Professional Documents

Culture Documents

Container Tank Specification

Uploaded by

Mamta RaybageCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Container Tank Specification

Uploaded by

Mamta RaybageCopyright:

Available Formats

REVISION: “R0”

DATE: 04/04/00

20’ TANK CONTAINER

STANDARD SPECIFICATION

MODEL NUMBER: 21 FSTD 2

QUOTATION NUMBER

PROPOSED BY: PREPARED FOR:

TRENCOR TANK CONTAINERS

-1-

1. Technical Characteristics

1.1 Design & Testing

Tank – in accordance with: IMDG, CFR 49, RID/ADR and ASME VIII, Div 1

US DOT Equivalent Thickness (mm): Standard

IMDG Equivalent Thickness (mm): 6 mm

Frame – in accordance with: ISO Standard 1496/3

1.2 ISO Type 1CC / 22T6

1.3 IMO Type 1

SI US

1.4 Nominal Capacity (-0 +1% Tolerance) 21 000 _ 5548 US gal

1.5 Frame Dimensions and Weight

Max Gross Weight 36 000 kg 79366 lb.

Tare Weight (± 3% Tolerance) 3850 kg 8488 lb.

Length 6058 mm 20 ft

Width 2438 mm 8 ft

Height 2591 8 ft 6 in

1.6 Tank Dimensions

Internal Diameter 2200 mm 86.61 in

Seam to Seam 4913 mm 193.425 in

Shell Minimum Thickness 4.403 mm 0.1733 in

Shell Order Thickness 4.7 mm 0.1850 in

Head Minimum Thickness

Knuckle 5.37 mm 0.2114 in

Crown 4.49 mm 0.1768 in

Corrosion Allowance 0 mm 0.0 in

Dished Ends Torispherical

1.7 Pressure & Temperature Rating

Tank Design Temperature 120 °C 246 °F

RID/ADR Calculation Pressure 6,0 bar 87,0 psi

Maximum Allowable Working Pressure 4,0 bar 58,0 psi

Test Pressure 6,0 bar 87,0 psi

Vacuum Pressure 0.4 bar 5,8 psi

Steam Heating

Maximum Allowable Working Pressure 7,0 bar 101,5 psi

Test Pressure (Hydrostatic) 10,5 bar 152,25 psi

1.8 Material of Construction

Framework EN 10210-1 S355 J2H (Hollow section)

50D or Equivalent (Tested to -40°C)

Corner Castings ISO Standard 1161

Shell DIN 171441 W1.4401 Low Carbon C ≤ 0.03%

Cold Rolled 2B (ASTM A 240-93B, 316)

Heads (Columbus Material) DIN 17440 W1.4401 Low Carbon C ≤ 0.03%

Hot Rolled, Ra ≤ 1.6 (ASTM A 240-93B, 316)

Vacuum Stiffening Rings ASTM A240 Gr. 304

Quote 21000 “R0”

-2-

2. Finish

Internal Welds Finish

Longitudinal Not ground, smooth low bead scotch brite polished

Circumferential Bottom ± 400 mm ground flush and polished (Ra ≤ 1.6)

Repairs Ground flush and/or polished (Ra ≤ 1.6)

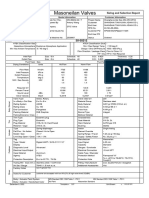

3. Tank Fitting and Accessories

3.1 Manhole

Supplier Swift

Dimensions 500 mm ID, Neckring Radius 1104 mm

Material 316 L

Description 8 point fixing

Gasket PTFE braided fibre, non-leaking type

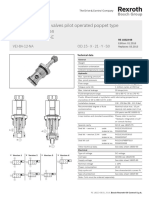

3.2 Safety Relief Valve

Supplier Perolo

Quantity One plus provision for a second valve

Description 2_” BSP Mega Superventix

Specifications +4,4 bar pressure only

Gasket Solid PTFE

Flanged Adaptor Yes

3.3 Air Inlet Valve

Supplier Perolo

Quantity One

Description 1 _” BSP with s/steel cap

Gasket PTFE

3.4 Top Discharge Provision

Quantity One

Dimensions DN 80 (3”)

