Professional Documents

Culture Documents

Test Plan: 9320A210: Pump Specification

Uploaded by

BaytolgaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Plan: 9320A210: Pump Specification

Uploaded by

BaytolgaCopyright:

Available Formats

Sayfa 1 / 7

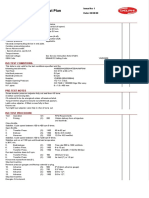

Test Plan: 9320A210

Applic: VISTA T2166

Issue No: 5

Date: 00/00/00

9320A210G 9320A210H 9320A211G 9320A211H 9320A214H

Pumps

9320A212G 9320A212H 9320A213G 9320A213H 9320A215G

covered:

9320A214G 9320A215H

PUMP SPECIFICATION

Rotation: Clockwise.

Governor type: Mechanical all-speed.

Gov. Link Length: 41.5 ± 0.5 mm.

Gov. Link Length: 10.1 ± 0.5 mm.

(DP210 Workshop Manual Section 4.6.4)

Plunger Diameter: 7.0 mm (4 off).

Drive Type: Supported shaft.

Transfer pressure: adjustable plus slope adjustment

Viscosity compensating device in end plate.

Cambox pressurising valve.

Servo Advance with:

- Speed advance, LLA & CA

Torque trimmer.

Boost control.

Solenoid voltage: See Service Instruction Note DT294.

OEM Code: 2644H013 Setting Code: XR/2/2350

OEM Code: 2644H605 Setting Code: XR/2/2350

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and

the

following test benches: HA3000/HA2500/HA700/AVM/PGM

Test Fluid: ISO 4113 at 40 ± 2°C.

Inlet feed pressure: 5.0 psi

Backleak pressure: 0.0 psi

Nozzles: YDB286 (BDL0S6844)

Nozzle Opening Pressure: 172 + 3 - 0 bar.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy.

H.P. pipes: 6 x 1.8 x 450 mm

PRE-TEST NOTES

Screw transfer pressure (outer) adjuster fully out and

then 4.5 turns in before commencing test (see S.I. Note DT340).

Transfer pressure (inner) adjuster to be screwed fully up, but

not locked.

CA solenoid to be de-energised unless otherwise stated.

Torque trimmer plug to be wound out until thread appears.

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

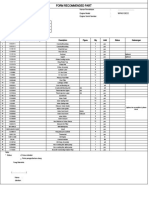

Sayfa 2 / 7

Boost control initial shimming: 1.4 mm.

Boost stroke : 1.7 to 1.9 mm.

Latch valve adjuster, if fitted, screw fully in then

8 turns out

Turn light load adjuster valve fully in ,then 2 turns out.

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

Obtain delivery from all

1. Priming (C) 200

injectors

and backleak.

Close throttle.

Stabilise. Cycle speed between 100 to 400

rpm 5 times.

Set boost pressure to 15.0 psi.

Open throttle.

Transfer

2. (S) 1100 90 to 92psi

Press

(outer)

3. Delivery (S) 1100 87.5 ± 0.5 mm3/st.

4. Governor (S) 1210 12.0 to 16.0 mm3/st.

Stabilise. Cycle speed between 100 to 1230

rpm 5 times.

Stabilise and run at 1100 rpm until backleak

temperature

is 38°C min.

Flow rate 500 to 1000

5. Back leakage. (C) 1100

cm3/min.

Cambox

6. (C) 600 5 to 10 psi

Press.

Transfer

7. (S) 600 As test (6 ) + 59.5 to 60.5psi

Press

(outer)

Cambox

8. (C) 1100 6 to 10 psi

Press.

Transfer (Press at test(8 ) + 82.5to

9. (S) 1100

Press 83.5psi)

(inner)

Transfer

10. (C) 600 As test (7 ) ± 1.0 psi

Press

Run test machine down to 0 rpm.

Transfer

11. (C) 100 Minimum 12 psi.

Press.

Transfer

12. (C) 1100 Press at test(9 ) ± 1.0psi

Press

(inner)

If incorrect repeat from test (7 ).

Stop test machine.

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

Sayfa 3 / 7

Remove pressure gauges and fit stop solenoid

or plug.

13. Advance (S) 500 0° (Datum advance gauge)

14. Advance (C) 750 0.3° Max.

15. Advance (C) 1050 0.8 to 1.2°.

16. Advance (C) 1100 0.8 to 1.2°.

Stop test machine.

