Professional Documents

Culture Documents

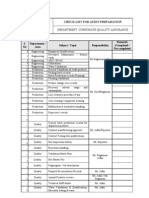

Pre-Productionactivities: Cutting Quality

Uploaded by

Puja Prasad0 ratings0% found this document useful (0 votes)

11 views3 pagesThis document outlines the quality control processes for a garment manufacturing company. It discusses pre-production activities like fabric inspection, size approval, and pattern development. It then covers quality control procedures for cutting, sewing, finishing, packaging, and inspection. Key steps include fabric receiving, marker checking, process mock ups, hourly quality reports, AQL audits, and defect tracking. The document provides definitions for different types of defects.

Original Description:

Original Title

content

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the quality control processes for a garment manufacturing company. It discusses pre-production activities like fabric inspection, size approval, and pattern development. It then covers quality control procedures for cutting, sewing, finishing, packaging, and inspection. Key steps include fabric receiving, marker checking, process mock ups, hourly quality reports, AQL audits, and defect tracking. The document provides definitions for different types of defects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views3 pagesPre-Productionactivities: Cutting Quality

Uploaded by

Puja PrasadThis document outlines the quality control processes for a garment manufacturing company. It discusses pre-production activities like fabric inspection, size approval, and pattern development. It then covers quality control procedures for cutting, sewing, finishing, packaging, and inspection. Key steps include fabric receiving, marker checking, process mock ups, hourly quality reports, AQL audits, and defect tracking. The document provides definitions for different types of defects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Introduction

1. Company profile

2. Quality Policy

Pre-ProductionActivities

Sample & raw material

Measurement

Colour

Light

Fabric and yran inspection

Trimming

5. Style File & Construction Details Sheet

6. Approved Trim Card

7. Fabric Inspection (4 Point Systems)

8. Trim Inspection

9. Fabric & Trim Inspection Result

10. Shade Blanket Records

11. Fabric Shrinkage Report

12.Fabric Segregation Record

13.Fabric & Trim Status

14.Line Sample

15.Size Set Approval for Pilot Run

16.Heard Patterns for Bulk Cutting

17.Finish Patterns

18.Pre-Production Meeting

19.Pre-Production Activities Completion

Cutting Quality

20. Style Cut Plan

21. Store Requisition

22. Fabric Receiving Record

23. Fabric Relaxing

24. Marker Checking

25. Layer Sheet

26. Spreading Checking

27.Cutting Inspection

28. Bundle Guide Chart

29. Printing Embroidery Send Out & Receive Record

30. Printing Inspection

31. Embroidery Inspection

Sewing Quality

32. Approved Sample for Bulk Production

33. QC Instruction

34. Line Feeding Report

35. Process Mock Up

36. Pilot/Trial Run Meeting

37. Bulk Cut Approval

38. 7/0 In Line Audit Report & Traffic Light System

39. In Process Hourly Quality Report

40. In Line Daily and Monthly Defect/Reject Summary

41. End Line Hourly Quality Report

42. Garments Measurement

43. AQL Audit at End Line

Finishing Quality& packaging

44. Approved Packing Sample

45. Approved Trim Card

46. QC Instruction

47. After Wash Checking-Hourly

48. Finishing Defect/Reject Daily and Monthly

49. Finishing Returns

50. AQL Audit at Finishing

51. Day Final/Packing Audit

52. Pre Final Audit

53. Organizational Chart

Inspection & Quality Assurance

Intial inspection

Inline inspection

Final inspection

Aql followed by adidas

Reject product

DEFINATION OF DEFECT

Critical defect

Major defect

Minor defect

judgment defect

conclusion

You might also like

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Fi TTQC3 OkDocument12 pagesFi TTQC3 OkMoklesur Rahman100% (1)

- TEXPORT SyndicateDocument36 pagesTEXPORT SyndicateManish Koundal100% (1)

- Technical Audit in Apparel IndustryDocument7 pagesTechnical Audit in Apparel IndustryRongdhonu MasumNo ratings yet

- Manual - Garment Quality ManagementDocument5 pagesManual - Garment Quality ManagementMd Majharul Islam100% (3)

- Diploma in Apparel Merchandising (LANKA CLOTHING)Document23 pagesDiploma in Apparel Merchandising (LANKA CLOTHING)shahdhk100% (1)

- D.2. Quality ManualDocument55 pagesD.2. Quality ManualMinal HadiNo ratings yet

- Quality Management System in Garments Manufacturing by SujanDocument27 pagesQuality Management System in Garments Manufacturing by SujanSujan sahaNo ratings yet

- Quality Control System in Garments Industry - Textile LearnerDocument5 pagesQuality Control System in Garments Industry - Textile LearnerMayaNo ratings yet