Specification Blank flange (4 x M16 on 160 mm PCD)

Gasket Klinger SIL C-4430 and PTFE

Remarks Provision is made for the future fitting of a clamped

3” butterfly valve and 3” syphon tube

Guide for Syphon tube Yes

Weld in flange Yes

Blind flange Yes

3.5 Thermometer

Supplier WIKA

Quantity One

Description Surface type, 100 mm dial diameter

Dual scale -20°C to 150°C, -4°F to 302°F

Type Gas in metal / Contact type

Position Rear end (8 o’clock)

3.6 Bottom Discharge

Supplier Perolo

Dimensions DN 80 (3”) opening diameter

Specification Internal valve – 30° foot valve

Gasket Klinger SIL C-4430 / PTFE Envelope

External valve – L.H. operated clamped

butterfly valve

Gasket Klinger SIL C-4430 / PTFE

3” BSP threaded connector closed by a stainless steel cap with

retaining chain

Remarks A remote control is connected to the internal valve handle with

Fusible link provision

Quote 21000 “R0””

-3-

3.7 Spillboxes

Quantity Two, manhole with safety relief, accessories

Position: On centre line around Manhole and Off centre around Top Discharge

Dimensions 945 mm x 750 mm and 550 mm x 400 mm

Material ASTM A240 316L, 2mm

Drain Pipes External

Material Reinforced plastic 25 mm NB

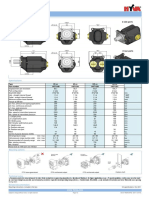

3.8 Steam Heating

Heating area 6.64 m_ (effective)

No. of runs 8

Inlet diameter _ inch BSP male threaded

Outlet diameter _ inch BSP male threaded

Drain valve Yes, _ inch BSP Ball Valve

End cap material PVC

3.9 Tank Treatment

Pickling

Internal Yes

External Welds & Heat marks

Passivation

Internal Yes

External Spillboxes only

Anti-stress lacquer Whole exterior of tank including skirts

3.10 Insulation and Cladding

Material Mineral Wool Polyurethane

Shell 30 mm (min 60kg/m_) 20 mm (min 35kg/m_)

Ends varies (min 60kg/m_)

Cladding 0,8 mm thick pre-painted white aluminium (Grade 3004 H32) or

equivalent

3.11 Walkway

Layout “T” Type

Width / thick 475 mm / 3.0 mm

Material Aluminium Grade 5042-0

3.12 Ladder

One ladder painted in 3 coat system 300 mm (32 x 32 mm section) wide is provided on the right

hand side of the rear frame. The ladder rungs are made from stainless steel and have an anti-slip

surface. One handhold is provided adjacent to the ladder.

3.13 Corner Protection

8 off per tank located at the top and bottom frame corners.

3.14 Earthing Connection

One stainless steel lug 50 x 30 x 3 mm, with 15 mm hole, located at rear of tank frame.

3.15 Document Holder

1-off PVC document holder 90 mm diameter 300 mm long.

Colour: Opaque

Drain hole diameter 6mm

3.16 Data Plates

One stainless steel data plate per tank as per code requirements.

3.17 Dipstick No Bracket : Yes

Quote 21000 “R0”

-4-

3.17 Calibration

Actual paper chart Yes, supplied in document holder

Calibration plate Yes, marked in litres and US gallons/cm, tack welded inside the main

Spillbox.

Chart Material 316 Stainless Steel

3.18 Frame Treatment

Surface Preparation Shot Blasting to SA 2,5 Finish

3.19 Painting of Frame

Coat Type DFT (min)

Primer Zinc Rich 30 micron

Intermediate Zinc Phosphate 40 micron

Top coat CTC free chlorinated rubber 50 micron

Colour of frame TBA (semi gloss)

RAL Number TBA

Supplier KCC

3.20 Decals

Standard, Mandatory decals:

