measurements should be made at points

distributed at roughly equal distances throughout the full length of the

fabric piece.

If full length is not used a sample length not less than 1 yard should be

used and width measurements should be taken at least 3 palces.

Then, in both cases, mean width should be calculated.

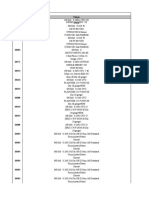

Calculations : The fabric geometrical parameters are calculated by using the

following formula :

1. Fabric thread density:

Textile testing Laboratory – II (17TXL76)

i. Ends per unit length in cm and inches (n1)

EPC = EPC = EPI ÷ 2.54

EPI =

ii. Picks per unit length in cm and inches (n2)

PPC = PPC= PPI ÷2.54

PPI =

2. Yarn count :

i. Warp yarn count in Ne and Tex

Ne = Tex = 590.54 ÷Ne

Tex =

ii. Weft yarn count in Ne and Tex

Ne =

Tex =

3. Yarn crimp % :

C = 100 ×(Y−¿F) ÷F

Where, C = Yarn crimp %

Y = Average of distance between bench marks on yarn after ÷

removal from fabric and straightend.

F = Average of distances between bench marks on yarn in fabric

i. Crimp in warp yarn % =

ii. Crimp in weft yarn % =

4. Yarn take up % :

t = (Y – F ) ×100 ÷ Y

Where, t = take up%

Y = Average of distance between bench marks on yarn after removal

from fabric and straightend.

F = Average of distances between bench marks on yarn in fabric

i. Warp yarn take up % =

ii. Weft yarn take up % =

5. Cover factor (k) :

i. Warp cover factor K1 = n1* √T1

=

Where, n1 = EPC, T1 = Warp yarn count in Tex

ii. Weft cover factor K2 = n2 * √T2

Textile testing Laboratory – II (17TXL76)

=

Where, n2 = PPC,T2 = weft yarn count in Tex

6. Fabric cover factor (Kc):

Kc = ( Kwarp + Kweft ) – Kwarp × Kweft ÷28

=

Fractional cover factor (warp) = n1 √T1 ÷ 266

=

Fractional cover factor (weft) = n2 √T2 ÷266

=

Fractional cover factor (Kc ) = Kwarp + K weft – (Kwarp× Kweft )

=

9. Fabric bulk density ( d F ) in g / cm3 :

d F = [ M ÷T ] =

Where, d F = fabric bulk density in g / cm3

M = fabric mass per unit area ( g / sq mt)

T = fabric thickness in cm

10. Fabric packing factor ( p F ) in g / cm3 :

p F = d F ÷d f

=

Where, d F = fabric bulk density in g / cm3

d f = density of cotton fibere in g / cm3 (1.54)

11. Fabric porosity ( P ) in % :

P = (1 −¿ d F ÷d f ) ×100

=

12. Fabric weight in ozs / sq yards

= 0.6857 S{n1 ( 1 + C1) ÷N1 + n2 ( 1 + C2) ÷ N2 }

=

13. Fabric mass / unit area in g / mt2 :

= 0.1 {n1 N1 (1 + 0.01 C1 ) + n2 N2 (1 + 0.01C2 ) }

=

14. Fabric thickness in mm and cm :

i. Fabric thickness in mm =

ii. Fabric thickness in cm =

15. Fabric interinsic area :

i = 1 - KC

Textile testing Laboratory – II (17TXL76)

=

Test results : The geometrical parameters of given fabric is measured as per the test

procedures and methods.

Sl.No Fabric Parameters Results

.

1. Fabric thread density EPC =

i. Ends per unit length PPC =

ii. Picks per unit length EPI =

PPI =

2. Yarn Count Ne =

i. Warp yarn count Tex =

ii. Weft yarn count Ne =

Tex =

3. Yarn Crimp C1 =

i. Warp yarn crimp C2 =

ii. Weft yarn crimp

4. Yarn take up t1=

i. Warp yarn take up t2=

ii. Weft yarn take up

5. Cover Factor K1 =

i. Warp cover factor K2 =

ii. Weft cover factor

6. Fabric Cover Factor Kc =

7. Fabric bulk density in g /cm3 dF=

8. Fabric Packing factor ( p) P=

9. Fabric weight in ozs /yd2 Ozs /yd2

10. Fabric weight in g /m2 g / m2

11. Fabric thickness mm

cm

12. Fabric interinsic area

13. Fbric Porosity %

Conclusions : Based on the test result, draw suitable conclusions.