Energise CA solenoid.

17. Advance (C) 700 3.8 to 5.5°.

De-energise CA solenoid.

2.8to 3.2° 37.0to

18. Advance - (S) 1100

41.0mm3/st

Light load Adjust throttle/torque screw

& LLA valve.

Run test machine down to 0 rpm.

19. Advance - (C) 1100 2.8to 3.2° 39.0 ± 2.0mm/3st.

Light load Use throttle/Torque screw.

20. Advance - (C) 1100 7.8to 8.2° 23.0 ± 8.0mm/3st.

Light load Use throttle/Torque screw.

21. Advance - (C) 700 1.8to 2.2° 48.0 ± 7.0mm/3st.

Light load Use throttle/Torque screw.

If correct continue with test (22), if not,

adjust shimming

and then repeat test(s) (from test 18).

Open throttle.

Stop test machine.

Fit CPS tool

Set boost pressure to 15.0 psi.

Torque Datum CPS reading to

22. (S) 1100

Trimmer 0.0mm.

Torque

23. (S) 600 Adj CPS to -0.3 to -0.45mm

Trimmer

CPS

Torque

24. (S) 700 Adj CPS to 0.07 to 0.11mm

Trimmer

CPS

Run test machine down to 0 rpm.

Torque

25. (C) 1100 As test (22) ± 0.05 mm

Trimmer

CPS

Torque

26. (C) 725 Check CPS is 0.4 to 0.9mm

Trimmer

CPS

Torque

27. (C) 625 Check CPS is 0.0 to -0.9mm

Trimmer

CPS

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

Sayfa 4 / 7

Torque

28. (C) 1100 As test (25) ± 0.1 mm

Trimmer

CPS

Set boost pressure to zero.

Torque As test (28) - 1.35 ± 0.30

29. (C) 1100

Trimmer mm

CPS

Set boost pressure to 9.0 psi.

Torque

30. (C) 1100 As test (28) ± 0.2 mm

Trimmer

CPS

If correct continue with test (31), if not,

adjust shimming

and then repeat test(s) (22 to 30 ).

Set boost pressure to 3.5 psi.

Torque

31. (C) 1100 As test (29) ± 0.2 mm

Trimmer

CPS

If correct continue with test (32), if not,

adjust shimming

and then repeat test(s) (22 to 31 ).

Set boost pressure to zero.

Screw latch valve adjuster fully in.

Latch Valve

32. /C) 250 CPS = -1.5 to -6.0 mm

(S

If incorrect, adjust LV pre-

load

& repeat test

Run test machine down to 0 rpm.

Torque

33. (C) 210 Check CPS is -0.5 to 1.5mm

Trimmer

CPS

Torque Check CPS is -1.5 to -

34. (C) 280

Trimmer 6.0mm

CPS

If incorrect or adjusted, stop machine and

repeat from test (32).

35. Delivery (C) 100 Minimum 70.0 mm3/st.

De-energise solenoid, wait 5

36. Shut-off - (C) 500

seconds.

Solenoid Max. 2.0 mm3/st.

Stop test machine.

Close throttle.

12.0 to 16.0 mm3/st.

37. Idle delivery (S) 405

Throttle closed.

38. Delivery (C) 510 Maximum 3.0 mm3/st.

Stop test machine.

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

Sayfa 5 / 7

Fit Max Fuel adjuster tool

Open throttle.

Set boost pressure to 15.0 psi.

Max.

39. (S) 1100 87.5 ± 0.3 mm3/st.

Delivery

Max. spread 5.0 mm3/st.

As test (39) + 11.0 ± 3.0

40. Delivery (C) 750

mm3/st.

41. Delivery (C) 1100 Record delivery mm3/st.

42. Governor (S) 1190 12.0 to 16.0 mm3/st.

43. Gov. cut-off (C) 1250 Maximum 3.0 mm3/st.

44. Delivery (C) 1100 Throttle as test (42).

Minimum as test (41) - 1.0

mm3/st.

Dynamic

45. Refer to SIN DT339

timing

Piezo sensor, outlet U

Off-set angle 184.7°

speed (S) 1100 Trigger level 25 %

.

ISO OVERCHECK PROCEDURE

.

The Overcheck section of this plan has been

developed in

conjunction with the Original Equipment

Manufacturer.