Description Quantity

Operator’s Code and Serial Number 6

Size and Type Code “22T6” 3

IMO 1 / IM 101 2

TC Impact Approved 2

UIC “IC70” 2

Weight (Max Gross Weight 36 000kg) 1

RID / ADR 2

Warning Overhead Electrical Cables 1

Working Pressure “4 Bar MAWP” 2

Earthing 1

Remote Control “EMERGENCY – PULL CABLE TO CLOSE” 1

Nominal Capacity (21 000_/5548 US Gal) 1

Classification Society (Bureau Veritas) 1

AAR 600 2

Foot Valve Warning 1

Steam Outlet 1

Steam Inlet Maximum Pressure 4 Bar 1

Manufacturer “Trencor” 3

No Walking 2

No Forklift 2

UIC “Super Heavy” 3

MAGW for UIC Rail 34000 kg 1

BSLT 1

Steam Heating Drain Valve 1

Height decal (2,6) 2

Customer Decals (Free Issue)

Decal Warranty: Mandatory Decals 7 years

Quote 21000 “R0”

-5-

4. Tests and Approvals

4.1 These tanks containers are constructed according to an approved design.

4.2 Each production unit is subject to testing and non-destructive examination as required by

ASME VIII Division 1, UIC and Suppliers own quality requirements. The independent

Inspection Authority, Bureau Veritas, inspects each unit.

4.3 The tank container has been specially tested and approved for a stacking load of

86400 kg per corner post, which corresponds to nine-high stacking.

4.4 The tank container fulfils the performance specification of the following International

Organization’s regulations and recommendations and is supplied with their Approvals /

Registrations.

US-DOT IMDG – (via US DOT)

TIR (Customs) CSC

RID / ADR Transport Canada

AAR 600 UIC (IC 70)

4.5 Radiography (UW51 and UW52)

Shell Spot

Dished Ends 100%

5. Documentation

The following documentation will be provided:

5.1 Details and GA drawings with indication of the serial number

5.2 Technical data sheet

5.3 Cleanliness Certificate issued by an Independent Party (one copy in plastic pouch in

document holder)

5.4 Initial Inspection Certificate

5.5 BV technical note / approvals

5.6 One set of Digital Photos per Contract

5.7 User’s Manual in English

Files must be prepared as specified hereafter:

1 x paper file

1 x CD ROM

6. Products (RID / ADR)

Approved for products in classes 3; 6.1; 8 & 9 as applicable.

Quote 21000 “R0”

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Trencor Electric (25k)Document72 pagesTrencor Electric (25k)Adades Safede EfdNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Vind Flow Data CompressDocument5 pagesVind Flow Data CompressMohan BabuNo ratings yet

- Technical Data Scaba Frielas PDFDocument1 pageTechnical Data Scaba Frielas PDFNicole FelicianoNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Leading Latin American manufacturer of cryogenic valves and pumpsDocument50 pagesLeading Latin American manufacturer of cryogenic valves and pumpsAlvaro Antonio Cristobal AtencioNo ratings yet

- TechnipFMC - Pipeline StrainersDocument6 pagesTechnipFMC - Pipeline StrainersYadir SánchezNo ratings yet

- TANK FULL SPECIFICATIONDocument4 pagesTANK FULL SPECIFICATIONGUSTAVONo ratings yet

- Complete Listing of Vessel ElementsDocument15 pagesComplete Listing of Vessel Elementsגרבר פליקסNo ratings yet

- Nozzle Reinforcement Calculations for N3 DRAIN NozzleDocument1 pageNozzle Reinforcement Calculations for N3 DRAIN NozzleNerubian AssasinNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- ScrewDownNonreturnValve PDFDocument2 pagesScrewDownNonreturnValve PDFokaNo ratings yet

- Reflex Type Guage GlassDocument6 pagesReflex Type Guage Glasschamaras.engNo ratings yet

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0fayyazdnvNo ratings yet

- Type 14b Butterfly Valve Data SheetDocument6 pagesType 14b Butterfly Valve Data SheetagrovadoNo ratings yet

- T50 TanksDocument5 pagesT50 TanksStephanie CarterNo ratings yet

- Mobin Data Sheet Sample-14000405Document12 pagesMobin Data Sheet Sample-14000405raulNo ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Rotameter Overview PDFDocument8 pagesRotameter Overview PDFSteve Goke AyeniNo ratings yet

- Bolt Torque Calculation - Apr19Document69 pagesBolt Torque Calculation - Apr19Raj SNo ratings yet