References :

Textile testing Laboratory – II (17TXL76)

1. BIS Handbook, B I S Publication 1985.

2. Pinciples of textile testing : an introduction to physical methods of testing textile

fiberes, yarns, and fabrics [by] J. E.Booth.

3. A Practical Guide to Textile Testing [by] Amurtha K, Woodhead Publishing India

In Textiles.

4. Physical Textile testing of Textiles – B.P.Soville, Wood Head-1999.

5. Textile Testing [by] JOHN H. SKINKLE.

6. https://www.researchgate.net/publication/335038934_Testing_of_Fibres_Yarns_a

nd_Fabrics_and_Their_Recent_Developments.

7. http://eacharya.inflibnet.ac.in/data-server/eacharya-

documents/53e0c6cbe413016f234436ed_INFIEP_8/15/ET/8_ENG-15-ET-V1-

S1__lesson.pdf.

MCQ QUESTIONS :

1. The areal density of a woven fabric will be least influnced by

o EPI

o PPI

o Yarn Count

Weave

2. Warp cover factor can be obtained if the values of the following parameters are

known

o EPI

o PPI

EPI and warp yarn count

o PPI and weft yarn count

3. Fabric thickness is related to

Sum of warp and weft diameter

o Sum of crimp heights

o Sum of yarn diameter and crimp height

o Sum of warp and weft spacing

4. Cover factor k =

o 1÷ 4 √ N

o 36e /√ N 1

n (threads per inch ) ÷ √ N

o 1 ÷√ N

Textile testing Laboratory – II (17TXL76)

5. The ratio of fabric mass per unit area to the fabric thickness in cm is

o Fabric cover factor

o Fabric thickness

o Fabric packing factor

Fabric bulk density

6. The difference between the total volume of a fabric and the total volume of fiber

in sample is calculated as percent of the total volume gives the _______

o Fabric packing factor

Fabric Porosity

o Fabric bulk density

o Fractional cover factor

7. Which of the following method is not used to measure the length of the fabric

o By using a measuring table

o By using measuring scale

o By using measuring machine (truemeter)

Fabric dissection method

8. Gram per unit square is the unit of ____________ fabric parameter.

o Fabric porosity

o Fabric bulk density

Fabric mass per unit length

o Fabric length

9. Which of the following is not used to measure fabric thickness

o Shirley thickness gauge

Screw gauge

o Reynolds and Branson thickness tester

o Mag Ana thickness tester

Textile testing Laboratory – II (17TXL76)

You might also like

- Chapter - Three: Yarn Count, Yarn Twist and Tensile TestingDocument57 pagesChapter - Three: Yarn Count, Yarn Twist and Tensile TestingGadisa AbrahimNo ratings yet

- Textile Testing Lab ObjectivesDocument8 pagesTextile Testing Lab ObjectivesSushma BalgarNo ratings yet

- Importance of Analysis of Fabric SampleDocument5 pagesImportance of Analysis of Fabric SampleRavi Jain75% (4)

- 1ci3pqr1q 814635Document5 pages1ci3pqr1q 814635Santosh50% (2)

- GATE 2005 - Question Paper TF: Textile Engineering and Fiber ScienceDocument25 pagesGATE 2005 - Question Paper TF: Textile Engineering and Fiber ScienceChandra Deep Mishra100% (1)

- Rotor PrincipleDocument12 pagesRotor PrincipleAnkit Balotia100% (1)

- Fabric Manufacturing StepsDocument15 pagesFabric Manufacturing StepsFazlul AzimNo ratings yet

- GATE Textile Fibres Study Material Book 2 FabricDocument15 pagesGATE Textile Fibres Study Material Book 2 FabricSantosh100% (1)

- Placement Training Knitting QuestionsDocument2 pagesPlacement Training Knitting QuestionsShailendra Mishra50% (2)