Providing all values are achieved, the pump

settings will

maintain the original homologated engine

performance. Failure to

attain any one of the values will indicate a

pump setting or

function failure and require further

investigation.

.

PRE-OVERCHECK NOTES

Dynamic timing - record zero angle - (refer to

DT339)

Drive shaft lock bolt to remain locked until

zero angle

recorded.

CA advance motor to be de-energised unless

otherwise stated.

No adjustments to be made unless otherwise

stated.

Close throttle.

Stabilise. Cycle speed between 100 to 400

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

Sayfa 6 / 7

rpm 5 times.

Set boost pressure to 15.0 psi.

Open throttle.

Stabilise. Cycle speed between 100 to 1240

rpm 5 times.

Stabilise and run at 1100 rpm until backleak

temperature

is 38°C min.

46. Advance (S) 500 0° (Datum advance gauge)

47. Advance (C) 1100 0.7 to 1.3°.

48. Advance (C) 750 0.3° Max.

49. Advance - (C) 1100 2.8to 3.2° 39.0 ± 4.0mm/3st.

Light load Use throttle/Torque screw.

7.8to 8.2° 23.0 ±

50. Advance - (C) 1100

10.0mm/3st.

Light load Use throttle/Torque screw.

51. Advance - (C) 700 1.8to 2.2° 48.0 ± 8.0mm/3st.

Light load Use throttle/Torque screw.

Stop test machine.

Energise CA solenoid.

52. Advance (C) 700 3.8 to 5.5°.

De-energise CA solenoid.

Open throttle.

Fit CPS tool

Set boost pressure to 15.0 psi.

Torque Datum CPS reading to

53. (S) 1100

Trimmer 0.0mm.

Torque

54. (C) 735 Check CPS is 0.4 to 0.9mm

Trimmer

CPS

Torque

55. (C) 615 Check CPS is 0.0 to -0.9mm

Trimmer

CPS

Set boost pressure to zero.

Move throttle lever to closed position for

tests (56 ).

56. Delivery (C) 520 Maximum 3.0 mm3/st.

Open throttle.

57. Delivery (C) 100 Minimum 70.0 mm3/st.

De-energise solenoid, wait 5

58. Shut-off - (C) 500

seconds.

Solenoid Max. 3.0 mm3/st.

Run test machine down to 0 rpm.

Set boost pressure to 15.0 psi.

59. Gov. cut-off (C) 1250 Maximum 3.0 mm3/st.

Run test machine down to 1000 rpm.

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

Sayfa 7 / 7

60. Delivery (C) 1100 85.5 to 89.5 mm3/st.

As test (60) + 11.0 ± 4.0

61. Delivery (C) 750

mm3/st.

Set boost pressure to zero.

As test (60) - 11.0 ± 3.0

62. Delivery (C) 1100

mm3/st.

Set boost pressure to 15.0 psi.

Dynamic

63. Refer to SIN DT339

timing

Piezo sensor, outlet U

Off-set angle 184.7°

speed (S) 1100 Trigger level 25 %

file://C:\Documents and Settings\user1\Local Settings\Temp\XmlTmp.html 17.03.2008

You might also like

- Motor Basico C9Document9 pagesMotor Basico C9GerardoNo ratings yet

- CAT Cross ReferenceDocument350 pagesCAT Cross ReferenceOzenildo Ferreira PondeNo ratings yet

- 104740-0976 - Ford RangerDocument6 pages104740-0976 - Ford RangerBaytolgaNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Optimize pump specification test plan titleDocument4 pagesOptimize pump specification test plan titleLIONN SOFTWARESNo ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- Test Plan for Perkins Vista A 80 KVA @ 15 KVA GeneratorDocument2 pagesTest Plan for Perkins Vista A 80 KVA @ 15 KVA Generatormarco rod100% (1)

- Ford HSDI pump specification and ISO test procedureDocument2 pagesFord HSDI pump specification and ISO test proceduretaniaNo ratings yet

- 101402-9770 Parts ListDocument3 pages101402-9770 Parts ListMihai-Eugen Popa100% (1)

- StanadyneDocument1 pageStanadyneJunior IungNo ratings yet

- Reliable Wheel LoaderDocument4 pagesReliable Wheel Loaderjonathan tbgNo ratings yet

- ZQYM Tech Limited: Independent Solution Provider For Diesel Injection Pump ProblemsDocument7 pagesZQYM Tech Limited: Independent Solution Provider For Diesel Injection Pump ProblemsEU VaNo ratings yet