- Sheet 1 of 4 Technical Data Sheet for Shell and Tube Heat ExchangerDocument4 pagesSheet 1 of 4 Technical Data Sheet for Shell and Tube Heat ExchangerSakthi VelNo ratings yet

- HB-4600031013-04-03-HD-001 (Bomba de Agua de SelloDocument2 pagesHB-4600031013-04-03-HD-001 (Bomba de Agua de SelloOscar GuerraNo ratings yet

- TubesheetDocument14 pagesTubesheethassnain iqbalNo ratings yet

- Mechanical Specifications of Different UnitsDocument7 pagesMechanical Specifications of Different UnitsTagbo ChukwudiNo ratings yet

- 20TPH Dump Condenser Datasheet 12-1-2022Document4 pages20TPH Dump Condenser Datasheet 12-1-2022Manoj BNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Optimize pump design for high water cut oil wellDocument5 pagesOptimize pump design for high water cut oil wellAli AliNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- Miniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsDocument2 pagesMiniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsMateusz SynowieckiNo ratings yet

- Diseño de MaquinaDocument18 pagesDiseño de MaquinaMiguel DominguezNo ratings yet

- Carcasa de FiltroDocument8 pagesCarcasa de FiltroJerson Arce AlbaNo ratings yet

- Pipe THK CalculationDocument2 pagesPipe THK CalculationchannajayamangalaNo ratings yet

- 10BFFRM2D0Document4 pages10BFFRM2D0Diego BarriosNo ratings yet

- Diaphragm - Type Diaphragm SealType L990.10Document4 pagesDiaphragm - Type Diaphragm SealType L990.10harglugurNo ratings yet

- Ebara Vertical Inline Pump - LPDADocument8 pagesEbara Vertical Inline Pump - LPDAGeorge CobraNo ratings yet

- Bulkhaul Standard NewDocument4 pagesBulkhaul Standard NewAntónio TrindadeNo ratings yet

- RB-801 Agitator Vessel Geometry & Design DetailsDocument8 pagesRB-801 Agitator Vessel Geometry & Design DetailsPrathmesh GujaratiNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- PV Elite 2020 Licensee: Tubesheet Check CalculationDocument8 pagesPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadNo ratings yet

- Data Sheet Lungo - 1000042831 - 02 - 1 PDFDocument2 pagesData Sheet Lungo - 1000042831 - 02 - 1 PDFMilan GrujićNo ratings yet

- Cryogenic Valves For Industrial Gas Applications-43-44Document2 pagesCryogenic Valves For Industrial Gas Applications-43-44Abdul Hadi RashidNo ratings yet

- S1.4.5.) Datasheet PRESSURE GAUGEDocument3 pagesS1.4.5.) Datasheet PRESSURE GAUGEEkoNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Inline Pump 35 MDocument10 pagesInline Pump 35 Mbipan rawatNo ratings yet

- Data SheetDocument5 pagesData SheetHardikNo ratings yet

- KRT-Caracteristicas TecnicasDocument41 pagesKRT-Caracteristicas TecnicasJjoseph MaquNo ratings yet

- Data Sheets for Oil and Gas Metering System StrainersDocument2 pagesData Sheets for Oil and Gas Metering System StrainersSales FlometriqNo ratings yet

- Heat Exchanger Plate TypeDocument1 pageHeat Exchanger Plate TypeDeepak jainNo ratings yet

- Spira X Sarco Fig 14Document2 pagesSpira X Sarco Fig 14Jacobus CalvelageNo ratings yet

- TDS Discstar G enDocument3 pagesTDS Discstar G enGabriela MontenegroNo ratings yet

- PHE SelectionsDocument67 pagesPHE SelectionsSelva Kumar Selva KumarNo ratings yet

- Drill Pipe Tool JointDocument1 pageDrill Pipe Tool JointJosh SabimanNo ratings yet

- Pipeline Strainer - SpecsDocument6 pagesPipeline Strainer - SpecsCristhian AyanomeNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- 1 110 Gauge Shutoff ValveDocument2 pages1 110 Gauge Shutoff ValveAinayya alfatimahNo ratings yet