- CH 3 Geometric Model To Predict Wowen Fabric PropertiesDocument60 pagesCH 3 Geometric Model To Predict Wowen Fabric PropertiesAmit pandeyNo ratings yet

- Draw Frame Hooks ControlDocument17 pagesDraw Frame Hooks ControlNeelakandan DNo ratings yet

- Fibers and Textiles Knowledge QuizDocument9 pagesFibers and Textiles Knowledge QuizPreeti RawatNo ratings yet

- SanforizingDocument2 pagesSanforizingFernando Harahap100% (1)

- FalseDocument8 pagesFalseShailendra MishraNo ratings yet

- Yarn AssignmentDocument10 pagesYarn AssignmentHIMASHA SAMARANAYAKANo ratings yet

- Fiber Fineness, Yarn Counts and ConversionsDocument11 pagesFiber Fineness, Yarn Counts and ConversionsBhaskar LoganathanNo ratings yet

- Combing FAQ's: Everything You Need to KnowDocument16 pagesCombing FAQ's: Everything You Need to KnowNasir Sarwar100% (2)

- 2.1 Quailty Control in SpinningDocument31 pages2.1 Quailty Control in SpinningRounoque ShishirNo ratings yet

- Quailty Control in SpinningDocument30 pagesQuailty Control in SpinningRounoque ShishirNo ratings yet

- Air Jet Spinning: Principles and Production of Fasciated YarnDocument7 pagesAir Jet Spinning: Principles and Production of Fasciated YarnAbi NikilNo ratings yet

- Melange YarnDocument2 pagesMelange YarnKingson_786100% (3)

- Textile TestingDocument20 pagesTextile Testingjayantver67% (3)

- Thermal Properties of Textile Fiber Introduction of Thermal PropertyDocument6 pagesThermal Properties of Textile Fiber Introduction of Thermal PropertyRashedul IslamNo ratings yet

- To Calculate The Count of Given Samples of Lap, Sliver, Roving and Yarn.Document2 pagesTo Calculate The Count of Given Samples of Lap, Sliver, Roving and Yarn.Ammar Naeem BhattiNo ratings yet

- TF Textile Gate 2011 Question PaperDocument17 pagesTF Textile Gate 2011 Question PaperShailendra Mishra100% (2)

- Factors Affecting Yarn StrengthDocument11 pagesFactors Affecting Yarn StrengthAbhishek ThakurNo ratings yet

- Fiber Testing MethodsDocument62 pagesFiber Testing MethodsshaifaliNo ratings yet

- Solved QP of Knit Tech April 2023Document4 pagesSolved QP of Knit Tech April 2023RajendrakumarNo ratings yet

- Winding Efficiency and CalculationDocument16 pagesWinding Efficiency and CalculationTanzila NusratNo ratings yet

- Textiles - DiplomaDocument9 pagesTextiles - DiplomamansiagrawalNo ratings yet

- Relationship Between Yarn Count and TwistDocument23 pagesRelationship Between Yarn Count and TwistMohammed Atiqul Hoque Chowdhury100% (1)

- Drafting Waves of SliversDocument4 pagesDrafting Waves of Sliversnalaka.sampathNo ratings yet

- Relation between yarn count GSM and cost of accessoriesDocument31 pagesRelation between yarn count GSM and cost of accessoriesMohammed Atiqul Hoque ChowdhuryNo ratings yet

- GATE 1992 - Question Paper TF: Textile Engineering and Fiber ScienceDocument19 pagesGATE 1992 - Question Paper TF: Textile Engineering and Fiber ScienceChandra Deep MishraNo ratings yet

- Yarn Making ProcessDocument4 pagesYarn Making ProcessAshwani MittalNo ratings yet

- 101 MCQs For Textile Tests and Competitive ExamsDocument17 pages101 MCQs For Textile Tests and Competitive Examszinabu abrha100% (1)

- Lecture ComberDocument20 pagesLecture ComberMD. Sharifuzzaman Joy100% (1)

- Packing of Fibers in YarnDocument6 pagesPacking of Fibers in YarnShamim Sarkar SamiulNo ratings yet

- TappetDocument10 pagesTappetoronno5No ratings yet

- Yarn Clearing SystemsDocument11 pagesYarn Clearing SystemsLohit MohapatraNo ratings yet

