Professional Documents

Culture Documents

Safe Work Procedure Waste Baler

Safe Work Procedure Waste Baler

Uploaded by

Osh 07170 ratings0% found this document useful (0 votes)

6 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesSafe Work Procedure Waste Baler

Safe Work Procedure Waste Baler

Uploaded by

Osh 0717Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Safe Work Procedure

Troubleshooting of Blockage Waste Baler and Cyclone

Edited by: Approved by: Created by: Date created /

Revision:

C - 22 April 2021

Mr. Ahmad Syouqi Mr. Ooi Cheng Keat Mr. Ahmad Syouqi

ISHE Dept ESHMR ISHE Dept R-1

Hazard Present: Personal Protective Equipment and Additional Training

Devices Required: Requirement:

• Cardboard cut on hands • Safety gloves • Job specific training

• Eye injury • Eye protection/Safety goggles • Safe lifting procedures

• MSD due to lifting, or • Hearing protection/Ear plug 32 dB

push/pulling • Closed toe shoes/Full cover safety

• Slip/trip shoes

• Noise induced hearing • Metal bar tool

loss • Hook tool

•Fall from high • Operation manual for baler

•Stuck in between •Safety Harness

Safe Work Procedure:

Troubleshooting of blockage

• If it seems to be inoperable (trouble shooting blockage) for any reason, stop

the baler and tell your supervisor immediately.

• Before performing maintenance, the baler and associated equipment,

including conveyors, cyclone and rams, must be locked and tagged out.

• Emergency stops should be easily accessible from any point along the

operating line, including on the infeed conveyor. Balers, conveyors and

cyclone should be interlocked so stopping one automatically stops the

other.

• Allow for safe clearances between machinery and adjacent aisles or

passageways, and clearly mark permanent aisles and passageways.

• Ground motors and other electrical equipment.

• Keep walking and working surfaces clean and dry and install railings or fall

protection where the vertical distance between these surfaces exceeds 4

feet.

• Designate and enforce a safety zone, which is where the operator of the

equipment must be while the equipment is operating.

• Keep suspended loads clear of walking and working areas, power lines,

obstructions, buildings and other hazardous locations.

• Provide suitable drainage in the baling pit or chamber.

• Operators of the machinery and of material handling equipment should

maintain positive contact with each either visually or by radio or a similar

device.

THIS TASK MUST ONLY BE PERFORMED BY TRAINED EMPLOYEES!!!

Safe Work Procedure:

Lock-Out Tag-Out (LOTO)

Safe work procedures must be followed when performing maintenance, housekeeping and

repair works on electrical equipment.

The Lock-Out Tag-Out (LOTO) system must be implemented. The system should cover

the following actions minimally:

• De-energising the machine before commencing any maintenance or repair;

• Turning off the machine;

• Deactivating energy isolating devices e.g., circuit breaker, disconnect switch;

• Setting lockout and/or tag-out control switches to an “off” or “safe” position;

• Releasing or blocking stored energy;

• Testing operating controls by pressing/turning the “on” position to ensure the

machine does not start up, then returning operating controls to the “off” position;

• Performing the necessary maintenance or repair;

• Removing tools and other items, and reinstalling machine guards when work is

completed;

• Removing locks and tags; and

• Turning on energy and testing to make sure machine is working properly.

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Book of Lost Spells (Necromancer Games)Document137 pagesBook of Lost Spells (Necromancer Games)Rodrigo Hky91% (22)

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooNo ratings yet

- October 2018 October 3 PDFDocument110 pagesOctober 2018 October 3 PDFIchim Lawinne MarieNo ratings yet

- Chemical Register List 2021 (25.05.2021)Document9 pagesChemical Register List 2021 (25.05.2021)Osh 0717100% (2)

- BSBOPS601 Learner Guide PDFDocument91 pagesBSBOPS601 Learner Guide PDFPalakNo ratings yet

- Working at Height Rev 4Document71 pagesWorking at Height Rev 4Adrian Seng100% (2)

- Safe Lifting and Rigging TrainingDocument84 pagesSafe Lifting and Rigging Trainingfaroz khan100% (2)

- Loading Unloading EquipDocument4 pagesLoading Unloading EquipSyed Fawad Adil100% (1)

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts Factsheetomar santosNo ratings yet

- Safety ManagementDocument19 pagesSafety ManagementDave Khyl Josol BosqueNo ratings yet

- High Voltage Safe Working ProcedureDocument10 pagesHigh Voltage Safe Working ProcedureYhon Tyang NdusunNo ratings yet