- Truck and Bus Report: New Power ProgressDocument52 pagesTruck and Bus Report: New Power ProgressRatnin PanityingNo ratings yet

- JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRDDocument6 pagesJCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRDMamta RaybageNo ratings yet

- Hyundai Sonata Embera: Car BrochureDocument13 pagesHyundai Sonata Embera: Car BrochureMamta RaybageNo ratings yet

- Hydraulic Components for Construction & Industrial MachineryDocument35 pagesHydraulic Components for Construction & Industrial MachineryEUROPARTS100% (6)

- KUBOTA MU5501 TESTDocument50 pagesKUBOTA MU5501 TESTMamta RaybageNo ratings yet

- Ipdqr 1684540Document2 pagesIpdqr 1684540Mamta RaybageNo ratings yet

- JCB Tracked Excavator JS 210 LC: Static DimensionsDocument8 pagesJCB Tracked Excavator JS 210 LC: Static DimensionsВолодимир КривкоNo ratings yet

- EMCO BRAKE GUIDEOperating Instructions for Emco Dynatorq Pvt. Ltd. DC Spring Applied Brake Type: - 14.458Document37 pagesEMCO BRAKE GUIDEOperating Instructions for Emco Dynatorq Pvt. Ltd. DC Spring Applied Brake Type: - 14.458Mamta RaybageNo ratings yet

- Ata 29 - Hydraulic System: GeneralDocument37 pagesAta 29 - Hydraulic System: GeneralSharpeEngineerNo ratings yet

- Diesel Progress Sourcing Guide 2021Document367 pagesDiesel Progress Sourcing Guide 2021Mamta RaybageNo ratings yet

- Ex 210LCHDocument2 pagesEx 210LCHMamta RaybageNo ratings yet

- HYVA GEAR PUMP ALPHA BI-4H3 SPECSDocument2 pagesHYVA GEAR PUMP ALPHA BI-4H3 SPECSMamta RaybageNo ratings yet

- Hylomar Universal Blue: Light GradeDocument2 pagesHylomar Universal Blue: Light GradeMamta RaybageNo ratings yet

- Bowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesDocument34 pagesBowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesMamta RaybageNo ratings yet

- Deutz-Fahr Agrolux-55 e tractor test reportDocument12 pagesDeutz-Fahr Agrolux-55 e tractor test reportMamta RaybageNo ratings yet

- B2 HK GB Kapitel GDocument33 pagesB2 HK GB Kapitel GMilan DjenicNo ratings yet

- Standard-Capabilities CDocument36 pagesStandard-Capabilities CMedo SowarNo ratings yet

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- Bomba Hidraulica para Trituradora TESABDocument8 pagesBomba Hidraulica para Trituradora TESABFerneli Moises Barbosa OjedaNo ratings yet

- BOSS Construction Equip PumpsDocument1 pageBOSS Construction Equip PumpsMamta RaybageNo ratings yet

- TR Cat Ramob STD Eng R04 0Document44 pagesTR Cat Ramob STD Eng R04 0ubaldo caraballoNo ratings yet

- Avcon Butterfly ValveDocument2 pagesAvcon Butterfly ValveMamta RaybageNo ratings yet

- TRIMA Front End Loadres & ImplementsDocument32 pagesTRIMA Front End Loadres & ImplementsMamta RaybageNo ratings yet

- Winch System-Mechanical-Electrical-Clutch-HydraulicDocument2 pagesWinch System-Mechanical-Electrical-Clutch-HydraulicMamta Raybage100% (1)

- Atlas Copco ZS Series BlowersDocument46 pagesAtlas Copco ZS Series BlowersMamta Raybage100% (1)

- Bonfigloili 500 TM GearboxDocument12 pagesBonfigloili 500 TM GearboxMamta Raybage100% (1)

- Roots Blower Guide For CementDocument8 pagesRoots Blower Guide For CementMamta RaybageNo ratings yet

- Mahindra XD3P BOLERO PDFDocument107 pagesMahindra XD3P BOLERO PDFMamta Raybage100% (6)

- Rail Design CriteriasDocument19 pagesRail Design CriteriasMamta Raybage100% (1)