- Gate 2011Document8 pagesGate 2011Bhuva_janaNo ratings yet

- Neps and Trash IndicatorDocument8 pagesNeps and Trash IndicatorShoaib ArifNo ratings yet

- Woven Fabric Geometry ModelsDocument21 pagesWoven Fabric Geometry ModelsShailendra Mishra100% (2)

- CH 2 Geometric Modelling of Fabric Structure (1) ADocument38 pagesCH 2 Geometric Modelling of Fabric Structure (1) AAmit pandeyNo ratings yet

- What Is AutolevellerDocument3 pagesWhat Is AutolevellersafiaNo ratings yet

- Process Control SpinningDocument25 pagesProcess Control SpinningNessre Zeine100% (2)

- KnittingDocument15 pagesKnittingReyad Billah100% (1)

- Blowroom CalculationDocument14 pagesBlowroom CalculationIrfan Ali100% (1)

- Production Calculation of Blow RoomDocument21 pagesProduction Calculation of Blow RoomAbel Taye100% (1)

- Study On Two For One Twisting PDFDocument11 pagesStudy On Two For One Twisting PDFGizachew ZelekeNo ratings yet

- 1.all Drafting System. All Parts of DraftingDocument3 pages1.all Drafting System. All Parts of DraftingRatul Hasan0% (1)

- SpinningDocument8 pagesSpinningAishee BhowmickNo ratings yet

- Blowroom Blending Methods for Fiber MixturesDocument3 pagesBlowroom Blending Methods for Fiber Mixturesmoosking100% (1)

- Mechanical Finishing of NonwovensDocument23 pagesMechanical Finishing of Nonwovensmahes_texNo ratings yet

- Sequence of Process in Worsted SpinningDocument4 pagesSequence of Process in Worsted SpinningArunraj Arumugam100% (4)

- Yarn WindingDocument22 pagesYarn WindingPRAKASH B. MALAKANE0% (1)

- Processing of Man-Made Fibres and Blended Textiles: BlendingDocument23 pagesProcessing of Man-Made Fibres and Blended Textiles: BlendinghawNo ratings yet

- 3D Woven FabricDocument9 pages3D Woven FabricCrystal NewmanNo ratings yet

- 7.0 Export Promotion OrganizationsDocument72 pages7.0 Export Promotion OrganizationsSushma BalgarNo ratings yet

- Apparel Testing and Quality ControlDocument13 pagesApparel Testing and Quality ControlSushma BalgarNo ratings yet

- Statistical Tables PDFDocument10 pagesStatistical Tables PDFAnas khanNo ratings yet

- Seam SlippageDocument1 pageSeam SlippageSushma BalgarNo ratings yet

- Advantage and Disadvantage of Conventional and Unconventional LoomsDocument18 pagesAdvantage and Disadvantage of Conventional and Unconventional LoomsSushma BalgarNo ratings yet

- Code to interface GSM module with Arduino to send SMS and make callsDocument2 pagesCode to interface GSM module with Arduino to send SMS and make callsSushma Balgar50% (2)

- Advantage and Disadvantage of Conventional and Unconventional LoomsDocument18 pagesAdvantage and Disadvantage of Conventional and Unconventional LoomsSushma BalgarNo ratings yet

- Textvision 2020: Garments For DisabledDocument3 pagesTextvision 2020: Garments For DisabledSushma BalgarNo ratings yet

- Topic: Supply Chain Management and World Class ManufacturingDocument22 pagesTopic: Supply Chain Management and World Class ManufacturingSushma BalgarNo ratings yet

- Applications of Medical TextilesDocument12 pagesApplications of Medical TextilesSushma BalgarNo ratings yet

- Topic: Supply Chain Management and World Class ManufacturingDocument22 pagesTopic: Supply Chain Management and World Class ManufacturingSushma BalgarNo ratings yet

- Applications of Medical TextilesDocument12 pagesApplications of Medical TextilesSushma BalgarNo ratings yet

- Topic: Supply Chain Management and World Class ManufacturingDocument22 pagesTopic: Supply Chain Management and World Class ManufacturingSushma BalgarNo ratings yet