- Ricoh DX2430Document124 pagesRicoh DX2430Amer Rafique89% (9)

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Physical Hazards 101Document24 pagesPhysical Hazards 101Mohamed AhmedNo ratings yet

- Manuale Tecnico MPC306 - Gr-c2 FSM en Final 190815Document1,124 pagesManuale Tecnico MPC306 - Gr-c2 FSM en Final 190815jarin tagliento100% (1)

- R F (H W C) :: Operations & Screening CrushingDocument7 pagesR F (H W C) :: Operations & Screening Crushingkmohamedkeita906No ratings yet

- AD302 - Tightening of BoltsDocument2 pagesAD302 - Tightening of BoltsdenismcnelisNo ratings yet

- Safety Abrasive WheelDocument32 pagesSafety Abrasive WheelMohamed Hichem GuesmiNo ratings yet

- Service Manual MPC 2030Document832 pagesService Manual MPC 2030liviumaraNo ratings yet

- Service Manual Ricoh AficioDocument448 pagesService Manual Ricoh Aficiodaltontech14% (7)

- 1.2 Isolation, Lockout, TagoutDocument62 pages1.2 Isolation, Lockout, TagoutEkant GoyalNo ratings yet

- 19 - Nacelles and Thrust ReversersDocument11 pages19 - Nacelles and Thrust Reversers郝帅No ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- Pearson Academic Collocation List PDFDocument42 pagesPearson Academic Collocation List PDFMuhammad Ashraf100% (8)

- SOP-Coil Winding MachinesDocument4 pagesSOP-Coil Winding MachinesRadhaKrishnan RNo ratings yet

- Sagada FrontDocument1 pageSagada FrontKalabit Penge0% (1)

- Safety and Health RulesDocument9 pagesSafety and Health RulesVholts Villa VitugNo ratings yet

- United Mining Industries "Health Safety and Environment General Rules"Document139 pagesUnited Mining Industries "Health Safety and Environment General Rules"Jakaria Al-MahmudNo ratings yet

- Construction Machinery Safety: By: John Eric M. CagatDocument33 pagesConstruction Machinery Safety: By: John Eric M. CagatyoakamuraNo ratings yet

- Hongkong v. Olalia, Jr. (CASE DIGEST)Document3 pagesHongkong v. Olalia, Jr. (CASE DIGEST)Samantha NicoleNo ratings yet

- 1-Machine SafetyDocument59 pages1-Machine Safetyᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔100% (3)

- Auditometric Namelist (Year2020) (Final Confirm Name List)Document22 pagesAuditometric Namelist (Year2020) (Final Confirm Name List)Osh 0717No ratings yet

- Copyreading ANSWER SHEETDocument10 pagesCopyreading ANSWER SHEETLuz Alinsunurin Dulog100% (2)

- LOTODocument31 pagesLOTORanganayaki Tirumale Srinivasa RangacharNo ratings yet

- COSH Module 2 - 3B Control of Safety Hazards (Synerquest) - CompressedDocument165 pagesCOSH Module 2 - 3B Control of Safety Hazards (Synerquest) - Compressedsui1981No ratings yet

- DIAPOSITIVAS INGLES AngrelDocument16 pagesDIAPOSITIVAS INGLES AngrelÁngel De Jesús Figueroa GutiérrezNo ratings yet

- Occupational Safety and Health Occupational Safety and Health in Construction in ConstructionDocument61 pagesOccupational Safety and Health Occupational Safety and Health in Construction in ConstructionJoe A. CagasNo ratings yet

- Lecture 3 - The Building EnvironmentDocument41 pagesLecture 3 - The Building EnvironmentYounq KemoNo ratings yet

- DD4450 Service ManualDocument240 pagesDD4450 Service ManualServnetTechnicianNo ratings yet

- Control of Hazardous Energy (Lockout/Tagout) : EM 385-1-1 Section 12Document32 pagesControl of Hazardous Energy (Lockout/Tagout) : EM 385-1-1 Section 12MirwaliNo ratings yet

- Electrical Safety There Are Common Hazards in The Electrical IndustryDocument6 pagesElectrical Safety There Are Common Hazards in The Electrical IndustryJohnrogel IlinganNo ratings yet

- Introduction To Mech MH SafetyDocument29 pagesIntroduction To Mech MH Safetybalamurugan sNo ratings yet

- Di-C15 FSM en Final 171210Document1,124 pagesDi-C15 FSM en Final 171210Stanescu BernardNo ratings yet