- Quality Control in Garments ProductionDocument22 pagesQuality Control in Garments Productioni_sonetNo ratings yet

- Laboratories Limited Corporate QA Department: Corporate Quality AssuranceDocument3 pagesLaboratories Limited Corporate QA Department: Corporate Quality AssurancePurushothaman SubramanianNo ratings yet

- Aim & Objective of Project: Richa & CoDocument31 pagesAim & Objective of Project: Richa & CoRanvijay Singh RathoreNo ratings yet

- Vastram ExportsDocument40 pagesVastram ExportsHarsha DuraiNo ratings yet

- APQP Documents and Elements Action Plan 2Document2 pagesAPQP Documents and Elements Action Plan 2Andras StegerNo ratings yet

- Shanto-M Ariam Uni Versity of Creative Technology: Module Name: Apparel Quality Management Module Code: AMM-2203Document5 pagesShanto-M Ariam Uni Versity of Creative Technology: Module Name: Apparel Quality Management Module Code: AMM-2203Md ZihadNo ratings yet

- BGMEA University of Fashion & Technology Department of Textile EngineeringDocument52 pagesBGMEA University of Fashion & Technology Department of Textile EngineeringNafis MahmudNo ratings yet

- Audit Checklist SOPDocument43 pagesAudit Checklist SOPthemba100% (4)

- Corbett Inspect Plan Web in ArDocument38 pagesCorbett Inspect Plan Web in ArShahid Hussain MallahNo ratings yet

- Quality Manual - Simba Fashions Ltd.Document143 pagesQuality Manual - Simba Fashions Ltd.ABDULNo ratings yet

- Apparel IndustryDocument53 pagesApparel Industryrajhossie9335100% (1)

- Best Practice of Garments Washing Factory SOP WORKDocument20 pagesBest Practice of Garments Washing Factory SOP WORKMd IslamNo ratings yet

- Cotton Ginning Plant OperatorDocument18 pagesCotton Ginning Plant Operatorsapphire207100% (1)

- For Line QC GPQ Training 1682907711Document9 pagesFor Line QC GPQ Training 1682907711ABDULNo ratings yet

- New Document CosmoDocument6 pagesNew Document CosmoSami GulemaNo ratings yet

- Apparel Production: Asif Elahi MangatDocument40 pagesApparel Production: Asif Elahi MangatAsif Mangat100% (1)

- Company Profile: Spinning Weaving Processing StitchingDocument20 pagesCompany Profile: Spinning Weaving Processing StitchingallanbethelNo ratings yet

- Study On Quality Control in Knit Garments ProductionDocument58 pagesStudy On Quality Control in Knit Garments Productionabid hassanNo ratings yet

- Amaan Work. 01Document21 pagesAmaan Work. 01Izhan ANo ratings yet

- Mandatory Documents and Records (Ref: ISO 9001:2008)Document4 pagesMandatory Documents and Records (Ref: ISO 9001:2008)Shashank ChhajerNo ratings yet

- U15GST006 Prod Desgn & Develop Jan 2018Document7 pagesU15GST006 Prod Desgn & Develop Jan 2018Sentthil KumarNo ratings yet

- Aqe Assign 2 BDocument6 pagesAqe Assign 2 Banisha gautamNo ratings yet

- Standard Operating Procedures 2Document78 pagesStandard Operating Procedures 2eeshachtr92% (12)

- Inspection and Quality ControlDocument15 pagesInspection and Quality ControlAnurag Goel100% (2)

- NPG Fabric InspectionDocument4 pagesNPG Fabric InspectionDivya SinghNo ratings yet

- Quality Control Program For An Apparel Manufacturing Unit: Assignment 2Document12 pagesQuality Control Program For An Apparel Manufacturing Unit: Assignment 2Amrita MitraNo ratings yet

- Internship Instructions FinalDocument4 pagesInternship Instructions Finalid workNo ratings yet

- GMP QCDocument29 pagesGMP QCBhavishya KandulaNo ratings yet

- Banswara Garment Syntex Limited: Presented By: Ketna Patel Asha Patel Mukesh JadavDocument55 pagesBanswara Garment Syntex Limited: Presented By: Ketna Patel Asha Patel Mukesh Jadavrohit008No ratings yet

- Textile Testing and Quality ControlDocument25 pagesTextile Testing and Quality ControlGreen University Textile100% (2)

- Internship at ARVIND APPARELSDocument84 pagesInternship at ARVIND APPARELSNeetek SahayNo ratings yet

- Apparel Quality ManagementDocument32 pagesApparel Quality Managementshawar6967% (3)

- Introduction of Project Quality Management: in Oil and Gas IndustryDocument20 pagesIntroduction of Project Quality Management: in Oil and Gas IndustrySufira WahyuniNo ratings yet