- db4429 5514Document4 pagesdb4429 5514WillianPachecoNo ratings yet

- Weichai Diesel Engine WD615-KatalogDocument55 pagesWeichai Diesel Engine WD615-KatalogВикторNo ratings yet

- C6.6 Connecting Rod FittingDocument5 pagesC6.6 Connecting Rod FittingsenNo ratings yet

- Isuzu 4BB1, 6BB1, 4BD1, 4BD1T, 6BD1T, 6BG1T, 6BD1, 6BG1 Diesel Engine Workshop ManualDocument216 pagesIsuzu 4BB1, 6BB1, 4BD1, 4BD1T, 6BD1T, 6BG1T, 6BD1, 6BG1 Diesel Engine Workshop ManualWs. SaFlukNo ratings yet

- HATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMDocument39 pagesHATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMEdmundas ŽemaitisNo ratings yet

- Torque Converter and Transmission Parts ListDocument58 pagesTorque Converter and Transmission Parts ListJose De Moura CamaraNo ratings yet

- BF4M 2011Document2 pagesBF4M 2011LUIS ANGEL100% (1)

- Hangcha 5 7TN1 PDFDocument2 pagesHangcha 5 7TN1 PDFTiagoNo ratings yet

- Deutz Manual bf4m1012Document490 pagesDeutz Manual bf4m1012Elvis Astorayme GalvezNo ratings yet

- Manual Motor Cat c9Document3 pagesManual Motor Cat c9Hammad AneesNo ratings yet

- WD12. Каталог запасных частейDocument43 pagesWD12. Каталог запасных частейSergeyNo ratings yet

- Mahle Product CatalogDocument16 pagesMahle Product CatalogDaniel Carrillo Barrios100% (1)

- Tiras de Bronze CatDocument8 pagesTiras de Bronze CatPedro Lorenço JorgeNo ratings yet

- Cylinder Head Gasket Sets and Seal Kits for Diesel EnginesDocument876 pagesCylinder Head Gasket Sets and Seal Kits for Diesel EnginesManuel Lupo ButronNo ratings yet

- Quotation Sheet: Jining Hengwang Mining Machinery Co.,LtdDocument2 pagesQuotation Sheet: Jining Hengwang Mining Machinery Co.,LtdMateo AristizabalNo ratings yet

- Cat Dcs Sis Controllers PDFDocument2 pagesCat Dcs Sis Controllers PDFCristian AntonioNo ratings yet

- 140H Motor Grader Clutch AdjustmentDocument6 pages140H Motor Grader Clutch AdjustmentLuan tobias santosNo ratings yet

- 3 Short Engine - Assembly (Rg40024)Document2 pages3 Short Engine - Assembly (Rg40024)Tyler Goodwin100% (1)

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBADocument3 pages216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBAubaldo caraballoNo ratings yet

- Massey Ferguson MF 185 TRACTOR (GB) Service Parts Catalogue Manual (Part Number 819615)Document14 pagesMassey Ferguson MF 185 TRACTOR (GB) Service Parts Catalogue Manual (Part Number 819615)hujiao6607280No ratings yet

- Analise de Falhas e ServiCos Lg918 To Lg968 Eng Rev1 2011Document60 pagesAnalise de Falhas e ServiCos Lg918 To Lg968 Eng Rev1 2011AUTOMAQ SERVICENo ratings yet

- Pneumatic Roller: Ready For Heavy-Duty RoadworkDocument2 pagesPneumatic Roller: Ready For Heavy-Duty RoadworkTaufiq AkbarNo ratings yet

- LeeBoy - 8816B - Paver Manual - Pavimentadora - ManualDocument282 pagesLeeBoy - 8816B - Paver Manual - Pavimentadora - ManualIGNACIONo ratings yet

- Army PartsDocument155 pagesArmy Partsejen_gl100% (1)

- Cylinder Head Td122Document1 pageCylinder Head Td122FilipposNo ratings yet

- Recommended Part WP6G125E22Document1 pageRecommended Part WP6G125E22Sutan RichardNo ratings yet

- 4R1040TA-Engine 82.5kVA 50Hz Rev00-1Document3 pages4R1040TA-Engine 82.5kVA 50Hz Rev00-1Suresh SekharNo ratings yet