- MP 7503spDocument1,960 pagesMP 7503spSebastian AlvaradoNo ratings yet

- Guidelines For Engineers Carrying Out ChecksDocument7 pagesGuidelines For Engineers Carrying Out ChecksSubhransu MohapatraNo ratings yet

- Batch - Ii ProjectDocument26 pagesBatch - Ii ProjectNamsad AlikhanNo ratings yet

- CESU Safe Practice in Power DistributionDocument26 pagesCESU Safe Practice in Power DistributionDevanand PallikuthNo ratings yet

- Risk Involved in Construction Works.Document10 pagesRisk Involved in Construction Works.Shaibal AhmedNo ratings yet

- 7 Electrical PDFDocument6 pages7 Electrical PDFMohammed AtefNo ratings yet

- Day 5-6 - SDocument83 pagesDay 5-6 - SNiravSaxenaNo ratings yet

- DR460 SP QST30 OpDocument90 pagesDR460 SP QST30 OpRamiro Joel Quiñonez RamosNo ratings yet

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- The Permit SystemDocument40 pagesThe Permit SystemJoshuaNo ratings yet

- Ricoh MP c2051 SM PDFDocument1,124 pagesRicoh MP c2051 SM PDFEugene100% (2)

- RICOH MPC2030 Service ManualDocument832 pagesRICOH MPC2030 Service Manualkingveli100% (4)

- LCT RT4000 ServiceDocument41 pagesLCT RT4000 ServicePhillip CampbellNo ratings yet

- BRGP 1Document360 pagesBRGP 1redaNo ratings yet

- Signgood Innovation MethodologyDocument3 pagesSigngood Innovation MethodologyJared Aaron CruzNo ratings yet

- Aficio MP C2550Document1,124 pagesAficio MP C2550marecalinNo ratings yet

- Mitsubishi I-Miev Isolation ProcedureDocument15 pagesMitsubishi I-Miev Isolation ProcedureJamaluddin SaatNo ratings yet

- Manual Rico Service PDFDocument2,757 pagesManual Rico Service PDFAlejandro José SosaNo ratings yet

- D45-50KS Maint Manual 732584 & Up (Rev. 7-09)Document92 pagesD45-50KS Maint Manual 732584 & Up (Rev. 7-09)Putra Dana100% (1)

- Lockout Tagout SW-2024TrainingDocument32 pagesLockout Tagout SW-2024TrainingIbrahim EsmatNo ratings yet

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts FactsheetJafar KhanNo ratings yet

- 119GM47EN Automatic Chain Barrier 24vDocument16 pages119GM47EN Automatic Chain Barrier 24vDaniel MikulandarNo ratings yet

- Sky Stage Ultra Boiler Platform (UM 36 100)Document14 pagesSky Stage Ultra Boiler Platform (UM 36 100)Scherloscobit CGNo ratings yet

- SG3120B SFNW Field Service Manual-WebDocument444 pagesSG3120B SFNW Field Service Manual-Webprint press (printpress.eg)No ratings yet

- Ear Plug ChecklistDocument1 pageEar Plug ChecklistOsh 0717No ratings yet

- Recommendation: Langkah-Langkah Penambahbaikan Bagi Mengurangkan Bising Berlebihan (Hp1) by EurofinsDocument9 pagesRecommendation: Langkah-Langkah Penambahbaikan Bagi Mengurangkan Bising Berlebihan (Hp1) by EurofinsOsh 0717No ratings yet

- Forest Stewardship Council (FSC) Chain of CustodyDocument25 pagesForest Stewardship Council (FSC) Chain of CustodyOsh 0717No ratings yet

- New Ammend Chemical Register (Draft 2)Document11 pagesNew Ammend Chemical Register (Draft 2)Osh 0717No ratings yet

- Survey For The Fatal Accident of The Contractor of Oji Paper YonagoDocument5 pagesSurvey For The Fatal Accident of The Contractor of Oji Paper YonagoOsh 0717No ratings yet

- Form 03 Job Responsibilities and Authorities FSC CocDocument1 pageForm 03 Job Responsibilities and Authorities FSC CocOsh 0717No ratings yet

- Kong Long Huat Sodium Chloride (PDV Salt), BI GHS (Rev.11012018)Document11 pagesKong Long Huat Sodium Chloride (PDV Salt), BI GHS (Rev.11012018)Osh 0717No ratings yet