- 02 Production Analysis APPCDocument7 pages02 Production Analysis APPCniceneha_nehaNo ratings yet

- Garment Industry DepartmentsDocument61 pagesGarment Industry DepartmentsIndu Vikasini100% (3)

- National Institute of Fashion Technology, GandhinagarDocument31 pagesNational Institute of Fashion Technology, GandhinagarSatyam SinghNo ratings yet

- Quality Manual MaduraDocument22 pagesQuality Manual MaduraAbhishek Yadav100% (1)

- Manufacturing Goods Control AssuranceDocument108 pagesManufacturing Goods Control Assurancemsandeepraja100% (1)

- Pdca Cycle: Plan-Do-Check-ActDocument13 pagesPdca Cycle: Plan-Do-Check-Actnikhil krNo ratings yet

- Working Process Woven & KnitDocument2 pagesWorking Process Woven & Knitmd. habibul islamNo ratings yet

- Technical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesFrom EverandTechnical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesNo ratings yet

- Session-3 Garment Manufacturing Unit: Prof. Lipsa Mohapatra FMS Dept., NIFT, BhubaneswarDocument17 pagesSession-3 Garment Manufacturing Unit: Prof. Lipsa Mohapatra FMS Dept., NIFT, BhubaneswarPuja PrasadNo ratings yet

- Production Planning and Control in GarmentsDocument2 pagesProduction Planning and Control in Garmentskbalabala100% (1)

- CH 5ADocument74 pagesCH 5AKavita ChowdharyNo ratings yet

- Apparel Manufacturing ProcessDocument46 pagesApparel Manufacturing Processroselyn ayensa100% (1)

- Content Audits and Inventories: A Handbook for Content AnalysisFrom EverandContent Audits and Inventories: A Handbook for Content AnalysisNo ratings yet

- Agent-Based and Individual-Based Modeling: A Practical Introduction, Second EditionFrom EverandAgent-Based and Individual-Based Modeling: A Practical Introduction, Second EditionRating: 4 out of 5 stars4/5 (4)

- Brand Ideology Se Se Inspired Hokar Design KiyaDocument5 pagesBrand Ideology Se Se Inspired Hokar Design KiyaPuja PrasadNo ratings yet

- Barcelos CaptionDocument9 pagesBarcelos CaptionPuja PrasadNo ratings yet

- Capturing The TeensDocument1 pageCapturing The TeensPuja PrasadNo ratings yet

- Sawjogjropppppppp AssigmentDocument30 pagesSawjogjropppppppp AssigmentPuja PrasadNo ratings yet

- ABOUT US For Social MediaDocument2 pagesABOUT US For Social MediaPuja PrasadNo ratings yet

- QUALITY INSPECTION 88888jjjjDocument4 pagesQUALITY INSPECTION 88888jjjjPuja PrasadNo ratings yet

- Diegetic SoundDocument5 pagesDiegetic SoundPuja PrasadNo ratings yet

- Stitch Class 100: Chain StitchDocument7 pagesStitch Class 100: Chain StitchPuja PrasadNo ratings yet

- Initial InspectionDocument2 pagesInitial InspectionPuja PrasadNo ratings yet

- Film Appreciation End Term AssignmentDocument27 pagesFilm Appreciation End Term AssignmentPuja PrasadNo ratings yet

- FR AntonyPT VisualgrammerDocument21 pagesFR AntonyPT VisualgrammerPuja Prasad100% (1)

- Demographic Segmentation Benefits: 8.1.1 DemographicsDocument4 pagesDemographic Segmentation Benefits: 8.1.1 DemographicsPuja Prasad0% (1)

- Effort Risk For Making Their Small Purchases. If Changes Are Made, The Layout Has To BeDocument1 pageEffort Risk For Making Their Small Purchases. If Changes Are Made, The Layout Has To BePuja PrasadNo ratings yet

- Adidas Policy On Modern SlaveryDocument5 pagesAdidas Policy On Modern SlaveryPuja PrasadNo ratings yet

- Fast Retailing: An Analysis of FDI and Supply Chain Management in Fashion RetailingDocument23 pagesFast Retailing: An Analysis of FDI and Supply Chain Management in Fashion RetailingPuja PrasadNo ratings yet

- Goodman Case 2Document31 pagesGoodman Case 2Puja PrasadNo ratings yet

- Lighting:! Controlling Shadows, Shape, Mood and Tone: P.S. Machinima Doesn't Have To Use These!Document21 pagesLighting:! Controlling Shadows, Shape, Mood and Tone: P.S. Machinima Doesn't Have To Use These!Puja PrasadNo ratings yet