- SDLG BrowsingDocument2 pagesSDLG BrowsingLukman ExmesNo ratings yet

- Deutz 1013 Agricultural Specs PDFDocument6 pagesDeutz 1013 Agricultural Specs PDFALWINo ratings yet

- Niigata 6nsd MDocument182 pagesNiigata 6nsd M박일호No ratings yet

- 310J, 310SJ, 315SJ, 325J, 410J, 310SJ TMC and 410J TMC Engines 4045DT060, 4045HT054, 4045TT094, and 4045TT095Document2 pages310J, 310SJ, 315SJ, 325J, 410J, 310SJ TMC and 410J TMC Engines 4045DT060, 4045HT054, 4045TT094, and 4045TT095Tomas GomezNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- 497TC TBL315VDocument48 pages497TC TBL315VKamaldeep SinghNo ratings yet

- Brosur Sany SY75CDocument2 pagesBrosur Sany SY75Cmbah petruk100% (1)

- 03heavy Duty20131231Document96 pages03heavy Duty20131231Edgar Rojas EspejoNo ratings yet

- OSS Engine Parts SectionDocument28 pagesOSS Engine Parts SectionEfrén ChávezNo ratings yet

- 00aa - LP-LPT 613-713 CatDocument341 pages00aa - LP-LPT 613-713 CatGen Abimbolar OdukaleNo ratings yet

- PC-K-Series-01-A MBH 4 CYLINDERDocument92 pagesPC-K-Series-01-A MBH 4 CYLINDERibrahim salemNo ratings yet

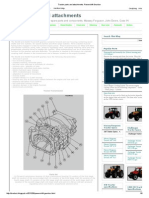

- Tractor Parts and Attachments: Powershift GearboxDocument6 pagesTractor Parts and Attachments: Powershift Gearboxaritmetics100% (1)

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- C4.4 & C6.6 Tool List: Number Name QTY Dealer CAT Function ToolDocument2 pagesC4.4 & C6.6 Tool List: Number Name QTY Dealer CAT Function ToolarasNo ratings yet

- Perkins 1106C-70TADocument5 pagesPerkins 1106C-70TAHendra100% (1)

- Measuring Electrical DeviceDocument14 pagesMeasuring Electrical Devicearum nadaNo ratings yet

- Perkins Engine 1106A-70TAG4 SERIES SPARE PARTSDocument2 pagesPerkins Engine 1106A-70TAG4 SERIES SPARE PARTSIbrahim Yunus0% (2)

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- 780 7540 Doowon PDFDocument10 pages780 7540 Doowon PDFAndy Anderson Limachi PeraltaNo ratings yet

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 pagesInjection Pump Test Specifications 093000-573#: ApproxBaytolgaNo ratings yet

- 9320A275K Parçalar PDFDocument10 pages9320A275K Parçalar PDFBaytolgaNo ratings yet

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 pageInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaNo ratings yet

- 104740-1022 W IsuzuDocument4 pages104740-1022 W IsuzuBaytolgaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©BaytolgaNo ratings yet

- tp04 Fuel Pump Test Data in LineDocument1 pagetp04 Fuel Pump Test Data in LineBaytolgaNo ratings yet

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 pageInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaNo ratings yet

- Direct Evolution EnhancementDocument2 pagesDirect Evolution EnhancementBaytolgaNo ratings yet

- 780 7540 Doowon PDFDocument10 pages780 7540 Doowon PDFAndy Anderson Limachi PeraltaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©BaytolgaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©BaytolgaNo ratings yet

- ZEXEL test values for ISUZU 4EE1 diesel fuel injection equipmentDocument5 pagesZEXEL test values for ISUZU 4EE1 diesel fuel injection equipmentBaytolgaNo ratings yet

- ZEXEL test values for diesel fuel-injection equipmentDocument5 pagesZEXEL test values for diesel fuel-injection equipmentBaytolgaNo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolgaNo ratings yet

- Brand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1Document44 pagesBrand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1BaytolgaNo ratings yet

- ZEXEL test values for diesel fuel-injection equipment adjustment specificationsDocument2 pagesZEXEL test values for diesel fuel-injection equipment adjustment specificationsBaytolga100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pages096000-4860 Toyata Hilux-4 Runner PDFBaytolgaNo ratings yet

- DP210 Pump Parts ListDocument3 pagesDP210 Pump Parts ListBaytolgaNo ratings yet