- Asset Draft Plan Form (Airflow Meter)Document2 pagesAsset Draft Plan Form (Airflow Meter)Osh 0717No ratings yet

- Harta Packaging Industries (Perak) Sdn. BHD.: FSC Daily Summary Report (Mock Test)Document2 pagesHarta Packaging Industries (Perak) Sdn. BHD.: FSC Daily Summary Report (Mock Test)Osh 0717No ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- Awetek Engineering Starch Crosslinking Agent PSA-30 (Rev.01032016)Document9 pagesAwetek Engineering Starch Crosslinking Agent PSA-30 (Rev.01032016)Osh 0717No ratings yet

- Awetek Engineering Starch Crosslinking Agent CMS-431 (Rev.01032016)Document10 pagesAwetek Engineering Starch Crosslinking Agent CMS-431 (Rev.01032016)Osh 0717No ratings yet

- Mega Wijayah Caustic Soda Flakes SDS - Rev. 2018Document9 pagesMega Wijayah Caustic Soda Flakes SDS - Rev. 2018Osh 0717No ratings yet

- Kong Long Huat Caustic Soda Flake, (BI) (Rev.2 02042018)Document14 pagesKong Long Huat Caustic Soda Flake, (BI) (Rev.2 02042018)Osh 0717No ratings yet

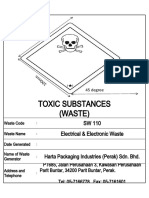

- Labelling For Chemical RegisterDocument24 pagesLabelling For Chemical RegisterOsh 0717No ratings yet

- Harta Perak Chemical List (Chemical Room) (HP1)Document1 pageHarta Perak Chemical List (Chemical Room) (HP1)Osh 0717No ratings yet

- Sebesta, Robert W: Nairobi CampusDocument3 pagesSebesta, Robert W: Nairobi CampusJustus MutuaNo ratings yet

- Financial Accounting 17th Edition by Williams ISBN Solution ManualDocument90 pagesFinancial Accounting 17th Edition by Williams ISBN Solution Manualjames100% (26)

- Happy Teacher DayDocument1 pageHappy Teacher DayPrincess Joy Andayan BorangNo ratings yet

- Rules For Writing Out DollarsDocument7 pagesRules For Writing Out DollarsDũng Đào TrungNo ratings yet

- Atmospheric Pollution and Environmental ChangeDocument209 pagesAtmospheric Pollution and Environmental Changeviqrisyam rizkyNo ratings yet

- Obj Day 1 Science DLLDocument5 pagesObj Day 1 Science DLLRoss AnaNo ratings yet

- Peacock Solar (SIP)Document41 pagesPeacock Solar (SIP)shivam67% (3)

- Minassian Full Reasons For JudgementDocument69 pagesMinassian Full Reasons For JudgementCityNewsTorontoNo ratings yet

- Kothis and KarbalaDocument3 pagesKothis and KarbalaMahak GuptaNo ratings yet

- Science Academy Saddar Gogera Okara: CH-11 Decision Constructs")Document1 pageScience Academy Saddar Gogera Okara: CH-11 Decision Constructs")Engr Naveed AhmedNo ratings yet

- Cheshire Cat IllusionDocument10 pagesCheshire Cat IllusionEd Mark Angel BellezaNo ratings yet

- Students Innovation Festival Space HackathonDocument6 pagesStudents Innovation Festival Space HackathonAsad ShadNo ratings yet

- Dolphin Station - Pre App Letter of IntentDocument3 pagesDolphin Station - Pre App Letter of Intentthe next miamiNo ratings yet

- ch05 Project Organisation September 2023Document65 pagesch05 Project Organisation September 2023Tota SimatupangNo ratings yet

- Vitalina Malakar: ObjectiveDocument2 pagesVitalina Malakar: Objectiveapi-560642428No ratings yet

- Grade 9Document60 pagesGrade 9Самал АжбеноваNo ratings yet

- Economics Presentation TB, CP, CDDocument22 pagesEconomics Presentation TB, CP, CDAbin MathewNo ratings yet

- PDF To WordDocument43 pagesPDF To WordKamrul HasanNo ratings yet

- MURLIDocument4 pagesMURLIrabinpadhanNo ratings yet

- MSD Unit 3 PPT-R1Document46 pagesMSD Unit 3 PPT-R1Vikas RathodNo ratings yet

- SWOT Analysis of Coca Cola: StrengthsDocument6 pagesSWOT Analysis of Coca Cola: StrengthsFaisal LukyNo ratings yet