- VILTER - Cool Compression Operation ManualDocument96 pagesVILTER - Cool Compression Operation ManualDiego Trinidad100% (1)

- Third Generation Air Winch SeriesDocument6 pagesThird Generation Air Winch Seriesvkannan07666No ratings yet

- (TP0A003) High Capacity Liquid Flow Metering and Proving Equipment For Offshore Crude Oil Storage and Transfer VesselsDocument8 pages(TP0A003) High Capacity Liquid Flow Metering and Proving Equipment For Offshore Crude Oil Storage and Transfer VesselsRoberto Carlos TeixeiraNo ratings yet

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocument24 pagesTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsFRANCISCONo ratings yet

- ATA28, Fuel Dash 8 Q 200Document77 pagesATA28, Fuel Dash 8 Q 200rav100% (1)

- Avk Series 2700 - High Pressure, Modern, Dry Barrel Hydrant Field Maintenance and Instruction ManualDocument29 pagesAvk Series 2700 - High Pressure, Modern, Dry Barrel Hydrant Field Maintenance and Instruction ManualNarendra Reddy BhumaNo ratings yet

- Bomba e Motor Sauer DanfossDocument18 pagesBomba e Motor Sauer Danfossalbsalves8645No ratings yet

- Kidde Natura™ Inert Gas System IG-541 Nitrogen Agent Cylinder AssemblyDocument4 pagesKidde Natura™ Inert Gas System IG-541 Nitrogen Agent Cylinder AssemblyJoseph HoNo ratings yet

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamNo ratings yet

- How Long Is An ODME Retained OnboardDocument17 pagesHow Long Is An ODME Retained OnboardU NaingNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Document33 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Luciano LiuzziNo ratings yet

- BE20 FS Technical ManualDocument342 pagesBE20 FS Technical ManualTiago Dreyer100% (3)

- CLD Series Pneumatic Diaphragm PumpsDocument2 pagesCLD Series Pneumatic Diaphragm PumpsDayo IdowuNo ratings yet

- AW139 00 Chapter 63Document94 pagesAW139 00 Chapter 63JamesNo ratings yet

- 3051Document84 pages3051Tamy AlexNo ratings yet

- Bosch Rexroth AG spare parts listDocument26 pagesBosch Rexroth AG spare parts listSergioCarlosQuispeJuradoNo ratings yet

- Wheeled Excavator Performance & SpecsDocument36 pagesWheeled Excavator Performance & SpecsDanielNo ratings yet

- Unprotected TC8225 7 PDFDocument428 pagesUnprotected TC8225 7 PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- Media Search - SEHS7292 - Using The 5P-4150 Nozzle Testing Group (0782)Document51 pagesMedia Search - SEHS7292 - Using The 5P-4150 Nozzle Testing Group (0782)marius.chitiga100% (1)

- 000-940008 4vista Including HS4V Installation and Operation Manual Rev DDocument168 pages000-940008 4vista Including HS4V Installation and Operation Manual Rev Djim McGinnisNo ratings yet

- Od15x21ys0 Vei 8a 12 Na PoppetDocument4 pagesOd15x21ys0 Vei 8a 12 Na PoppetGabrielNo ratings yet

- Sweety Quick 60Document43 pagesSweety Quick 60eng1knockerNo ratings yet

- A200 ManualDocument36 pagesA200 ManualJose Augusto Troestch RíosNo ratings yet

- Permeability ReportDocument21 pagesPermeability ReportMaclean Jacob Eneotu100% (3)

- Lincoln P203Document88 pagesLincoln P203ANo ratings yet

- API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsDocument2 pagesAPI 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsNilesh MistryNo ratings yet

- Dakota Encased Glass Tube RotametersDocument17 pagesDakota Encased Glass Tube RotametersNibinNo ratings yet

- Eaton Fuller RTLO 14913A Transmission Parts ManualDocument36 pagesEaton Fuller RTLO 14913A Transmission Parts ManualpowermanagerNo ratings yet

- 6M70 Gr34BDocument28 pages6M70 Gr34BNeoGaraNo ratings yet

- D E F Op InstDocument85 pagesD E F Op Instwilber100% (2)