- DP210 Pump Parts ListDocument3 pagesDP210 Pump Parts ListBaytolgaNo ratings yet

- 101401-7321 - Isuzu Şampi̇yonDocument4 pages101401-7321 - Isuzu Şampi̇yonBaytolgaNo ratings yet

- 104745-7770 - NissanDocument3 pages104745-7770 - NissanBaytolgaNo ratings yet

- 104745-7770 - NissanDocument3 pages104745-7770 - NissanBaytolgaNo ratings yet

- 9161Document5 pages9161BaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 2305-2308 FMM Micro ProjectDocument16 pages2305-2308 FMM Micro Project2306 Reuben NoronhaNo ratings yet

- Lecture On CompressorDocument72 pagesLecture On CompressorYan ManurungNo ratings yet

- Schroedahl ArvDocument19 pagesSchroedahl ArvfadzilharmanNo ratings yet

- Learning Outcomes:: Some Other Ways of Classifying CompressorsDocument18 pagesLearning Outcomes:: Some Other Ways of Classifying CompressorsRyan CalicaNo ratings yet

- Valve ScheduleDocument70 pagesValve SchedulekarparabhusawalNo ratings yet

- TK 40847Document111 pagesTK 40847معمر حميدNo ratings yet

- Pneumatic Fuel Valve Test Pump Type: VPU 1100.2 MKI/MKII: Instruction ManualDocument20 pagesPneumatic Fuel Valve Test Pump Type: VPU 1100.2 MKI/MKII: Instruction Manualvoldemar51rusNo ratings yet

- Midterm ExaminationDocument2 pagesMidterm ExaminationKristine Joy BagaporoNo ratings yet

- Tablas CeneguelDocument1 pageTablas CeneguelMargarito Robles KingNo ratings yet

- Equipment Maintenance Log Template 03Document2 pagesEquipment Maintenance Log Template 03Thoni LacknerNo ratings yet

- Charge Air System of Alco LocosDocument44 pagesCharge Air System of Alco LocosmajjisatNo ratings yet

- NETZSCH-Oilfield-Upstream en 03 14a PDFDocument44 pagesNETZSCH-Oilfield-Upstream en 03 14a PDFabrahan_landaezNo ratings yet

- ASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Document5 pagesASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Rafael Esteban BarriaNo ratings yet

- Everything You Need to Know About PumpsDocument4 pagesEverything You Need to Know About PumpsJireh LoquinarioNo ratings yet

- P&ID Pipe Line Specifications ReportDocument4 pagesP&ID Pipe Line Specifications Reportinggar satriaNo ratings yet

- Detailed Technical Report.Document1 pageDetailed Technical Report.RaziKhanNo ratings yet

- Christmas BonusDocument3 pagesChristmas BonusJazmin RamosNo ratings yet

- Axial Compressor CalculationDocument8 pagesAxial Compressor CalculationJiun Cai OngNo ratings yet

- New Price List CPVC 2021Document2 pagesNew Price List CPVC 2021Yash ShanishvaraNo ratings yet

- NTT Data JKT3 Delivery (At Site) 20200602.REV.7Document1 pageNTT Data JKT3 Delivery (At Site) 20200602.REV.7agung sudarsonoNo ratings yet

- 03 Water Cooled ChillersDocument64 pages03 Water Cooled Chillersvenkiram88No ratings yet

- Sumamry SepDocument279 pagesSumamry SepMuhammad Tahir AbbasNo ratings yet

- 04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemDocument16 pages04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemДен СтаднікNo ratings yet

- Venturi ReportDocument8 pagesVenturi Reportstephen kangereNo ratings yet

- Development of a T53 Engine Computer ModelDocument42 pagesDevelopment of a T53 Engine Computer ModelpcatruongNo ratings yet

- FIX BQ Hydrant FXDocument28 pagesFIX BQ Hydrant FXfredyNo ratings yet

- Hir Purchase List CSDDocument57 pagesHir Purchase List CSDAbdullah ShabbirNo ratings yet

- IHP ReportDocument16 pagesIHP ReportDev MaratheNo ratings yet

- Automatic acetylene switchover systemDocument3 pagesAutomatic acetylene switchover systemAbdullah FazilNo ratings yet

- Anderson Greenwood 200, 400, 500, 700 and 800 CatalogDocument68 pagesAnderson Greenwood 200, 400, 500, 700 and 800 CatalogdianamontesNo ratings yet