- SilksyllDocument83 pagesSilksyllSushma BalgarNo ratings yet

- Avy Doll Crochet PatternDocument45 pagesAvy Doll Crochet PatternLia Vágvölgyi73% (11)

- Fabric PoDocument80 pagesFabric PoHAMMADHRNo ratings yet

- Filling Station - Elizabeth BishopDocument14 pagesFilling Station - Elizabeth BishopTadhg MccarthyNo ratings yet

- Ruining Artisans and HandicraftsDocument4 pagesRuining Artisans and HandicraftsMadhavan SeenivasanNo ratings yet

- Yarn Dyed WashDocument1 pageYarn Dyed WashSaidur Rahman SajibNo ratings yet

- SilkDocument21 pagesSilkSarah KhanNo ratings yet

- SOP of Fabric Inspection - Knitting - Clothing 27 02Document1 pageSOP of Fabric Inspection - Knitting - Clothing 27 02Swarnabandu AthukoralaNo ratings yet

- Yang Yang - Love Couple PDFDocument16 pagesYang Yang - Love Couple PDFLucia Céspedes100% (4)

- Pattern FrostythesnowmanDocument19 pagesPattern FrostythesnowmanMagali Loisirs100% (4)

- KARIGAR Catalogue 490 PDFDocument32 pagesKARIGAR Catalogue 490 PDFBibiana CarvajalNo ratings yet

- Juki T016Document18 pagesJuki T016Ana Cecilia/aaron Amilivia CarabajalNo ratings yet

- Measuring, Marking & Cutting Tools for SewingDocument1 pageMeasuring, Marking & Cutting Tools for Sewingcharisse moralNo ratings yet

- 3 WarpingDocument32 pages3 Warpingআবু সাঈদ সায়েমNo ratings yet

- Little Squirrel DIY Crochet PatternDocument12 pagesLittle Squirrel DIY Crochet PatternAnastasia Mouse100% (4)

- Rieter k42 Brochure 2539 v3 - 89691 en PDFDocument28 pagesRieter k42 Brochure 2539 v3 - 89691 en PDFAjay Singh ShekhawatNo ratings yet

- 4 Arts and Crafts of Mindanao: ScoreDocument11 pages4 Arts and Crafts of Mindanao: ScoreCryzel MuniNo ratings yet

- Men S TrousersDocument24 pagesMen S TrousersNishant BhadaniNo ratings yet

- Visual Arts Reflective JournalDocument53 pagesVisual Arts Reflective JournalThats kinda sus thoughNo ratings yet

- (Animales) ErizoDocument16 pages(Animales) ErizoArpalieus67% (3)

- Textile Finishing-Chapter 1Document49 pagesTextile Finishing-Chapter 1Shresha DasNo ratings yet

- Strike Off Submission Form For AsicsDocument56 pagesStrike Off Submission Form For AsicsMaria MurilloNo ratings yet

- Bobbin Compatibility Chart by Machine BrandDocument19 pagesBobbin Compatibility Chart by Machine BrandJohnathon Paul GeaslerNo ratings yet

- Synthetic Web Tie Downs: Recommended Standard Specification FORDocument19 pagesSynthetic Web Tie Downs: Recommended Standard Specification FORDiego RodriguezNo ratings yet

- White 2221 Sewing Machine Instruction ManualDocument46 pagesWhite 2221 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- A09 - Various Timelines of Fashion HistoryDocument26 pagesA09 - Various Timelines of Fashion HistorysampleuNo ratings yet

- Toyota Embroidery ManualDocument101 pagesToyota Embroidery ManualAttila HabaczellerNo ratings yet

- AIO Gusset TutorialDocument6 pagesAIO Gusset TutorialKira100% (3)

- Monkey D. Luffy Crochet PatternDocument7 pagesMonkey D. Luffy Crochet PatternJeffryNo ratings yet

- Twinkle Little Stars Cushion Cover: Designed by Ana Morais SoaresDocument6 pagesTwinkle Little Stars Cushion Cover: Designed by Ana Morais SoaresErika EspinolaNo ratings yet

- Zetex Spec SheetDocument2 pagesZetex Spec SheetDidier MarneffeNo ratings yet